# Custom LVDS Cable Assembly Manufacturer

High-Performance Low Voltage Differential Signal Cable Assembly Solutions

Sino-conn LVDS Cable Assemblies are designed for high-speed data transmission in displays, automotive electronics, and industrial equipment. We offer custom solutions with no MOQ, fast delivery, and OEM/ODM support. Featuring EMI shielding, precision manufacturing, and reliable performance, our cables meet diverse application needs with flexible, high-quality production.

Why choose LVDS Cable Assembly from sino-conn

Sino-Conn delivers high-performance LVDS cable assemblies with precise impedance control, excellent signal integrity, and low electromagnetic interference. Designed for high-speed data transmission in displays, cameras, and industrial equipment, each assembly is customized for reliability and manufactured under strict quality standards with over 16 years of industry expertise.

Flexible Pinout and Length Customization for LVDS Assemblies

We provide flexible customization for LVDS cable assemblies, including pin definition, cable length, wire gauge, and connector orientation. This enables customers to adapt easily to various PCB layouts and device dimensions while maintaining signal integrity. Ideal for both prototyping and volume production.

High-Speed Differential Signaling with Low EMI Interference

LVDS cables offer outstanding signal stability for high-speed data transmission with minimal electromagnetic interference. Our twisted-pair shielded structure ensures clean signals for display, camera, or industrial automation systems—especially critical in medical and automotive electronics.

Wide Compatibility with FH, DF, FI Series Connectors

Our LVDS cable assemblies support a broad range of connector types including FH, DF, and FI series in various pitches (0.5mm, 1.0mm, etc.). Whether you need vertical, right-angle, or locking types, we ensure precise mating and reliable contact for diverse applications.

Fast Prototyping and Engineering Drawing Support

We deliver engineering drawings within 30 minutes and provide custom CAD-to-PDF files for customer confirmation before production. Our rapid sampling service allows you to validate form, fit, and function in as little as 2–3 days.

Ultra-Thin, Flexible, and Durable Cable Structure

Our LVDS cables are designed to be ultra-thin and highly flexible, making them ideal for compact electronic systems. The multi-layer insulation and robust shielding ensure excellent mechanical endurance and signal stability in bending environments.

Comprehensive Certifications and Full-Scale Quality Control

All LVDS assemblies are ISO, UL, ROHS, REACH, PFAS compliant. We perform three stages of inspection: in-process, final, and pre-shipment. 100% of units are tested to ensure full compliance and long-term reliability.

Detailed specifications and parameters of LVDS Cable Assemblies

| No. | Pin Definition | Connector Model | Cable Spec | Length (mm) | Cable Structure | Sheath Material |

|---|---|---|---|---|---|---|

| 1 | 10-pin straight | FH12-10S-0.5SH | Custom | Custom | Flat | Kapton tape |

| 2 | 20-pin differential pair | DF14-20S-1.25C | Custom | Custom | Flat | Conductive cloth tape |

| 3 | 30-pin split type | FI-R30S-A1 | Custom | Custom | Flat | Teflon tape |

| 4 | 40-pin 1-to-2 | DF9-41S-1V | Custom | Custom | Round | Nylon braided sleeve |

| 5 | 15-pin single-ended | FH26-15S-0.3SHW | Custom | Custom | Flat | PVC sleeve |

| 6 | 50-pin GND shielding | DF40HC(3.0)-50DS | Custom | Custom | Flat | Teflon sleeve |

| 7 | 60-pin twisted pair | FH52-60S-0.5SH | Custom | Custom | Flat | Nano tape |

| 8 | 14-pin high-temp design | FI-X14S-A | Custom | Custom | Molded | PTFE wrap |

| 9 | 8-pin compact | DF11-8DP-2DS | Custom | Custom | Round | Acetate cloth tape |

| 10 | 24-pin EMI protection | FH28-24S-0.5SH | Custom | Custom | Flat | Aluminum foil + cloth |

At Sino-conn, we understand that every customer’s application is unique. That’s why all our LVDS cable assemblies are fully customizable—from connector models and pin definitions to cable length, structure, and wrapping materials. Whether you’re developing prototypes or managing volume production, we tailor the right LVDS cable solution to fit your exact electrical and mechanical needs.

Customized LVDS Cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

30 Pin LVDS Cable with Locking Bra

40 Pin LVDS Cable

40 Pin LVDS Micro Coax Cable

51 Pin LVDS Cable

Battery Connector Cable 8 Pin

Camera Signal Transmission Cable

Full HD LVDS Cable

LVDS Cable 30 Pin 0.4mm Pitch

LVDS Cable 30 Pin

LVDS Cable Assembly

LVDS Cable Connector 10 Pin

LVDS Cable for LED TV

LVDS Coaxial Cable 20 Pin

LVDS Connector Cable 20 Pin

LVDS Controller Cable

LVDS Display Cable 1.25mm Pitch

LVDS Display Cable 20 Pin

LVDS Display Cable 40 Pin

LVDS Display Cable

LVDS Display Micro Coax Cable 30 Pin

LVDS eDP Cable 20 Pin

LVDS eDP Cable

LVDS Micro Coax Cable 30 Pin

LVDS Micro Coax Cable

LVDS Ribbon Cable 0.4mm Pitch

LVDS Ribbon Cable

Ribbon IDC Cable Assembly

Product details display

Each LVDS cable assembly features tightly controlled impedance, high-flexibility wires, and robust shielding for superior signal transmission. Available in customized lengths, pin configurations, and connector types, all products are engineered to meet specific application needs across industrial, automotive, and display systems.

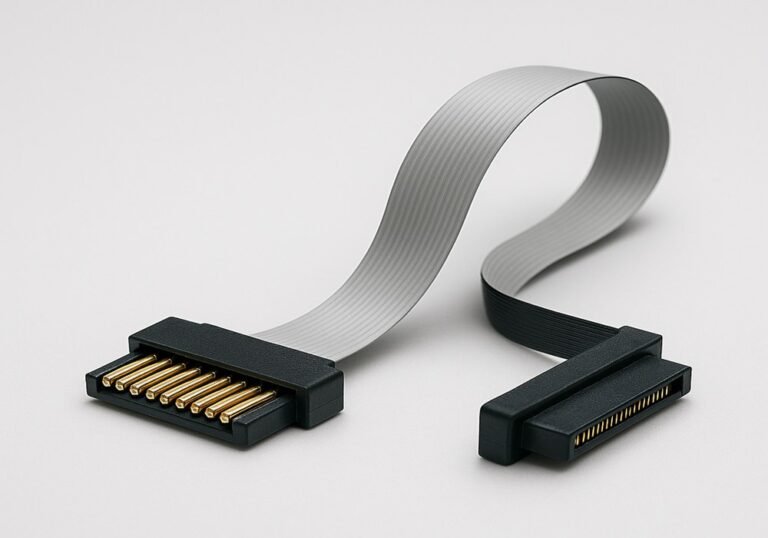

Gold-Plated Precision Connectors for Stable Contact

Each LVDS cable assembly features precision-engineered gold-plated connectors to ensure superior conductivity and stable signal transmission. The gold plating resists oxidation and reduces contact resistance, which is critical for applications involving frequent mating cycles or long-term exposure to temperature changes. Combined with injection-molded housings, the connectors offer secure mechanical alignment and are compatible with both original brands and verified alternatives. This connector quality ensures reliable electrical performance across a wide range of industrial, consumer, and automotive display systems.

- Gold-plated terminals ensure low contact resistance and anti-corrosion.

- Precision injection-molded housing guarantees consistent mechanical fit.

- Compatible with both original and equivalent connectors.

- Validated for 5,000+ mating/unmating cycles without failure.

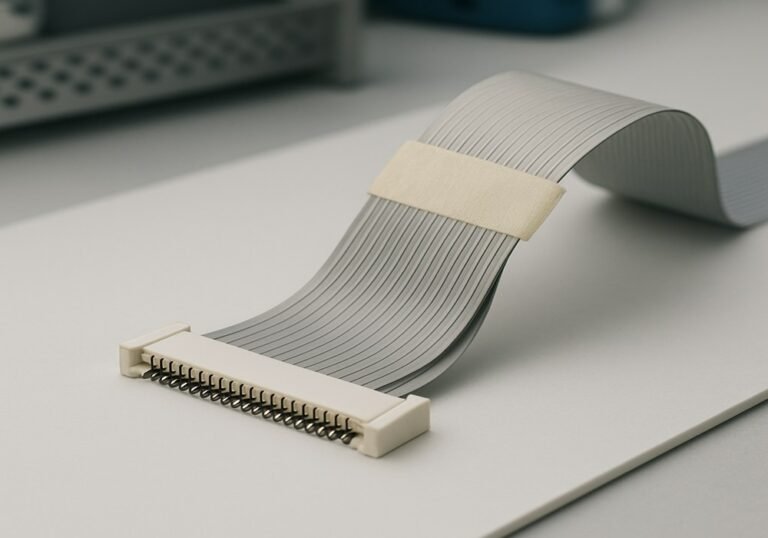

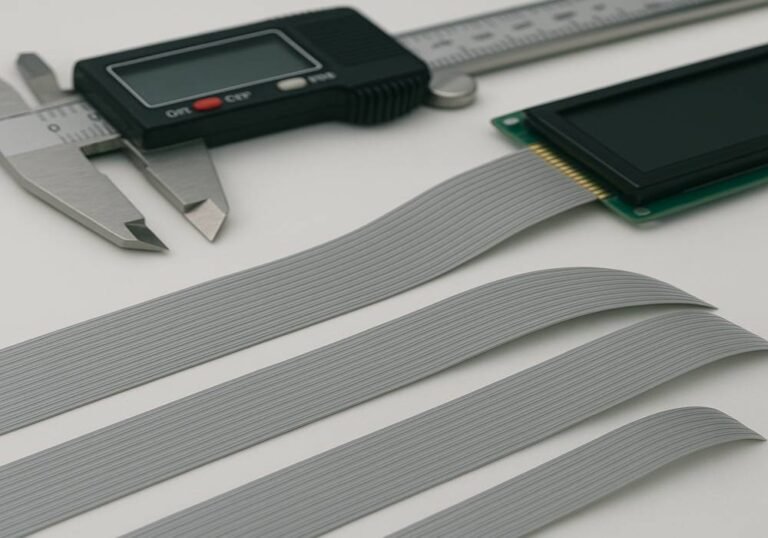

High-Flex Flat Cable Structure for Compact Devices

Our LVDS cable assemblies use flat flexible cable (FFC) structures that allow tight bending and space-saving routing, ideal for compact electronic devices. This structure reduces thickness while maintaining signal quality and physical durability. The cables can be folded or routed in narrow internal spaces without affecting performance, making them suitable for laptops, tablets, automotive dashboards, and display modules. Our FFCs are available in various conductor counts and can be tailored for different pitch sizes, ensuring a precise fit into your application.

- Flat construction enables ultra-thin profile installation.

- Supports frequent flexing in motion-intensive environments.

- Designed for narrow spacing between PCBA and LCD.

- Conductor count and pitch are fully customizable.

Dual Shielding with Foil and Braided Mesh Layers

Our LVDS cables feature dual-layer shielding that includes aluminum foil and copper braided mesh. This combination provides excellent EMI protection for both high and low-frequency signals, ensuring signal clarity even in noisy environments such as industrial control rooms, medical displays, and automotive head units. The shielding also improves mechanical integrity and grounding performance. This construction meets stringent noise suppression standards while preserving cable flexibility and lightweight handling, making it ideal for compact yet demanding systems.

- Aluminum foil shields against high-frequency EMI.

- Braided copper mesh reinforces grounding.

- Reduces internal crosstalk between differential pairs.

- Certified for EMI-sensitive environments (e.g. automotive, medical).

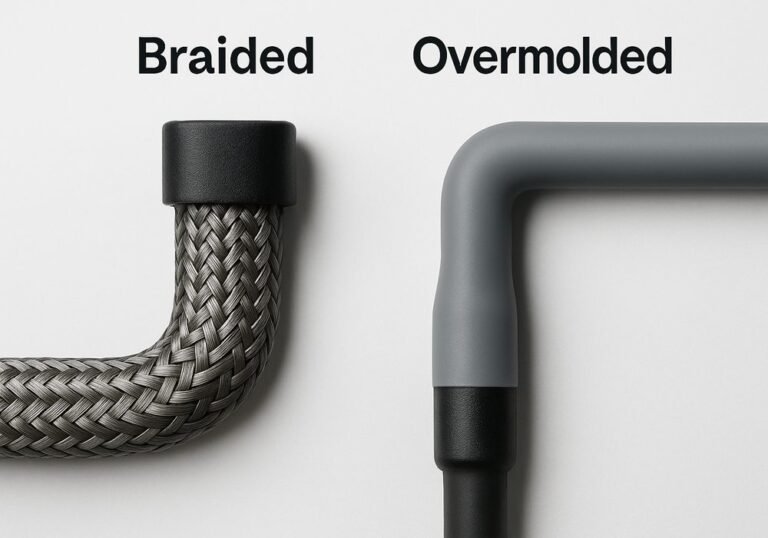

Flexible Jacket and Routing Structure Options

In precision electronics and compact mechanical systems, cable routing must adapt to diverse spatial and motion constraints. Our LVDS cable assemblies offer a variety of routing structures including flat, round, spiral, twisted, and branched harness styles. These structures are complemented by protective jackets such as PVC, silicone, Teflon, braided mesh, or overmolded rubber to meet thermal, mechanical, or EMI shielding demands. Whether your application involves tight bends, motion hinges, or 3D cable channels, we deliver configurations that minimize stress points while maximizing signal stability and mechanical endurance.

- Round, flat, spiral, twisted, or branched configurations available

- Jacket options: PVC, FEP, silicone, woven mesh, overmolded rubber

- Designed for narrow spaces or mobile mechanical assemblies

- Supports routing through hinges, sliders, 3D brackets, and cable trays

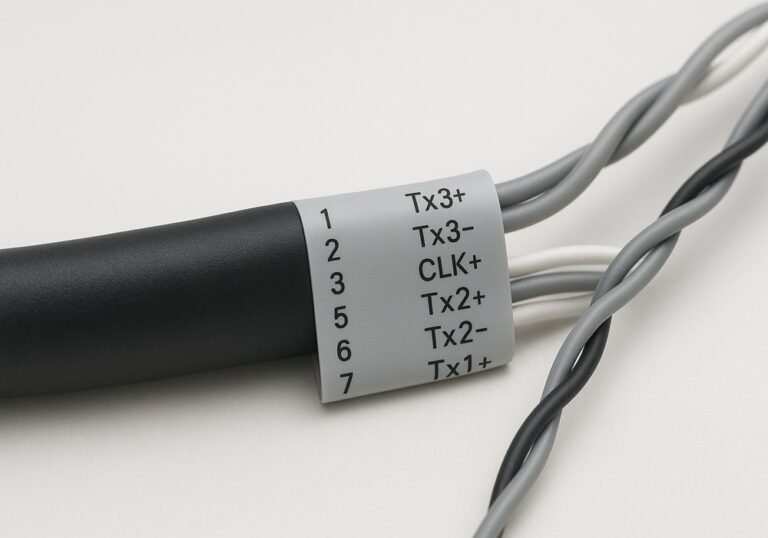

Visual Cable ID and Pin Sequence Management

For complex harness configurations, cable identification and pin-sequence management are essential for efficient installation and troubleshooting. We offer custom heat-shrink or label-based ID systems to clearly indicate connector orientation, signal names, and pin mapping. Each cable can be color-coded or printed with part number, revision, and sequence index, reducing confusion during assembly and improving traceability. This approach is especially useful in multi-branch LVDS applications, LCD integration, and low-volume engineering builds.

- Custom labels or color-coded heat-shrink markers

- Printed part number, pinout, or signal name

- Aids rapid connector orientation and wiring validation

- Improves traceability and reduces assembly errors

Precision Assembly for Fine-Pitch Micro Connectors

Our production process is optimized for fine-pitch connectors (0.3mm to 1.0mm pitch) commonly used in LVDS applications. These include micro series such as DF40, FH52, FI-R, and similar types. We use precision wire stripping, automatic crimping, and optical inspection to ensure consistent contact alignment and zero damage during handling. All terminations are verified under magnification, and cables undergo continuity and impedance tests to meet strict display and signal system requirements.

- Supports 0.3mm, 0.5mm, 0.8mm, 1.0mm pitch connectors

- Optical inspection for crimp and pin alignment

- Cleanroom-compatible assembly process

- Ideal for LCD panels, camera modules, and compact PCBs

--- Customized Capabilities Services and Processes

Customize your LVDS Cable Assembly

As a professional custom LVDS cable assembly manufacturer with over 16 years of experience, Sino-Conn offers comprehensive customization services tailored to meet the exact requirements of global clients. From initial design consultation to prototyping and mass production, every process is engineered for precision and flexibility.

Custom options include specific wire gauges, shielding types, cable lengths, pin-to-pin configurations, and various connector brands such as JST, Hirose, Molex, and more. Advanced production lines and automated crimping, soldering, and testing equipment ensure high-speed, high-consistency manufacturing.

Services cover OEM/ODM development, rapid sampling within 5–7 days, free design support, and full compliance with ISO, RoHS, and UL standards. A dedicated engineering team works closely with clients to develop LVDS cable solutions optimized for applications in displays, medical devices, automotive systems, robotics, and industrial control.

Every assembly undergoes 100% electrical testing, impedance verification, and quality inspections before delivery—ensuring performance, durability, and signal integrity in every cable. Sino-Conn is committed to delivering cost-effective and application-specific solutions that help clients accelerate their product development and go-to-market timelines.

Customized Capabilities Services and Processes

Customize your LVDS Cable Assembly

Customized service

At Sino-conn, our service is designed for speed, precision, and engineering clarity. From your first inquiry to final shipment, we integrate technical support directly into every step.

- We assign dedicated engineers to each project, ensuring that your specifications are understood and translated into production-ready drawings within 30–72 hours.

- For urgent projects, we offer video-based technical consultations, enabling real-time discussions on pinout logic, routing complexity, or EMI shielding design.

- Whether you’re a R&D engineer or OEM integrator, we support 1-piece prototyping, fast iterations, and continuous feedback loops.

- All products undergo full inspection (in-process + final + pre-shipment), with compliance reports for UL, RoHS, ISO, REACH, and PFAS included by default.

- Our multilingual sales and support team enables fast quoting, drawing confirmation, and seamless communication—no matter your time zone.

By bridging product definition with real-time technical service, we help customers reduce iteration cycles and accelerate project launches.

Ultimate service

At Sino-conn factory, we believe that technical excellence must be matched by service excellence. Our ultimate service philosophy is built around responsiveness, reliability, transparency, and long-term partnership.

- We operate a 24-hour response window for all inquiries, with typical replies delivered within 2–8 working hours, no matter your region or time zone.

- Each project is managed by a dual-core team—one technical engineer + one account manager—ensuring both design logic and commercial priorities are covered.

- We support flexible production arrangements for urgent projects, including expedited sampling in 2–3 days and mass production within 10–14 days.

- All communications, from RFQs to engineering confirmations, are archived and traceable. Digital sign-off systems ensure clarity and mutual accountability.

- We provide lifetime technical support, including post-shipment troubleshooting, drawing updates, and version upgrades—even years after delivery.

No matter how complex your project or how specific your needs, our team is committed to being your most reliable partner—from first inquiry to final installation and beyond.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

High-Speed LVDS Cable for Drone Gimbal Systems – Light, Shielded, and Reliable

“Sino-conn didn’t just supply cable—they became a key contributor to our drone system performance. Their speed, expertise, and flexibility helped us meet a strict timeline with zero rework.”

Carlos Herrera, Electronics Integration Lead

Location:Valencia, Spain

Ultra-Thin LVDS Cable for Portable Ultrasound – Medical Grade, EMI-Stable, Easy to Integrate

“We needed a supplier who understands medical compliance, miniaturization, and fast iteration. Sino-conn hit all three targets. The cables perform flawlessly in the field.”

Dr. Amelia Ross, Imaging Device Program Manager

Location: Boston, USA

High-Speed LVDS Cable for Machine Vision – Shielded, Accurate, Long-Distance Transmission

“We needed precision-grade cables with industrial durability. Sino-conn delivered on both. Their attention to shielding detail and connector fit saved us weeks in system debugging.”

Felix Lang, Automation Systems Architect

Location:Valencia, Spain

industry Application of LVDS cable assemblies

LVDS cable assemblies are widely used in medical devices, robotics, automotive systems, drones, industrial automation, and consumer electronics, ensuring high-speed data transmission, low EMI, and stable performance in demanding environments.

Automotive Infotainment Systems

Application Scenario :

LVDS cable assemblies are widely deployed in automotive infotainment systems, enabling high-speed signal transmission between head units, digital dashboards, and in-vehicle displays. These environments often present challenges such as space constraints, EMI interference, and high-temperature variations. LVDS cables are valued for their ability to maintain low-voltage, differential signaling with minimal crosstalk, making them ideal for high-resolution video transfer. With increasing demand for intelligent cockpits and rear-seat entertainment, custom LVDS cable assemblies ensure stable, interference-free performance and precise mechanical fit even under continuous motion, vibration, and temperature fluctuations.

Equipment & Products:

- LVDS cable assemblies for head units and car monitors

- Camera interface harnesses for infotainment modules

- Display link cables for digital dashboards

Industry Challenges:

- Tight space for internal routing

- EMI from automotive power systems

- Continuous flexing and vibration

Solutions:

- Slim-profile cables with tight-bend radius

- Foil and braid shielding for signal integrity

- High-flex jackets for durability and safety

Automotive Infotainment System – Stable Signal in Vibrating Environments

Application Scenario:

Modern vehicles demand advanced infotainment systems with crisp display output, fast response, and robust signal transmission. LVDS cable assemblies are crucial in connecting the central unit to displays, cameras, and control panels—especially in environments subject to constant vibration and EMI interference. Our customized LVDS solutions ensure stable differential signal transmission and shielded routing, even within dynamic or harsh under-dashboard areas.

Equipment & Products:

- Car infotainment units

- Dashboard display panels

- Reversing cameras

Industry Challenges:

- High vibration zones

- EMI from engine compartments

- Limited routing space

Solutions:

- Flexible flat cable design

- EMI shielding with aluminum foil

- Custom lengths for short runs

Industrial Display Modules – Long-Distance Noise-Free Transmission

Application Scenario:

In factory automation and CNC systems, remote displays are often placed meters away from control units. LVDS cable assemblies provide a cost-effective way to deliver high-resolution video over long distances with minimal signal loss. Our designs support custom EMI shielding and industrial-grade jacketing, ensuring signal clarity in environments full of electrical motors and power lines.

Equipment & Products:

- Industrial HMI displays

- Control system motherboards

- Machine vision terminals

Industry Challenges:

- Long transmission distance

- High ambient EMI

- Mechanical abrasion risks

Solutions:

- Twisted-pair shielded design

- Reinforced outer jackets

- Precision impedance control

Consumer Laptops & Tablets – Ultra-Slim Internal Wiring

Application Scenario:

Space-saving is critical in thin laptops and tablets. LVDS cable assemblies offer compact high-speed connections between the motherboard and display, enabling FHD or 4K transmission with minimal thickness. Our solutions use micro coaxial or flat flexible layouts, designed to bend around hinges and within tight bezels while maintaining shielding and signal integrity.

Equipment & Products:

- Ultrabook LCD displays

- Tablet mainboards

- Embedded camera modules

Industry Challenges:

- Ultra-slim housing

- Frequent hinge movement

- Low tolerance for EMI

Solutions:

- Micro-coax cable structure

- High-flex jacket materials

- Pre-tested cable curvature

Surveillance & Security Systems – Stable Video Over Extended Cable Runs

Application Scenario:

High-resolution surveillance monitors require noise-free image transmission from networked cameras to central monitors. LVDS cables are deployed in control rooms and security infrastructure to bridge image processors and output units. Our shielded twisted-pair assemblies ensure stable 1080p or 4K video quality even over extended lengths, with low skew and excellent crosstalk suppression.

Equipment & Products:

- Control room monitors

- NVR boards and I/O

- High-res camera decoders

Industry Challenges:

- Interference from power lines

- Signal degradation over distance

- Rack-mounted space constraints

Solutions:

- Low-skew cable architecture

- Dual-layer shielding

- Pre-labeled cable routing

Automotive Cluster Display – Real-Time Data with Zero Latency

Application Scenario:

Digital instrument clusters in vehicles require real-time data transfer between the ECU and the display. LVDS cable assemblies enable low-latency, high-bandwidth links supporting speedometers, navigation, and warning systems. Our automotive-grade designs use compact connectors and customized shielding for immunity against ignition system noise and environmental vibration.

Equipment & Products:

- Digital dashboard clusters

- Vehicle ECU units

- Speed & sensor modules

Industry Challenges:

- Real-time signal transmission

- Engine-induced EMI

- Tight dashboard compartments

Solutions:

- Low-jitter cable assemblies

- High-temp shielded jackets

- Compact automotive headers

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our custom cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is an LVDS cable assembly and what is it used for?

An LVDS cable assembly is used for high-speed, low-power digital signal transmission, typically in displays, industrial cameras, automotive, and medical devices.

Can you provide custom pinouts and cable lengths?

Yes. We support full customization, including pin-to-pin design, length, shielding, and jacket material per your requirements.

Can you match the exact connector brand we request?

Yes. We offer both original-brand and compatible alternatives based on budget and lead time preferences.

Do you have a product specification sheet?

Yes. We provide detailed datasheets covering structure, materials, dimensions, electrical specs, and certifications.

Can I get samples? What's the lead time?

Yes. Standard sample lead time is 7–14 days. Urgent samples can be arranged within 2–3 days.

What's the MOQ for orders?

No MOQ. We support orders starting from 1 piece for prototyping or sample evaluation.

Can I send a reference cable for duplication?

Yes. We can reverse engineer based on a physical sample and provide matching specs and drawings.

How fast can you provide technical drawings?

We usually provide CAD/PDF drawings within 1–3 working days; urgent requests can be completed within hours.

What certifications do you provide?

Our cables comply with UL, ISO9001, RoHS, REACH, PFAS-free, and can issue COC/COO when needed.

What shielding options are available?

We offer foil, braid, or combined shielding for EMI reduction depending on your EMI requirements.

Do you support twisted pair or single-ended wiring?

Yes, we support both, with impedance control to suit your differential or single-ended design.

Do you provide impedance-controlled designs (e.g. 100Ω)?

Yes. We can match impedance per your requirement for LVDS, V-by-One, or other high-speed signals.

Can we schedule a video call to discuss our design?

Absolutely. We welcome video meetings for better understanding and faster project alignment.

How is product quality guaranteed?

We conduct 3-step 100% inspection: in-process QC, finished QC, and final outgoing QC.

Do you accept urgent mass production orders?

Yes. For urgent cases, mass production can start within 3–5 days after confirmation.

Do you provide both male and female connector assemblies?

Yes. We offer all combinations—male to female, female to female, or customized setups.

What's the difference between original and compatible connectors?

Original has longer lead time and higher price; compatible types are flexible, affordable, and widely stocked.

Can you help recommend suitable connectors for my project?

Yes. Based on your signal type, pitch, and space limits, our engineers suggest optimal options.

Can I choose cable color or printing?

Yes. Jacket color, printing, and even logo labeling can be customized upon request.

How do I get a quote quickly?

Send us drawing, photo, or specs. We typically reply with a quote within 1–6 hours.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China