custom battery cable assembly manufacturer

Looking for battery cable assemblies that combine reliability, flexibility, and top performance? Sino-conn provides fully customized solutions for OEMs, engineers, and distributors. From 6AWG to 4/0 AWG, our cables support high-current applications with UL, RoHS, and ISO certification. We deliver samples in 3 days and full production in just 2 weeks. Whether you need branded or cost-effective alternatives, we have the right connector and layout for your needs. No MOQ, fast response, and full engineering support – start your project with us today.

Why choose battery cable assembly from sino-conn

Choose Sino-Conn for battery cable assemblies that offer superior customization, certified materials, and rapid turnaround. Our assemblies meet strict industry standards with flexible specs, no MOQ, and full inspection, making them ideal for demanding OEM, industrial, and energy storage applications.

Fast Sample Turnaround, No MOQ Required

We provide ultra-fast sample delivery for battery cable assemblies – as quick as 2-3 days. No minimum order quantity is required, making it ideal for prototypes, R&D trials, and small-volume runs. Whether you need just one custom cable or a few variations for testing, we can handle it swiftly and professionally. Combined with 30-minute drawing delivery and rapid quotation, our service helps clients reduce project timelines and testing costs significantly.

Original and Alternative Connector Options

We offer both genuine and compatible connector options to meet different budget and lead time requirements. Original parts ensure high-end brand compliance, while alternatives provide flexibility and shorter delivery for small batches. Our engineering team ensures all connectors—whether original or replacement—maintain full electrical and mechanical compatibility. This flexibility enables global clients to control cost without sacrificing performance or reliability.

Triple Quality Inspection Before Shipment

To ensure zero-defect delivery, every battery cable assembly undergoes a triple inspection process. This includes in-process checks during manufacturing, full inspection after assembly, and final testing before shipment. Each step is documented to maintain traceability. Our strict QC ensures consistent electrical performance, mechanical strength, and visual integrity. For industries like automotive, energy storage, and heavy equipment, this guarantees reliability even in harsh environments. Clients can rest assured that every cable meets international standards like UL, ISO, and RoHS before leaving our factory.

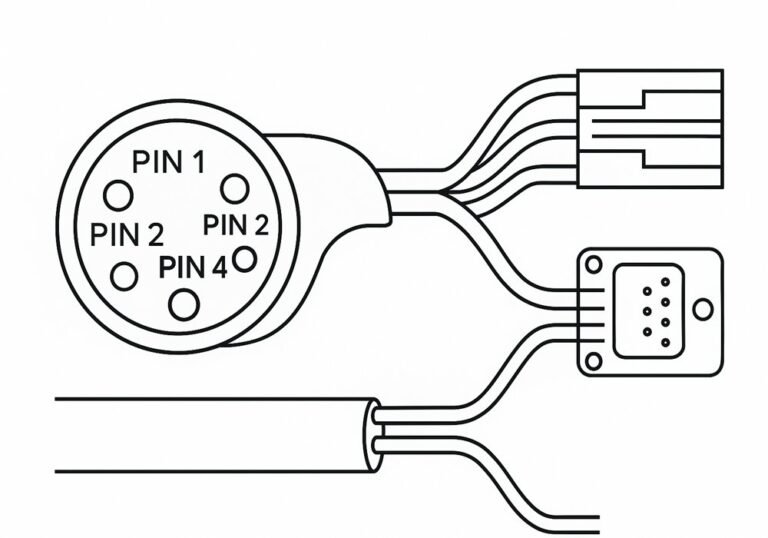

Full Customization of Cable Structure and Layout

We offer complete customization of cable structure, including conductor size, insulation material, shielding layer, jacket type, and cable layout. Whether you need 2-wire or 5-wire configurations, split branches, twisted pairs, or tight-bend routing, our engineers can design according to your system’s exact electrical and mechanical requirements. We support CAD drawings in PDF format for confirmation before production. This flexibility helps clients in energy, automotive, and industrial control fields implement unique wiring strategies for efficiency, space optimization, or EMI reduction. We turn complex cable needs into production-ready solutions.

Certified for Global Compliance: UL, RoHS, ISO

Our battery cable assemblies are manufactured under strict quality systems and meet major global standards, including UL, RoHS, ISO 9001, and REACH. Certificates of Compliance (CoC), Country of Origin (CoO), and PFAS-free declarations are available for each batch. This makes our products suitable for regulated industries such as EV manufacturing, energy storage systems, and medical equipment. We support third-party lab testing and document verification for customer audits. With full certification support, you can confidently use our cables in global markets without regulatory concerns.

Competitive Pricing with Tiered Solutions

We provide tiered pricing solutions tailored to different customer types—OEMs, engineers, and trading companies. Whether you need branded parts for final integration or compatible parts for bulk production, we match the solution to your budget. Our in-house production, flexible sourcing, and optimized assembly processes reduce costs while maintaining quality. From low-cost options for distributors to premium assemblies for end-users, we help you stay competitive in your market. With no MOQ and fast quotes, you get full pricing transparency and maximum flexibility.

Detailed specifications and parameters of battery cable assembly

Our battery cable assemblies are fully customizable, and the technical specifications vary significantly depending on customer requirements. Each design is tailored based on specific applications, electrical load, connector compatibility, environmental conditions, and industry standards. Whether it’s a simple one-to-one configuration or a complex multi-branch layout with mixed connectors, we work closely with clients to deliver optimal solutions. From conductor size and pinout definition to insulation materials and jacket types, every detail can be customized to ensure perfect fit and function. This flexibility is what sets us apart in high-reliability industries.

| No. | Definition (Pin Connection) | Connector Model | Wire Gauge | Length (mm) | Sheath Type | Sheath Material |

|---|---|---|---|---|---|---|

| 1 | 2-pin straight | AMP Superseal 1.5 | Custom | Custom | Circular | (PVC Sheath) |

| 2 | 3-pin right angle | Deutsch DT04 | Custom | Custom | Flat | (Teflon Sheath) |

| 3 | 4-pin inline | Molex MX150 | Custom | Custom | Molded | (Nylon Braid) |

| 4 | 6-pin Y-split | TE Connectivity HDP20 | Custom | Custom | Circular | (Conductive Fabric) |

| 5 | 8-pin modular | JST VH | Custom | Custom | Flat | (Teflon Tape) |

| 6 | 2-pin waterproof | Amphenol AT Series | Custom | Custom | Molded | (Acetate Cloth) |

| 7 | 3-pin shielded | Hirose DF13 | Custom | Custom | Circular | (Nano Tape) |

| 8 | 5-pin high-current | Anderson SB50 | Custom | Custom | Flat | (PVC Sheath) |

| 9 | 4-pin shielded inline | LEMO FGG | Custom | Custom | Molded | (Nylon Braid) |

| 10 | 2-pin quick-disconnect | TE Mate-N-Lok | Custom | Custom | Circular | (Teflon Sheath) |

Customized battery cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

XT90 Battery Cable Connectors with 12AWG Wire for Car and RC

EC5 Battery Cable Connectors with 12AWG Wire for Vehicle and Drone

4 Gauge Positive and Negative Battery Cable with Ring Terminals

2 Gauge Battery Jumper Cable with Alligator Clips

Automotive Battery Cable Assembly with Anderson Quick Connectors

Marine Battery Cable Assembly 2 Gauge with Tinned Copper Lugs

Product details display

Explore detailed product specifications for our custom battery cable assemblies, including conductor size, insulation material, terminal types, current rating, voltage capacity, and environmental resistance. Each display features close-up images and precise dimensions to help you evaluate quality and compatibility before ordering.

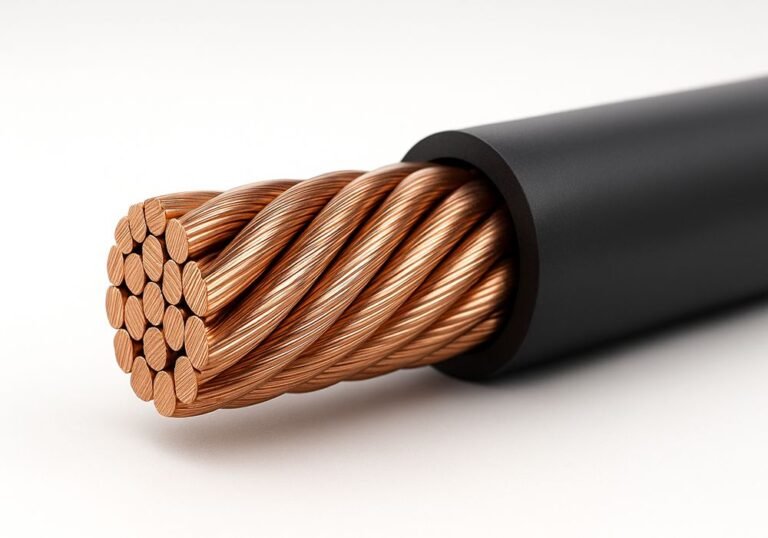

Multi-Stranded Copper Conductor Core

Our battery cable assemblies use multi-stranded oxygen-free copper (OFC) conductors to ensure high performance in current transmission and cable flexibility. This design provides superior electrical and mechanical advantages for demanding applications.

- Enhanced Conductivity: The use of OFC improves current flow and reduces power loss, especially in high-amperage systems like EV batteries and UPS.

- Superior Flexibility: Fine strands reduce stiffness, enabling tight bends and easier installation in confined spaces.

- Vibration Resistance: Multi-strand construction absorbs movement and minimizes fatigue, making it ideal for dynamic environments.

- Customization Ready: Strand count, gauge, and bundling style can be tailored to match electrical load and spatial constraints.

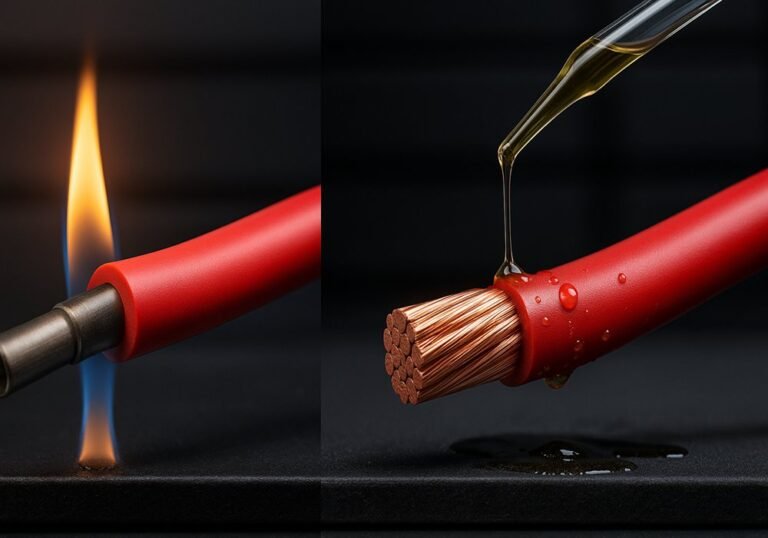

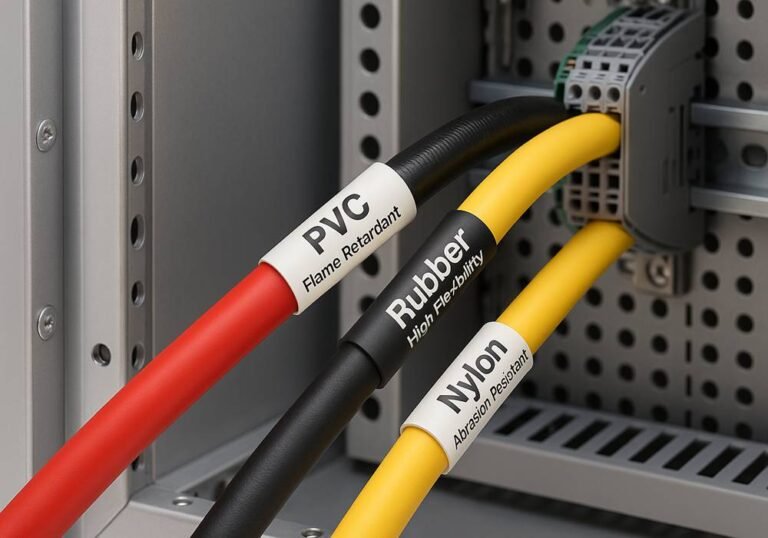

High-Flex Insulation Jacket Design

The insulation jacket of our battery cable assemblies is designed to balance flexibility, durability, and safety across multiple environments. We select materials according to customer applications and compliance needs.

- Material Options: Available in XLPE, silicone, PVC, and TPE, each suited for different temperature, oil, or UV exposure needs.

- Mechanical Durability: Prevents cracking, abrasion, and deformation under frequent movement.

- Safety Compliant: Flame-retardant, RoHS-compliant, and free from halogen/PFAS for global regulatory compatibility.

- Color Coding & Thickness Customization: Available in various colors for identification; jacket thickness customizable for routing or protection needs.

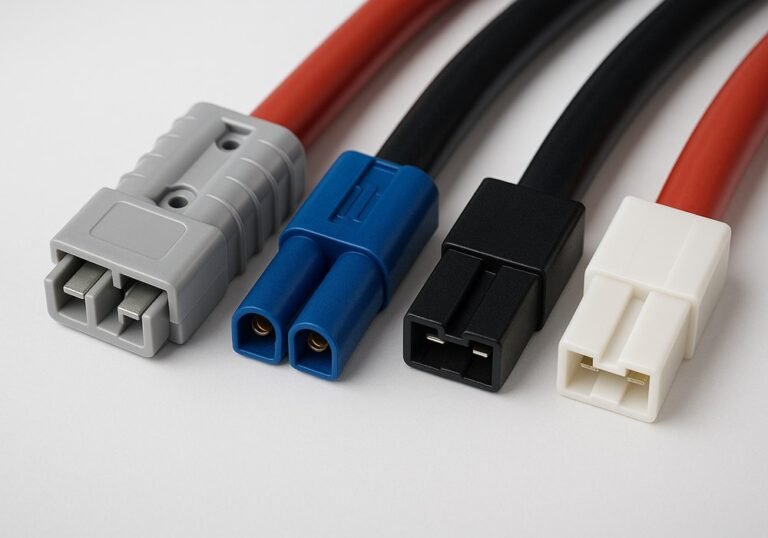

Precision Crimping and Connector Compatibility

We ensure secure and reliable termination in every battery cable assembly by applying precision crimping techniques and ensuring broad connector compatibility.

- Consistent Crimp Quality: All terminations are processed using calibrated tooling, ensuring accurate shape and minimal contact resistance.

- Connector Flexibility: Supports both original and replacement options such as Anderson, Molex, Amphenol, EC5, etc.

- Mechanical Strength Verified: Pull force tests confirm the durability of every crimp joint under mechanical stress.

- Application Matching: We recommend suitable connectors based on voltage, current, and environmental sealing needs.

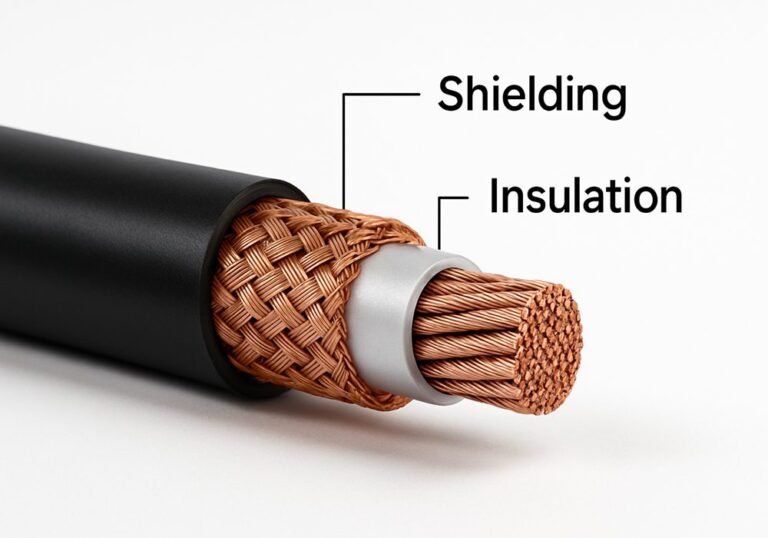

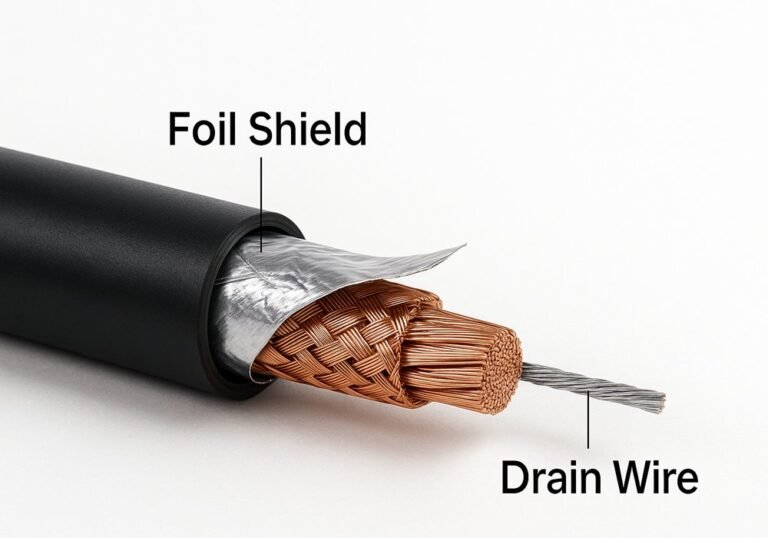

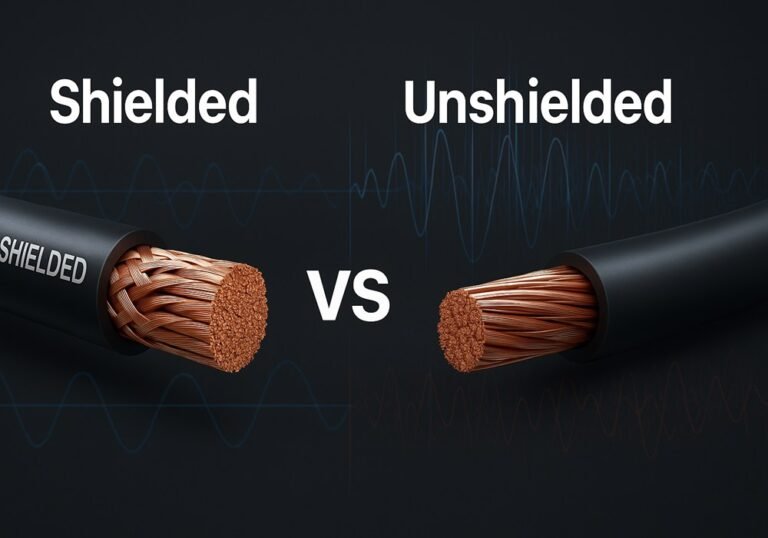

Shielding Structure and EMI Protection

To ensure signal integrity and reduce electromagnetic interference (EMI), our battery cable assemblies can be equipped with high-performance shielding layers. These are essential in environments with high electrical noise or sensitive electronics.

- Shielding Types: Braided copper, aluminum foil, or hybrid layers available depending on required attenuation level.

- EMI-Sensitive Applications: Suitable for use near inverters, motor controllers, and high-frequency switching power supplies.

- Grounding Support: Shield terminations can be grounded to metal housings or external drain wires for complete EMI suppression.

- Optional Design: Shielding is available as an optional add-on to standard cables, allowing clients to balance performance and cost.

Outer Jacket Options and Sheathing Structures

Our outer jacket solutions provide mechanical protection, environmental resistance, and identification for battery cables. Clients can choose from various jacket styles and materials to meet industry-specific requirements.

- Sheathing Styles: Round, flat, molded, split-branch designs available for different space constraints.

- Material Choices: PVC tubing, Teflon sleeves, nylon braid, nano-tape, or acetate cloth for fire, oil, UV, or chemical resistance.

- Visual Identification: Jackets can be color-coded, printed, or layered for easier routing and maintenance.

- Application-Oriented Customization: We design sheath structures to withstand abrasion, impact, or external fluid exposure in automotive, marine, and industrial applications.

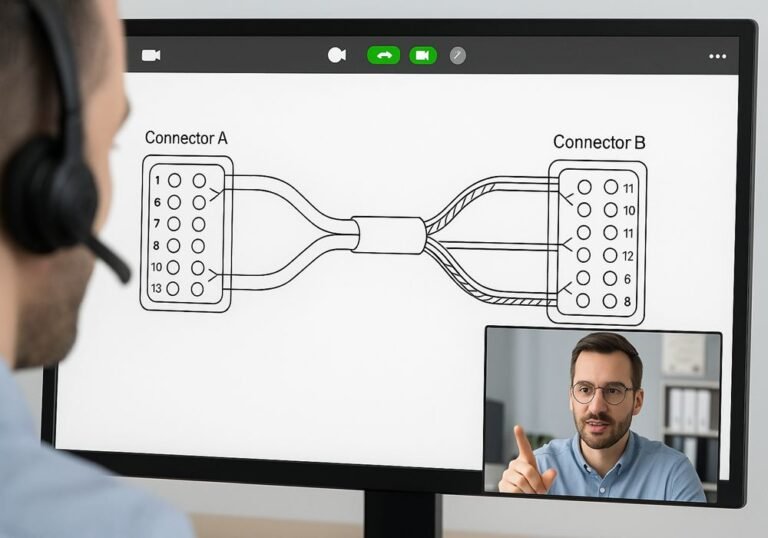

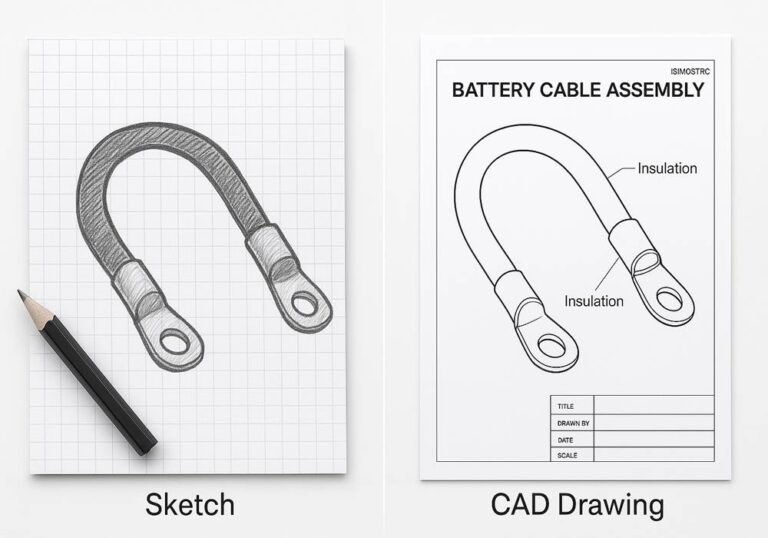

Custom Drawings and Engineering Support

We provide full engineering support and fast technical drawing services for every battery cable assembly project. From concept to production, our team helps customers achieve precision fit and functional design.

- Rapid Drawing Turnaround: 2D CAD + PDF drawings available within 30 minutes to 3 days, depending on complexity.

- Full Customization: Pinout definition, routing layout, connector mating, and mounting points tailored per project.

- Pre-Production Approval: All drawings are submitted to clients for confirmation before manufacturing starts.

- Collaborative Support: Our engineers can join live video calls to clarify specs or adjust designs on the fly.

--- Customized Capabilities Services and Processes

Customize your battery cable assembly

Discover our customized capabilities, services, and processes for battery cable assemblies. From flexible length and connector type selection to rapid prototyping and CAD drawing support, we deliver tailored solutions that meet your exact technical and application needs. Our streamlined design-to-production workflow ensures speed, precision, and quality at every stage.

Customized Capabilities Services and Processes

Customize your battery cable assembly

We believe every cable should fit the application—not the other way around.

Customization Capabilities

We believe every cable should fit the application—not the other way around.

At Sino-conn, customization is not a special service; it’s our standard. From single-wire connections to complex multi-branch assemblies, we tailor every detail of your battery cable assembly to match real-world application scenarios.

Our customization capabilities include:

- Cable Geometry & Layout: Choose from round, flat, molded, or Y-branch formats based on installation constraints.

- Electrical Configuration: Fully customizable pinout definition, conductor size (from 10AWG to 4/0), and current capacity support.

- Materials & Durability: Select insulation and jacket materials for high temp, flame-retardant, oil-resistant, UV-proof or halogen-free requirements.

- Connector Flexibility: Original brands (Anderson, Molex, Amphenol) or compatible alternatives available to suit budget and system.

- EMI Shielding & Hybrid Design: Optional shielding structure and combined power/signal cable assemblies supported.

Customization is how we help you succeed.

Whether you’re working in automotive, energy storage, marine, or medical sectors, we build to spec—not to stock. No MOQ, fast drawings, and expert engineers ensure every project is efficient, flexible, and accurate from concept to production.

Great products start with great service—and we deliver both.

At Sino-conn, we don’t just manufacture battery cable assemblies—we partner with our clients to deliver fast, technical, and responsive support from inquiry to delivery. We understand that cable performance depends on more than materials; it also relies on process, communication, and accountability.

Here’s what our exceptional service includes:

- Immediate Response: RFQs answered in 30 minutes, engineering drawings within hours.

- Collaborative Support: Engineers join video calls to understand and refine your requirements in real time.

- Transparent Process: Every project includes drawing confirmation, progress updates, and test result sharing.

- Delivery Commitment: Sample ready in 2–3 days, mass production in 2 weeks—rush orders accepted.

- Global Compliance: UL, ISO, RoHS, COC, REACH, and PFAS documentation available for every order.

- No Barriers: No MOQ, customized labels, multilingual communication, international packaging standards.

We make your success our responsibility.

When you work with us, you’re not buying a cable—you’re gaining a team that’s committed to solving your problems, exceeding your expectations, and helping your project succeed under pressure.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Michael leads the battery systems team at a German EV startup. He contacted us when their in-house team failed to find a cable assembly with sufficient flexibility and EMI shielding for tight battery compartments.

Application Scenario:

The cable was used in a modular electric vehicle battery pack, requiring ultra-flexible insulation, tight bend radius, and low signal interference. We provided a customized battery cable assembly with TPE jacket, multi-stranded OFC conductors, and braided shielding. Drawings were delivered within 2 hours and prototypes shipped in 3 days.

“ Sino-conn exceeded our expectations. Their speed, customization accuracy, and real engineering support made them feel like part of our internal team. We’ll definitely use them again for future battery module projects.”

Michael Chen

R&D Director, Munich, Germany

Ravi manages sourcing for a large OEM manufacturing diesel generators. He needed reliable battery cable assemblies that could handle harsh temperatures and maintain stable conductivity under vibration.

Application Scenario:

The battery cable assembly was used in backup power units for telecom towers across India. We recommended a 2AWG copper conductor with silicone insulation and crimped M10 ring terminals, tested for -40°C to 120°C and 1000+ vibration cycles. All orders included UL and ISO certificates.

“We’ve worked with many suppliers, but few match Sino-conn’s commitment. The cable quality is rock solid, and their team was open to modifying even small technical details. Very reliable partner for us.”

Ravi Kumar

Procurement Manager, Pune, India

Emily works for a medical device OEM that produces high-voltage surgical equipment. She reached out with strict compliance requirements for halogen-free, flame-retardant battery cables in small quantities.

Application Scenario:

The cables were used inside surgical power units, requiring low smoke, zero halogen materials, UL approval, and custom labeling. We delivered a no-MOQ solution with quick-turn CAD drawings, PVC-free insulation, and complete documentation including REACH and PFAS reports.

“Sino-conn delivered exactly what we needed. No MOQ, fast drawings, and complete certifications made onboarding painless. Their team knew what compliance means in the medical field—truly professional.”

Emily Torres

Senior Buyer, Austin, USA

industry Application of battery cable assembly

Battery cable assemblies from Sino-Conn are widely used in automotive, industrial machinery, renewable energy systems, marine equipment, and medical devices. Designed for high-current transmission and durability, our cables ensure stable power delivery in demanding environments. Whether for EVs, backup power systems, or heavy equipment, our assemblies meet industry-specific safety and performance standards.

Telecom Backup Power Systems

Application Scenario: Backup power solutions in telecom base stations

Devices & Products: DC power units, battery racks, telecom base stations, inverters

Industry-Specific Needs:

- Stable low-voltage power delivery over long cable runs.

- Flexibility to route cables through tight cabinets or conduits.

- Flame-retardant and low-smoke materials to meet telecom safety standards.

Solutions We Provide:

- Battery cables with low-resistance stranded copper core and customized voltage drop optimization for long-distance routing.

- Flat or semi-flexible cable structures with high-bending endurance for narrow routing paths.

- Sheaths made from LSZH or PVC flame-retardant material with full RoHS/REACH certification.

Offshore Wind Power Systems

Solution: Salt-corrosion resistant power transmission Application Scenario: Between nacelle and tower base Equipment/Products: 10MW turbines, pitch control systems Industry Pain Points:

- Saltwater penetration in harsh marine environments

- Constant cable twisting during yaw movements

- Limited maintenance windows

Our Solution:

- Titanium-nickel alloy armored cables

- 360° rotating connector systems

- Built-in tension monitoring RFID tags

- Pressurized nitrogen-filled terminal boxes

Telecom Backup Power Systems

Application Scenario: Backup power solutions in telecom base stations

Devices & Products: DC power units, battery racks, telecom base stations, inverters

Industry-Specific Needs:

- Stable low-voltage power delivery over long cable runs.

- Flexibility to route cables through tight cabinets or conduits.

- Flame-retardant and low-smoke materials to meet telecom safety standards.

Solutions We Provide:

- Battery cables with low-resistance stranded copper core and customized voltage drop optimization for long-distance routing.

- Flat or semi-flexible cable structures with high-bending endurance for narrow routing paths.

- Sheaths made from LSZH or PVC flame-retardant material with full RoHS/REACH certification.

Industrial AGV Power Wiring

Application Scenario: Automated Guided Vehicles (AGVs) in manufacturing facilities

Devices & Products: Battery modules, motor controllers, charging interfaces, power switches

Industry-Specific Needs:

- High vibration resistance for mobile environments.

- Durable insulation to handle frequent charging/discharging cycles.

- Compact routing with customizable lengths and terminal orientations.

Solutions We Provide:

- Reinforced terminal crimping and anti-vibration design to maintain firm connections in mobile equipment.

- Use of flexible, high-durability cable insulation (such as silicone or TPE) resistant to mechanical fatigue.

- Custom cable assemblies with defined length, shape, and plug direction tailored to each AGV chassis layout.

EV Battery Interconnection Wiring

Application Scenario: Electric Vehicle (EV) Battery Systems

Devices & Products: Battery packs, BMS (Battery Management Systems), high-current power modules, charging systems

Industry-Specific Needs:

- High-voltage and high-current tolerance under dynamic load conditions.

- Excellent thermal and chemical resistance inside battery compartments.

- Reliable EMI shielding to ensure BMS signal integrity.

Solutions We Provide:

- Custom-designed battery cable assemblies with UL-certified terminals and pure copper conductors rated for 600V–1000V applications.

- Use of high-performance insulation (e.g., XLPE or TPE) and flame-retardant sheaths for long-term thermal stability.

- Multi-layer shielding structures to protect sensitive signal cables from electromagnetic interference and cross-talk.

Aerospace Ground Support Equipment

Solution: Lightning protection power distribution system

Application scenario: Airport aircraft tractor

Equipment products: 90V electric tractor, charging pile

Industry pain points:

– Risk of lightning surge during thunderstorms

– Extreme operating temperature of 55°C to 70°C

– Strict FAA/SAE AS50881 certification requirements

Solution:

– Carbon nanotube surge dissipation conductive layer

– Polar grade flexible insulation material

– MS3116 military quick-release connector

– Avionics anti-interference shielded wiring

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

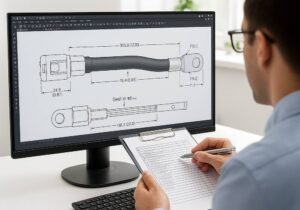

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized battery cable assembly services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I customize the cable length and terminal type?

Yes, we support full customization including length, terminal types (ring, spade, bullet), and cable routing shapes to meet specific layout requirements.

Do you provide drawings before production?

Yes. We provide CAD drawings (PDF format) for customer confirmation before production. Most drawings are ready within 1–3 days, some in 30 minutes.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

What certifications do your cables have?

Our battery cable assemblies are compliant with UL, ISO, ROHS, REACH, and can provide COC/COO upon request.

Are your connectors genuine or compatible alternatives?

Both options are available. We can use original branded connectors or high-quality equivalents depending on budget, lead time, and availability.

What materials are used in your battery cable assemblies?

We use oxygen-free copper conductors, silicone/TPE/PVC insulation, and flame-retardant jackets. Options include EMI-shielded, oil-resistant, or UV-proof materials for harsh environments.

How do you handle requests from customers unfamiliar with technical specs?

We accept images, basic descriptions, or reference samples. Our team will guide the spec design and recommend solutions.

What is a battery cable assembly and where is it used?

A battery cable assembly is a custom-built cable system designed to connect batteries to power systems. It is widely used in automotive, industrial machinery, energy storage, marine, and telecom equipment.

Do you offer design suggestions based on application?

Yes, our engineers will propose the most suitable cable design based on your current, voltage, routing, and operating environment.

Can I get twisted pair or shielded pair configurations?

Yes. We offer twisted pair and various shielding options including foil, braid, or conductive fabric for EMI control.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China