custom circular cable assemblies manufacturer

Built for demanding industrial and automation environments, our circular cable assemblies offer superior shielding, flexible configurations, and precise connections. From robotics to control panels, we deliver reliable signal and power performance with fast lead times, zero MOQ, and full customization support to match your exact design.

Why choose circular cable assemblies from sino-conn

Sino-Conn stands out as a trusted provider of circular cable assemblies due to our precision customization, fast prototyping, and full compliance with international certifications. Whether you need exact pin configurations, EMI shielding, or rugged materials for industrial use, we deliver tailored solutions with rapid turnaround. Choose Sino-Conn for consistent quality, no-MOQ flexibility, and expert engineering support.

Flexible Connector Configurations for Every Application

We offer a wide range of connector types, including M5, M8, M12, M23, 7/8″, and custom variants to match your exact application. Whether your project requires angled, straight, panel-mount, or waterproof styles, our circular cable assemblies ensure seamless integration with high compatibility and long-term reliability.

100% Full Inspection and Quality Assurance System

Every circular cable assembly undergoes 100% full inspection—during production, post-assembly, and pre-shipment. We conduct visual checks, continuity tests, pinout verification, and labeling review. This thorough process guarantees consistent performance and quality reliability in every delivery we make.

Rapid Customization with Drawing and Sample Support

We provide fast and flexible customization services: drawing turnaround in 30 minutes, sample delivery in 3 days. You can customize pinout, connector style, and routing. All drawings are confirmed before production to guarantee accuracy, efficiency, and excellent adaptation to your application scenario.

Certified for Global Standards and Harsh Environments

Our circular cable assemblies are certified with UL, ISO9001, RoHS, REACH, and PFAS compliance, ensuring safe use in industrial, automotive, and medical environments. With excellent resistance to UV, oil, flame, and temperature extremes, they deliver stable performance even under outdoor or rugged conditions.

Wide Material Compatibility for Custom Applications

Our circular cable assemblies can be built with PUR, PVC, TPE, or silicone jackets, matched with braided, foil, or combo shielding based on your EMI environment. From high-flex robotics to harsh chemical plants, our material flexibility ensures performance and safety in every configuration.

No MOQ, Fast Delivery, Flexible for All Scales

We support prototyping, small batches, and high-volume production with no MOQ restrictions. Samples can be ready in as fast as 3 days, and mass production within 2 weeks. Our efficient scheduling and flexible capacity make us ideal for urgent and scalable cable assembly needs.

Detailed specifications and parameters of circular cable assemblies

| No. | Pin Definition | Connector Model | Cable Spec | Length (mm) | Jacket Form | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 3-pin signal | M8 male/female | Custom | Custom | Round | PVC sleeving |

| 2 | 4-pin power/signal mix | M12 A-coded | Custom | Custom | Round | Nylon braided mesh |

| 3 | 5-pin data | M12 D-coded | Custom | Custom | Molded | PVC sleeving |

| 4 | 8-pin Ethernet | M12 X-coded | Custom | Custom | Round | Teflon tubing |

| 5 | 12-pin sensor control | M23 connector | Custom | Custom | Round | Nylon braided mesh |

| 6 | 4-pin waterproof | 7/8″ waterproof | Custom | Custom | Molded | TPU overmolding |

| 7 | 2-pin DC power | M5 connector | Custom | Custom | Round | PVC sleeving |

| 8 | 6-pin automation I/O | M12 B-coded | Custom | Custom | Round | Conductive fabric tape |

| 9 | 3-pin signal shielded | M8 shielded | Custom | Custom | Round | Aluminum foil + braid |

| 10 | Custom multi-pin combo | Hybrid connector | Custom | Custom | Round | Acetate cloth tape |

Each circular cable assembly we produce is fully customizable in terms of pinout, connector type, cable length, shielding structure, and jacket material. The table above lists only common examples, but actual production configurations depend entirely on each customer’s unique application and technical requirements. This flexibility is at the core of our engineering capability.

Customized circular cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

waterproof m12 connector circular cable assemblies

Waterproof M12 Circular Connector D-Code Cable Assembly

Waterproof Circular Plug Connector Cable Assembly

waterproof circular cable assemblies

m12 to rj45 circular cable assemblies

circular power connector cable assemblies

circular connector cable assemblies with open wire end

circular connector cable assemblies

Armored Circular Cable Assembly RF Shielded

8 Pin Circular Connector Cable Assembly Overmolded

5 Pin Round Connector Circular Cable Assembly (DMX Lighting)

5 Pin Round Circular Connector Cable Assembly (XLR Pro Audio)

3 Pin Circular Plug Connector Cable Assembly (XLR Audio)

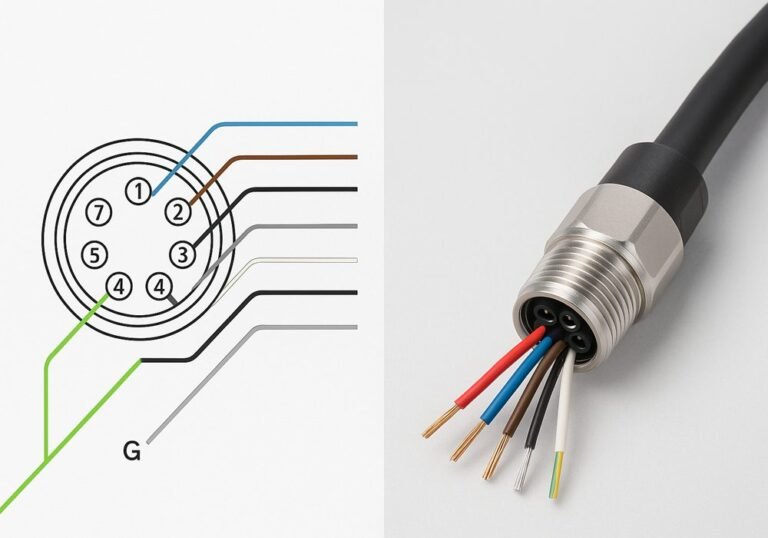

Product details display of circular cable assemblies

Explore the detailed specifications of our circular cable assemblies, including connector types, cable materials, shielding options, voltage ratings, and temperature resistance. Each product is engineered for durability, flexibility, and high signal integrity. View close-up photos, structure diagrams, and dimensional data to understand how our assemblies meet demanding industrial and commercial applications.

Connector Interface Precision and Fit

The precision of the connector interface is essential to ensuring signal integrity and mechanical stability in circular cable assemblies. At sino-conn, each connector head—whether M8, M12, or M23—is manufactured with tight tolerances, gold-plated contacts, and optimized thread design. This enables seamless mating, minimizes signal loss, and ensures a secure fit even under vibration or movement. Our assembly process includes multi-point testing to guarantee that every connector achieves consistent mechanical insertion force and electrical conductivity. High mating cycles and IP-rated variants are also available to support long-life and harsh environment use cases.

- Gold-plated contacts for optimal conductivity and corrosion resistance.

- Threaded, snap-lock, or bayonet interface options ensure stable fit.

- Compatible with IP67/IP68 designs for harsh environments.

- Each connector tested for contact resistance and mating force.

Layered Cable Structure and Shielding Design

A robust layered cable structure ensures durability, signal integrity, and EMI protection in circular cable assemblies. Our standard build includes a central conductor core, inner insulation, a tightly braided or foil shield, and an outer jacket made from PUR, PVC, or TPE. This multi-layered design not only resists mechanical stress and interference but also supports flexible bending, vital in dynamic applications like robotics or vehicles. Each layer is selected based on application-specific needs to achieve an optimal balance of strength, weight, and electrical performance. Additional shielding methods like dual-layer foil + braid are available for critical EMI control.

- Central tinned copper or solid copper conductors for stable transmission.

- Fluoropolymer or PVC insulation for temperature and voltage protection.

- Braided or foil shield blocks EMI and crosstalk effectively.

- PUR, TPE, or silicone jackets provide abrasion and oil resistance.

IP-Rated Waterproof and Dustproof Performance

Circular cable assemblies often operate in demanding industrial environments where moisture, dust, and oil can compromise performance. At sino-conn, we design our connectors and cable overmolds to meet IP67/IP68 protection standards. This includes O-ring sealing, integrated overmolding, and press-fit contact engineering. The result is a fully sealed solution that ensures uninterrupted operation in wet, dusty, or submerged conditions. These assemblies are ideal for outdoor sensors, machinery, and automotive applications. Optional gel-filled or double-seal variants are also available for environments with pressure or high humidity.

- IP67/IP68 waterproof sealing with integrated O-rings and molded backshells

- Protects against water ingress, dust particles, and chemical sprays

- Ideal for outdoor, underwater, or high-humidity environments

- Optional gel-fill or dual-seal configurations for enhanced protection

Custom Pinout and Signal Mapping Flexibility

Circular cable assemblies often serve diverse devices with varying signal requirements. sino-conn offers full customization of pin configurations and internal wiring to match specific protocols such as CAN, RS-485, Ethernet, or analog signal chains. Our engineers collaborate closely with clients to define wire color codes, shielding groups, and grounding schemes that ensure signal clarity and noise suppression. Whether you need straight-through, cross-wired, or multi-signal hybrid cables, we deliver precise assemblies that reduce integration errors and installation time. We also offer full documentation including wiring diagrams and continuity test reports for quality assurance.

- Custom pin assignments for data, power, and signal integrity.

- Support for CAN bus, RS-485, Ethernet, analog/digital combinations.

- Color-coded wires and labeled connectors minimize wiring errors.

- Full test documentation with pinout charts and continuity results.

Bending Flexibility and Motion Endurance

Circular cable assemblies often operate in dynamic environments, requiring high bending flexibility and extended motion life. Our cables are engineered with ultra-flexible stranded conductors, TPE or silicone jackets, and high-flex shield designs. These assemblies maintain consistent performance even after millions of bend cycles, ideal for robotics, drag chain systems, and machine tools. We perform dynamic bending tests at high frequency to ensure long-term durability without compromising signal integrity. This flexibility does not come at the cost of robustness—our cables maintain full EMI protection and mechanical strength, offering optimal performance in continuous movement applications.

- Ultra-flexible stranded copper cores for repeated dynamic bending.

- High-flex TPE, PUR, or silicone jackets resist wear and maintain shape.

- Passed 3 million+ cycles in dynamic motion lab testing.

- Ideal for robotics, automated arms, and track systems.

Waterproof and Chemical-Resistant Jacket Materials

Circular cable assemblies are often deployed in wet, outdoor, or chemically harsh industrial settings. To meet these challenges, we offer cable jackets made of premium-grade PUR, TPE, or fluoropolymers. These materials are inherently resistant to water ingress, oils, fuels, solvents, and corrosive agents. Combined with molded or sealed connector interfaces (IP67/IP68), our assemblies maintain full functionality in environments like food processing, factory automation, marine systems, or chemical plants. We perform immersion and spray testing per IEC and NEMA standards. The jacket materials are also halogen-free and flame-retardant, meeting global safety regulations such as UL, RoHS, and REACH.

- PUR, TPE, and fluoropolymer jackets for waterproof and chemical resistance.

- Molded strain relief and overmolding for sealed, IP-rated interfaces.

- Halogen-free and flame-retardant per UL VW-1 and IEC 60332.

- Suitable for harsh conditions: food machinery, marine, or automation plants.

--- Customized Capabilities Services and Processes

Customize your circular cable assemblies

Discover our customized capabilities, services, and manufacturing processes tailored for circular cable assemblies. From connector selection, pinout definition, and material customization to EMI shielding, drawing support, and flexible prototyping—we deliver precise, scalable solutions. Our team ensures every order is backed by fast response times, engineering expertise, and full compliance with international certifications.

Customized Capabilities Services and Processes

Customize your circular cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, customization is not just a service—it’s the core of our value proposition. Our circular cable assemblies are designed to meet the most demanding technical and application-specific requirements across industries such as medical, automotive, industrial automation, and aerospace. Whether you are building a high-frequency signal interface or a ruggedized power solution, our engineering team is ready to transform your concept into a reliable solution.

● Tailored Connector Configurations:

We support a wide range of connector types (M5, M8, M12, M23, 7/8”, etc.), pin layouts (3–24 pins), coding formats (A, B, D, X, Y), and interface types (screw-lock, push-pull, bayonet) to meet signal, power, or hybrid needs.

● Customized Cable Design:

From cable diameter, shielding structure, and bend radius to EMI protection, IP rating, and temperature resistance, every aspect can be tailored. We offer cable jackets in PVC, PUR, TPE, and silicone for different flexibility and environmental resistance levels.

● Drawing & Rapid Prototyping:

We provide CAD and 3D PDF drawings within 1–3 days upon request, and offer rapid prototyping with lead times as fast as 3 days. Final drawings are always confirmed by the customer before production begins.

● Zero MOQ, Flexible Adjustments:

No minimum order quantity. Length, color, pinout, connector orientation, and even labeling or overmolding can be freely adjusted—even for just one piece.

● Full Compliance & Material Control:

All products can be produced in compliance with RoHS, REACH, UL, ISO, and PFAS requirements. We guarantee full material traceability and documentation for every order.

Our Commitment to Outstanding Service

At sino-conn, we believe that excellent service is just as important as product performance. Our clients work on high-stakes, precision-driven projects—and we treat their needs with equal urgency and dedication.

- Speed First: We deliver 2D drawings in as fast as 30 minutes, provide quotes within hours, and offer sample production in just 3 working days.

- Zero MOQ & High Flexibility: Whether it’s one cable or ten thousand, we treat every project seriously. From R&D prototypes to urgent field replacements, we respond quickly.

- Communication Transparency: We support real-time updates, video calls, collaborative CAD revisions, and multilingual communication (EN/DE/JP).

- Professional Documentation: Each project is tracked with full inspection reports, CAD files, RoHS/REACH/UL documentation, and S-parameter test data.

- Full Lifecycle Support: From the first inquiry to after-sales technical consultation, we provide one-on-one service, always fast and responsive.

We don’t just sell semi rigid cable assemblies—we build trust, reduce risk, and deliver confidence. That’s what true service means to us, and what you can expect from sino-conn.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Robotics Arm Integration – Zero Downtime Cable Performance

We were launching a new 6-axis robotic arm series for automotive production, requiring ultra-flexible circular cable assemblies with superior EMI shielding and over 5 million flex life cycles. Traditional suppliers couldn’t meet both mechanical durability and signal stability under constant motion.

sino-conn exceeded expectations from day one. Their engineering team reviewed our CAD in under an hour and proposed a reinforced M8 circular solution with tighter bend radius, 360° copper braided shielding, and halogen-free jacket—all within our spec envelope. They even adjusted connector orientation to fit our panel constraints.

The prototypes arrived in 4 days. In our dynamic cable track tests, signal loss remained below 0.03 dB, and cable jackets showed zero microcracks even after 5.2 million cycles. The documentation package (RoHS, UL, CE) was thorough and FDA-grade compliant.

We’ve since standardized Sino-conn as our sole supplier for robotic cable systems. Their speed, precision, and ability to iterate with us on complex configurations is what makes them a true engineering partner.

“Sino-conn combines flexibility with serious technical depth. We trust them for every high-motion cable project.”

Thomas Meier, Senior Automation Engineer

Surgical Navigation System – Customized Cable for Medical Precision

Our surgical navigation platform demanded a compact, sterilizable, and EMI-shielded circular cable assembly that could integrate seamlessly with our imaging probes. The cable had to be lightweight for surgeon comfort and yet robust enough to transmit real-time positional and imaging signals without degradation—especially during high-precision procedures.

We approached Sino-conn with a rough outline and connector preference. Within 24 hours, their engineering team proposed a custom circular connector assembly using TPU sheathing, silver-plated copper conductors, and dual-layer EMI shielding. Not only did they match our technical needs, but they also accounted for FDA material compliance and provided detailed drawings and certifications (ISO 13485, RoHS).

We received 3D prototypes within 3 days and production samples in 6 days. The cable fit our handpiece perfectly, and it passed all flex and sterilization cycle tests. The precision and cleanliness of their build was outstanding.

“They understood both our clinical constraints and technical needs. Sino-conn is more than a supplier—they’re an extension of our R&D team.”

Dr. Olivia Bennett, Biomedical Device Engineer

Location: Boston, USA

Smart Agriculture Automation – Reliable Cabling in Harsh Environments

Our agricultural automation project aimed to control irrigation, sensor data collection, and motorized valve systems over large outdoor fields. We required circular cable assemblies that could handle IP67 waterproofing, UV exposure, and temperature extremes, while maintaining reliable signal and power transmission across long distances.

Sino-conn proposed a robust M12 connector-based circular cable with UV-stabilized PUR jacket, tinned copper conductors, and molded overmold sealing. They helped us test for both dust ingress and high-pressure water spray. The assemblies passed both IP67 and IP68 tests and were delivered with REACH and CE documentation.

The cables were easy to install across our distributed network of control boxes and sensors, and performed flawlessly even after weeks of monsoon rain. Sino-conn also maintained consistent quality across multiple batches, something we previously struggled with from local vendors.

“We needed ruggedness and consistency. Sino-conn delivered both—and faster than expected.”

Rajesh Kumar, Automation Project Manager

Location: Pune, India

Location: Stuttgart, Germany

industry Application of circular cable assemblies

Circular cable assemblies are widely used in industries such as medical devices, industrial automation, telecommunications, aerospace, and transportation. Their robust construction, EMI shielding, and secure connections make them ideal for environments requiring reliability, durability, and compact multi-pin connectivity. Our custom circular assemblies meet diverse application needs with precision and compliance.

Industrial Robotics Cabling

Application Scenario: In high-performance industrial robotics systems, circular cable assemblies are widely used to connect sensors, actuators, and control units in robotic arms and motion platforms. These environments involve continuous mechanical movement, oil exposure, and tight bending radii. For example, in automotive manufacturing lines or CNC machining centers, cable assemblies must withstand frequent flexing and EMI-heavy environments, while maintaining accurate data and power transmission.

Devices & Products:

- Robotic arms and servo motors

- CNC machines and motion controllers

- Industrial sensors and actuators

Industry-Specific Requirements:

- Continuous dynamic motion and high flex cycles

- Resistance to oil, dust, and industrial coolants

- EMI shielding for precise signal transmission

Solutions:

- Use of PUR-sheathed cables with enhanced torsional and bending flexibility

- Shielded twisted pairs and braided EMI shields for noise immunity

- M12 or M23 connectors with IP67 sealing for oil- and dust-proof protection

Medical Equipment Wiring Solution

Application Scenario: Modern medical devices such as imaging systems, diagnostic analyzers, and patient monitoring units demand compact, sterile, and interference-free cable solutions. Circular cable assemblies are used to connect internal modules within MRI scanners, ultrasound systems, and ICU monitors. These systems operate in sensitive environments where precision, hygiene, and longevity are crucial. For instance, in MRI machines, the cable assemblies must ensure stable data transmission without affecting the magnetic field, while also withstanding daily disinfection and limited space routing.

Devices & Products:

- MRI scanners and CT machines

- Ultrasound diagnostic systems

- ICU monitoring units and patient beds

Industry-Specific Requirements:

- Zero-interference signal transmission within high-sensitivity environments

- Biocompatibility and chemical resistance for frequent cleaning

- Compact routing with low-profile connector options

Solutions:

- Use of medical-grade, halogen-free sheathing materials with high dielectric strength

- Shielded construction with ultra-low capacitance for signal integrity

- Circular mini-connectors with quick-locking and sterilizable housings

Railway Control System Cabling

Application Scenario:

In railway automation systems, circular cable assemblies play a crucial role in connecting signaling units, brake controllers, and onboard monitoring electronics. These systems require high mechanical reliability and consistent signal quality over long distances and across various temperature and vibration extremes. In high-speed train networks, for example, cables must endure constant vibration, outdoor exposure, and electromagnetic interference from power systems, all while maintaining real-time communication accuracy.

Devices & Products:

- Train brake control units and sensor arrays

- Signal relays and PLC-based communication modules

- Trackside sensor networks and onboard display systems

Industry-Specific Requirements:

- High vibration resistance and operational safety

- Wide temperature tolerance (from -40°C to +85°C)

- Shielded construction to avoid EMI from high-voltage systems

Solutions:

- Use of flame-retardant, abrasion-resistant PUR or TPE jackets

- Circular connectors with threaded locking to resist vibration

- Double-shielded cable structures for enhanced signal protection

Renewable Energy Equipment Cabling

Application Scenario:

Circular cable assemblies are essential components in wind turbines and solar inverters, where reliability under harsh weather, UV radiation, and mechanical stress is crucial. In wind energy systems, these cables connect sensors, pitch motors, and control electronics inside the nacelle and tower, often exposed to vibration, moisture, and high voltage. Solar farms, similarly, require long-life, flame-retardant cables that can be installed underground or inside metal conduits, resisting corrosion and maintaining signal clarity for decades.

Devices & Products:

- Wind turbine pitch control units and yaw drives

- Solar inverters and power distribution boxes

- Environmental sensors and grid communication interfaces

Industry-Specific Requirements:

- UV, ozone, and moisture resistance for outdoor deployment

- Extended temperature range (-40°C to +90°C) and flame resistance

- Long-term electrical and EMI performance in high-power systems

Solutions:

- Use of UV-stabilized, halogen-free jackets with high tensile strength

- Sealed circular connectors with corrosion-resistant contacts

- Multicore twisted pair design with double shielding to maintain data fidelity

Offshore Engineering Control Cabling

Application Scenario:

Offshore engineering systems such as oil platforms, underwater ROVs (Remotely Operated Vehicles), and ocean observation buoys require circular cable assemblies that can withstand extreme pressure, saltwater corrosion, and electromagnetic interference. In these marine environments, cables must ensure real-time control, power supply, and data transmission over long distances, often through harsh subsea or deck-exposed conditions. For example, underwater cables for ROVs must flex under pressure and remain watertight at depths exceeding 1000 meters.

Devices & Products:

- Subsea ROV control systems

- Offshore drilling platform sensors and power units

- Marine observation buoys and communication modules

Industry-Specific Requirements:

- Saltwater corrosion resistance and high IP waterproofing

- Long-distance signal stability and mechanical endurance

- Shielded construction for subsea EMI and lightning surge protection

Solutions:

- Use of TPU or XLPE jackets with marine-grade anti-corrosive coatings

- Circular metal shell connectors with IP68/IP69K sealing

- Hybrid cable cores (signal + power) with reinforced tensile braid and double shielding

Wind Turbine Pitch System Cabling

Application Scenario:

Modern wind turbines rely on precise pitch control systems to optimize blade angle in response to wind speed, ensuring efficiency and protecting structural integrity. Inside the turbine hub and nacelle, circular cable assemblies are critical for connecting the pitch motor, control unit, sensors, and slip rings. These cables must endure continuous rotation, vibration, and wide temperature fluctuations in offshore and onshore installations.

Devices & Products:

- Wind turbine pitch motor drive unit

- Pitch angle sensors and control modules

- Nacelle slip ring signal & power systems

Industry-Specific Requirements:

- Continuous flexing and torsion resistance inside rotating nacelles

- Excellent shielding to protect sensor signals from EMI

- Low-temperature flexibility and flame-retardant materials

Solutions:

- Circular cables with finely stranded conductors and PUR jackets

- EMC-shielded cable assemblies with multi-core hybrid design

- IP-rated bayonet or threaded connectors for vibration-proof locking

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized circular cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What are circular cable assemblies used for?

Circular cable assemblies are commonly used for industrial automation, robotics, sensors, medical equipment, and outdoor power or signal transmission due to their secure locking, shielding, and IP-rated designs.

Can I customize the cable length and connector type?

Yes, both cable length and connector type (M5, M8, M12, M23, etc.) can be fully customized based on your requirements.

Do you support angled connector configurations?

Yes. We offer straight, right-angle, and custom-molded connector configurations for flexible routing.

What materials are available for the outer jacket?

Available jacket materials include PVC, PUR, TPE, and halogen-free options, selected based on environmental or mechanical needs.

Can you meet IP67 or IP68 waterproof ratings?

Yes. Our circular cable assemblies can meet IP67/IP68 levels with molded or O-ring sealed connectors.

What certifications do your products comply with?

Our products are compliant with ISO, RoHS, REACH, UL, CE, and offer PFAS declarations when needed.

What is the MOQ for circular cable assemblies?

We support low MOQ. Even 1 piece is acceptable for sample or prototype evaluation.

What information should I send to get a quote?

Please send connector type, pin count, cable length, cable specs, shielding needs, and target quantity.

Can I request branded or original connectors?

Yes. We support both original branded connectors and cost-effective equivalents, per your choice.

Can you support video calls for technical discussion?

Yes. We offer video calls with our engineers or sales team for direct communication.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China