custom power cord assembly manufacturer

Looking for reliable, certified power cord assemblies that meet your exact requirements? At Shenzhen Sino-conn, we deliver fully customizable solutions—any length, plug, or insulation. Fast samples, no MOQ, and global compliance with UL, ISO, RoHS, and more. Let’s make your connection simple, strong, and smart.

Why choose power cord assembly from sino-conn

Choosing power cord assemblies from Sino-Conn means selecting reliability, customization, and speed. We offer fully tailored solutions—down to length, connector, voltage, and insulation—with zero MOQ, rapid prototyping, and guaranteed certifications like UL, ISO, and ROHS. Whether you need original brand connectors or cost-effective alternatives, our team ensures quick drawing support, flexible pricing for OEMs or trade clients, and 100% full inspection for quality assurance.

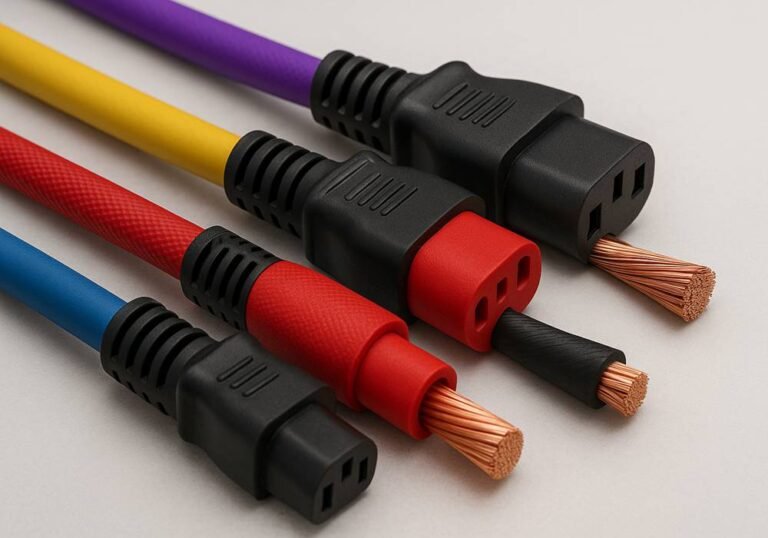

Fully Customizable Cable Length, Plug, and Jacket Material

We offer complete customization for your power cord assembly—choose any cable length, plug type (EU/US/IEC), or outer jacket material such as PVC, rubber, or silicone. This flexibility ensures perfect fit for industrial, medical, or consumer electronics applications. No MOQ and fast design turnaround.

30-Minute Drawings, 3-Day Samples, Ultra-Fast Turnaround

We provide rapid technical drawings within 30 minutes and can deliver custom power cord samples in as fast as 3 days. This speed allows you to validate your design quickly, shorten your development cycle, and reduce time-to-market for your products.

Certified Quality: UL, ISO, RoHS, REACH Compliant

Our power cord assemblies meet strict global standards including UL, ISO 9001, RoHS, and REACH. We also support PFAS-free and halogen-free requirements. Each cable undergoes 100% inspection and comes with full documentation including COC and COO, ensuring confidence for regulated industries.

Engineering-Oriented Design Support for R&D Teams

We collaborate closely with engineers to provide full technical support—from CAD drawings to sample optimization. Whether it’s an unusual connector, special pin-out, or a specific bend radius, we can turn your concept into a reliable product. Most drawings delivered within 30 minutes.

Triple Quality Inspection Ensures Zero Defect Delivery

Every power cord assembly undergoes 100% inspection—during processing, after completion, and before shipment. Our triple-check system guarantees stable performance, accurate pinouts, and zero-defect delivery. We maintain strict records and visual QC for each batch to ensure full traceability.

No MOQ and Fast Delivery for Urgent Projects

We support ultra-flexible order quantities starting from just 1 piece, with urgent sample delivery in 2–3 days and mass production in as fast as 2 weeks. Whether you’re prototyping or scaling up, we offer reliable lead times to keep your project on schedule.

Detailed specifications and parameters of power cord assembly

| No. | Definition (Pinout Type) | Connector Model | Cable Spec | Length (mm) | Cable Shape | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 3-pin AC Plug to IEC C13 | US NEMA 5-15P to C13 | Custom | Custom | Round | PVC Sleeve |

| 2 | 2-pin Euro Plug to C7 | Europlug (CEE 7/16) | Custom | Custom | Round | PVC Sleeve |

| 3 | 3-pin UK Plug to IEC C5 | BS1363 to Cloverleaf | Custom | Custom | Round | Rubber + Nylon Braiding |

| 4 | 3-pin AC to Bare Wire | Schuko to Open End | Custom | Custom | Round | Teflon Tape |

| 5 | IEC C14 to IEC C13 | C14 Male to C13 Female | Custom | Custom | Round | PVC Sleeve |

| 6 | US Plug to Ring Terminal | NEMA Plug to Ring Lug | Custom | Custom | Flat | Heat Shrink + Cloth Tape |

| 7 | IEC C20 to IEC C19 | C20 Male to C19 Female | Custom | Custom | Round | Nylon Braided Mesh |

| 8 | AC Plug to Waterproof End | US Plug to IP67 End | Custom | Custom | Molded | Molded PVC Jacket |

| 9 | C13 to DC Connector | IEC C13 to DC 5.5/2.1 | Custom | Custom | Round | Flame-Retardant PVC |

| 10 | AC Plug to Faston Tab | EU Plug to 6.3mm Tab | Custom | Custom | Flat | PVC + Conductive Tape |

Each power cord assembly we produce is fully customizable based on customer-specific requirements. From pin configurations and connector models to jacket material and terminal types, no two assemblies are exactly alike. This flexibility allows us to serve engineers, OEMs, and distributors with solutions optimized for performance, safety, and compliance across various industries.

Customized power cord assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

Anderson DC Custom Power Cable Assembly 50A 600V

Custom Battery Power Cable Assembly AWG2 with Ring Terminals

Custom IEC C5 to NEMA 1-15P Power Cord Assembly

Custom Molded Power Cord Adapter NEMA 5-15P to C13

Custom Molded Power Cord NEMA 1-15P Assembly

Custom Molded Power Cord NEMA L6-30P to NEMA 14-50P Adapter

Custom Molded Power Cord with NEMA 1-15P Plug and Ring Terminal Assembly

Custom Power Cable 6-Pin Industrial Cord Assembly

Custom NEMA L14-30P to CS 6364 Power Cord Assembly

Custom Power Cable with Anderson Connector Assembly

Custom Power Cord NEMA 15P 3-Prong Assembly

Product details display

Our product details display provides an in-depth look at Sino-Conn’s custom power cord assemblies, including connector types, cable structures, materials, voltage/current ratings, EMI shielding, flexibility, temperature resistance, and environmental protection features. High-resolution images of both overall and close-up views are included to help clients evaluate product quality and structure before ordering.

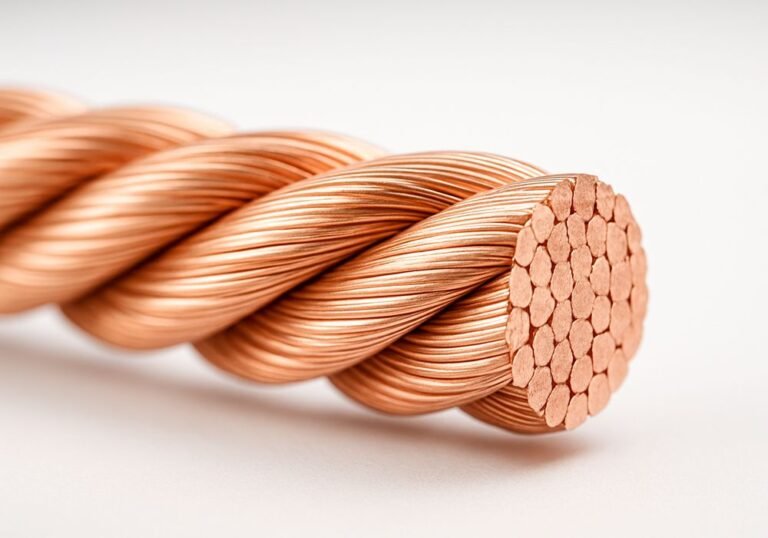

Robust Internal Structure and Insulation Integrity

Our power cord assemblies are built with premium-grade copper conductors and highly durable insulation materials to ensure stable electrical performance and extended lifecycle. Each assembly features tightly twisted multi-stranded copper cores for flexibility and conductivity, protected by an outer jacket tailored for its working environment—PVC, rubber, silicone, or XLPE. These internal constructions are crucial for safe, long-term use across consumer, industrial, or automotive settings. Whether under stress, bend, or high temperature, our cable integrity delivers reliability.

- Multi-stranded oxygen-free copper for excellent conductivity

- Optional jackets: PVC, rubber, XLPE, silicone

- Inner insulation and outer jacket engineered for heat and abrasion resistance

- Cross-sectional integrity verified through bend and cutaway testing

High Durability Against Harsh Environmental Conditions

Designed for demanding applications, our power cords maintain functionality in environments exposed to heat, UV, oil, and chemicals. We use flame-retardant, corrosion-resistant, and halogen-free materials that comply with international safety standards. Whether installed outdoors under direct sunlight or routed through oily industrial zones, our cables maintain structure, insulation, and performance. For long-term reliability, every material is tested for aging, abrasion, and chemical resistance under simulated working conditions.

- UV- and oil-resistant jackets for outdoor/industrial use

- Flame-retardant and halogen-free options available

- Cable jackets remain stable under 105–200°C

- Withstands moisture, dust, and mechanical abrasion

Broad Compatibility and Application Flexibility

Our assemblies support a wide variety of plug types and connector standards—US, EU, UK, IEC, and more—ensuring global compatibility. Each cord is configured based on its application requirements, from power distribution in data centers to industrial automation systems. Jacket types, conductor size, and connector orientation can be customized for flexible routing and integration. This versatility allows our cables to be used across home appliances, EV chargers, server cabinets, and medical devices.

- Customizable plugs: US, EU, UK, IEC, NEMA, Schuko

- Connector orientation and strain relief customization

- Available in straight, angled, or waterproof versions

- Color-coded jackets and labels for organized wiring

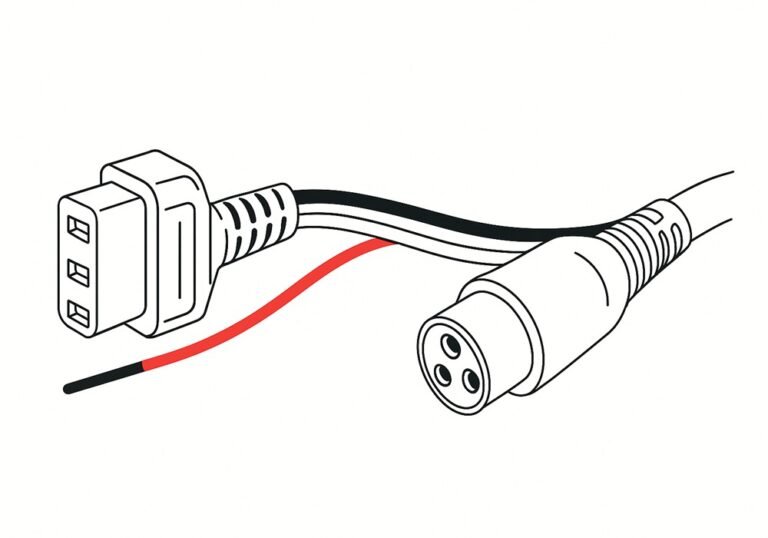

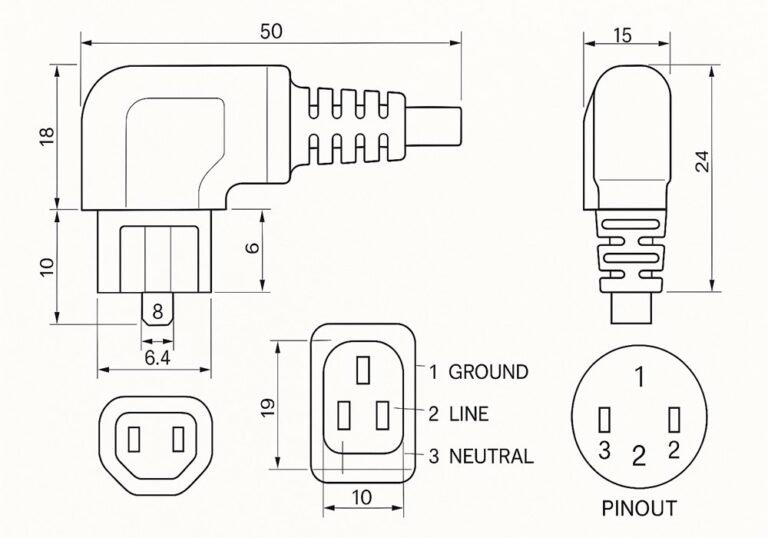

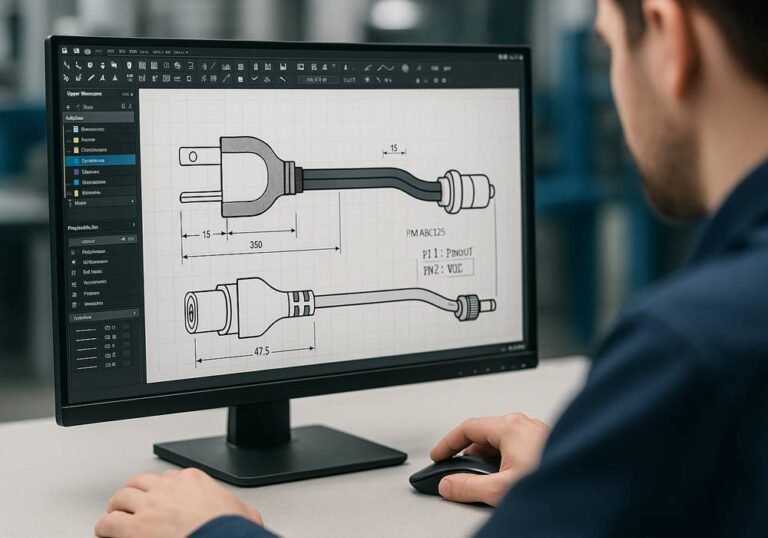

Precision Drawings and Connector Configuration Support

We provide accurate technical drawings with dimensioned views and detailed pinout definitions to help engineers visualize and verify every connection. Whether customers submit a model number, sample, or technical spec, we respond quickly with custom drawings in CAD/PDF formats. Our support includes connector orientation, pin-to-pin wiring, and labeling requirements. This technical precision ensures smooth prototyping and integration into your application, even for complex or non-standard layouts.

- Custom CAD drawings delivered within 30 minutes to 3 days

- Drawings include dimensions, pin labels, and wire map

- Clear connector specifications with mating compatibility

- Approval drawings before production ensures zero error

Comprehensive Quality Control and Certifications

All of our power cord assemblies undergo 100% full inspection before delivery—including in-process, final, and pre-shipment testing. We ensure each product meets the highest international standards, such as UL, ISO 9001, RoHS, and REACH. Certifications and compliance documents (e.g. COC, COO, PFAS) are available upon request. We maintain traceability on every unit via barcode and labeling systems. This guarantees your product is safe, certified, and ready for regulated markets and demanding applications.

- 3-step full inspection: in-process, final, and pre-shipment

- Global certifications: UL, ISO, RoHS, REACH, PFAS

- Barcode traceability and batch tracking system

- Compliance documents: COC, COO, test reports available

Flexible Lead Time, No MOQ, and Fast Samples

We eliminate traditional constraints by offering fast delivery and no minimum order quantity. From 1-piece urgent samples to full-scale production, our system adapts to your project stage. Samples can ship in as little as 2–3 days, with mass production starting in just 2 weeks. Whether you’re validating a prototype or fulfilling a high-volume project, we deliver on time with reliable logistics and transparent progress tracking.

- No MOQ: orders from 1 piece accepted

- Urgent samples in 2–3 working days

- Mass production ready in 2–4 weeks

- Real-time order tracking and shipment updates

--- Customized Capabilities Services and Processes

Customize your power cord assembly

Sino-Conn offers fully customized power cord assembly services tailored to your exact requirements—whether it’s cable length, connector type, pin configuration, insulation material, or environmental resistance. From rapid CAD drawing in 30 minutes to 3-day sampling and 100% quality inspection, our streamlined process ensures precision, flexibility, and speed at every stage of your order.

Customized Capabilities Services and Processes

Customize your power cord assembly

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, customization is not a side service—it is the foundation of our power cord assembly business. We understand that no two customers share the same technical standards, usage environments, or regional compliance needs. That’s why every assembly we manufacture is tailored from scratch to meet your exact requirements.

Details:

- Connector Configurations:Support for all major types—IEC, NEMA (US), EU, UK, DC barrel, Faston tabs, and more. Whether it’s standard or hybrid, we can source or match it.

- Cable Length & Pin-Out:Fully customizable cable length (from centimeters to meters) and internal pin configuration based on your wiring logic or signal/power map.

- Jacket & Insulation Materials:Options include PVC, silicone rubber, TPE, nylon braided mesh, and halogen-free or oil-resistant sheathing for different application environments.

- Electrical & Environmental Specs:Tailored to required voltage, current, EMI shielding, flame retardancy, temperature range, and flexibility (bending radius).

- Documentation & Compliance:We support UL, ISO 9001, RoHS, REACH, PFAS-free requirements, and deliver COC/COO with each batch if needed.

- Engineering Support:CAD-to-PDF drawing generation within 30 minutes; 3D layout review, BOM optimization, and connector matching advice available at no extra cost.

Our Commitment to Outstanding Service

At Sino-conn, we go beyond supplying power cord assemblies—we deliver a seamless, worry-free experience from the first inquiry to final delivery. Our goal is to simplify the purchasing process, reduce your risk, and help you succeed faster.

What Makes Our Service Exceptional:

Fast Response Time:

Drawings and quotes delivered within 30 minutes; urgent inquiries handled within the same business day.

Video Communication Support:

Real-time video calls available for technical reviews, connector confirmation, and remote inspections.

Professional Technical Sales:

Sales reps are trained to understand cable structure, electrical parameters, and connector compatibility.

Clear Drawing & Sample Approval:

Every project includes confirmed CAD drawings before production to ensure zero deviation.

Transparent Production & QC:

Visual updates, production progress reports, and QC photos are shared proactively throughout the order process.

Complete Compliance & Documentation:

We provide UL, ISO, RoHS, REACH, PFAS-Free, and COC/COO support for regulated industries.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

360+ global clients trust sino-conn’ premium service

Medical equipment projects

We were developing a portable diagnostic unit for hospital use, and our biggest concern was sourcing a power cord that was UL-certified, anti-bacterial, and 100% safe for clinical environments. Our internal team needed samples urgently to meet an investor review deadline. I sent a hand-drawn sketch and expected a 3-day wait—Sino-conn sent me a full CAD drawing in 30 minutes.

Their engineers even recommended a silicone jacket that met our ISO 13485 hygiene standards. I had a fully working sample in just 3 days. The cord’s flexibility, pinout precision, and certifications were spot on. What impressed me most wasn’t just the speed, but how accurately they understood what a medical product team needs—compliance, traceability, and zero error.

Sino-conn helped us stay on track and win our board’s green light for pre-production. I now treat them as a technical partner, not just a supplier.

David L.

Senior Project Engineer,United States

Industrial Automation Projects

We were upgrading our industrial cabinets and needed a flame-retardant power cord that could withstand 24/7 use in a high-temperature environment. One end needed to be a Schuko plug and the other a Faston-tab, and we only had a vague legacy drawing.

Most suppliers said “too difficult.” But Sino-conn replied within an hour, reviewed our drawing, and proposed a Teflon-insulated solution. They updated the drawing and sent it back the same day. Four days later, the samples were ready—and they worked perfectly.

What really stood out was the constant feedback—photos, progress updates, and a full QC checklist. The cables were well-built, the fit on the terminal block was precise, and their thermal durability exceeded expectations. We’ve now switched all cabinet lines to Sino-conn.

Markus S.

Purchasing Director,Germany

Smart home appliance OEM project

We manufacture smart appliances and needed a reliable power cord that met UL, BIS, and CE—but still fit within a tight budget. Our previous supplier had long delays and severe yellowing issues on PVC jackets, which hurt our brand image.

Sino-conn offered a molded NEMA plug with an anti-yellowing PVC jacket. They also suggested using an alternate certified connector to save cost. In 2 days, I had five detailed samples with test reports. I was impressed.

Their packaging was clean, the SKUs matched perfectly, and they completed our 5,000 pcs batch in under three weeks. I appreciated their ability to balance price, compliance, and delivery time. We’ve since expanded the partnership across multiple product lines.

Ravi M.

OEM Production Manager,India

industry Application of power cord assembly

Power cord assemblies from Sino-Conn are widely used across diverse industries such as medical devices, industrial automation, data centers, consumer electronics, automotive systems, and military-grade equipment. Their robust construction and custom adaptability ensure safe, stable, and compliant power delivery, even in demanding environments with high temperature, EMI interference, or outdoor exposure.

Solution 1: Medical Equipment Power Supply Cabling

Application Scenario:

In modern medical environments, reliable power cord assemblies are essential for diagnostic and life-support equipment. In a cardiac ICU, where ventilators, patient monitors, and infusion pumps operate 24/7, any interruption in power transmission can be life-threatening. The cables not only need to meet stringent electrical standards but must also withstand repeated sterilization, tight routing around equipment stands, and accidental tugging by healthcare staff. Furthermore, the hospital’s biomedical engineering team requires different cord configurations to match global plug standards and connector types across devices imported from various countries. Our custom power cord assemblies provide medical-grade insulation, anti-bacterial sheath options, and modular connector configurations—ensuring safety, compatibility, and uninterrupted power delivery.

Equipment & Products:

- Ventilators

- ECG/EEG Monitors

- Infusion Pumps

- Custom Power Cord Assemblies (IEC C13, C14, C19, Europlug, US 3-prong)

Industry Pain Points:

- Power cords must withstand repeated sterilization without degradation.

- Compatibility with various imported equipment and plug standards.

- Need for flexible, non-kinking routing in tight medical spaces.

Our Solution:

- Use of medical-grade, sterilization-resistant jacket materials (e.g., TPU, silicone).

- Customized pin-outs and international plug combinations.

- Flexible structure with fine-stranded copper and compact shielding.

Solution 2: High-Reliability Power Cords for Data Centers

Application Scenario:

In large-scale data centers, uninterruptible power supply (UPS) systems and power distribution units (PDUs) must maintain continuous, stable operation 24/7. Even a millisecond of power interruption can cause data corruption or costly system downtime. Power cord assemblies are deployed throughout racks, servers, cooling units, and backup systems to ensure reliable power transmission under high current loads and dense cable routing environments. The cables must also withstand elevated ambient temperatures and electromagnetic interference from adjacent equipment.

Equipment & Products Involved:

- Devices: UPS, PDU cabinets, rack-mount servers, HVAC cooling units

- Products: Shielded heavy-duty power cord assemblies with molded connectors, temperature-resistant outer jackets

Industry-Specific Pain Points:

- High temperatures in server rooms require heat-resistant cables.

- Limited cable space demands ultra-flexible routing solutions.

- UPS systems require certified and flame-retardant materials for safety compliance.

Our Solutions:

- We use UL and RoHS-certified high-temp PVC or rubber sheathing with -40°C to +105°C tolerance.

- Our custom cord assemblies support tight-bend radii and compact routing through rack corners.

- Every cord passes 100% electrical testing and comes with full compliance documentation (UL, ISO, REACH).

Solution 3: Low-EMI Power Cords for Precision Medical Equipment

Application Scenario:

In modern hospitals and diagnostic laboratories, advanced imaging devices such as MRI scanners, CT machines, and ultrasound systems rely on uninterrupted and interference-free power to operate accurately. Any electrical noise or EMI (electromagnetic interference) may distort sensitive signals, affecting diagnostic precision or damaging internal circuits. Power cord assemblies in these systems must comply with medical-grade safety standards, use low-leakage shielding materials, and often be color-coded for easy identification during maintenance. Furthermore, flexibility and wear resistance are essential as devices are moved and repositioned frequently in confined clinical spaces.

Equipment & Products Involved:

- Devices: MRI scanners, CT systems, ultrasound diagnostic devices, portable X-ray units

- Products: Low-EMI power cord assemblies with medical-grade PVC or silicone jackets, IEC or custom molded connectors

Industry-Specific Pain Points:

- EMI and RFI interference can compromise imaging accuracy.

- Hospital-grade materials must meet UL 60601 or IEC 60601-1 standards.

- Cable must be durable for frequent repositioning and cable drag on hospital floors.

Our Solutions:

- Shielded twisted pair designs and conductive sheaths to minimize EMI/RFI.

- Use of biocompatible and UL-certified medical jacket materials.

- Reinforced strain reliefs and abrasion-resistant sheathing for extended service life.

Solution 4: Flexible Power Cords for Smart Home & Portable Devices

Application Scenario:

With the explosive growth of smart home devices and portable electronics, manufacturers are under increasing pressure to deliver sleek, lightweight, and efficient designs that operate safely across global power standards. Products such as smart speakers, wireless chargers, home automation hubs, and handheld vacuum cleaners require power cord assemblies that are not only compact and flexible, but also certified for use in various countries. Additionally, aesthetics matter—power cords must match product housing or be discreetly hidden within enclosures. The assembly must also accommodate high production throughput in OEM facilities, ensuring stable quality and easy integration into automated production lines.

Equipment & Products Involved:

- Devices: Smart speakers, robot vacuums, Wi-Fi routers, IoT hubs

- Products: Compact power cords with flat or round cable styles, molded connectors, international plug types (e.g., US, EU, UK, AU)

Industry-Specific Pain Points:

- Power cords must meet global certification requirements (UL, CE, CCC, etc.)

- Design constraints require slim, flexible cables that fit compact housings

- OEM lines demand high-volume, consistent assembly quality

Our Solutions:

- One-stop certification support with UL, CE, CCC, RoHS documentation

- Slim-profile round or flat cable assemblies in customized colors and lengths

- Standardized production fixtures and IPC-trained assembly teams for high output consistency

Solution 5: Durable Power Cord Assemblies for Solar and Wind Installations

Application Scenario:

As renewable energy systems such as solar panels and wind turbines expand into residential, commercial, and off-grid markets, the demand for weather-resistant, long-lifespan, and safe power cord assemblies grows dramatically. These power cords often connect inverters, charge controllers, and battery storage modules, and must operate under intense heat, humidity, dust, and mechanical vibration. Whether installed on rooftops, solar farms, or offshore platforms, they must remain stable over years of exposure without degradation. These applications also require specific certifications, halogen-free and flame-retardant materials, and secure connector locking to ensure safety and prevent power loss. OEMs and EPCs need reliable supply partners who can quickly customize cords for different voltage systems and installation conditions.

Equipment & Products Involved:

- Devices: Solar inverters, charge controllers, wind turbine controllers

- Products: Outdoor-grade power cord assemblies with locking connectors, flame-retardant sheaths, customized voltages (DC/AC)

Industry-Specific Pain Points:

- Harsh environments with UV, dust, water, and mechanical vibration

- Long-term durability required for 10–25 years of operation

- Electrical safety and international compliance (e.g., TUV, UL)

Our Solutions:

- Use of UV-stabilized, halogen-free, flame-retardant cable jackets

- Custom molding and sealing for IP67/IP68-rated connectors

- Full documentation support for TUV, UL, and REACH compliance

Solution 6: Custom Power Cords for Smart Homes and Embedded Electronics

Application Scenario:

With the rapid adoption of smart home technologies, from intelligent air purifiers and robotic vacuum cleaners to IoT-enabled kitchen appliances, the demand for compact, safe, and customizable power cord assemblies has become essential. These devices are often compact, used in tight spaces, and require lightweight cables that still provide high reliability and safety. Aesthetic appearance, quiet operation, and resistance to frequent plug-in/out cycles are also important. Smart appliance OEMs often seek cable solutions that match their product designs while complying with global safety certifications. For example, a European home appliance may require VDE-compliant plugs, flame-retardant insulation, and silent magnetic shielding to minimize EMI. Integration with PCB headers or flexible PCB terminations is also rising in popularity.

Equipment & Products Involved:

- Devices: Smart ovens, robot vacuums, intelligent humidifiers, smart speakers

- Products: Lightweight power cords with EU/US/UK plugs, flexible strain relief, EMI shielding, flame-retardant jackets

Industry-Specific Pain Points:

- Small internal space and tight routing needs

- High cycle durability and EMI control in compact units

- Global certification requirements (UL, VDE, CCC, CE)

Our Solutions:

- Design thin-gauge, bendable cables with soft PVC or silicone jackets

- Provide silent EMI shielding and magnetic insulation for low noise

- Offer country-specific plug and cable certifications on request

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can you provide a full specification sheet for your power cable assemblies?

Yes, we offer complete datasheets including voltage rating, wire gauge, materials, shielding, and temperature tolerance.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Do you accept custom designs for power cable assemblies?

Absolutely. We can fully customize length, pin-out, connector type, shielding, and insulation materials.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

What kind of cables do you use in assemblies?

PVC, rubber, silicone, braided, shielded, and halogen-free cables are all available.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China