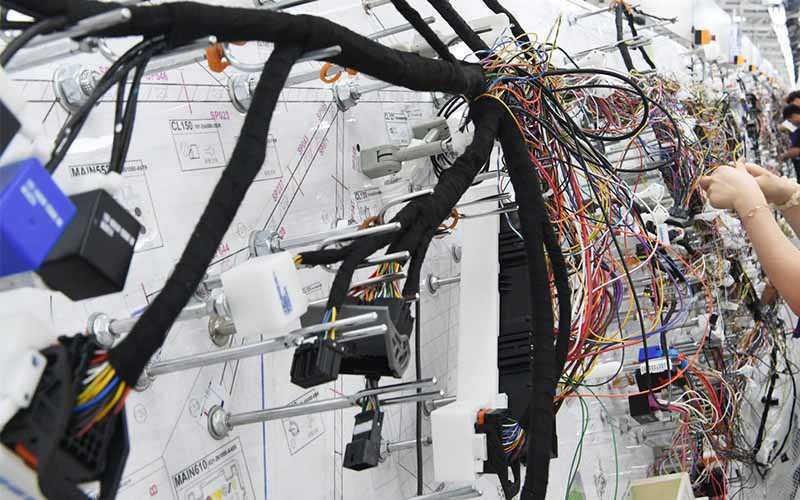

Modern defense systems—whether mounted on fighter jets, warships, or tactical vehicles—rely on one hidden but indispensable element: military assemblies. These specialized cable harnesses power radars, transmit encrypted signals, and keep life-critical systems running in extreme conditions. Without them, communication collapses, navigation fails, and missions risk disaster.

Military assemblies are specialized wiring harnesses and cable systems designed for defense, aerospace, and mission-critical environments. They ensure reliable power and signal delivery under extreme conditions such as heat, vibration, salt spray, or electromagnetic interference. Built to MIL-Spec standards, they use advanced conductors, insulation, and connectors to achieve high durability, signal integrity, and ease of maintenance.

Imagine a pilot mid-mission: if the avionics harness fails due to EMI, the radar screen goes black. That split-second could determine mission success—or failure. That’s why the military invests so heavily in tested, certified, and customized assemblies. Stick with me, and we’ll explore what they are, what they’re made of, the problems they solve, and why Sino-conn is trusted worldwide to deliver them.

What Are Military Assemblies and Why Are They Important?

Military assemblies are wiring systems built to military specifications (MIL-Spec). They are important because they ensure uninterrupted power and signal delivery in critical defense systems, from weapons control to communications, even under harsh conditions.

Military assemblies are not “ordinary wires.” They are designed as lifelines of defense electronics. Every missile guidance system, every submarine sonar, every ground vehicle relies on assemblies that guarantee performance. Importance lies in four pillars:

- Operational Reliability – Assemblies provide continuous function despite shock, vibration, or extreme climates.

- Safety Compliance – Meeting MIL-STD-810 (environmental) and MIL-STD-461 (EMI) ensures systems are combat-ready.

- Interoperability – Assemblies connect legacy systems with next-gen platforms, ensuring seamless integration across branches.

- Mission Assurance – Faults are not acceptable; failure can compromise an entire mission.

What Are the Three Military Departments?

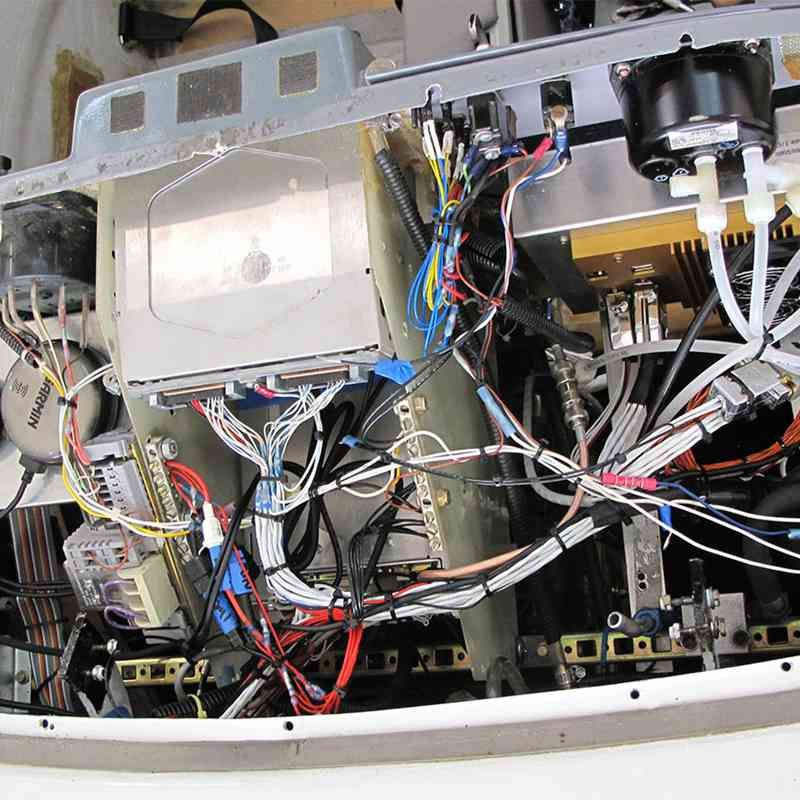

The U.S. has three primary military departments—Army, Navy, and Air Force. Each depends on assemblies differently: the Army for armored vehicles and communications, the Navy for sonar and shipboard power, and the Air Force for avionics and navigation.

Military Assemblies Across Departments

| Military Department | Typical Applications | Assembly Requirements | Example Systems |

|---|---|---|---|

| Army | Armored vehicles, battlefield communications, missile launch systems | Ruggedized, shock-resistant, modular harnesses | Tanks, mobile command units |

| Navy | Shipboard power distribution, sonar, radar, navigation | Salt-spray resistant, corrosion-proof, EMI-shielded | Warships, submarines |

| Air Force | Avionics, navigation, radar, weapons control | Lightweight, vibration-proof, high-temp insulation | Fighter jets, drones |

This comparison shows how each department depends on assemblies differently, which underlines the need for suppliers like Sino-conn to provide fully customized solutions across land, sea, and air applications.

Which Materials Are Commonly Used in Military Assemblies?

Military assemblies use advanced materials like silver- or nickel-plated copper conductors, PTFE/ETFE insulation, multi-layer EMI shielding, and MIL-DTL connectors. These materials ensure conductivity, reliability, and compliance with MIL-Spec standards under extreme conditions such as high heat, vibration, and electromagnetic interference.

Choosing the right material is the foundation of mission success. Every component—from the inner conductor to the outer jacket—directly affects reliability, weight, and cost.

- Conductors

- Tinned copper: Cost-effective, corrosion-resistant, widely used in vehicle harnesses.

- Silver-plated copper: Superior conductivity, ideal for high-frequency radar or RF.

- Nickel-plated copper: High-temperature endurance, perfect for jet engines or missile systems.

- Insulation & Jacketing

- PTFE (Teflon): -65°C to +200°C operation, chemical resistance.

- ETFE / XL-ETFE: Thin-wall, lightweight, radiation-resistant.

- PEEK: Exceptional strength, withstands long-term heat.

- Polyurethane / Silicone: Flexible, abrasion- and flame-resistant, good for field equipment.

- Shielding Options

- Braided copper shielding: Durable and flexible, resists EMI.

- Aluminum/polymer foil: Lightweight, used in portable gear.

- Hybrid shielding: Combines layers to protect from EMP (electromagnetic pulse).

- Outer Jackets

- Fluoropolymers: Non-flammable, UV- and oil-resistant.

- Polyurethane: Resists cuts, ideal for ground vehicles.

- Silicone rubber: High flexibility, medical or aerospace harnesses.

- Connectors

- MIL-DTL-38999: High-pin-count, rugged, for aircraft & tanks.

- MIL-C-26482: Compact, widely used in handheld or ground gear.

- Fiber-optic connectors: Critical for modern secure communications.

Procurement teams often request custom reports with OD (outer diameter), flexibility rating, flame-retardant grade, impedance values, EMI shielding %, and RoHS/REACH statements before approving a supplier. Sino-conn provides full specs and CAD drawings within 3 days (sometimes within 30 minutes for urgent cases).

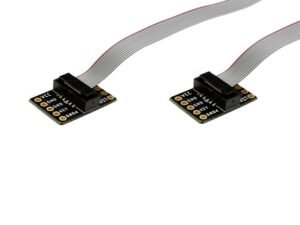

How Many Types of Military Assemblies Exist?

Military assemblies come in types such as circular harnesses, flat ribbon harnesses, coaxial assemblies, fiber optic harnesses, and hybrid systems, all designed for specific defense needs.

The type of assembly depends on mission goals:

- Circular MIL-Spec Harnesses – Aircraft and armored vehicles.

- Flat Ribbon Harnesses – Lightweight electronics.

- Coaxial Harnesses – Radar and RF communication.

- Fiber Optic Harnesses – High-speed, interference-free data.

- Hybrid Harnesses – Combine power + signal + RF.

- Custom Harnesses – Built to exact mission drawings.

What Is the Military Assembly Area?

In logistics, the “assembly area” is where troops and equipment gather before operations. Cable assemblies play a role here too—mobile radar, comms tents, and power distribution rely on rugged harnesses set up in these staging zones.

What Problems Do Military Assemblies Solve?

Military assemblies solve problems of EMI, environmental extremes, and mission-critical reliability by offering durable, shielded, and lightweight cabling solutions.

- Reliability Under Fire: Harsh environments demand assemblies that work flawlessly.

- Weight Management: Aircraft save fuel when wiring is lighter.

- EMI & EMP Control: Shielded cables ensure uninterrupted comms.

- Ease of Maintenance: Modular design reduces downtime.

Military Assemblies: Problems, Solutions, and Benefits

| Problem | Assembly Solution | Operational Benefit |

|---|---|---|

| Harsh environments (heat, vibration, salt spray) | High-temp insulation (PTFE, ETFE), rugged jackets | Continuous reliability under extreme conditions |

| Weight sensitivity in aircraft & vehicles | Lightweight materials, flat ribbon harnesses | Lower fuel consumption, higher payload capacity |

| Electromagnetic interference (EMI/EMP) | Braided copper/foil shielding, hybrid shielding layers | Stable and secure communications & radar signals |

| Frequent maintenance downtime | Modular, standardized harnesses | Faster repair and reduced operational delays |

| Training durability (ADT use) | Flexible, bend-resistant, quick-connect assemblies | Long service life even with repetitive use |

These solutions not only tackle the toughest challenges in military operations but also set the stage for compliance with global military standards, which we’ll explore next.

What Is ADT in the Military?

Active Duty Training (ADT) involves specialized equipment simulations. Assemblies used here must endure repeated use, bending, and quick-connect features to train soldiers effectively.

Do Military Assemblies Need to Meet Global Standards?

Yes. Military assemblies must comply with MIL-STD-810 (environmental), MIL-STD-461 (EMI), ISO 6722, UL safety, and environmental standards like RoHS and REACH. These certifications ensure assemblies are safe, reliable, and legally compliant worldwide.

Compliance is often the deciding factor in whether a defense buyer chooses a supplier. Global standards exist to guarantee that assemblies survive combat environments and meet export regulations.

- Core Military Standards

- MIL-STD-810: Tests for vibration, salt fog, altitude, shock.

- MIL-STD-461: Ensures EMC (electromagnetic compatibility).

- MIL-DTL Connector Standards: Ensure mechanical and electrical consistency across vendors.

- International Standards

- ISO 6722 (EU): Defines cable performance for automotive and aerospace use.

- SAE J1128 (US): Governs automotive wiring.

- JIS C3406 (Japan): Precision standards for Japanese OEMs.

- GB/T 12528 (China): Domestic low-voltage harness compliance.

- Safety & Environmental Certifications

- UL: Flame resistance, insulation integrity.

- RoHS: Restricts hazardous substances (lead, cadmium, mercury).

- REACH: EU regulation ensuring safe chemical use.

- PFAS-Free / Halogen-Free: Growing global demand for fire safety and environmental compliance.

- Regional Differences

- The U.S. enforces UL + SAE.

- Europe requires RoHS/REACH + ISO.

- Japan demands JIS compliance + OEM approvals.

- China emphasizes GB/T + humidity resistance.

Military Assembly Compliance Snapshot

| Standard | Scope | Region / Industry |

|---|---|---|

| MIL-STD-810 | Environmental tests | Global military |

| MIL-STD-461 | EMI / EMC | Global military |

| ISO 6722 | Cable performance | EU automotive/aerospace |

| UL | Flame & safety | USA/global export |

| RoHS / REACH | Environmental safety | EU/global export |

Buyers always ask: “Can your product be exported with full documentation?” Sino-conn provides UL, ISO, RoHS, REACH, PFAS-free certificates, along with COC/COO (Certificates of Conformity/Origin). This removes procurement risk, speeds up customs clearance, and ensures products can enter EU, US, and Asia-Pacific defense supply chains.

How Can Sino-conn Support Your Military Assembly Needs?

At Sino-conn, we don’t just supply cables—we provide mission-critical assurance.

- Speed: Samples in 2–3 days, bulk in 2 weeks.

- Flexibility: No MOQ; 100% customization.

- Accuracy: CAD-to-PDF drawings for client approval before production.

- Choice: Genuine or equivalent connectors available.

- Quality: 3-level QC (process, final, pre-shipment).

- Certificates: ISO, UL, RoHS, REACH, PFAS-free.

Whether you’re an engineer testing a prototype, an OEM integrating into aircraft, or a defense contractor needing volume, Sino-conn ensures your assemblies meet every global and military standard.

Conclusion

Military assemblies are the invisible backbone of defense technology. They ensure communication, power, and safety across the harshest terrains—from desert tanks to naval fleets. Built with specialized materials, tested against international standards, and engineered for adaptability, these assemblies solve critical defense challenges.

Looking for custom-built military assemblies that meet MIL-Spec and global certifications? Contact Sino-conn today to request drawings, samples, or a quote. Your mission success begins with the right connections.