custom industrial cable assemblies manufacturer

Custom industrial cable assemblies engineered for harsh environments. Whether you need oil-resistant, high-flex, or EMI-shielded solutions, we deliver precision-made cables with short lead times, strict quality control, and global certifications. Designed to meet automation, control, and machinery needs worldwide.

Why choose industrial cable assemblies from sino-conn

Choose Sino-Conn for industrial cable assemblies backed by over 18 years of expertise, zero MOQ, rapid turnaround, and 100% quality assurance. Our solutions meet UL, ISO, RoHS, and REACH standards, and are fully customizable for demanding environments — including automotive, automation, and energy sectors.

High‑Flexibility Cables to Navigate Tight Industrial Spaces

Our industrial cable assemblies feature highly flexible, fine‑stranded conductors and optimized jacket formulations—ideal for crowded control panels, robotic arms, and tight machine layouts. These cables resist kinking, bending fatigue, and maintain signal integrity under continuous motion. Perfect for robotics and motion control systems, this solution ensures long-term reliability and reduces downtime caused by cable failure or repeated flexing issues.

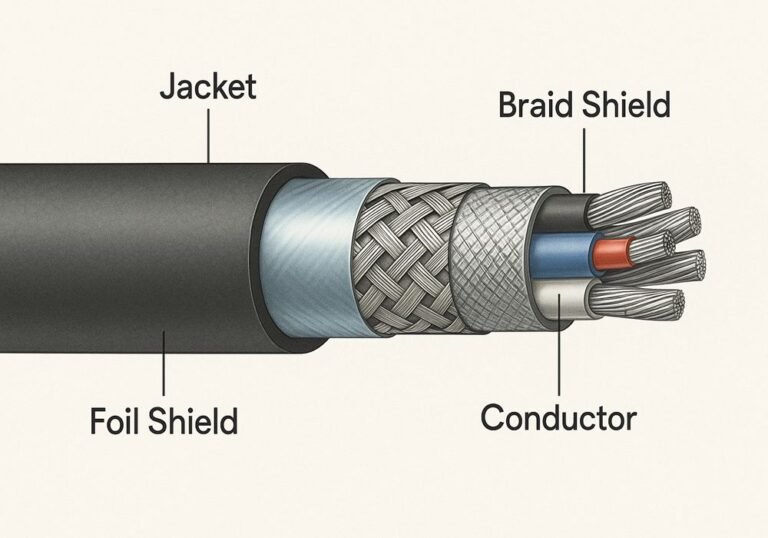

Reliable EMI Shielding for Industrial Environments

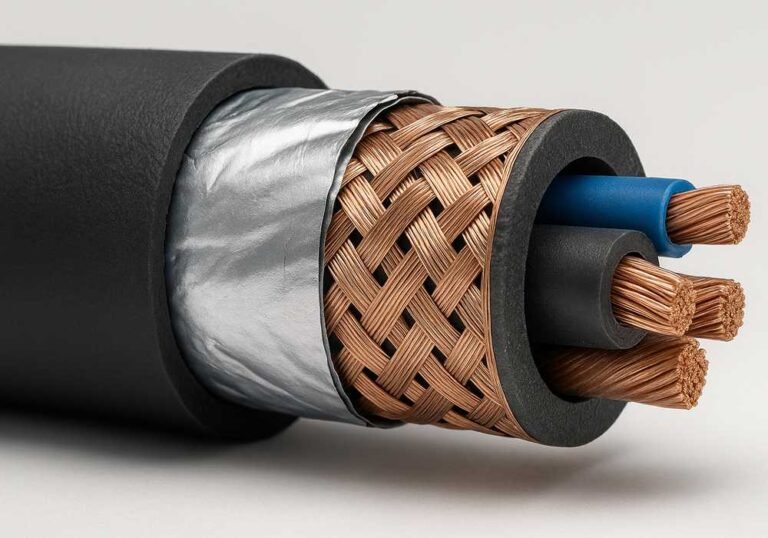

Our cable assemblies utilize advanced shielding methods such as braided copper, aluminum foil, or hybrid layers to block electromagnetic interference. These shields ensure clean signal transmission in high‑EMI environments like motor drives, VFDs, and factory automation systems. Ideal for applications requiring stable data or power delivery, our EMI solutions meet industrial EMC standards and support long‑term performance under continuous electromagnetic stress.

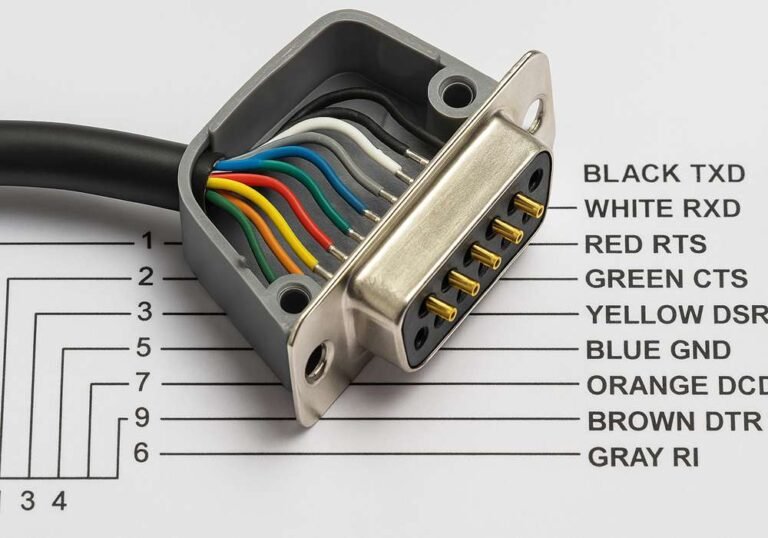

Custom Pinout and Connector Configuration Support

We offer fully customizable pinout configurations and connector options to meet specific functional needs. Whether you need D-sub to circular, Molex to waterproof plug, or terminal block to RJ45, we can match and assemble per your design. Our engineering team provides fast drawing and technical support to ensure pin compatibility and wiring accuracy, helping customers streamline their assembly process and avoid costly mismatches.

Resistance to Oil, Flame, UV, and Chemicals

Our industrial cables are engineered for harsh environments. Jacket materials such as TPE, PUR, and PVC offer excellent resistance to oil, flame, UV, and chemicals. This ensures durability in outdoor setups, machinery with lubrication systems, or chemical processing zones. Our cables comply with UL, CE, RoHS, and REACH standards, and deliver long service life without degradation—ideal for industries like oil & gas, manufacturing, and chemical automation.

Low MOQ and Rapid Prototyping Capabilities

We support ultra-low MOQ starting from just 1 unit and deliver prototypes within 2–3 days. This enables fast project validation and reduces lead time for testing. Ideal for R&D teams, custom engineering requests, or niche applications, our quick turnaround allows clients to evaluate and iterate before scaling. Drawings are provided in 30 minutes for most standard connector assemblies.

Certified and Globally Compliant Assemblies

Our industrial cable assemblies meet global standards including UL, CE, RoHS, REACH, ISO9001, and optional PFAS/COC/COO certifications. This ensures compatibility with export requirements and acceptance in regulated sectors such as medical, automotive, and automation. We help clients reduce audit risks and accelerate time-to-market with documentation packages tailored to industry compliance.

Detailed specifications and parameters of industrial cable assemblies

| No. | Pinout Definition | Connector Model | Cable Specification | Length (mm) | Jacket Type | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 2-pin power + ground | M12 A-coded Male | Custom | Custom | Round | PVC tubing |

| 2 | 4-wire signal (shielded) | D-sub 9-pin Female | Custom | Custom | Molded | Nylon braided mesh |

| 3 | 8-wire Ethernet | RJ45 Cat6 Shielded Plug | Custom | Custom | Round | Iron-fluorine sleeve |

| 4 | 3-phase power + ground | CEE 5-pin Plug | Custom | Custom | Round | Teflon tape |

| 5 | Servo control (6 wires) | Circular 7-pin Connector | Custom | Custom | Molded | Conductive fabric |

| 6 | CANbus + power (5 wires) | M12 X-coded Male | Custom | Custom | Round | Acetate cloth |

| 7 | Motor drive (3 wires) | Molex Mini-Fit Jr. | Custom | Custom | Flat | PVC sleeve |

| 8 | Signal + shield + drain | AMP TE 8-pin | Custom | Custom | Molded | Nano tape |

| 9 | High-temp sensor (2 wires) | Thermocouple Mini Plug | Custom | Custom | Round | Teflon sleeve |

| 10 | Dual Ethernet + ground | Dual RJ45 Industrial | Custom | Custom | Molded | Braided copper shield |

Every industrial application is different, and so are the cable assemblies that support them. At Sino-conn, we specialize in custom industrial cable solutions tailored to each client’s specific requirements. From unique pinouts and connector combinations to specialized jacket materials and shielding structures, we engineer each assembly for exact performance needs. Whether you are building for automation, robotics, or harsh environments, we help you get the precise configuration that fits.

Customized industrial cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

DB15 to Terminal Block & 12Pin Control Cable Assembly

Custom 12 Pin Industrial Tyco Cable Assembly

Product details display of industrial cable assemblies

Explore detailed specifications of our industrial cable assemblies, including connector types, cable structure, voltage/current ratings, EMI shielding, insulation materials, and durability features like heat, oil, and UV resistance. Each assembly is shown with clear photos, technical drawings, and full customization options for your industry needs.

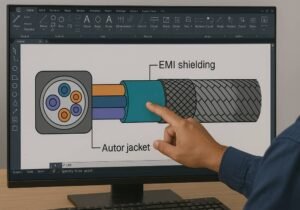

Multi-Layer Shielding for Industrial Interference Protection

Our industrial cable assemblies utilize multi-layer shielding technology to deliver superior performance in electrically noisy environments. Each cable is constructed with a combination of foil shielding, braided copper, and optional ferrite cores, ensuring minimal signal degradation even in heavy-duty manufacturing and factory automation settings. This shielding design is particularly effective in high-EMI zones such as robotic arms, motor drives, and PLC control panels. By preventing cross-talk and electromagnetic interference, our cables help maintain the integrity of signal and power lines in mission-critical applications across industrial automation, transportation systems, and energy infrastructure.

- Triple-layer EMI shielding: foil + braid + optional ferrite

- Stable transmission in high-voltage and motor environments

- Compatible with shielded connectors for complete grounding

- Reduces noise in automation and power control loops

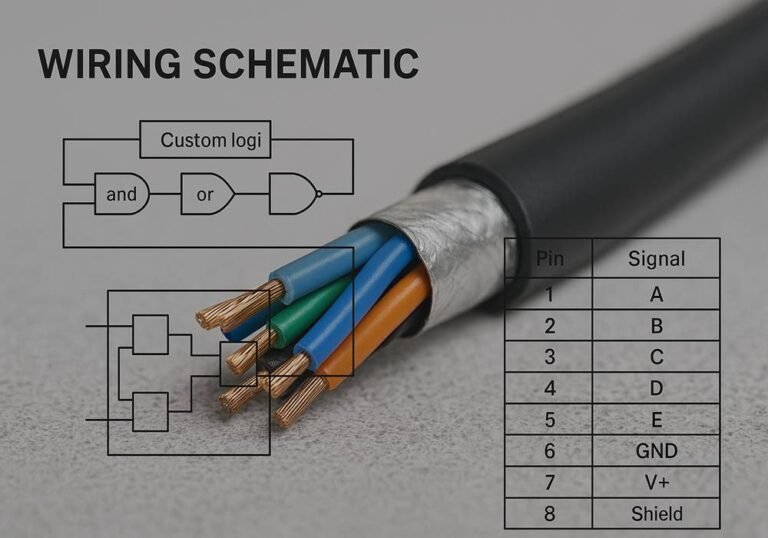

Custom Pinout and Wiring Configuration for Any Device

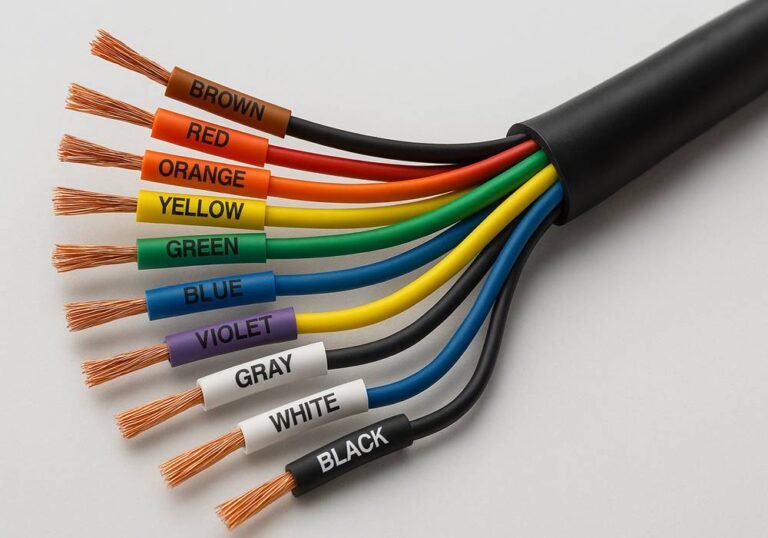

Our industrial cable assemblies are fully customizable in pinout and internal wiring layout to meet the exact electrical and control requirements of your equipment. From 2-pin power lines to 50+ pin signal/control hybrids, we support any configuration across standard and proprietary connectors. With precision crimping and automated continuity testing, each assembly is mapped and verified for signal integrity and functional correctness. Whether your application involves CAN bus, RS485, sensor-actuator loops, or multi-voltage systems, we tailor the wiring logic to match your interface pin-for-pin, ensuring seamless integration without the need for rewiring on-site.

- Support for custom pinouts: symmetrical, cross, pass-through, or mapped

- Clear wire ID and labeling for quick installation

- Matched to sensor, control board, or PLC input/output logic

- Electrical test report and schematic diagram available for every order

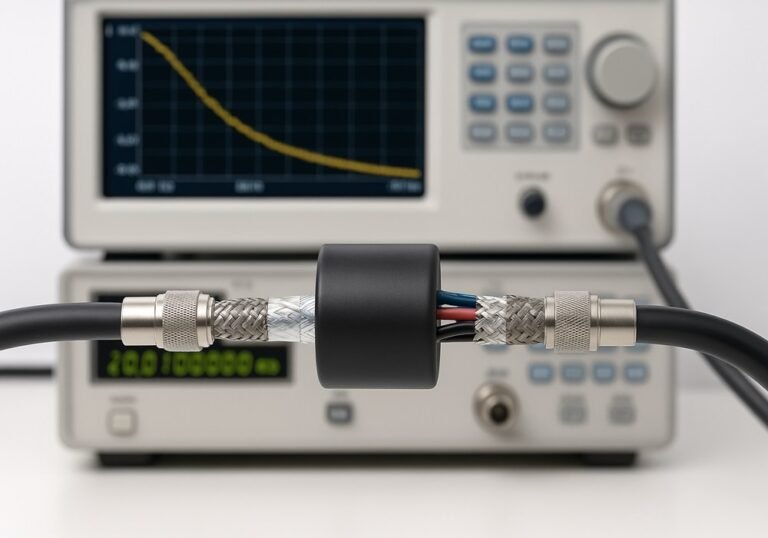

Multiple Shielding Options for EMI and Noise Protection

Our industrial cable assemblies are available with a range of shielding solutions to combat EMI (electromagnetic interference), signal cross-talk, and power line noise in harsh environments. Whether you are installing cables in factories with motor drives, high-voltage systems, or RF-sensitive instrumentation, we offer single, double, braided, foil, or composite shielding based on your system’s risk level. Each layer is applied with precise tension and coverage to maintain signal fidelity and ensure EMC compliance. This shielding not only enhances transmission stability but also protects sensitive components and ensures longer operational life.

- Single-layer, double-layer, or hybrid shielding (foil + braid)

- Options: aluminum foil, copper foil, tinned copper braid, or metal-wrapped mesh

- Shielding coverage ≥85% to reduce RF/EMI exposure

- Shielded terminations with grounding lugs or EMI boots available

High-Temperature and Chemical-Resistant Jacket Materials

In demanding industrial environments, cable assemblies must endure extreme temperatures, oils, acids, UV rays, and abrasive movement. Our industrial cables feature a wide selection of jacket materials specifically chosen for their resistance to heat and chemicals. From fluoropolymers like FEP and PTFE to flexible PVC, TPE, or silicone, we tailor the outer sheathing based on the operating environment. These jackets maintain insulation integrity under continuous flexing, high-pressure steam, or corrosive exposure—ensuring safety and cable longevity in the most punishing industrial setups.

- Jacket material options: FEP, PTFE, TPU, PVC, silicone rubber

- Rated for up to 200°C continuous operation (depends on material)

- Resistant to oil, acid, UV, ozone, and salt fog

- Flexible and flame-retardant grades available upon request

EMI/RFI Shielding for Signal Integrity

Industrial cable assemblies often operate in environments filled with electromagnetic and radio frequency interference. Our cables incorporate advanced shielding designs—including aluminum foil, copper braid, and dual-layer combinations—to protect signal transmission against EMI and RFI. These shielding structures reduce noise, prevent signal cross-talk, and ensure clean communication for data, control, or power lines. Depending on the application, we adjust shielding coverage density, layering style, and grounding methods to meet both standard and mission-critical requirements.

- Shielding types: aluminum foil, tinned copper braid, or combination

- Coverage density customizable up to 95%

- Dual-layer EMI/RFI shields for high-speed data transmission

- Grounding termination solutions offered upon request

Strain Relief and Mechanical Reinforcement

Industrial cable assemblies must endure frequent movement, tension, and vibration without failure. To enhance durability, our cables feature engineered strain relief components such as overmolded boots, heat-shrink sleeves, and high-tensile yarns. These elements absorb mechanical stress at connector joints, reducing the risk of conductor breakage or insulation wear. For dynamic applications such as robotics or drag chain systems, we reinforce both ends of the cable to prolong service life and maintain electrical integrity. This ensures safe, uninterrupted operation even under constant motion or harsh conditions.

- Custom overmolded strain relief available for each connector type

- Kevlar yarns or fiber braids added to enhance pull strength

- Heat-shrink tubing secures cable-to-connector transitions

- Dynamic flex reinforcement for drag chain and robotic use

--- Customized Capabilities Services and Processes

Customize your industrial cable assemblies

Discover our fully customized services for industrial cable assemblies — from pinout definition, cable length, and connector type to material selection and unique structural designs. We offer rapid CAD drawing support, flexible engineering solutions, and efficient production workflows to meet urgent timelines and specialized application requirements.

Customized Capabilities Services and Processes

Customize your industrial cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Custom Engineering to Match Every Industrial Need

At Sino-conn, we provide full-spectrum customization for industrial cable assemblies to ensure optimal performance and compatibility with your application. From structure and shielding to connector pinouts and materials, every detail can be tailored to meet exact specifications.

- Flexible Structural Design: We design cables for different applications—flat, round, overmolded, or split-harness—based on your layout and environment.

- Connector Adaptability: Whether your system uses standard MIL, M12, RJ45, or proprietary connectors, we match or redesign to meet form and function.

- Material Versatility: Choose from PVC, TPE, silicone, FEP, or halogen-free materials to meet environmental and safety requirements.

- Signal Integrity Engineering: We fine-tune shielding, grounding, impedance, and EMI layers to maintain high signal fidelity.

- Rapid Drawing Turnaround: Within 30 minutes to 3 days, you receive precise CAD+PDF drawings for confirmation before production.

- No MOQ Limitations: From 1 piece to 100,000 units, we support low-volume trials and large-scale orders alike.

With Sino-conn, customization is not just a service—it’s a promise to build exactly what your system demands.

Our Commitment to Outstanding Service

Unmatched Support Throughout Your Project Lifecycle

Our team believes that great cable assemblies are not just built in factories—they are built through proactive communication, precision service, and ongoing support. With Shenzhen Sino-conn, you get more than a cable—you gain a reliable technical partner from concept to shipment.

- Lightning-Fast Quotation & Drawing: Need a quote and drawing today? Our engineering and sales team can respond within 30 minutes in urgent cases.

- Transparent Communication: Whether it’s BOM clarification, connector cross-reference, or tolerance consultation, we respond clearly and professionally via video call or email.

- Multi-Level QC Assurance: We implement process, completion, and pre-shipment inspections—each cable assembly is 100% tested before delivery.

- Documentation Ready: Certificates like UL, ISO, RoHS, REACH, and test reports (COC/COO) are ready to support your compliance needs.

- After-Sales Guarantee: We track your shipment, ensure every delivery meets specs, and provide free technical troubleshooting if needed.

No matter your scale or urgency, we deliver not just quality cables—but exceptional service that engineers, buyers, and OEMs trust.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

We were developing a next-generation automated conveyor system for a large food processing facility. The harsh industrial environment, with high humidity and frequent washdowns, required a highly customized cable solution that could withstand water, corrosion, and mechanical wear.

I reached out to Shenzhen Sino-conn with only a rough drawing and a long list of specifications. To my surprise, their technical team responded within an hour, and within 24 hours, I received a preliminary design and quote. Their ability to rapidly interpret our technical needs and offer practical suggestions was outstanding.

The cables they delivered met all our UL and RoHS requirements, featured reinforced IP-rated connectors, and had an EMI-shielded structure with PVC and Teflon jacketing. Most importantly, they performed perfectly during field testing — no signal dropouts, even under constant flex and high-pressure cleaning.

Their team was incredibly responsive during prototyping and production. They provided detailed CAD drawings and revised them quickly based on our feedback. I truly appreciate their flexibility, speed, and technical depth. It’s rare to find a supplier who treats even 20-piece pilot orders with this level of attention.

“Absolutely professional and responsive. The quality and engineering support exceeded our expectations. Highly recommended for industrial automation solutions.”

David L.

Senior Project Engineer, USA

Our company manufactures CNC machines for small and mid-sized workshops across India. We had consistent issues with cable assemblies breaking down due to vibration, dust ingress, and inconsistent power delivery. Most local suppliers couldn’t meet the long-term durability standards we required, and we were losing time and money on frequent replacements.

When I discovered Sino-conn, I was impressed by how quickly they understood our needs. I sent them detailed diagrams and use conditions, and within 48 hours, they sent back a fully tailored solution with cost options for both branded and cost-efficient connector versions.

The cable assemblies they delivered had rugged nylon braided jackets, anti-vibration mounts, EMI shielding, and tight-seal connectors. We conducted field tests over 6 weeks and saw no performance drop. Installation was smooth, and feedback from our technicians was excellent.

What stood out was their flexibility — they adjusted lengths, modified connector pinouts, and even helped us redesign a portion of the harness layout for better airflow inside our CNC cabinets.

“These guys go the extra mile. They treated our mid-sized order like a large enterprise project. The quality, response speed, and willingness to adapt really stood out.”

Priya Nair

Procurement Manager, India

As a senior engineer in charge of prototyping industrial robotic arms for hazardous environments, I had very specific requirements. The cables needed to be flame-retardant, oil-resistant, and maintain flexibility under constant motion. Our previous suppliers either overcharged for customization or couldn’t meet performance standards during testing.

Working with Sino-conn was a turning point. I submitted a drawing with detailed mechanical and electrical constraints. Within just one day, their team returned a precise CAD drawing, followed by a sample within four days. The cable used a hybrid insulation system with Teflon and PVC, featured dual-layer EMI shielding, and had precision overmolded connectors for vibration resistance.

In field trials, it operated perfectly across 2 million flex cycles. Even in high-temperature zones and where hydraulic oil was present, the performance didn’t degrade. Their engineering team was quick to respond and even proactively suggested an optimized routing scheme that reduced internal cable stress.

“I’ve worked with several manufacturers in Europe and Asia, but none were as responsive or technically thorough. The team at Sino-conn helped us move from prototype to production with total confidence.”

Lars Becker

R&D Engineer, Germany

industry Application of industrial cable assemblies

Industrial cable assemblies from Sino-Conn are widely used across automation systems, heavy machinery, robotics, energy infrastructure, medical equipment, and aerospace applications. Designed for high performance in demanding environments, they offer excellent EMI shielding, flexibility, and durability under extreme temperatures, vibrations, and chemical exposure.

Solution 1: Industrial Automation Wiring for Smart Factories

Application Scenario:

In modern smart factories, industrial automation systems have become increasingly complex, requiring thousands of interconnections between robotic units, motion control devices, sensors, and industrial computers. These environments operate continuously in high-speed cycles, where machinery performs precise, synchronized operations under conditions of heat, vibration, and dust. Cable assemblies must endure repeated movement within drag chains, resist EMI from multiple power and signal lines, and fit into tight routing paths without failure. In such systems, a cable malfunction can halt the entire production line, causing costly downtime and maintenance.

Equipment & Products:

- Robotic arms, PLC cabinets, conveyor actuators

- Drag-chain grade shielded cables, circular connectors

Industry Pain Points:

- Frequent EMI interference due to proximity of signal and power lines

- Cable fatigue and failure from continuous bending in motion tracks

- Connector instability under vibration, dust, or oil exposure

Solutions:

- Multi-layer shielding (foil + braid) to protect signal integrity

- High-flex drag chain cables rated for 5M+ bend cycles

- IP67 circular connectors with locking features and dustproof design

Solution 2:Weatherproof Cable Assemblies for Remote Utility Operations

Application Scenario:

In remote outdoor utility installations—such as transformer stations, wind turbine controllers, and solar inverters—industrial cable assemblies must perform reliably despite exposure to rain, UV radiation, temperature extremes, and fluctuating power loads. These systems are often unmanned and located in rural or coastal areas where maintenance is infrequent, and cable damage can go unnoticed for long periods. Failures not only disrupt regional energy distribution but also require costly field repairs. Cables must be weatherproof, mechanically reinforced, and capable of maintaining signal integrity over long distances, often through conduit or buried lines. Assembly quality directly determines operational uptime and regulatory compliance in the energy sector.

Equipment & Products:

- Smart switchgear, solar inverters, power distribution boxes

- UV-resistant sheathed cables, IP68-rated connectors

Industry Pain Points

- Long-term UV and weather exposure degrading outer jacket materials

- Moisture ingress causing insulation failure and corrosion

- Difficult access and high labor cost for emergency cable replacement

Solutions:

- UV-stabilized, halogen-free jackets with enhanced outdoor aging resistance

- Waterproof sealing and gel-filled terminations for long-term insulation

- Pre-labeled, modular cable sets for fast installation and field replacement

Solution 3:Reinforced Cable Assemblies for Vibration-Intensive Environments

Application Scenario:

In the construction and mining industries, cable assemblies used in excavators, bulldozers, drilling rigs, and concrete mixers must withstand constant mechanical shocks, oil exposure, and dust ingress. These machines operate in extremely harsh conditions—gravel pits, underground shafts, or mobile platforms—where temperature shifts, cable flexing, and high amperage transmission are routine. Cable damage can lead to hydraulic control failure, data interruption in CAN bus systems, or even machine downtime, incurring significant project delays. An ideal solution must offer high-flex life, abrasion resistance, oil-proof insulation, and reliable signal transmission in electrically noisy environments.

Equipment & Products:

- Excavators, hydraulic control units, mobile power boxes

- PUR-jacketed industrial cables, shielded multi-core assemblies

Industry Pain Points:

- Continuous vibration and cable movement cause conductor fatigue and insulation cracks

- Oil and grease exposure lead to jacket degradation and short circuits

- Electromagnetic interference affecting control signal stability in sensors and controllers

Solutions:

- High-flex, oil-resistant PUR jackets with embedded reinforcement layers

- Multi-layer shielding (foil + braid) for anti-EMI performance in noisy environments

- Custom overmolding and strain relief boots to reduce connector stress and fatigue

Solution 4: Precision Cable Assemblies for High-Speed Data and Power Transmission

Application Scenario:

In Industry 4.0 environments, smart factories rely on interconnected robotic arms, PLCs, motion control systems, and vision inspection modules. These systems operate in dynamic environments with continuous movement, real-time feedback loops, and tight synchronization across devices. The cabling infrastructure must support high-speed signal integrity, noise shielding, flexibility, and seamless integration into cable tracks or robotic joints. Downtime due to cable failure or signal distortion can halt automated lines and affect throughput. Cable assemblies in these scenarios must comply with automation-grade standards, offer durability in repetitive flex cycles, and maintain consistent electrical characteristics.

Equipment & Products:

- PLCs, robotic arms, conveyor sensors, servo motors

- High-flex shielded Ethernet, hybrid power+signal cables, drag chain cables

Industry Pain Points:

- Signal loss or EMI interference in long or high-speed digital transmission

- Cable jacket degradation due to repetitive flexing or tight bending radius

- Connector stress and failure due to constant robotic motion and vibration

Solutions:

- Industrial-grade CAT6A/CAT7 cables with double shielding and twisted-pair integrity

- High-flex TPE or PUR outer jackets tested for >10 million flex cycles

- Molded connectors with locking mechanisms and custom strain relief designs

Solution 5: High-Reliability Industrial Cables for Railway Automation

Application Scenario:

Modern railway systems rely on highly synchronized control systems for signaling, switching, and communication between central command and field infrastructure. These systems operate under extreme conditions: outdoor environments, electromagnetic interference from high-voltage lines, and frequent vibration from moving trains. Whether it’s in signaling control cabinets, trackside switch boxes, or train-mounted communication modules, cable assemblies must offer reliable performance, environmental sealing, and compliance with railway safety standards. Failures could disrupt schedules, endanger passengers, or cause equipment downtime.

Devices and Products:

- Trackside signal controllers, switch actuator modules, train-to-ground communication units

- IP-rated multi-core cables, halogen-free railway-certified power and data assemblies

Industry Pain Points:

- Exposure to moisture, UV radiation, and corrosive elements in outdoor installations

- Signal distortion or data loss due to electromagnetic fields from nearby power systems

- Vibration-induced connector loosening or insulation fatigue in train-mounted systems

Our Solutions:

- Use of IP67/IP68-rated assemblies with UV-resistant, halogen-free TPE jackets for outdoor protection

- EMI shielding with multi-layer foil and braided armor to ensure signal integrity

- Lockable circular connectors with anti-vibration design and heat-resistant insulation (up to 105°C)

Scenario 6: Durable Cabling Solutions for Renewable Energy Equipment

Application Scenario:

In modern wind power farms, each turbine operates in a remote and elevated environment where harsh conditions such as temperature fluctuations, high humidity, UV radiation, and strong vibrations are common. The internal control units of a wind turbine—such as pitch systems, yaw motors, and generator controllers—require continuous and stable power and data transmission to ensure efficiency and safety. Cables must maintain signal integrity over long vertical runs, with high resistance to moisture ingress and mechanical stress. Industrial cable assemblies play a critical role in this infrastructure, forming the nervous system of turbine automation and monitoring systems.

Equipment and Products:

- Pitch controller, nacelle sensors, wind speed transducers, generator interface

- UV-resistant, flame-retardant cable assemblies with reinforced shielding and IP-rated connectors

Industry Challenges:

- Exposure to moisture, salt air, and extreme temperatures leads to cable degradation

- Continuous rotational and vibrational motion demands high-flex, fatigue-resistant materials

- Installation space within nacelles is limited, requiring compact, pre-terminated assemblies

Our Solutions:

- Use of flame-retardant and UV-resistant cross-linked polyolefin jackets with water-blocking gel

- Multi-strand, fine-gauge conductors and braided shielding ensure high flex life and EMI protection

- Modular, compact cable assemblies pre-tested for drop-in installation with minimal routing footprint

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized industrial cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is an industrial cable assembly used for?

Industrial cable assemblies are used to transmit power, signals, or data in factory automation, heavy machinery, control panels, and harsh environments.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Can you customize the cable length and pinout?

Yes, all our cables are fully customizable, including length, pinout configuration, connector type, and outer material.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

What industries do your cable assemblies serve?

Automation, robotics, energy, communication, medical devices, transportation, and more.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China