custom flat flex cable manufacturer

From initial concept to final assembly, our custom flat flex cables are built to deliver exceptional performance in confined spaces. Support includes fast prototyping, original or alternative connectors, CAD drawing in 30 minutes, and complete quality inspection. Ideal for OEMs and product engineers worldwide.

Why choose flat flex cable from sino-conn

Choose flat flex cables from Sino-Conn for unmatched flexibility, durability, and customization. With over 18 years of experience, we offer high-quality FFC/FPC solutions tailored to your specific needs, including various pitch sizes, materials, and connector types. Our cables are UL, ISO, and ROHS certified, ensuring reliable performance across industries like automotive, medical, consumer electronics, and more. Get fast samples, precise drawings, and flexible lead times.

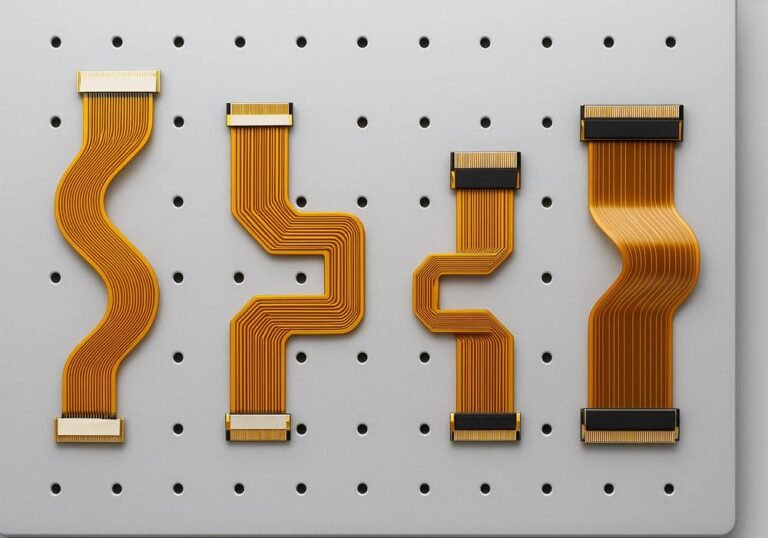

Fully Customizable Design: Pitch, Pin Count, Layout and Length Options

We offer complete customization for flat flex cable assemblies—choose your pitch (0.5mm to 2.54mm), conductor count, insulation type, layout, and cable length. Our engineering team supports rapid drawing and prototyping within hours. Whether you need single-sided FFC or complex folded structures, we manufacture exactly to your requirements with guaranteed compatibility and precision fit.

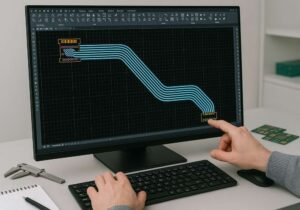

Rapid Prototyping with 30-Minute CAD and 2–3 Day Samples

We specialize in fast-turn FFC/FPC cable prototyping. Our team can deliver CAD drawings within 30 minutes and produce samples within 2–3 days. This service is ideal for engineers in the R&D stage or OEM clients with urgent timelines. Whether it’s a small batch or a unique structure, our rapid workflow minimizes delays and supports real-time product development.

Wide Compatibility with OEM, ZIF, LIF and Custom Connectors

Our flat flex cables support a wide range of connector options, including ZIF, LIF, and OEM-style terminals. We also provide compatible alternatives for high-end brand connectors to suit various cost and supply preferences. Whether you’re sourcing exact originals or functional equivalents, we ensure electrical compatibility, mechanical fit, and strong signal performance across all connector types.

Excellent Flexibility and Bend Radius for Dynamic Motion Applications

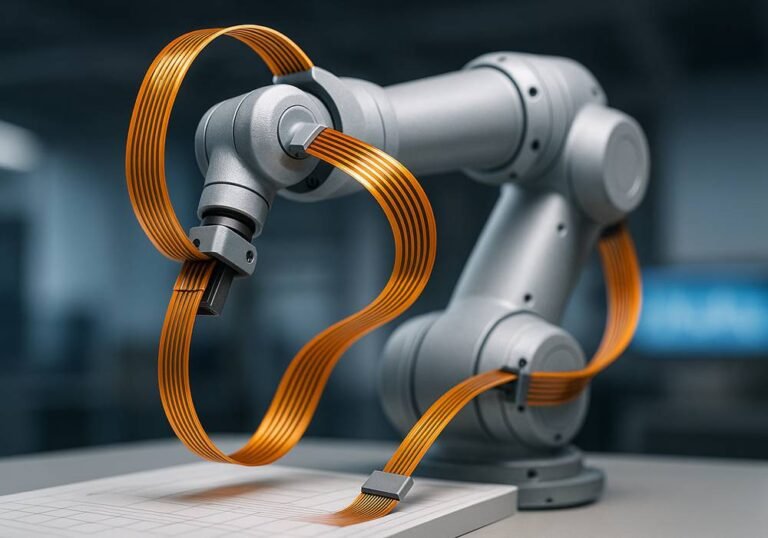

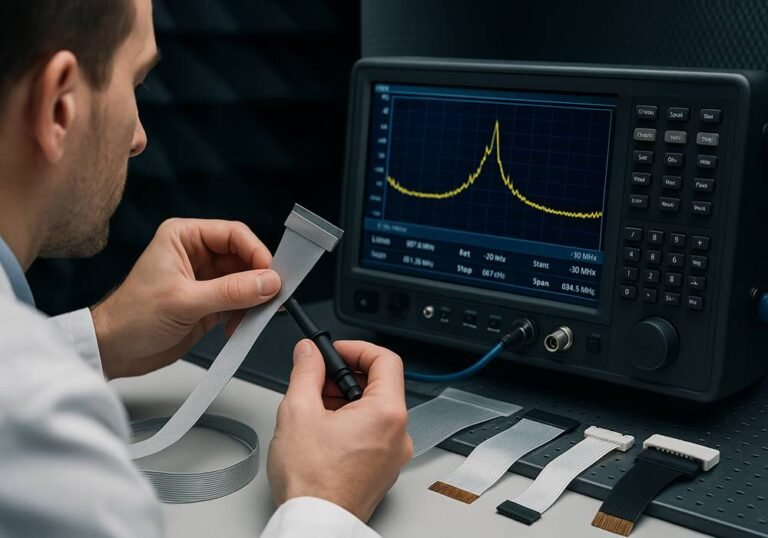

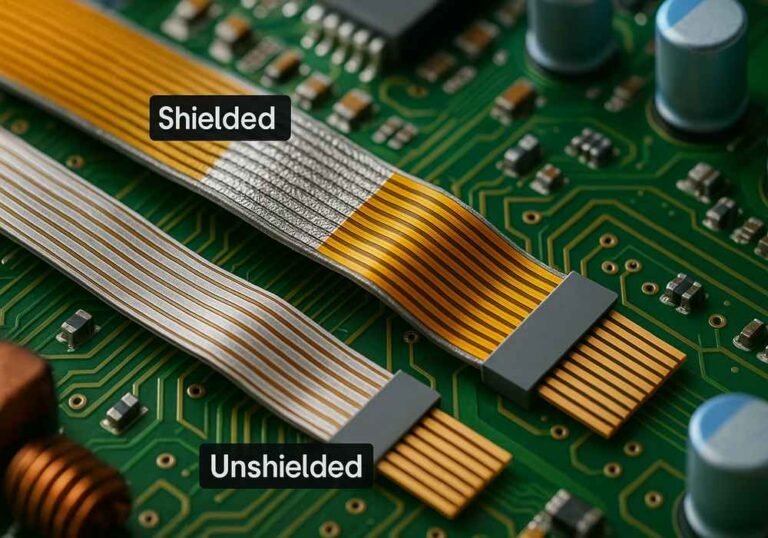

Our flat flex cables are engineered for high flex life and tight bend radii, making them ideal for dynamic motion environments such as printers, robotics, medical devices, and folding displays. They are tested to withstand millions of bending cycles without signal degradation or insulation failure. We also offer reinforced and shielded structures for enhanced durability in high-vibration and high-frequency applications.

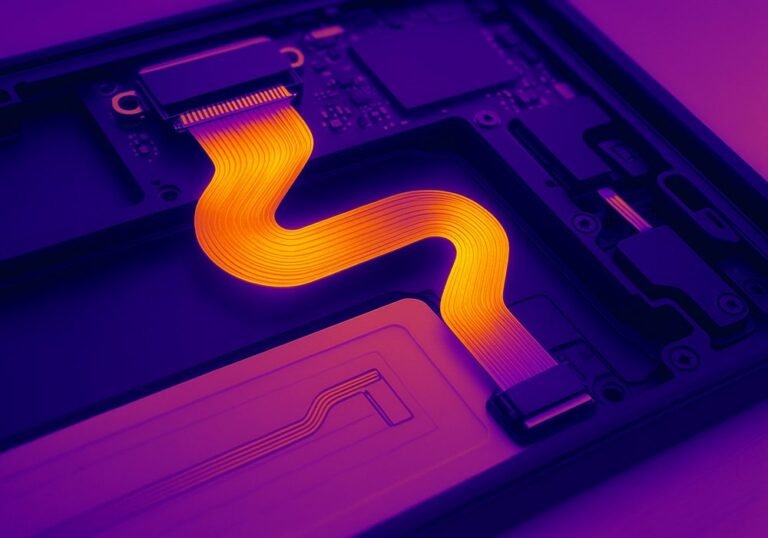

High Signal Integrity with Optional EMI Shielding and Grounding Layers

Our custom flat flex cables ensure stable and clean signal transmission even in noisy environments. We offer optional EMI shielding films, grounding layers, and insulation enhancements to reduce crosstalk and external interference. These configurations are widely used in high-speed data, audio, medical imaging, and industrial control applications, where signal clarity is critical for system performance.

Low MOQ, Global Delivery, and Full Certification Support

We support projects of all sizes with no minimum order quantity (MOQ) and fast delivery worldwide. Whether you’re ordering 1 piece for prototyping or 10,000 for production, we scale flexibly. Our cables are RoHS, REACH, UL, ISO, and PFAS compliant, and we provide COC, COO, and test reports upon request. Perfect for startups, OEMs, and distributors needing flexibility, compliance, and global service.

Detailed specifications and parameters of flat flex cable

| No. | Definition | Connector Model | Cable Specification | Length (mm) | Covering Type | Covering Material |

|---|---|---|---|---|---|---|

| 1 | 1:1 straight pinout | 0.5mm ZIF 10P | custom | custom | Flat | PET tape |

| 2 | Crossed pinout | 1.0mm LIF 20P | custom | custom | Flat | Conductive fabric |

| 3 | 1:1 reversed pinout | 1.25mm housing 16P | custom | custom | Flat | PVC sleeving |

| 4 | Folded layout, reversed | 0.5mm ZIF 30P | custom | custom | Folded | Acetate cloth tape |

| 5 | Center-out dual head | 2.54mm DIP 26P | custom | custom | Flat | Nylon braided mesh |

| 6 | One-end breakout | 1.0mm ZIF 40P | custom | custom | Flat | Nano adhesive tape |

| 7 | U-shape layout | 0.5mm LIF 15P | custom | custom | Folded | Teflon tape |

| 8 | Mixed pitch design | 0.5mm + 1.0mm combo | custom | custom | Flat | Teflon sleeving |

| 9 | Grounded shielded version | 1.0mm housing 24P | custom | custom | Flat | EMI shielding film + PVC |

| 10 | One to two breakout cable | 2.0mm dual-end 20P | custom | custom | Round molded | Molded PVC |

Flat flex cable designs are highly application-specific, and technical requirements can vary dramatically depending on layout, signal integrity, EMI conditions, connector compatibility, and mechanical routing. For this reason, we provide fully customized assemblies tailored to each customer’s design drawing, pinout, and environment. Our engineering team works closely with clients to deliver the optimal configuration—no matter how standard or complex the request is.

Customized flat flex cable styles

Trusted by 350+ global brands,1000+ styles have been developed.

10 pin 1.0mm FFC cable A type flat flex cable wire

10 pin custom fpc cable with gold finger flex connector

20 pin lvds cable 0.4mm pitch micro coax connector KEL USL00 custom flex cable

20 pin FPC cable 0.5mm custom flex connector

Product details display Of flat flex cable

Explore the product details of our flat flex cables, designed for superior performance and versatility. Our cables come in various configurations, including different pitches, materials, and insulation types to meet your specific needs. With options for high-temperature resistance, EMI shielding, and flexibility, our flat flex cables are ideal for use in applications such as automotive, consumer electronics, and medical devices. High-quality materials, precise engineering, and customization options are guaranteed to deliver optimal performance.

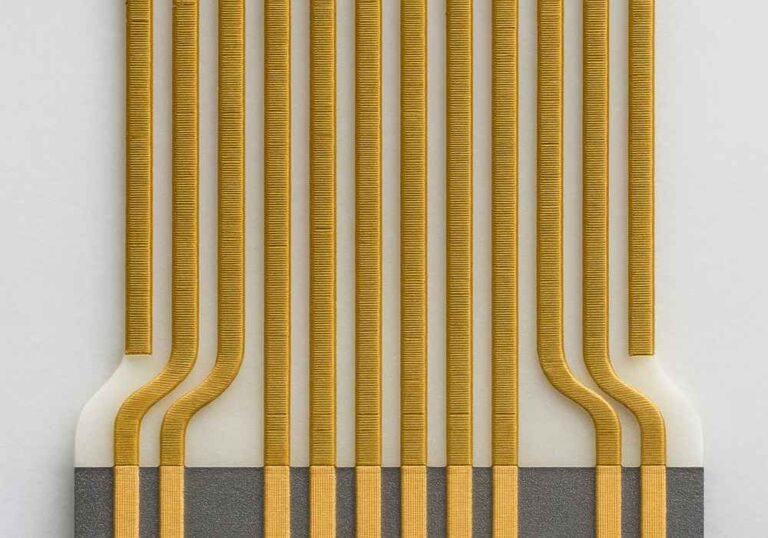

High-Precision Copper Traces for Stable Signal Transmission

The core of every custom flat flex cable lies in its precisely etched copper conductors. Our cables utilize ultra-flat, oxygen-free copper foil with uniform thickness to ensure optimal signal integrity and low resistance. Each trace is laid out with micron-level accuracy to support high-speed data transmission and minimal crosstalk. Whether the cable is for automotive cameras, medical sensors, or LCD modules, this copper layer guarantees stable performance across demanding environments. Our copper traces are compatible with SMT processes and can be designed with single-sided or double-sided layouts, depending on routing needs.

- Ultra-flat copper foil: Ensures low contact resistance and reduces the risk of cracking during repeated flexing.

- Consistent conductor thickness: Maintains impedance control across differential pairs and signal lines.

- Oxygen-free copper material: Enhances electrical performance and supports high-frequency operation.

- Flexible layout design: Trace width and spacing can be tailored for single-ended or differential signaling.

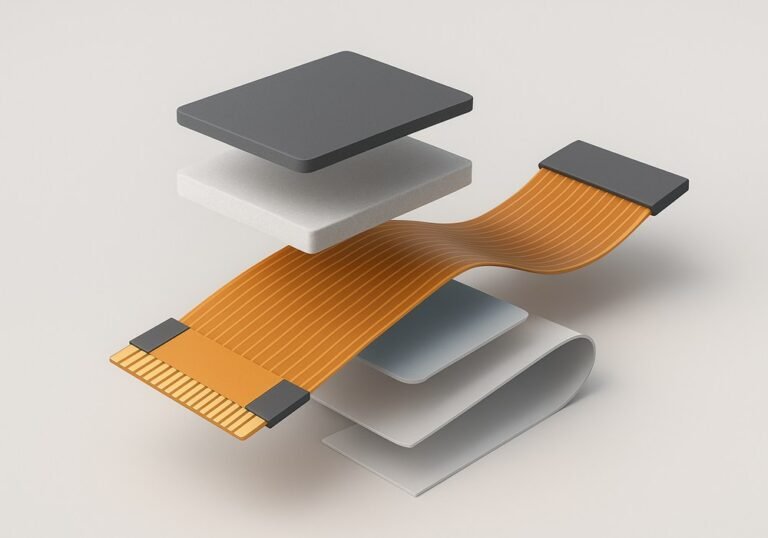

High-Durability Insulation Layer with Custom Material Options

The insulation layer plays a critical role in protecting flat flex cables from environmental stress, electrical interference, and mechanical wear. We offer a variety of insulation materials, including PET, PI (Kapton), and high-temperature-resistant Teflon, to accommodate different applications and durability requirements. These layers are precisely laminated over the copper conductors to ensure dielectric strength, long flex life, and resistance to abrasion or chemical exposure. Whether used in mobile electronics, medical diagnostics, or automotive dashboards, our insulation solutions enhance the reliability and lifecycle of the cable. Multiple thickness grades and flame-retardant options are available to meet custom standards.

- PET and PI films: Offer high dielectric strength and good thermal stability in compact applications.

- Teflon insulation: Ideal for harsh environments requiring heat and chemical resistance.

- Optional flame-retardant coatings: Meet UL94 V-0 or customer-specific fire safety standards.

- Custom thickness levels: From 0.035mm to 0.1mm depending on flexibility and shielding needs.

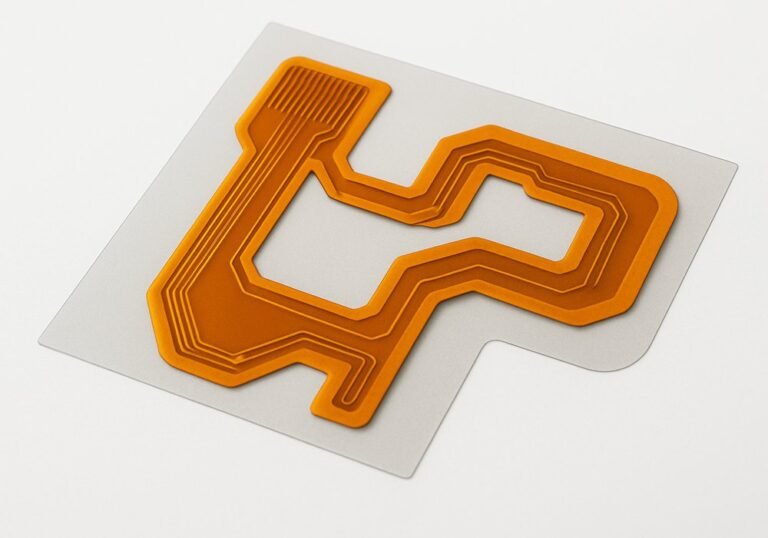

Flexible Bending Structure for Dynamic and Compact Routing

One of the most critical advantages of flat flex cables is their ability to bend, twist, and route through tight spaces without compromising performance. Our FFC/FPC assemblies are engineered with highly flexible substrates and controlled pitch to accommodate S-bends, U-bends, or 180° folds. Whether the routing path requires a single-plane curve or complex three-dimensional weaving, our cable structures maintain signal stability and mechanical reliability. This flexibility is essential in compact devices such as foldable screens, medical probes, cameras, and industrial robots, where rigid cabling would fail. Optional reinforcement layers are available for repeated dynamic flexing.

- Tight bend radius: Supports routing through hinges and articulated parts without stress damage.

- Reinforced fold zones: For repeat bending over millions of cycles in dynamic motion.

- Multi-axis flexibility: Enables routing in X, Y, and Z directions in 3D assemblies.

- Anti-crack construction: Reduces fatigue in high-flex zones and sharp angles.

Reliable Connector Interface with Multiple Termination Compatibility

The performance of any flat flex cable assembly is only as good as its interface. That’s why we place great emphasis on termination compatibility and connector reliability. Our cables can be terminated with a wide range of standard and custom connectors including ZIF, LIF, DIP, and housing types. We support both original brand connectors and compatible alternatives to match price, lead time, and availability. To ensure consistent signal quality and mechanical stability, each termination undergoes crimping, insertion, and pull-force testing. Whether for automatic insertion in PCB assembly lines or manual plug-and-play use, our connectors are optimized for secure and repeatable mating.

- ZIF, LIF, and housing connectors: Available in multiple pitch sizes from 0.5mm to 2.54mm.

- Support for original or compatible brands: Balance between quality, budget, and delivery.

- Terminal reinforcement options: Add back support for automated assembly handling.

- 100% insertion and retention testing: Ensures reliable connection under vibration or repeated use.

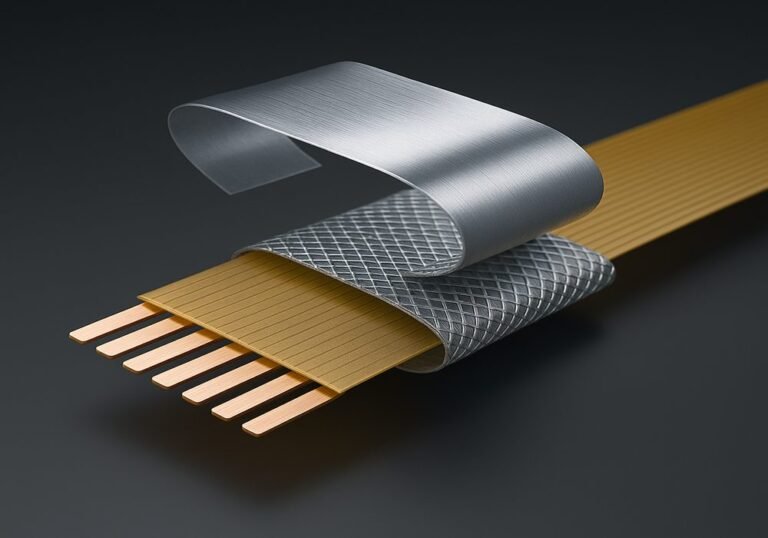

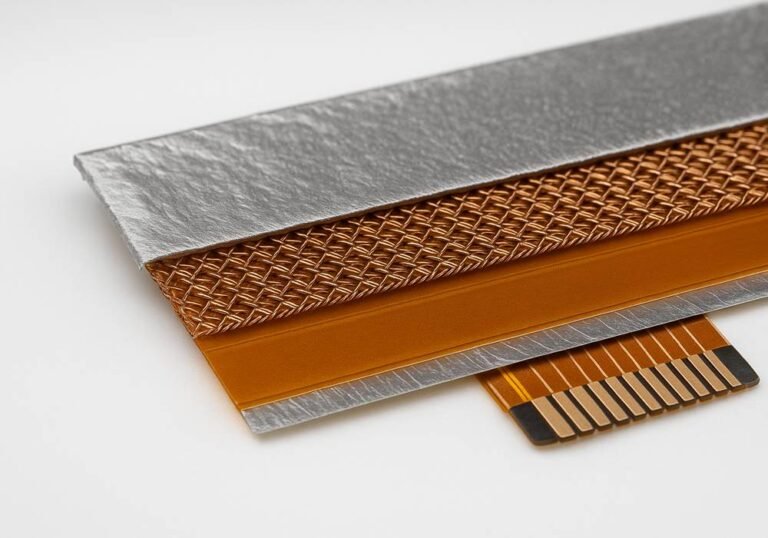

Multi-Layer Shielding Options for EMI and Signal Crosstalk Protection

To ensure signal integrity in complex electronic systems, our custom flat flex cables support multi-layer shielding structures. These configurations include conductive adhesive layers, aluminum-mylar foil, copper mesh, and grounding lines integrated into the cable profile. Shielding is essential in applications like high-speed displays, automotive infotainment systems, medical equipment, and wireless communication modules, where EMI or signal crosstalk can cause data loss or performance degradation. We offer full or partial shielding options based on routing conditions and connector compatibility. All shielding designs are validated by impedance testing and conducted noise simulations to meet global EMC compliance requirements.

- Aluminum-mylar foil and copper mesh: Provide 360° EMI protection and reduce external interference.

- Conductive adhesive and drain wire: Enable easy grounding and PCB interface connection.

- Partial vs. full shielding design: Based on layout density and signal sensitivity.

- EMC pre-compliance ready: Optimized for consumer electronics and automotive certification.

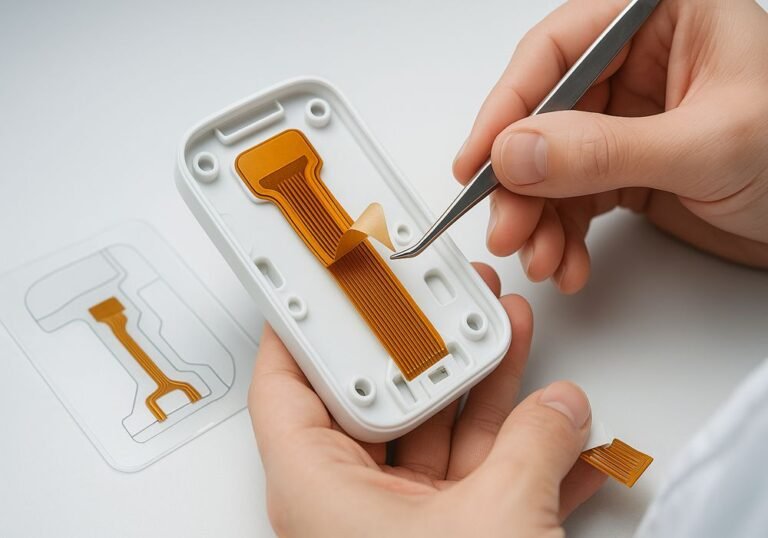

Precision Die-Cutting and Backing for Form-Fit Assembly Applications

In advanced applications where flat flex cables must follow complex 3D contours or integrate into tight assemblies, precision die-cutting and backing layers are essential. We offer high-accuracy die-cut services that match enclosure geometry and connector alignment, enabling easy plug-and-play installation. Adhesive backings, reinforcement pads, and shape retention features can be added to support peel-and-stick mounting or mechanical anchoring. This process is especially critical in foldable devices, camera modules, medical probes, and wearables where space is limited and placement accuracy is key. Our die-cutting tolerances can reach ±0.1mm, with tooling support available for both prototyping and mass production.

- ±0.1mm die-cutting tolerance: Supports high-precision alignment in constrained spaces.

- Adhesive backing options: For quick positioning during assembly or service.

- Stiffener and foam layers: Improve dimensional stability and vibration absorption.

- Tooling support available: For custom-shaped layouts in prototypes or mass orders.

--- Customized Capabilities Services and Processes

Customize your flat flex cable

At Sino-Conn, we specialize in providing customized solutions for flat flex cable assemblies to meet the unique requirements of each client. Our services include detailed design consultations, fast prototyping, and precise engineering to ensure the highest quality products. We offer flexibility in customization, including specific lengths, connector types, materials, and performance features such as high-temperature resistance and EMI shielding. Our streamlined process ensures quick turnaround times, from concept to production, while maintaining rigorous quality control at every stage. Whether you need a one-off prototype or a large-scale production run, our dedicated team is committed to delivering tailored, reliable solutions for any application.

Customized Capabilities Services and Processes

Customize your flat flex cable

At Shenzhen Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Unmatched Customization for Your Application-Specific Needs

At Sino-conn, we understand that no two flat flex cable applications are the same. That’s why we offer full-spectrum customization services to ensure every cable assembly is built exactly to your performance, layout, and compliance requirements. From initial drawings to mass production, every stage is handled by engineers who specialize in flexible cable design and assembly. We empower customers across industries—automotive, medical, consumer electronics, and industrial automation—to bring their design ideas to life with speed, precision, and reliability.

- Pitch & Pin Count: Available in 0.5mm, 1.0mm, 1.25mm, 2.54mm, or custom-defined spacing.

- Conductor Layout: Support for straight-through, reversed, crossover, U-fold, or Z-bend structures.

- Connector Interface: Compatible with ZIF, LIF, DIP, housing, or dual-head terminations.

- Insulation Materials: PET, PI, Teflon, or specified flame-retardant or halogen-free types.

- EMI Shielding Options: Full or partial shielding with aluminum-mylar, copper mesh, and grounding.

- Die-Cut & Forming: Precision cutting, reinforcement pads, and adhesive backing tailored to fit unique mechanical constraints.

Service That Engineers Trust and Buyers Remember

At Sino-conn, we don’t just deliver custom flat flex cables—we deliver an experience built on trust, speed, and technical depth. Our goal is to help every customer—from engineers in R&D labs to purchasers in large OEM factories—achieve rapid turnaround with zero compromise on quality or communication. We understand that cable customization is more than manufacturing—it’s technical collaboration.

What Makes Our Service Exceptional:

- Fast Response: We reply to inquiries within hours, and provide quotes and drawings within 30 minutes to 3 hours depending on complexity.

- Engineering Support: Our sales team works side-by-side with engineers to help optimize structures, pinouts, and connectors—even if there’s no complete drawing.

- Flexible Sampling: Whether you need 1 piece for evaluation or 100 for pilot production, we deliver quickly—often within 2–3 days.

- Online Communication: We offer direct video communication to review drawings, prototypes, and changes with your team in real time.

- Zero MOQ & Rapid Shipping: No minimum order quantity, and global logistics support ensures fast, reliable delivery to over 60 countries.

- Full Certifications & Test Reports: All shipments come with RoHS, ISO, REACH, UL, and if needed, PFAS, COC, and COO documentation.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

350+ global clients trust sino-conn’ premium service

I was leading a development project for an in-vehicle infotainment system when we hit a major issue. The FFCs from our original supplier failed EMI and vibration testing, and our design space was extremely tight. I needed a cable solution that could be folded, shielded, and still pass automotive-grade reliability tests.

Sino-conn truly impressed me. Within 24 hours of reaching out, their engineering team proposed a custom flat flex cable with reinforced shielding, a 1.0mm pitch, and ZIF connectors. They sent me a CAD drawing in two hours and samples in three days. Most importantly, their cable passed all our tests — thermal cycling, EMI shielding, and vibration — on the first attempt.

What stood out was not just their speed, but how well they understood automotive requirements. Thanks to their support, we kept our timeline and avoided delays in our OEM partnership.

“Sino-conn’s technical precision and responsiveness are on another level. I give them a solid 5-star rating.”

Andreas Müller

Senior Electronics Engineer

Location: Stuttgart, Germany

As an engineer working on high-speed machine vision systems, signal integrity is my top concern. We were designing a compact camera module for factory inspection lines, and the conventional FFC cables we tested couldn’t handle the 3.5Gbps data rate without crosstalk and jitter issues.

I approached Shenzhen Sino-conn with our problem. Their team didn’t just say “yes”; they asked the right questions — impedance requirements, shield layer placement, connector mating cycles. Within a day, they proposed a double-sided shielded flat flex cable using silver-plated copper and custom adhesive layering. They even simulated the signal performance for us.

Once we received the prototypes, the signal quality was nearly flawless — eye diagrams showed excellent integrity. Their team also supported us through connector matching and provided CAD and Gerber files without delay.

“Sino-conn delivers solutions, not just cables. I rate them 5 stars for technical understanding and execution.”

Kazuki Tanaka

Optical Systems Engineer

Location: Osaka, Japan

We were developing a next-generation portable ECG device and needed a flat flex cable assembly that was ultra-thin, biocompatible, and could withstand over 10,000 bend cycles. The cable would be routed through a hinged wearable casing, so flexibility and fatigue resistance were mission-critical.

I contacted Sino-conn after reading about their work on biomedical cable solutions. To my surprise, their team scheduled a video call the next day. Their engineer reviewed our CAD design and suggested a PTFE-based insulation combined with a thermoplastic elastomer jacket for added durability and skin compatibility.

In just three days, we had a prototype in hand — ultra-thin, yet strong and soft to the touch. Even after aggressive fatigue testing, the cable maintained full signal function. They even provided REACH and ISO 13485 certifications proactively, which made our compliance process seamless.

“Sino-conn is not just a supplier, but a development partner. Their team made our clinical goals achievable.”

Dr. Laura Hoffmann

Medical Device Product Manager

Location: Munich, Germany

industry Application of flat flex cable

Flat flex cables are widely used across various industries due to their compact design, flexibility, and reliable performance. In the automotive industry, they are utilized for power transmission and signal connections in tight spaces. In consumer electronics, flat flex cables are integral in devices like smartphones, laptops, and wearables, offering space-saving solutions without compromising performance. The medical field also benefits from their use in diagnostic equipment, medical devices, and sensors. Additionally, flat flex cables are ideal for industrial automation, robotics, and aerospace applications, providing robust, high-performance connections in demanding environments. Their versatility makes them an essential component for numerous high-tech applications.

Ultra-Flexible Flat Flex Cables for Medical Diagnostic Systems

Application Scenario:

In advanced medical diagnostic equipment such as ultrasound systems, ECG monitors, and portable imaging units, compact design and signal integrity are critical. Flat flex cables (FFCs) are preferred over round cables due to their superior flexibility, ultra-thin profiles, and minimal EMI interference. In these devices, FFCs are typically used to connect circuit boards, sensors, and control panels where space is limited and frequent movement occurs. The cables must endure continuous folding or sliding mechanisms within diagnostic probes or handheld units, often in high-humidity, sterilized environments. With patient safety and data precision on the line, only highly reliable and medically compliant cabling solutions can meet the requirements.

Equipment & Products:

- Portable ultrasound probes

- ECG monitoring consoles

- Flat flex cables with medical-grade insulation and precise pinouts

Industry Pain Points:

- Limited internal space for routing cables in portable diagnostic devices.

- Demand for consistent, noise-free signal transmission in sensitive monitoring equipment.

- Regulatory compliance with medical-grade safety and sterilization standards.

Solutions:

- Ultra-thin and flexible cable designs (<0.1mm thickness) allow compact routing in handheld devices.

- Shielded FFCs with impedance control ensure accurate signal transmission with reduced EMI.

- Use of biocompatible, sterilizable insulation materials meeting ISO 10993 and RoHS standards.

Ultra-Thin Flex Cables for Next-Gen Foldable Electronics

Application Scenario:

The rise of foldable smartphones, tablets, and wearable devices has introduced new challenges for internal cabling. These devices require extremely thin, flexible, and reliable cables that can endure thousands of bending cycles without degradation. Traditional round wires are too bulky and inflexible for such compact, dynamic structures. Custom flat flex cables (FFC) have become the go-to solution for manufacturers looking to minimize cable thickness while maximizing durability and signal integrity. In foldable smartphones, FFCs are typically routed through the hinge section, delivering power and data to the display and control board during continuous folding and unfolding.

Equipment & Products:

- Foldable smartphones

- Smartwatches and wearable displays

- FFC with ultra-thin copper conductors and polyimide insulation

Industry Pain Points

- Cable fatigue and breakage due to repetitive folding.

- Limited internal space in compact device housings.

- Need for high-speed signal transmission without EMI noise.

Solutions:

- Use of fine-stranded copper and precision laminated structures for enhanced bend life.

- Ultra-thin profile (≤0.1mm) fits tight hinge spaces.

- EMI shielding and controlled impedance for stable high-speed performance.

Flat Flex Cable Solutions for Automotive Display Systems

Application Scenario:

Modern vehicles integrate multiple display units including central infotainment panels, digital instrument clusters, and head-up displays. These systems require high-speed, EMI-protected data transmission between ECUs and LCD/TFT modules through tight spaces within dashboards. Flat flex cables are preferred for their ability to handle LVDS/eDP signals with precision routing and minimal EMI interference. Compared to traditional wiring harnesses, FFCs reduce weight and bulk, streamline assembly, and allow for custom pin-out arrangements. In automotive environments where vibration, heat, and long-term reliability are critical, reinforced FFCs with heat-resistant insulation and EMI shielding ensure stable performance and long lifespan.

Equipment & Products:

- Automotive LCD and OLED display panels

- Infotainment head units and digital instrument clusters

- Flat flex cables with EMI shielding and heat-resistant jackets

Industry Pain Points:

- Space constraints within vehicle dashboards and display modules.

- EMI interference degrading high-speed signal quality.

- Thermal expansion and vibration compromising cable reliability.

Solutions:

- Use of ultra-thin FFCs with customized pitch and tight bending radius for narrow spaces.

- Shielded FFCs designed to support high-speed LVDS/eDP protocols with low EMI emission.

- Automotive-grade materials with high heat resistance and vibration absorption for long-term use.

Custom Flat Flex Cable Solutions for High-Fidelity Medical Imaging

Application Scenario:

Medical diagnostic systems, such as ultrasound machines, CT scanners, and portable X-ray units, require precise and noise-resistant internal connections between sensors, imaging boards, and display units. Flat flex cables (FFCs) are favored due to their compact size, flexibility, and reliable signal integrity. In clinical environments, cables must resist frequent movement, sterilization procedures, and electromagnetic interference. Sino-conn provides custom FFCs with medical-grade insulation, EMI shielding, and customized length and pin-out configurations, ensuring optimal performance in space-constrained, hygiene-sensitive environments. Our cables are also available with UL/ISO/ROHS certifications, and we offer rapid prototyping (2–3 days) to meet urgent project timelines.

Equipment & Products:

- Custom FFCs with EMI shielding and medical-grade jackets

- Internal signal connections between sensors and control boards

- Diagnostic ultrasound, CT, MRI, and X-ray systems

Industry Pain Points:

- Limited internal space and complex cable routing inside medical devices.

- High requirement for signal clarity in noisy hospital environments.

- Strict hygiene standards requiring cleanable, sterilization-compatible cables.

Solutions:

- Ultra-flexible, ultra-thin FFCs that allow precise routing in compact enclosures.

- Enhanced EMI shielding and impedance-matched FFCs to ensure signal accuracy.

- Medical-grade insulation materials that withstand cleaning agents and sterilization cycles.

Ultra-Thin Custom FFCs for Next-Gen Wearables and IoT Devices

Application Scenario:

Wearable electronics—such as smartwatches, fitness trackers, AR glasses, and wireless earbuds—demand ultra-compact, lightweight, and durable internal interconnects. Flat Flex Cables (FFCs) are critical for connecting battery modules, sensors, display interfaces, and wireless modules within minimal space. As consumer expectations rise for sleeker designs and enhanced performance, manufacturers need custom cables that meet strict tolerances, high bend endurance, and mass production consistency. Shenzhen Sino-conn offers precision-engineered FFCs with flexible pin-outs, tight pitch spacing, and halogen-free flame-retardant materials tailored to wearable environments. We support small MOQ orders and can deliver rapid design and sampling support within 48 hours.

Devices and Products:

- Smartwatches, earbuds, AR/VR headsets

- Internal signal and power routing within ultra-thin housings

- Custom FFCs with ≤0.5mm pitch and flexible shielding

Industry Pain Points:

- Extremely limited internal space in compact wearable devices

- Repetitive bending and twisting during daily use

- High demand for lightweight, eco-friendly, and safe materials

Our Solutions:

- Ultra-thin, ultra-narrow FFCs with fine-pitch design (e.g., 0.3mm–0.5mm)

- High-flex life cable materials supporting 100,000+ bend cycles

- Flame-retardant, halogen-free, and skin-friendly insulation options

Rugged FFC Solutions for Robotics, Automation, and Factory Control Systems

Application Scenario:

Modern industrial automation relies heavily on reliable internal wiring within control panels, sensors, HMIs, and robotic systems. Flat Flex Cables (FFCs) are favored in these environments for their space-saving profiles, flexibility, and ease of routing. However, industrial environments also demand superior mechanical strength, resistance to oil, vibration, and heat. Sino-conn provides custom FFCs designed to withstand industrial-grade conditions with options like PET/PI insulation, reinforced stiffeners, EMI shielding, and customized termination types. Our cables are optimized for servo motor controls, PLCs, robotic joints, and touch interface connections in production lines and CNC systems.

Equipment and Products:

- Robotic arms, PLCs, HMIs, CNC control panels

- Custom FFCs with reinforced ends and high-temperature insulation

- Options with EMI shielding and adhesive stiffeners

Industry Challenges:

- Exposure to high vibration, heat, oil, and electromagnetic interference

- Frequent motion or flexing at robotic joints or cable tracks

- Limited routing space within dense control panels

Our Solutions:

- PET or polyimide insulated FFCs with heat and oil resistance

- EMI-shielded flexible cables with high flex endurance

- Reinforced terminations and stiffener options for stable mounting

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a spiral cable assembly?

We can provide a wide range of connectors including ZIF, LIF, board-to-board, and custom-end connectors per your requirements.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Can I customize the pinout and shape of the cable?

Yes, we support full customization of pin configuration, cable shape, pitch, and termination style.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

Do you support halogen-free and flame-retardant options?

Yes, our materials meet halogen-free and flame-retardant standards.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China