custom ethernet cable assemblies manufacturer

Looking for high-performance Ethernet cable assemblies that meet your unique specifications? At Sino-conn, we deliver custom solutions with precision—any length, connector type, or shielding option. From fast-turn samples to bulk orders, we ensure unmatched quality, EMI protection, and competitive pricing. Let us be your trusted partner in connectivity.

Why choose ethernet cable assemblies from sino-conn

Sino-Conn offers high-quality custom ethernet cable assemblies tailored to meet your specific needs. With durable materials, advanced shielding options, and industry-standard compliance, our cables provide reliable and high-performance connectivity. Whether for industrial, medical, or telecom applications, trust us for flexible, fast, and customized solutions that ensure seamless data transmission.

Ultra-Customizable Ethernet Assembly Solutions

Our Ethernet cable assemblies offer complete customization—length, shielding, pinout, jacket material, and connector orientation. Whether you’re building industrial networks, powering PoE systems, or working on compact automation designs, we adapt each cable to your exact requirements. From single prototypes to bulk production, our engineering team ensures the structure and specs match seamlessly. No MOQ. Rapid prototyping. Perfect fit for your unique applications.

Rapid Prototyping with 30-Minute Engineering Response

We understand speed matters. Our engineering team responds within 30 minutes to provide drawings and quotes, helping you get your Ethernet cable assembly project moving faster. From concept to CAD to PDF, we finalize your drawing in as little as 30 minutes, or within 3 days for complex needs. Samples can be delivered in as fast as 3 days. This rapid response capability gives our clients a crucial edge in product development and time-to-market.

Wide Connector Compatibility: Original & Alternative Brands

Our Ethernet cable assemblies support both original brand connectors (e.g. TE, Molex, Hirose) and high-quality alternatives. Clients can choose based on cost, lead time, or performance. Original brands are preferred by end-users for stability and compliance, while alternatives offer faster delivery and better pricing for OEMs or cost-sensitive projects. We stock both options, ensuring flexible, reliable sourcing with stable functionality. Let us help you balance quality and budget without compromise.

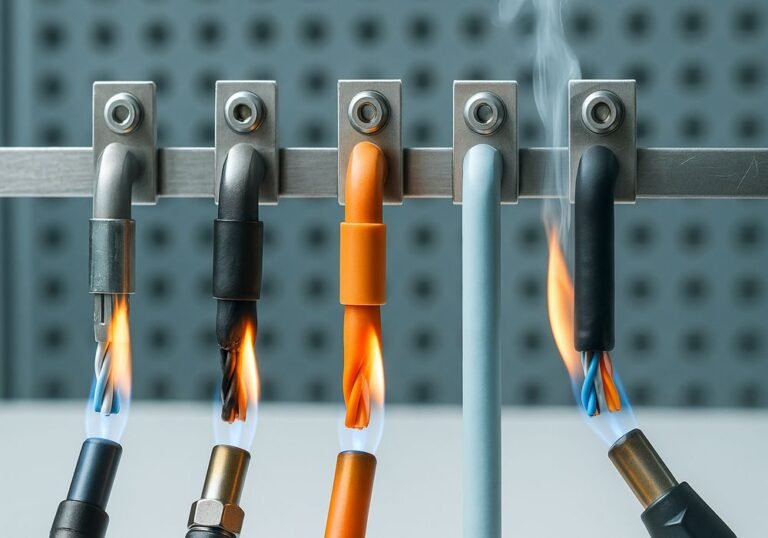

Engineered for Harsh Environments: Industrial-Grade Durability

Our Ethernet cable assemblies are built to withstand extreme industrial conditions—heat, cold, oil, UV, chemicals, and mechanical stress. We offer PVC, PUR, and LSZH jackets, plus shielded constructions (SF/UTP, S/FTP) to ensure performance in high-EMI environments. These cables are ideal for factory automation, outdoor networking, and transportation systems. With certified flame-retardant, anti-corrosive, and abrasion-resistant materials, our assemblies ensure reliable long-term operation wherever they’re installed.

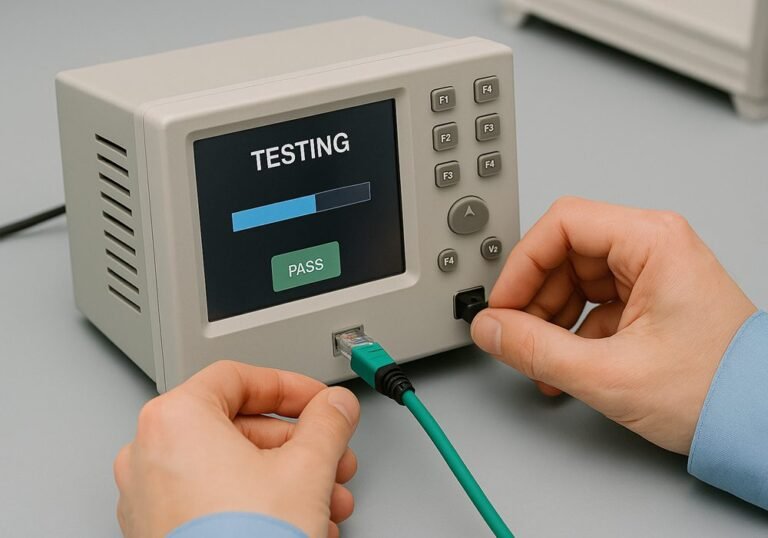

100% Full Inspection with Triple Quality Check

Every Ethernet cable assembly we deliver undergoes 100% full inspection, including in-process, post-assembly, and pre-shipment checks. Our triple-check workflow ensures every piece meets electrical, mechanical, and visual standards. Whether for end-use deployment or OEM integration, we guarantee zero-defect quality and traceability. Each assembly is tested for continuity, impedance, EMI shielding, and connector integrity. Our quality system helps you eliminate downstream issues and build lasting customer trust.

Flexible MOQ and Global Engineer Communication Support

We offer complete flexibility—no MOQ required. Whether you need 1 piece for testing or thousands for production, we support your needs. More importantly, our bilingual engineers are available for live video calls to help refine your design, solve technical issues, and accelerate development. This level of communication and service, rarely offered by traditional suppliers, allows us to deeply understand your application and deliver more precise Ethernet cable assemblies that perform reliably in your system.

Detailed specifications and parameters of ethernet cable assemblies

| No. | Definition | Connector Type | Cable Spec | Length (mm) | Jacket Style | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | T568B Straight | RJ45 Male to RJ45 Male | Custom | Custom | Round | / PVC Jacket |

| 2 | T568A Crossover | RJ45 Male to RJ45 Male | Custom | Custom | Round | Teflon Jacket |

| 3 | Industrial Shielded | M12 X-code to RJ45 | Custom | Custom | Round | Nylon Braided |

| 4 | PoE+ Compliant | RJ45 to RJ45 (8P8C) | Custom | Custom | Round | PVC Jacket |

| 5 | Ultra Flex | RJ45 to RJ45 with bend relief | Custom | Custom | Flat | Acetate Cloth |

| 6 | EMI Shielded | RJ45 Male to RJ45 Male | Custom | Custom | Round | Conductive Cloth |

| 7 | Outdoor Rated | RJ45 with waterproof head | Custom | Custom | Round | Nano Tape |

| 8 | Panel Mount | RJ45 to panel-mount RJ45 | Custom | Custom | Molded | Teflon Tape |

| 9 | Industrial PoE | M12 D-code to RJ45 | Custom | Custom | Round | Nylon Braided |

| 10 | Signal Breakout | RJ45 to terminal block | Custom | Custom | Flat | PVC Jacket |

The above table represents only a portion of our commonly produced Ethernet cable assemblies. In reality, every project is different—customers often have unique requirements regarding connector definitions, shielding, pinouts, cable lengths, jacket styles, and materials. At Sino-conn, we specialize in custom-built solutions tailored to your application. Whether you need a single prototype or full-scale production, our engineering team will work with you to define, design, and deliver the right Ethernet cable assembly for your needs.

Customized ethernet cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

UTP Cat 6 Ethernet Cable RJ45 LAN Cable 1M-50M

RJ45 Ethernet Cable Black LAN Cable Assembly

Cat 7 Ethernet Cable Shielded RJ45 High Speed Network Cable

Cat 7 Ethernet Cable RJ45 Shielded High Speed LAN Cable

Ethernet Cable Splitter RJ45 LAN Extension Cable with Switch

Ethernet Cable Splitter RJ45 LAN Extender Coiled Cord

Cat 8 Ethernet Cable Shielded RJ45 Network Cord

Cat 6 Ethernet Patch Cable RJ45 Gold Plated Connector

Cat 6 Ethernet Cable Blue RJ45 LAN Network Cable

Cat 6 Ethernet Cable 15m RJ45 High Speed LAN Cable

Cat 6 Ethernet Cable 5m RJ45 Network Cable

Industrial Ethernet Cable RJ45 to M12 Connector

Cat 6 Ethernet Cable 50m RJ45 to RJ45 Network Cable

Product details display

Explore the detailed specifications of our custom Ethernet cable assemblies, designed to meet a wide range of industry needs. Our product details include precise dimensions, materials, voltage ratings, and shielding options, ensuring optimal performance and reliability. Whether for high-speed data transmission or harsh environments, our cables offer superior quality and customization options tailored to your exact requirements.

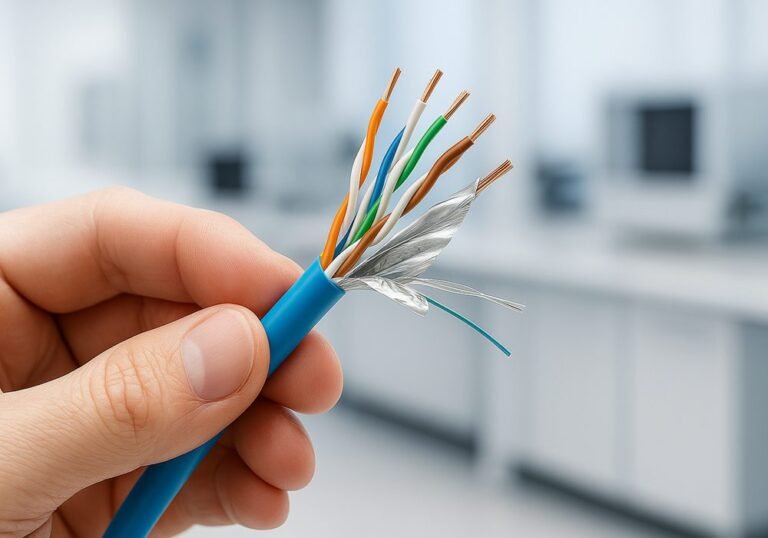

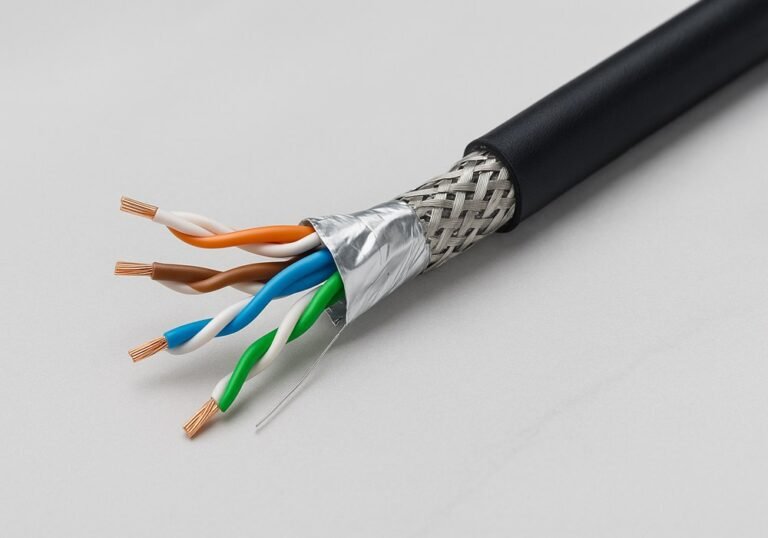

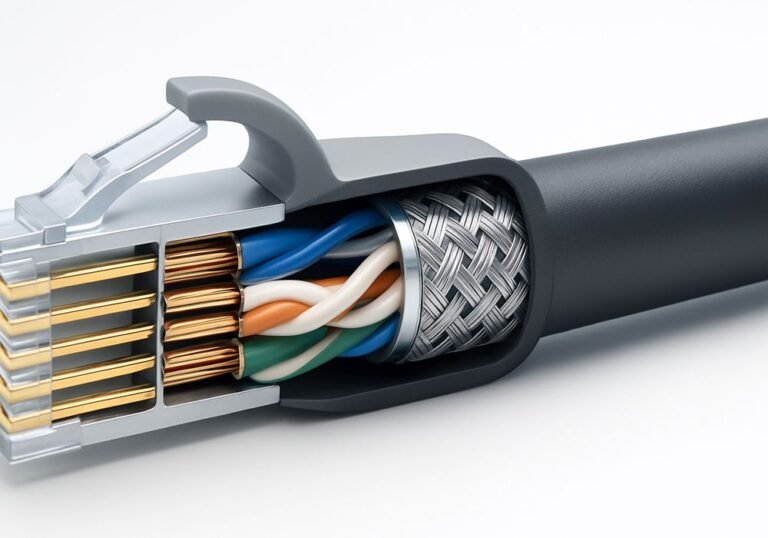

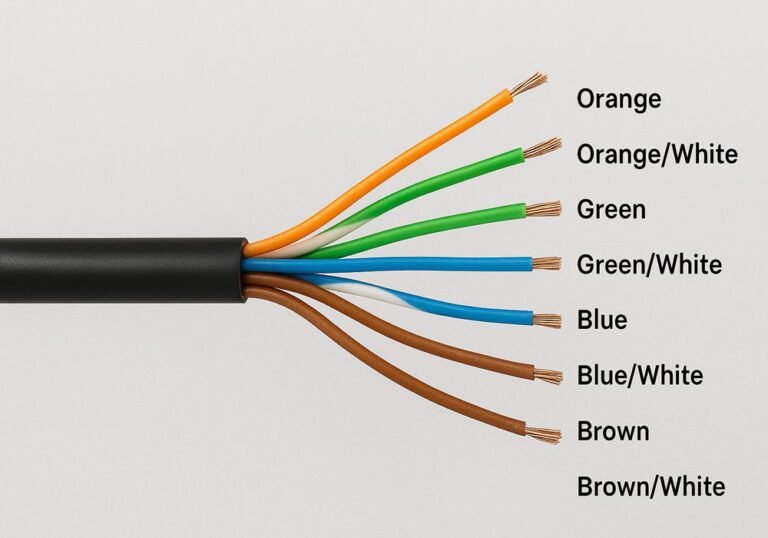

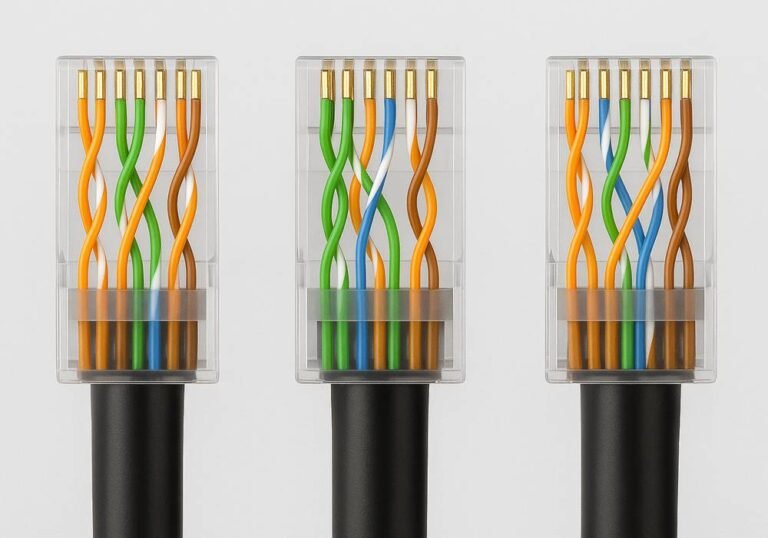

High-Performance Twisted Pair Structure

One of the core features of our Ethernet cable assemblies is the optimized twisted pair structure, which ensures signal integrity and reduced crosstalk in high-speed data transmission. Whether for Cat5e, Cat6, or Cat6a assemblies, our tightly balanced twist ratios maintain impedance consistency and high-frequency performance.

- Optimized Twist Ratio: Precisely controlled twist pitch for each pair reduces electromagnetic interference (EMI) and crosstalk.

- Signal Integrity: Maintains stable signal transmission over long distances, ideal for PoE and Gigabit Ethernet.

- Shielding Compatibility: Works effectively with various shielding options such as U/FTP or SF/UTP.

- Category Versatility: Supports a wide range of Ethernet categories including Cat5e, Cat6, Cat6a, and Cat7.

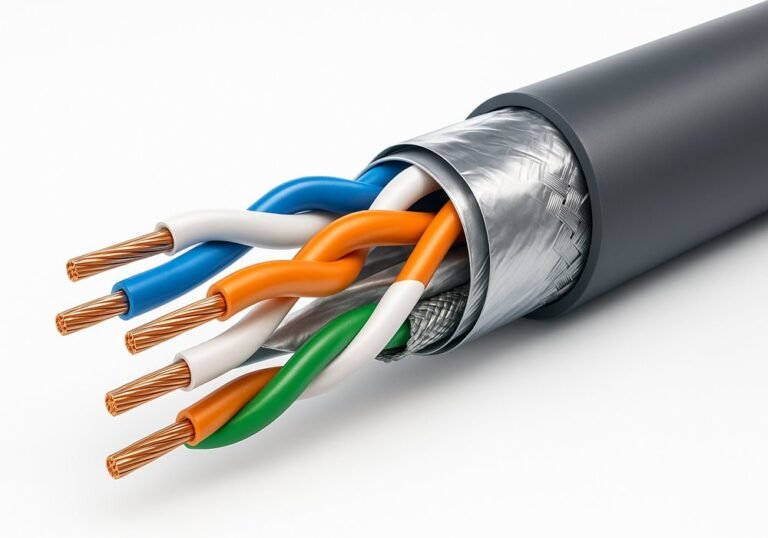

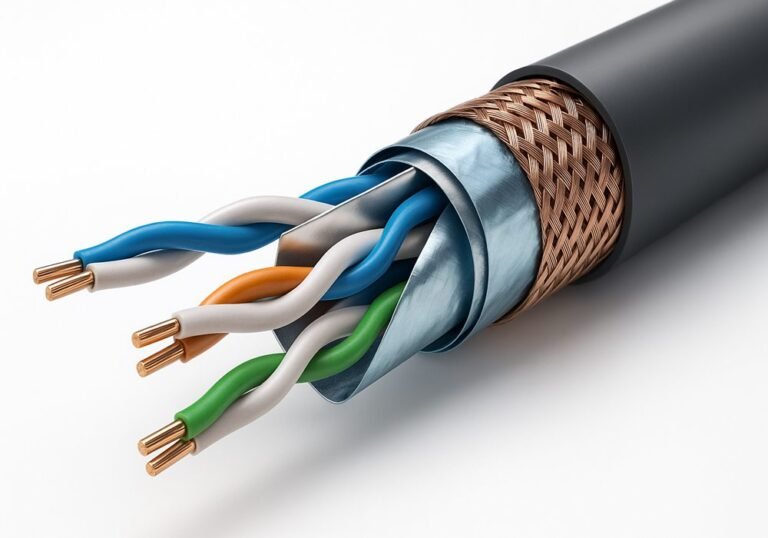

Multi-Layer Shielding for EMI Protection

Electromagnetic interference (EMI) is one of the leading causes of signal degradation in Ethernet cabling. Our cable assemblies are engineered with multiple shielding layers to protect against EMI and maintain consistent performance even in high-noise industrial environments.

- Aluminum Foil Shielding: Each twisted pair is wrapped with foil to block internal crosstalk.

- Braided Shield Layer: A high-density copper braid adds an extra layer of protection against external interference.

- Ground Wire Integration: Optional ground wires for enhanced signal stability and safety.

- EMI-Critical Applications: Ideal for factory automation, data centers, and mission-critical systems.

Durable Jacket Materials for Industrial Use

The outer jacket of Ethernet cables plays a critical role in protecting the internal structure. We offer a wide variety of jacket materials to suit different environments—from indoor office installations to outdoor or chemical-exposed locations.

- PVC Jacket: Cost-effective and flame-retardant for general use.

- LSZH Jacket: Halogen-free and low-smoke material for safety-sensitive areas.

- PUR Jacket: Resistant to oil, abrasion, and chemicals—perfect for industrial automation.

- Teflon Jacket: Extreme temperature resistance for aerospace and defense applications.

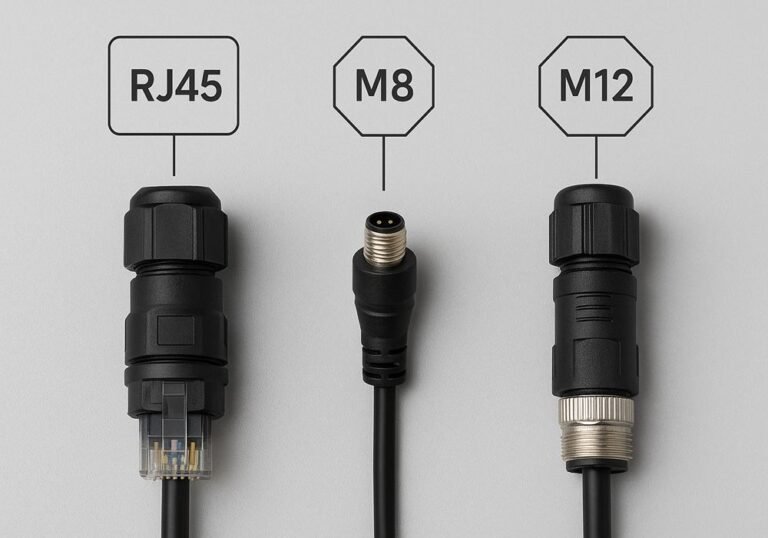

Precision-Engineered Connector Terminations

Reliable Ethernet connectivity starts with the connectors. At Shenzhen Sino-conn, every connector termination is done with precision to ensure mechanical stability, electrical integrity, and long-term durability. We support a wide range of connector types, including RJ45, M12, M8, and IP67 waterproof interfaces.

- Secure Crimping: All connectors are applied using professional crimping tools to prevent signal loss or pin disconnection.

- Strain Relief Design: Custom molded boots or overmolds prevent cable damage from bending or pulling.

- Connector Compatibility: Support for original brand and high-quality alternatives.

- Environmental Sealing: Waterproof versions available for harsh outdoor or industrial environments.

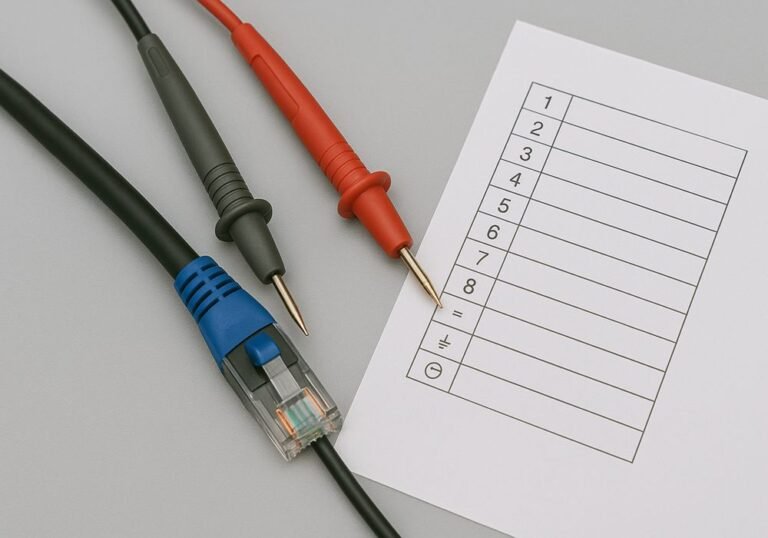

Flexible Pinout & Signal Mapping Customization

Many applications require non-standard Ethernet pinouts or mixed-signal mappings (data + power + control). We offer fully customizable pinout configurations to meet complex system integration needs. Every cable is labeled and tested to ensure accurate connectivity.

- Custom Pin Assignments: Tailored to meet proprietary devices, embedded systems, or automation controllers.

- Mixed Signal Support: Combine Ethernet signals with other protocols or power lines.

- Labeling & Traceability: All pinouts are documented, labeled, and verified.

- Cross-Compatibility: Designed to connect dissimilar ports between two devices.

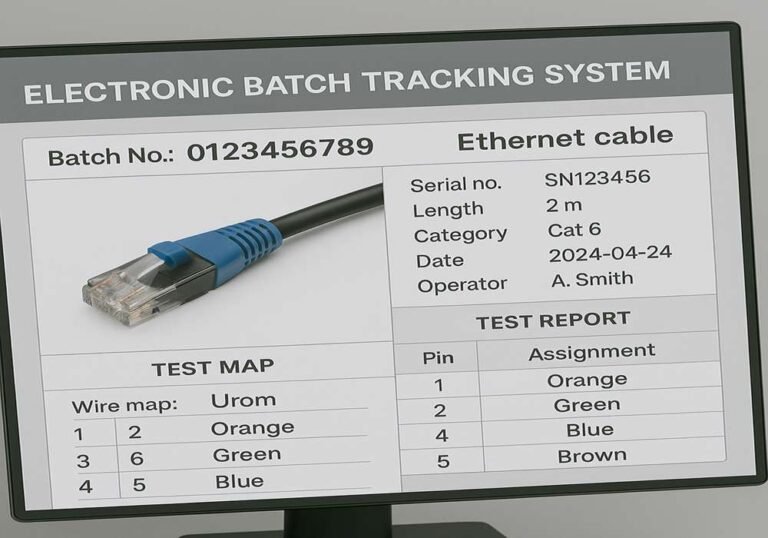

Zero-Defect Testing Workflow & Traceability

Each Ethernet cable assembly undergoes a strict zero-defect workflow, including in-line process inspections, continuity and impedance tests, shielding verification, and a final QC sign-off. Every unit is traceable via serial number and batch documentation.

- 3-Stage Quality Check: Process inspection, finished product test, pre-shipment inspection.

- Functional Testing: Continuity, shielding, impedance, and connector integrity verification.

- Serialized Traceability: Each cable carries unique ID for production record lookup.

- Detailed Test Reports: Provided upon request for quality assurance or compliance.

--- Customized Capabilities Services and Processes

Customize your ethernet cable assemblies

Our customized Ethernet cable assemblies are designed to meet your specific needs, with flexible options for length, shielding, connectors, and materials. We provide comprehensive services, including detailed technical drawings, fast prototyping, and full-scale production. With our advanced manufacturing processes and commitment to quality, we ensure that every assembly is tailored to your requirements and performs reliably in your application. Our expertise and responsive support make us the ideal partner for your custom cable assembly needs.

Customized Capabilities Services and Processes

Customize your ethernet cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Shenzhen Sino-conn, we provide highly customizable Ethernet cable assemblies tailored to your exact technical and operational requirements. Our flexible design and production system allows us to accommodate a wide range of application-specific needs, from prototyping to full-scale manufacturing.

Our customization capabilities include:

- Cable length & structure: Fully customizable lengths, shielding methods (U/UTP, F/UTP, S/FTP), and internal core layout.

- Pinout & wiring schemes: Standard or non-standard Ethernet pinouts, hybrid signal/power/control configurations.

- Connector types: Support for RJ45, M8, M12, D/X-code, IP67-rated interfaces, and more.

- Jacket materials: Options include PVC, LSZH, PUR, Teflon, braided nylon, and anti-oil or flame-retardant jackets.

- Compliance standards: RoHS, REACH, UL, ISO9001, COC, COO and other certifications available.

- Labeling & packaging: Barcoded, serialized, or color-coded solutions for OEM or factory integration.

Our Commitment to Outstanding Service

We believe exceptional products must be backed by exceptional service. At Shenzhen Sino-conn, our customer service philosophy is built on speed, accuracy, flexibility, and clear communication—from initial inquiry to post-sale support.

What makes our service truly stand out:

- Fast response: We provide drawings and quotations within 30 minutes of inquiry in most cases.

- Engineering support: Real-time video calls, technical consultations, and one-on-one engineering discussion available.

- No MOQ, fast sampling: 1-piece minimum, 2–3 day rapid prototyping for urgent needs.

- Full transparency: Real-time updates, clear documentation, production visibility at every stage.

- 100% inspection: Each cable undergoes triple testing before shipment to ensure zero defect delivery.

- Multilingual service: English, Chinese, and technical bilingual support available throughout the project.

- After-sales assurance: Timely feedback, follow-up tracking, and guaranteed resolution to any issue.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

We began working with Michael, a senior R&D engineer at a U.S.-based medical device company, when his team needed a custom Ethernet cable assembly for a new patient monitoring system. The project required a shielded Cat6 cable with LSZH jacket, customized pinout, and dual RJ45-to-M12 X-coded connectors to comply with hospital-grade standards.

Michael provided a rough drawing and technical notes, and within 45 minutes, our engineering team responded with a complete CAD and pinout proposal. In just 3 days, we delivered the sample, and it passed all their EMI and mechanical reliability tests. The client’s procurement team later followed up for a 2,000 pcs order with serialized labeling and full UL documentation.

“Shenzhen Sino-conn’s responsiveness and engineering precision were unmatched. The speed and quality were exactly what our medical application required. 5 stars!”

Michael Reed

Senior R&D Engineer,United States

Lars, working with a German industrial automation firm, approached us to design Ethernet cable assemblies capable of operating reliably in an oil-rich, high-vibration environment. The cables needed PUR jackets, M12 D-coded connectors on one end, and RJ45 on the other—lengths customized for each robot arm.

Our team held a video call with their engineering department, discussed dynamic bend radius, and designed overmolded strain relief. We sent 3 different prototypes within 72 hours for comparison. Lars’ team selected the final version after intensive torque and flex testing. Full production (5,000 sets) followed, with labeled batch tracking and REACH-compliant materials.

“Perfectly engineered for industrial harshness. Sino-conn didn’t just deliver cables—they delivered reliability. Definitely our preferred partner in China.”

Lars Schneider

Technical Purchasing Manager,Germany

Yuki’s company in Japan develops marine-grade communication systems and needed a highly corrosion-resistant Ethernet cable assembly for use on ocean research vessels. The requirements were very specific: Cat6a double-shielded cable, stainless steel RJ45 connectors, and waterproof IP67 sealing with silicone overmold.

After providing us a system layout diagram, Yuki was surprised that we returned a full production-ready drawing within 1 hour. Our rapid sample turnaround (2 days) helped their sea trial timeline stay on track. After deployment, the cables maintained flawless signal integrity in high salt and humidity conditions for 6 months.

“Professional, precise, and incredibly fast. This kind of performance is rare even among domestic suppliers. Strongly recommend.”

Yuki Tanaka

System Integration Engineer,Japan

industry Application of ethernet cable assemblies

Ethernet cable assemblies are widely used across various industries for reliable data transmission. They play a critical role in networking, telecommunications, industrial automation, and more. Whether it’s for high-speed connections in data centers, robust industrial systems, or home and office networks, our custom Ethernet cable assemblies provide the necessary performance, durability, and flexibility to meet the demands of each specific application.

Solution 1: Reliable Ethernet Connectivity for Smart Factory Networks

Application Scenario:

In industrial automation systems, Ethernet cable assemblies are essential for enabling real-time control, high-speed data communication, and efficient machine coordination. These assemblies connect PLCs, sensors, HMIs, and robotic systems in demanding manufacturing environments, ensuring low-latency performance and robust reliability for 24/7 operations.

Equipment & Products:

- PLC controllers

- HMI touchscreens

- Industrial robots

- Proximity and optical sensors

- Shielded CAT6A Ethernet cables

- M12 and RJ45 industrial-grade connectors

Industry-Specific Challenges:

- High electromagnetic interference (EMI) from surrounding machinery compromises data signals.

- Continuous flexing and mechanical strain cause standard cables to fail prematurely.

- Operating conditions involve high temperature, vibration, and oil exposure.

Our Solutions:

- Implement foil + braid double-shielding and twisted pair layouts to mitigate EMI.

- Use PUR-jacketed, high-flex cable structures with integrated strain relief boots.

- Select connectors rated for industrial temperatures and oil resistance, ensuring stable long-term operation.

Solution 2: High-Throughput Ethernet Assemblies for Dense Network Racks

Application Scenario:

Modern data centers demand ultra-fast, high-density connectivity between servers, switches, and storage systems. Ethernet cable assemblies play a critical role in minimizing latency, ensuring consistent data flow, and maintaining thermal efficiency in tightly packed rack environments. Proper cable planning and shielding directly impact uptime and performance.

Equipment & Products:

- 1U/2U rack-mounted servers

- High-speed network switches

- Blade servers and NAS/SAN storage systems

- SFP+ and QSFP+ to RJ45 adapters

- Slim CAT6/6A Ethernet cables

- LSZH-jacketed patch cords for rack use

Industry-Specific Challenges:

- Space constraints in server cabinets lead to excessive cable congestion and airflow blockage.

- High data throughput (10G/40G) requires shielded cables with precise impedance control.

- Fire safety compliance is mandatory, especially in large-scale enclosed environments.

Our Solutions:

- Offer ultra-slim Ethernet assemblies with optimized bend radius and minimal OD to improve airflow and accessibility.

- Utilize low-skew, impedance-controlled twisted pair construction with individually shielded pairs for signal integrity.

- Use LSZH (Low Smoke Zero Halogen) jackets to meet international fire safety standards.

Solution 3: Ruggedized Ethernet Assemblies for Harsh Industrial Networks

Application Scenario:

Industrial automation environments such as manufacturing lines, robotic arms, and control cabinets rely on stable, real-time data communication to synchronize operations. Ethernet cable assemblies used here must withstand exposure to oil, vibration, electromagnetic interference, and temperature fluctuations. Inconsistent signal quality can lead to system delays, production errors, and safety risks.

Equipment & Products:

- PLC controllers and HMIs

- Robotic arms and CNC machines

- Field switches and remote I/O modules

- Industrial CAT5e/CAT6 cables with shielded twisted pair (STP)

- Waterproof RJ45 connectors with locking caps

- Oil-resistant PUR or TPE cable jackets

Industry-Specific Challenges:

- Strong EMI interference from motors, drives, and high-power machinery disrupts Ethernet signals.

- Exposure to oil, chemicals, and dust can degrade traditional PVC cables.

- Dynamic movements and vibration often lead to broken conductors or loose connector interfaces.

Our Solutions:

- Utilize double-shielded STP structures and EMI-rated connectors to ensure signal integrity.

- Adopt industrial-grade cable jackets like PUR or TPE that resist oil, abrasion, and chemicals.

- Design flexible strain reliefs and vibration-proof locking mechanisms for durable performance.

Solution 4: High-Performance Ethernet Assemblies for Intelligent Building Systems

Application Scenario:

Modern smart buildings integrate various IoT and control subsystems such as lighting, access control, HVAC, video surveillance, and energy management. These systems require reliable Ethernet connections for device-to-device communication, centralized control, and remote monitoring. Cable routing within complex wall cavities, ceiling ducts, and equipment racks demands flexible, low-profile Ethernet assemblies with long service life.

Equipment & Products:

- PoE (Power over Ethernet) cameras and access controllers

- Smart thermostats and HVAC controllers

- Lighting control modules and touch panels

- Slim-profile CAT6 patch cables with PVC or LSZH jackets

- Angled RJ45 connectors and keystone jacks for space-saving installation

Industry-Specific Challenges:

- Limited space for cable routing in narrow conduits and densely packed control cabinets.

- Fire safety regulations require low-smoke, halogen-free materials.

- Large number of endpoints (sensors, lights, cameras) leads to signal crosstalk and congestion.

Our Solutions:

- Provide ultra-flexible, slim-profile Ethernet assemblies that can bend through tight pathways.

- Use flame-retardant, LSZH-compliant materials to ensure building code conformity.

- Offer fully shielded STP/FTP cables with precise impedance control for low-crosstalk transmission.

Solution 5: Low-Latency Ethernet Cable Assemblies for AV Signal Transmission

Application Scenario:

In broadcast control rooms and recording studios, high-speed, low-latency Ethernet transmission is essential for real-time audio/video signal routing, IP-based live streaming, editing, and synchronization between various AV equipment. These environments are sensitive to jitter and EMI interference, so shielding, signal integrity, and precision craftsmanship are non-negotiable.

Equipment & Products:

- IP-based video switchers and audio mixers

- PTZ cameras and streaming encoders

- Control consoles and networked audio interfaces

- Low-jitter CAT6A/CAT7 STP cables

- Gold-plated RJ45 connectors with latch protection

Industry-Specific Challenges:

- Broadcast-grade installations require extremely low latency and lossless data transfer.

- EMI from lighting rigs, power amplifiers, and other AV devices can affect transmission quality.

- Frequent connection/disconnection causes connector fatigue and damage.

Our Solutions:

- Provide CAT6A/CAT7 fully shielded cable assemblies with sub-millisecond latency and excellent signal fidelity.

- Use precision-braided shielding and twisted pair geometry to mitigate EMI and maintain integrity.

- Offer durable, gold-plated RJ45 connectors with strain relief and reinforced latches for long-term usage.

Solution 6: Ruggedized Ethernet Cable Assemblies for Power Grid and Utility Networks

Application Scenario:

Ethernet cable assemblies are widely used in smart grid systems, substations, and energy monitoring terminals to connect programmable logic controllers (PLCs), intelligent electronic devices (IEDs), and SCADA systems. These applications require rugged performance in outdoor or semi-outdoor environments with extreme temperatures, electromagnetic interference, and mechanical stress.

Equipment & Products:

- SCADA remote monitoring terminals

- Substation Ethernet switches

- Outdoor PLCs and IED sensors

- Industrial-grade CAT6/CAT7 STP cables

- UV-resistant PVC or Teflon jackets

Industry-Specific Challenges:

- Cables are exposed to UV, moisture, oil, and extreme temperatures, risking insulation degradation.

- Strong EMI from high-voltage equipment and RF noise in substations can corrupt Ethernet signals.

- Infrequent maintenance access requires long-term reliability and minimal failure rates.

Our Solutions:

- Use UV-resistant, oil-resistant, and flame-retardant jackets with Teflon/PVC to ensure durability in harsh environments.

- Employ double-layer shielding and twisted pair designs to resist EMI and ensure signal stability.

- Provide overmolded RJ45 connectors and reinforced locking mechanisms for field reliability.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Can you customize the length and connector type of Ethernet cable assemblies?

Yes, we offer full customization including length, jacket color, connector types (RJ45, M12, etc.), shielding, and pinout configuration.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Can you provide product drawings and specifications?

Yes, we can provide CAD drawings and detailed specs within 1-3 days. PDF versions are included for all quotations and order confirmations.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

Can I use my own brand or logo on the cables?

Yes, OEM and ODM services are supported. We can print your logo or label on the cable and packaging.

What types of Ethernet cables do you offer?

We supply CAT5e, CAT6, CAT6A, CAT7, with options like STP/UTP, PVC/LSZH jackets, and industrial-grade designs.

Do you offer overmolded Ethernet connectors?

Yes, we provide overmolded RJ45 and M12 connectors for better durability, waterproofing, and strain relief.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China