custom wire loom cable manufacturer

Need precision, protection, and flexibility in your cable management? Shenzhen Sino-conn provides custom wire loom solutions tailored for automotive, industrial, and robotics applications. From split tubing to braided sleeving, we engineer to your specs—fast delivery, no MOQ, and full certifications. Let’s build your ideal loom.

Why choose wire loom cable from sino-conn

Discover the advantages of choosing wire loom cables from Sino-Conn. Our custom solutions offer exceptional durability, flexibility, and high performance across various industries. With advanced materials, precise designs, and strict quality control, we ensure the reliability and safety of every assembly. Trust Sino-Conn for your custom wire loom cable needs and experience superior manufacturing standards.

Flexible Structure, Fit Any Complex Routing

Our custom wire loom features an exceptionally flexible structure that adapts easily to tight bends, multiple branches, and confined installations. Whether for automotive, robotics, or industrial applications, it ensures tidy routing without cable strain or damage. The split tubing or braided sleeving styles can wrap and protect cables in irregular environments. This adaptability saves labor time and avoids frequent re-routing in production lines.

Wide Range of Materials and Certifications Available

We offer custom wire loom solutions using materials such as PE, PP, PA, PET, PVC, and fire-retardant compounds to meet different environmental and safety needs. Whether you require heat resistance, oil-proofing, UV protection, or halogen-free properties, we can match your application. All our products comply with key certifications like UL, RoHS, ISO9001, REACH, and PFAS-free requirements, helping you easily pass audits and meet regulatory standards in automotive, medical, or industrial sectors.

Rapid Customization: Drawings Ready in 30 Minutes

At Sino-conn, we understand the urgency of product development. That’s why our engineering team provides accurate CAD-to-PDF technical drawings within 30 minutes to 3 hours, depending on complexity. For custom wire loom projects, we analyze your requirements, design the structure, define dimensions, and confirm connector types swiftly—so your R&D team gets immediate feedback. This fast response helps shorten development cycles and increases your competitiveness in fast-moving markets.

No MOQ, Fast Delivery Even for 1 Piece

We support flexible order quantities starting from just one piece—perfect for R&D samples, small-batch pilot runs, or urgent projects. Our streamlined process allows us to deliver wire loom prototypes within 3 days and bulk orders in as fast as 2 weeks. Whether you’re an engineer validating a new design or an OEM buyer facing tight timelines, Shenzhen Sino-conn ensures reliable, rapid fulfillment without the burden of high MOQs.

Support Both Genuine and Compatible Connectors

We offer the flexibility to use either original-brand (genuine) or high-quality compatible (replacement) connectors according to your needs. Genuine connectors are ideal for projects requiring strict compliance, while compatible options help reduce cost and lead time without compromising functionality. Our in-stock inventory includes both types, enabling faster delivery and broader selection. Whether your focus is performance, certification, or budget, we deliver the right solution without delay.

Triple Quality Inspection, Zero Defect Commitment

Every custom wire loom produced by Sino-conn undergoes a rigorous three-step quality control process: in-process inspection, post-assembly inspection, and pre-shipment inspection. Each stage checks for structural integrity, connector fit, and overall functionality. This ensures that even the smallest batches meet the same reliability standards as mass production. We commit to delivering only defect-free assemblies, making us a trusted supplier for industries where failure is not an option.

Detailed specifications and parameters of wire loom cable

Each wire loom we produce is unique—designed specifically to meet the customer’s routing, connector, shielding, or installation requirements. The examples above are only representative; in actual projects, configurations may vary significantly in pin definitions, loom structure, length, or bundling materials. Whether the client needs EMI shielding, waterproofing, special heat resistance, or specific connector compatibility, we analyze and create a matching solution from scratch. This level of customization is what makes our custom wire loom truly “customized.”

| No. | Definition (Pin Configuration) | Connector Model | Cable Spec | Length (mm) | Loom Type | Sheath Material |

|---|---|---|---|---|---|---|

| 1 | 1-to-1 | JST XH-6P | Custom | Custom | Round | PVC tubing |

| 2 | Cross-wired | Molex 51021-4P | Custom | Custom | Flat | Nylon braided |

| 3 | Shielded 1-to-1 | Hirose DF13-6P | Custom | Custom | Round | Aluminum foil + conductive cloth |

| 4 | T-wired (3-way split) | SM 2.54-3P | Custom | Custom | Formed | Acetate cloth |

| 5 | Parallel 2-to-2 | JST PH-4P | Custom | Custom | Flat | Teflon tape |

| 6 | 1-to-2 Fork | Molex Micro-Fit | Custom | Custom | Formed | PVC + nylon mesh |

| 7 | Reverse 1-to-1 | Dupont 2.54-5P | Custom | Custom | Round | PVC spiral wrap |

| 8 | Differential signal matched | IPEX MHF4 | Custom | Custom | Flat | Nano adhesive tape |

| 9 | Power + signal mixed | JST VH-3P + 2P | Custom | Custom | Round | Nylon braided |

| 10 | Twisted pair with shield | Molex Picoblade | Custom | Custom | Round | Teflon tubing |

Customized wire loom cable styles

Trusted by 300+ global brands,1000+ styles have been developed.

Automotive Power Supply Wire Loom with Waterproof Fuse Holder

Automotive Split Wire Loom Harness with Waterproof Connectors

Automotive Split Wire Loom with Heavy Gauge Power Leads

Braided Custom Wire Loom with Waterproof Connectors

Custom Automotive Wiring Loom with PVC Wrap & Ring Terminals

Product details display of wire loom cable

Explore the detailed specifications of our custom wire loom cables. Our products are designed with precision to meet industry standards for durability, flexibility, and performance. With customizable lengths, materials, and configurations, our wire loom cables are ideal for a variety of applications. Whether you need a specific design or material, we provide tailored solutions to fit your exact requirements.

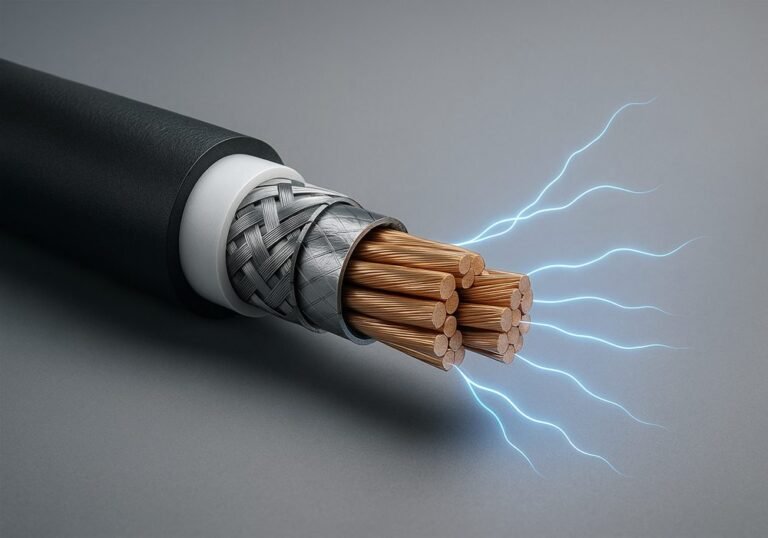

Multi-Stranded Copper Conductors for Flexible and Stable Transmission

Our custom wire looms are engineered with high-purity multi-stranded copper conductors, delivering outstanding flexibility and electrical stability across all applications. This structure provides superior durability in environments with vibration, bending, or movement.

- The conductors consist of multiple oxygen-free copper strands, ensuring high conductivity and low resistance.

- Twisting the strands tightly minimizes signal loss and improves current flow.

- Multi-strand designs absorb vibration better than solid-core wires, extending cable life.

- Wire gauges from 0.08mm² to 2.0mm² are available to meet various current requirements.

- All copper is RoHS and REACH compliant and passes 100% electrical testing.

- Ideal for automotive, robotics, industrial controls, and medical systems requiring both performance and reliability.

High-Precision Sheathing Structure for Demanding Environments

Our custom wire loom assemblies utilize advanced sheathing structures tailored to harsh operating environments. These layered systems protect the inner conductors and ensure consistent mechanical and electrical performance.

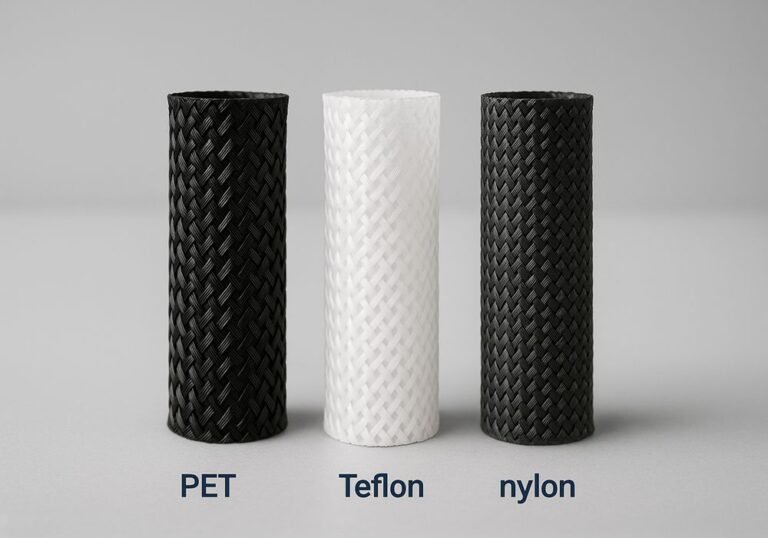

- Sheathing options include PVC, Teflon (PTFE), PET braided sleeving, nylon wrap, and conductive fabric.

- Available in round, flat, spiral, and molded shapes to suit different spatial and flexibility needs.

- Each layer (inner insulation, shielding, outer jacket) is precisely aligned to ensure durability.

- Materials are selected based on temperature resistance, oil-proofing, flame retardancy, or EMI shielding.

- Standard OD tolerance control ensures easy integration into panels and enclosures.

- Optional printing, color-coding, and sealing enhance usability and assembly efficiency.

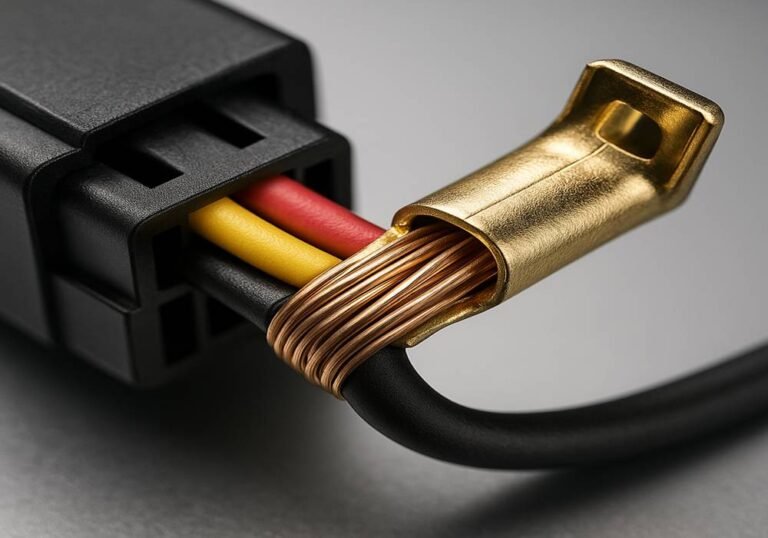

Precision Connector Termination with Strong Compatibility

Connector quality directly impacts signal stability. Our termination process ensures reliable mating, signal integrity, and mechanical strength—whether using original-brand or compatible connectors.

- Supports JST, Molex, Hirose, DuPont, IPEX, and other standard models.

- Termination is performed via precision crimping with pull force calibration.

- Visual and mechanical testing is done on every terminated end.

- Overmolding, epoxy potting, or heat-shrink sealing can be applied as needed.

- Pinouts, polarities, and locking structures are verified to ensure correct mating.

- Customers can choose between genuine or cost-effective alternatives based on lead time and pricing.

Efficient EMI Shielding for Reliable Signal Integrity

In high-interference environments, signal quality depends on robust EMI shielding. Our wire looms are designed with multi-layer EMI barriers to protect data and control lines.

- Shielding options: aluminum foil, tinned copper braid, conductive fabric, or hybrid layers.

- Grounding wires or drain lines ensure proper discharge to chassis.

- Shielding coverage up to 98% for foil, 85% for braid, verified through EMI testing.

- Tight integration between shielding and sheath prevents slippage during installation.

- Suitable for medical devices, industrial controls, RF modules, and automotive ECUs.

- Compliance with UL, ISO, and CE standards ensures global usability.

Flexible Multi-Branch Routing for Complex Wiring Needs

Our wire looms support advanced multi-branch designs to simplify complex wiring installations. Whether it’s T-shaped, Y-split, or radial layouts, we tailor each routing path to fit your mechanical constraints and terminal locations.

- Ideal for robotics, medical systems, automotive dashboards, and server racks with multiple endpoints.

- All branches are organized with specific routing angles and lengths, based on 3D CAD planning.

- Custom overmold or heat-shrink joints reinforce branch transitions and prevent cable movement.

- Signal and power lines can be split without cross-interference, using labeled or color-coded wires.

- Each branch maintains consistent shielding and mechanical integrity, ensuring long-term reliability.

- Final assemblies are tested for continuity and strength across all split points.

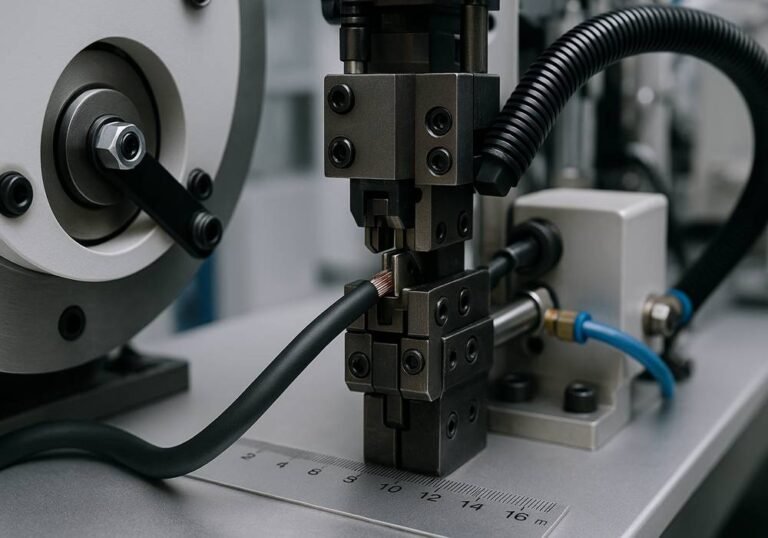

Triple-Stage Quality Inspection Ensures Zero-Defect Delivery

We guarantee every custom wire loom is defect-free through a strict three-stage quality control process: in-process inspection, post-assembly testing, and final shipment checks.

- In-process checks include crimp quality, sheath alignment, and conductor integrity.

- After assembly, 100% of looms undergo electrical continuity and visual inspection.

- Before shipping, we verify connector orientation, labeling, and packaging to avoid mix-ups.

- Each order is traceable with inspection reports, photos, and batch numbers.

- Testing covers mechanical strength, wire resistance, insulation thickness, and flame compliance.

- This system ensures our wire looms perform reliably in critical environments like aerospace, defense, and medical equipment.

--- Customized Capabilities Services and Processes

Customize your wire loom cable

At Sino-Conn, we offer highly customizable wire loom cable solutions tailored to your specific needs. Our comprehensive design and manufacturing services include precise adjustments in length, materials, and configurations. With a focus on quality control, we ensure that each product meets rigorous standards. Our efficient processes, including quick prototyping and fast production times, make us a trusted partner for your wire loom cable requirements. Let us provide you with the perfect solution for your industry needs.

Customized Capabilities Services and Processes

Customize your wire loom cable

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Shenzhen Sino-conn, customization is at the heart of our wire loom solutions. We empower engineers, OEMs, and project developers to shape every detail according to application-specific needs.

- We support a wide range of connectors (standard and custom) including Molex, JST, Hirose, and automotive-grade types.

- Wire gauges and conductor types are tailored to voltage/current requirements.

- Sheathing options include PVC, Teflon, braided nylon mesh, flame-retardant, and halogen-free materials.

- We accommodate multi-branch designs, twist and fold structures, and high-flexibility routing.

- Shielding can be EMI-grade foil, braided, or layered composite.

- Pin configurations (straight-through, crossover, custom) are precisely mapped.

- Wire identification includes color coding, laser-printed numbers, or barcode labels.

- CAD drawings are delivered within 30 minutes for review.

- We ensure all components meet certifications like UL, RoHS, ISO, and REACH.

From design optimization to final inspection, our customization process ensures full compatibility, reliability, and compliance.

Our Commitment to Outstanding Service

At every step of the custom wire loom journey, Shenzhen Sino-conn offers best-in-class service rooted in speed, professionalism, and attention to detail.

- We respond to inquiries within 30 minutes to 3 hours, providing clear quotations and CAD files.

- Each project is assigned a dedicated account manager to ensure one-on-one communication.

- We support real-time updates, engineering video calls, and same-day CAD revisions.

- Prototypes can be delivered globally in as fast as 2–3 days.

- Documentation includes drawings, inspection reports, compliance certificates (UL, RoHS, PFAS, etc.), and labeling specs.

- We offer zero MOQ, enabling startups and large OEMs alike to test designs.

- 100% quality inspection is performed during production, after assembly, and before shipment.

- Secure packaging and serialized labeling ensure products arrive in perfect condition.

This full-spectrum service ensures that from concept to delivery, your custom wire loom project is supported with precision and care.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario: Electric Bicycle Control Harness System

“We needed a durable wire loom solution for our e-bike control system that could handle high current and resist heat. Shenzhen Sino-conn delivered a custom multi-branch loom with Teflon sheathing and gold-plated terminals. The CAD drawing was done in less than 30 minutes, and the prototype was shipped in just three days. The performance exceeded expectations, and the service was impressively responsive.”

Michael Jensen

Munich, Germany, R&D Engineer

Application Scenario: Home Appliance Harness Assembly for Smart Washing Machines

“Our smart washing machine assembly line needed flame-retardant and halogen-free wire looms with precise pin mapping. Shenzhen Sino-conn’s engineering team helped optimize our configuration and delivered mass production in under 3 weeks. Their zero MOQ policy allowed us to test fast, and the delivery was always on schedule.”

Priya Nair

Bangalore, India, OEM Production Manager

Application Scenario: Automotive Sensor Interconnect Cabling for Tier 1 Suppliers

“As a distributor working with Tier 1 automotive suppliers, our biggest need was traceability and rapid customization. Sino-conn offered barcode labeling, complete certification sets, and continuous updates throughout production. Their customer manager even joined a video call with our client to confirm specs live.”

David Martinez

San Diego, USA, Electronic Component Distributor

industry Application of wire loom cable

LVDS cable assemblies are widely used in medical devices, robotics, automotive systems, drones, industrial automation, and consumer electronics, ensuring high-speed data transmission, low EMI, and stable performance in demanding environments.

Industrial Robotics Wiring

Application Scenario: Cable routing in robotic arms and automated systems in smart factories

Equipment and Products: Multi-axis industrial robots, servo motors, I/O modules, control units

Industry-specific needs:

- Requires high-flex and abrasion-resistant looms that endure millions of bend cycles.

- Must protect cables from EMI in high-frequency environments.

- Demand quick turnaround for prototypes due to evolving automation layouts.

Solutions: Shenzhen Sino-conn provided custom wire looms with braided nylon sleeving and EMI-resistant foil shielding. We supported split-branch routing for modular joints and used high-flex silicone-insulated wires to maintain durability. Our engineering team delivered CAD drawings within 2 hours and shipped prototypes within 3 working days.

Medical Device Harness Integration

Application Scenario: Internal wiring for patient monitoring systems in portable medical devices

Equipment and Products: ECG monitors, portable ultrasound, infusion pumps

Industry-specific needs:

- Medical-grade insulation, biocompatibility, and RoHS/REACH compliance

- Noise-free transmission and reliable pin mapping

- White or light-colored looms for visibility during inspections

Solutions: We delivered FDA-compliant, halogen-free wire looms using TPE jackets and gold-plated terminals. Wire pairs were twisted to reduce crosstalk. Each assembly was inspected under magnification, and a final report with continuity and insulation resistance test was provided.

Automotive Sensor and ECU Harness

Application Scenario: Wire looms for powertrain sensors and control modules in electric vehicles

Equipment and Products: ECU units, temperature sensors, battery modules, charging systems

Industry-specific needs:

- Withstand extreme temperature and vibration in under-hood environments

- Must support precise signal transmission for real-time control

- Require modular connectors for easy assembly and maintenance

Solutions: Our wire looms used high-temp-rated Teflon tubing with multi-layer shielding. We integrated waterproof connectors and heat-resistant nylon mesh for thermal stability. All assemblies passed ISO/TS automotive testing, with custom pinout verified through digital schematics before mass production.

Aerospace Cabin System Cabling

Application Scenario: Internal wire loom integration for cabin lighting and control panels in commercial aircraft

Equipment and Products: Overhead lighting, control buttons, infotainment panels

Industry-specific needs:

- Must meet FAA flame retardant standards and weight requirements

- Require labeled, color-coded looms for fast installation and troubleshooting

- Need flexible routing across tight, pre-defined cabin pathways

Solutions: We supplied lightweight, halogen-free wire looms using UL94V-0 rated sheathing. Our assemblies used FEP-coated conductors with color-coded shrink tubing for visibility. All wiring harnesses were labeled with printed markers and packed per aircraft cabin layout schematics for plug-and-play installation.

Agricultural Machinery Wire Management

Application Scenario: Internal and external wire routing in modern smart farming equipment

Equipment and Products: Precision planters, GPS-enabled tractors, irrigation control units

Industry-specific needs:

- Cables must withstand exposure to dust, mud, UV, and fluctuating outdoor temperatures

- Require waterproof sealing and high tensile strength

- Easy field maintenance and modular repair capability are essential

Solutions: We engineered IP67-rated wire looms using flame-retardant polyethylene sleeves and double-sealed junctions. All assemblies included UV-resistant outer sheaths and color-coded terminals. Quick-disconnect waterproof connectors were applied to allow fast field replacement. Full CAD routing maps were delivered with installation instructions.

Agricultural Equipment Harnessing

Application Scenario: Wire loom solutions for smart farming machinery in rugged field environments

Equipment and Products: GPS-guided tractors, harvesting machines, irrigation control panels

Industry-specific needs:

- Must resist mud, moisture, UV exposure, and mechanical shock

- Requires quick repair and modular replaceability in field operations

- Cable routing must allow movement through multiple articulation points

Solutions: We provided wire looms using sealed corrugated tubing and IP67-rated connectors. Each harness was coated with UV-stabilized PVC and used reinforced clips for impact resistance. Quick-disconnect interfaces and schematic-labeled bundles simplified on-site maintenance.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized wire loom services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I customize the wire loom length, shape, and pinout?

Yes. We fully support custom lengths, shapes, pin configurations, connector types, and shielding structures to fit your exact design requirements.

Do you provide drawings before production?

Yes. We provide CAD drawings (PDF format) for customer confirmation before production. Most drawings are ready within 1–3 days, some in 30 minutes.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

What certifications do you have?

Certifications include UL, RoHS, REACH, ISO 13485 (medical), IEC 61754 (industrial). PFAS/COC/COO docs available upon request.

Are your connectors genuine or compatible alternatives?

Both options are available. We can use original branded connectors or high-quality equivalents depending on budget, lead time, and availability.

What materials are used in your wire looms?

We use PVC, PET, nylon, Teflon®, silicone, and metal shielding (e.g., aluminum foil, braided copper) for high-temperature, abrasion, or chemical resistance needs.

How do you handle requests from customers unfamiliar with technical specs?

We accept images, basic descriptions, or reference samples. Our team will guide the spec design and recommend solutions.

Can your wire looms be used in high-frequency signal applications?

Yes. We offer low-loss and shielded configurations for high-speed data and RF signal routing.

Can I choose specific colors for the wires or sleeving?

Yes. We offer full customization of wire colors, outer sleeving, and labeling to match your color coding or brand guidelines.

Can I get twisted pair or shielded pair configurations?

Yes. We offer twisted pair and various shielding options including foil, braid, or conductive fabric for EMI control.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China