custom overmolded cable assemblies manufacturer

Built to endure. Our overmolded cable assemblies deliver robust, waterproof, and custom-fit connectivity for harsh environments. Get high performance, reliable signal transmission, and complete design flexibility—all backed by fast delivery and engineering support. Inquire now to experience precision in every connection.

Why choose overmolded cable assemblies from sino-conn

Choose overmolded cable assemblies from Sino-conn for superior durability, reliable performance, and customized design options. Our assemblies provide excellent strain relief, environmental protection, and secure connections, making them ideal for demanding industrial and electronic applications where quality and longevity are critical.

Superior Strain Relief and Waterproof Protection

Our overmolded cable assemblies offer unmatched strain relief and IP-rated waterproof sealing, ensuring optimal performance even under continuous bending, pulling, or harsh environments. The molded structure integrates seamlessly with the cable and connector, preventing dust, oil, and moisture ingress. This robust construction dramatically increases product life and reliability, making it ideal for outdoor, automotive, and industrial applications.

Customizable Length, Connector, and Pin Configuration

We support full customization of cable length, connector type, and pinout configuration to meet diverse application needs. Whether it’s USB, M12, circular, or custom connectors, we can match exact specs, support OEM drawings, and quickly modify designs. This flexibility helps engineers and integrators build optimized systems with no compromises on performance or compatibility.

Fast Prototyping and Rapid Production Capability

With a 30-minute CAD drawing turnaround and 3-day prototype delivery, our team supports urgent development timelines. For bulk orders, our lean manufacturing line ensures 2-week delivery with 100% inspection. This makes us an ideal partner for time-sensitive OEM and engineering projects.

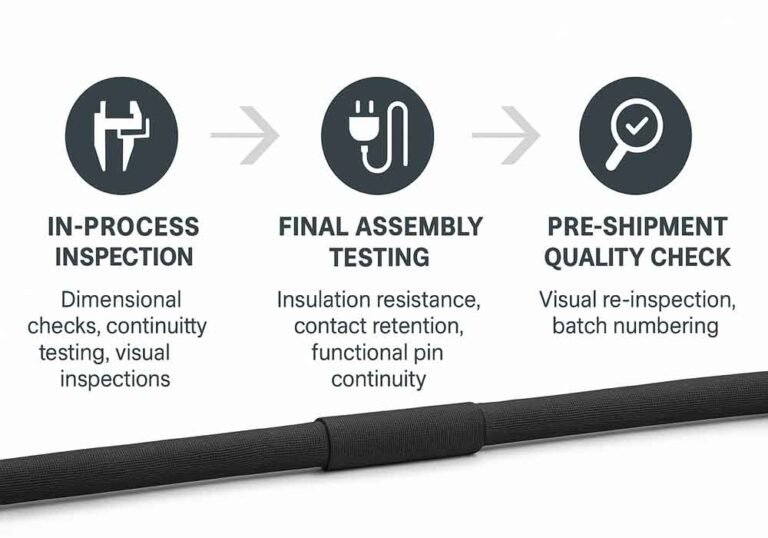

Strict Quality Control with Triple Inspection

Every automotive wire harness assembly undergoes a rigorous triple-inspection process—during production, post-assembly, and before shipment. This ensures that each unit meets our strict quality standards and functions flawlessly in demanding automotive environments. Whether for OEMs or high-end applications, our 100% full inspection policy guarantees product reliability and customer confidence.

Military-grade durability: 10,000+ bend cycles, IP68 & UV resistance certified

Our overmolded cable assemblies are engineered for extreme environments, meeting military (MIL-STD-810) and industrial (IP68/IP69K) standards. We utilize high-grade TPE (thermoplastic elastomer) and silicone materials that withstand 10,000+ dynamic bend cycles without failure – critical for robotics, automotive wiring, and heavy machinery. UV-resistant formulations prevent degradation in outdoor applications, while IP68 sealing ensures waterproof performance even in submersible conditions. Independent testing confirms 5X longer lifespan vs. standard cables. Engineers trust our assemblies for mission-critical applications where reliability cannot be compromised.

100% Quality Inspected with Full Certification

Every overmolded cable assembly undergoes triple-stage quality checks: during processing, after assembly, and before shipment. We hold ISO, UL, RoHS, REACH, PFAS, and more certifications. This rigorous inspection process ensures consistent performance and peace of mind across industries from automotive to medical.

Detailed specifications and parameters of overmolded cable assemblies

| No. | Definition (Pin Configuration) | Connector Model | Cable Spec | Length (mm) | Overmold Shape | Overmold Material |

|---|---|---|---|---|---|---|

| 1 | 4-pin straight male | XLR-4M | Custom | Custom | Circular | Conductive fabric |

| 2 | 8-pin right-angle female | RJ45-8F | Custom | Custom | Rectangular | Thermoplastic elastomer (TPE) |

| 3 | 12-pin vertical header | Mini-DIN-12 | Custom | Custom | Oval | Silicone rubber |

| 4 | 24-pin dual row | D-Sub-24 | Custom | Custom | Flat ribbon | PVC sleeve |

| 5 | USB-C 24-pin reversible | USB4-TYPE-C | Custom | Custom | Ergonomic grip | Nanofiber tape |

| 6 | 6-pin aviation connector | GX16-6 | Custom | Custom | Cylindrical | PTFE tape |

| 7 | 9-pin circular waterproof | M12-9 | Custom | Custom | Tapered | Neoprene |

| 8 | 15-pin SATA power | MOLEX-15 | Custom | Custom | L-shaped | Nylon braided sleeve |

| 9 | 2-pin DC power jack | DC-005 | Custom | Custom | Rounded | Flame-retardant PE |

| 10 | HD44 multi-contact | HD-44 | Custom | Custom | Complex geometry | Electrically conductive silicone |

Overmolded cable assemblies are inherently customized products, and each configuration is tailored to meet specific application needs across industries. The connector types, pin definitions, cable lengths, and overmold materials vary significantly depending on electrical, mechanical, and environmental requirements. At Sino-conn, we don’t offer one-size-fits-all solutions—instead, we collaborate closely with clients to engineer assemblies that are precisely matched to their system design, durability expectations, and functional constraints.

Customized overmolded cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

Custom Overmolded VGA Male to Male Cable Assembly

Custom Overmolded USB + 3.5mm Audio to Terminal Cable Assembly

Custom Overmolded RJ45 Male to Female Cable Assembly

Custom Overmolded DC Male to Blue Terminal Cable Assembly

Custom Overmolded DB15 to Terminal Cable Assembly

Product details display of overmolded cable assemblies

Explore the product details of Sino-conn overmolded cable assemblies, including materials, connector types, cable specifications, and performance features. Each assembly is engineered for durability, signal integrity, and environmental protection, ensuring reliable operation across diverse industrial and electronic applications.

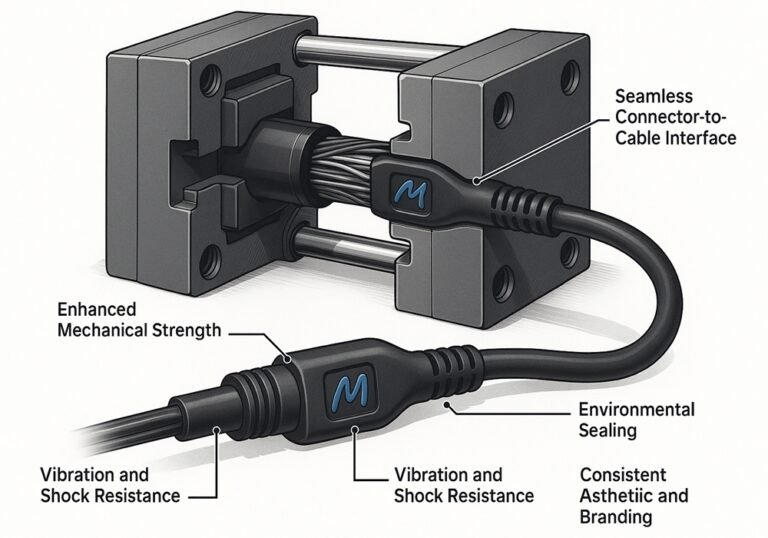

Integrated Overmolded Construction

The integrated overmolded construction is one of the core features of our cable assemblies. This process offers multiple advantages in both function and reliability:

- Seamless Connector-to-Cable Interface: The injection molding process fuses the connector and cable housing, eliminating potential failure points caused by gaps, loose fits, or inconsistent manual assembly.

- Enhanced Mechanical Strength: The overmold layer provides structural reinforcement, making the joint area highly resistant to bending, pulling, and twisting, which extends the product’s service life.

- Environmental Sealing: The molded interface acts as a barrier against moisture, dust, oil, and chemical ingress, ensuring IP-rated protection and excellent outdoor durability.

- Vibration and Shock Resistance: Ideal for automotive and industrial applications, the shock-absorbing overmold helps to reduce internal stress on the solder joints or terminals.

- Consistent Aesthetic and Branding: The molding process also enables logo printing, color coding, and surface texturing, contributing to visual quality and product traceability.

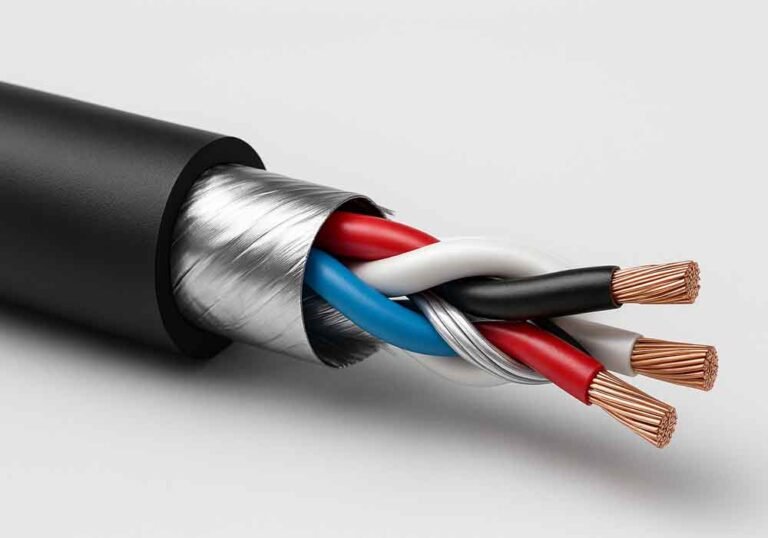

High-Performance Cable Jacket Materials

The outer jacket material plays a critical role in the durability and safety of overmolded cable assemblies. At Sino-conn, we offer a wide range of materials based on application-specific requirements:

- PVC (Polyvinyl Chloride): Economical and flexible, suitable for general industrial and commercial use, with flame-retardant and oil-resistant properties.

- TPE (Thermoplastic Elastomer): Offers excellent flexibility and environmental resistance, ideal for applications requiring repeated bending or exposure to harsh chemicals.

- FEP/PTFE (Teflon): Withstands high temperatures and provides superior chemical and UV resistance, often used in medical, aerospace, and defense-grade cables.

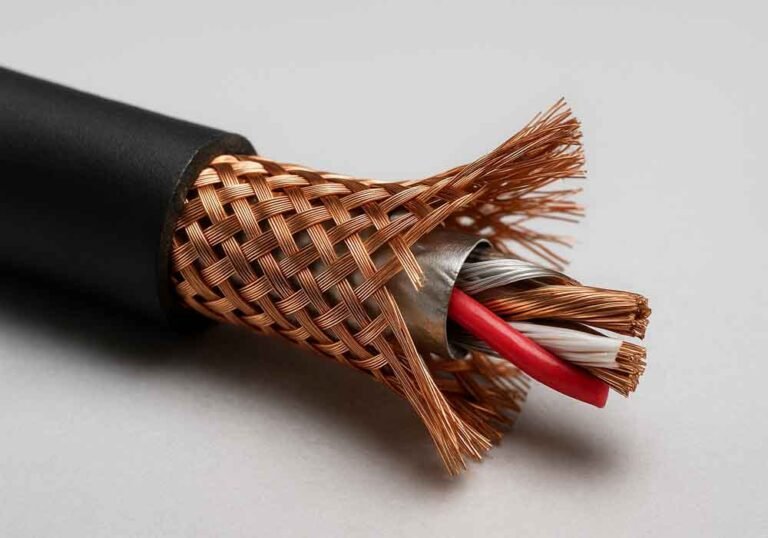

- Braided Nylon Mesh: Commonly added as an outer layer to increase abrasion resistance and provide a rugged aesthetic, useful in robotics or automotive harnesses.

- Customization Available: We support dual-layer jackets and hybrid material combinations depending on client specifications.

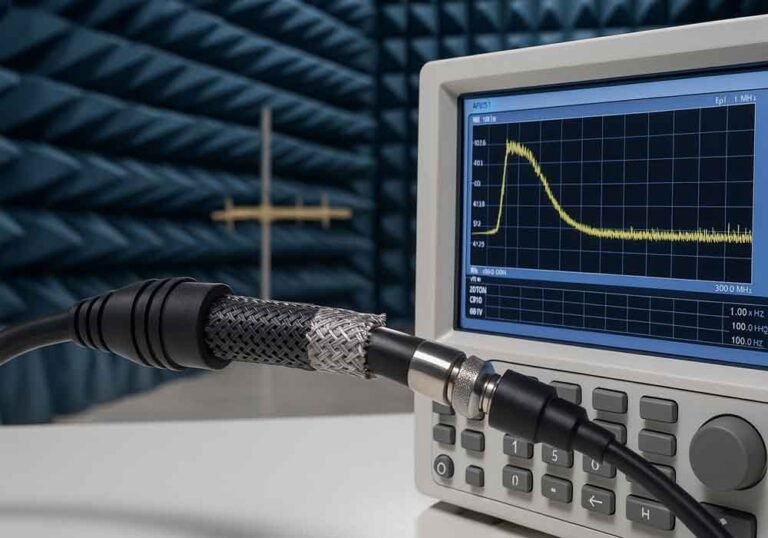

Shielding Structure and EMI Protection

Shielding is essential for protecting sensitive signal lines from external electromagnetic interference. Our overmolded cable assemblies feature the following shielding strategies:

- Aluminum Foil Shielding: Wraps tightly around the conductor pairs, providing 100% coverage and excellent high-frequency noise blocking, ideal for data and video transmission cables.

- Braided Copper Shielding: Offers superior mechanical durability and effective low-frequency EMI suppression, often used in power and industrial control systems.

- Combination Shielding: Some assemblies feature both foil and braid layers to achieve optimal EMI and RFI protection across a wide frequency spectrum.

- Grounding Options: Shield terminations can be connected to ground pins or drain wires, ensuring system-level protection and reduced EMI leakage.

- Application Examples: Common in USB, HDMI, RS232, CANbus, and sensor signal cables used in automotive, robotics, and medical electronics.

Reliable Overmolding Process and Housing Finish

A flawless overmolding process is key to both performance and appearance. At Sino-conn, we strictly control every stage of molding to ensure a professional finish:

- Precision Mold Tooling: We utilize high-accuracy steel molds to ensure tight dimensional tolerances and repeatable consistency across thousands of units.

- Defect-Free Molding: Our production process eliminates common issues like voids, air bubbles, flow marks, or surface cracking, ensuring every part is visually and mechanically robust.

- Material Compatibility: The overmold resin (typically TPU or TPE) is carefully matched to the cable jacket and connector material to ensure bonding strength and long-term durability.

- Surface Customization: We support custom textures (matte, glossy, or grain finish), laser-etched or molded logos, and even multi-color overmolding for easier product identification.

- Tested and Verified: Every batch undergoes pull tests and visual inspections to ensure adhesion quality and structural soundness.

Precision Wrapping and Uniform External Finish

The appearance and structure of the wrapping layer directly affect the durability, heat resistance, and aesthetic quality of automotive wire harnesses. Our wire harnesses are wrapped using industry-standard materials and strictly controlled processes to ensure consistent results. Key features include:

Clean and uniform tape wrapping:Heat-resistant tapes like cloth tape, PVC tape, and Teflon tape are applied with controlled tension to avoid wrinkles, overlaps, or exposed wires.

Machine-assisted or manual precision wrapping:Depending on the application and shape complexity, we combine automated wrapping machines with skilled manual work for tight corners and small branches.

Visual consistency for OEM branding:We ensure consistent wrapping direction, overlap width, and tail finish, aligning with automotive OEM visual standards and inspection requirements.

Multiple wrapping styles:Round, flat, or molded styles are available to suit interior harnesses, trunk lines, or dashboard installations.

Enhanced protection:Tapes are selected based on mechanical protection, temperature resistance, flame retardancy, and chemical compatibility for underhood or cabin use.

Custom color and material options:We support black, gray, and color-coded tapes for circuit distinction, and provide eco-friendly materials meeting RoHS/REACH compliance.

100% Inspection Workflow and Certification System

Our commitment to quality is embedded in every step of the manufacturing process. We implement a rigorous three-stage inspection workflow and back our products with international certifications:

- In-Process Inspection: During cable preparation and overmolding, each assembly undergoes dimensional checks, continuity testing, and visual inspections to identify early defects.

- Final Assembly Testing: Once fully assembled, products are tested for insulation resistance, contact retention, and functional pin continuity using specialized fixtures.

- Pre-Shipment Quality Check: Before packaging, all items are visually re-inspected and labeled with batch numbers for traceability.

- Certifications: Our products comply with ISO 9001:2015, UL, RoHS, REACH, PFAS-free, and can be supplied with COC (Certificate of Conformance) and COO (Certificate of Origin) upon request.

- Zero Defect Goal: Each item is traceable, and we offer 100% functional test reports upon batch completion, giving customers confidence in large-scale applications.

--- Customized Capabilities Services and Processes

Customize your overmolded cable assemblies

Sino-conn offers full customization for overmolded cable assemblies, including connector type, cable length, material, molding design, and performance requirements. Our tailored solutions ensure precise specifications, reliable quality, and fast turnaround to meet the unique demands of your applications.

Customized Capabilities Services and Processes

Customize your Overmolded Cable Assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, customization is not a feature—it’s our foundation. Overmolded cable assemblies are inherently application-specific, and we empower our clients with a complete customization ecosystem to meet electrical, mechanical, and environmental needs with total flexibility.

Our overmolded cable customization capabilities include:

Connector Flexibility

We support original or compatible connectors including USB, HDMI, RJ45, D-sub, M8, M12, GX16, aviation, and medical types. Customer-specified brands and models are fully supported.

Pinout & Wiring Configuration

Custom wiring logic, mirrored layouts, twisted pair assignments, and ground shielding layouts are all implemented to exact customer requirements.

Cable Material Options

PVC, TPE, FEP, silicone, halogen-free, and high-flex cables can be used depending on temperature, bending radius, flame rating, and application type.

Shielding & EMI Control

Multiple shielding methods available including aluminum foil, braided copper mesh, and dual-layer designs for maximum EMI suppression in harsh environments.

Overmold Shape & Finish

From compact circular shapes to flat or angled builds, we offer custom mold design, surface texturing, logo engraving, and multi-color molding.

Environmental Protection Design

We support waterproof (IP67/IP68), UV-resistant, oil-proof, flame-retardant, and corrosion-resistant builds for use in automotive, outdoor, and industrial scenarios.

Zero MOQ, Full Engineering Support

We support prototype orders from just 1 piece, and provide full CAD/PDF drawing assistance within 30 minutes of request. Production lead time: 3 days for samples, 2 weeks for bulk.

Our Commitment to Outstanding Service

For Sino-conn, delivering great service is as crucial as delivering great cables. We don’t just manufacture overmolded cable assemblies—we offer a fully guided, human-centered experience to make your job easier and faster.

Key service highlights include:

Rapid Response & Quotation

We respond to standard inquiries within 2 hours and provide same-day quotations with drawing support in as little as 30 minutes.

Engineer-Led Sales Communication

Each client is supported by a technically trained sales engineer who can understand your drawing, propose solutions, and provide real-time feedback.

Visual & Transparent Process

From sample review to production tracking, we offer full photo documentation, real-time video meetings, and screen sharing for drawing validation.

Flexible Scheduling

Our production lines operate under lean scheduling. We offer prioritized orders for urgent projects and update clients at each milestone.

Pre-Production Confirmation

All orders go through design approval, material verification, and overmold structure validation before production starts.

Full Certification Archive

ISO, UL, RoHS, REACH, PFAS, and custom test reports are stored and retrievable for every batch, ensuring easy compliance and repeatability.

Global Logistics Clarity

We provide accurate HS code documentation, flexible packaging, and multi-channel global shipping including FedEx, UPS, DHL, and sea freight.

This is not just technical service—it’s trust, visibility, and speed, built for professionals who expect more.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario: Automotive seat heater and airbag deployment wiring harness

“We required complex multi-branch overmolded cables with mixed signal and power lines in our seat module prototypes. Sino-conn delivered fast-turnaround samples with precise pinouts, original TE connectors, and a clean overmold finish. Their support on documentation, 3D drawings, and automotive compliance saved us weeks of development time. Exceptional service!”

David Müller

Stuttgart, Germany, R&D Engineer

Application Scenario:Oil-resistant sensor cables for engine vibration monitoring (IP69K rated, PUR-TPE hybrid jacket)

“Their 15-day rapid delivery of 5,000 customized M12 assemblies reduced our cable failure rate from 12% to 0.3%, achieving $400k annual savings in downtime costs. The glove-friendly blind-mate design was exactly what our maintenance teams needed.”

Carlos Herrera

Automotive Electronics Production Director

Application Scenario:Subsea tidal turbine cables (316L stainless steel overmolding, <0.5μA leakage at 200m depth)

“The only supplier whose solution passed 18-month saltwater testing. Their pressure simulation videos gave us confidence to deploy these cables in North Sea conditions where others failed within 6 months.”

Emma Johansen

Offshore Procurement Manager

industry Application of overmolded cable assemblies

Overmolded cable assemblies from Sino-conn are widely used in automotive, medical, industrial automation, telecommunications, and consumer electronics. Their robust design ensures durability, water resistance, and reliable signal transmission, making them ideal for demanding and high-performance applications across multiple industries.

High-Flex Overmolded Cables for Robotics and CNC Machinery

Application Scenario:

In industrial automation environments, especially robotics and CNC machining systems, cables are subjected to frequent movement, bending, and high EMI (electromagnetic interference) environments. The wiring must be robust, flexible, and reliable over millions of flex cycles.

Devices and Products:

Industrial robots, CNC machines, servo motors, drag chain systems, IO extension modules, signal relays.

Industry-Specific Requirements:

Industrial customers require overmolded cable assemblies that are:

Resistant to repetitive motion (over 10 million flex cycles)

Shielded against EMI to protect sensitive signals

Oil-resistant and flame-retardant due to harsh factory environments

Custom pin-out and split branches for multi-axis systems

Easy to install with identification markers

Solution Provided:

Sino-conn delivers custom-engineered overmolded cable assemblies with:

Reinforced TPE/PUR molding for flexibility and chemical resistance

Multi-layer braided shielding with aluminum foil and copper mesh

Optional nylon braided outer jackets for drag chain integration

Laser-marked connectors for port matching

CAD-defined internal routing and custom splitters for modular installations

Crash-Safe High-Voltage Sensing Networks

Scenario: Real-time monitoring of 800V battery modules in extreme vibration environments

Equipment/Products:

- 600V UL1571-rated silicone cables

- Overmolded CAN bus connectors with HVIL detection

- Flame-retardant (UL94 V-0) TPU jackets

Industry Pain Points:

- Vibration-induced fretting corrosion at connection points

- Thermal runaway risks from arc flashes

- EMI interference from inverters corrupting BMS signals

Solutions:

- Anti-fretting design with gold-nickel dual-plated contacts

- Arc-quenching ceramic-filled overmold compounds

- Double-shielded twisted pair construction (100MHz-1GHz, >60dB reduction)

Overmolded Signal Harnesses for Mobile MRI Systems

Scenario: Secure signal and power transmission inside high-magnetic, shielded medical environments

Equipment/Products:

- Shielded twisted pair medical cables

- Overmolded D-sub and circular connectors

- Low-toxicity, halogen-free TPU jackets

Industry Pain Points:

- Signal integrity affected by magnetic interference

- Sterility and biocompatibility standards for patient safety

- Cable strain during equipment movement

Solutions:

- Magnetic field-insulated cable design with foil+braid shielding

- Medical-grade overmolding compounds (ISO 10993 compliant)

- Molded strain reliefs with flex zones for repeated bending

Impact-Resistant Data Transmission

Scenario: Underground mineral scanning equipment in ATEX Zone 0

Equipment/Products:

- MSHA-approved PUR-jacketed cables

- Tungsten-reinforced overmolds

- IS (Intrinsic Safety) barriers

Industry Pain Points:

- Rockfall-induced cable shearing

- Methane-rich explosive atmospheres

- Condensation-induced short circuits

Solutions:

- 8-ton crush-resistant armor design

- Spark-free copper-tin alloy contacts

- Hermetic sealing stops water ingress at 300m depth

Overmolded Signal Harnesses for Mobile MRI Systems

Scenario: Secure signal and power transmission inside high-magnetic, shielded medical environments

Equipment/Products:

- Shielded twisted pair medical cables

- Overmolded D-sub and circular connectors

- Low-toxicity, halogen-free TPU jackets

Industry Pain Points:

- Signal integrity affected by magnetic interference

- Sterility and biocompatibility standards for patient safety

- Cable strain during equipment movement

Solutions:

- Magnetic field-insulated cable design with foil+braid shielding

- Medical-grade overmolding compounds (ISO 10993 compliant)

- Molded strain reliefs with flex zones for repeated bending

USDA-Compliant Washdown Cabling

Scenario: High-pressure cleaning environments in meat packing plants

Equipment/Products:

- IP69K-rated STOOW cables

- FDA-grade silicone overmolds

- Embedded RFID tags for traceability

Industry Pain Points:

- Bacterial growth in cable crevices

- Caustic cleaner degradation

- Frequent equipment repositioning

Solutions:

- Seamless overmold geometry (zero microbial traps)

- pH-resistant compounds (3-year lifespan at pH12)

- 500,000+ flex-cycle TPE-jacketed conductors

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized overmolded cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is an overmolded cable assembly?

An overmolded cable assembly is a cable and connector unit where the connector is encased in molded plastic or rubber, providing enhanced strain relief, waterproofing, and mechanical protection.

Can you provide CAD drawings before production?

Absolutely. We offer CAD + PDF drawings within 1–3 days for all custom orders, with faster turnaround in 30 minutes when needed.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

What certifications do you have?

Certifications include UL, RoHS, REACH, ISO 13485 (medical), IEC 61754 (industrial). PFAS/COC/COO docs available upon request.

Are connectors original or compatible alternatives?

Both: Original brands (TE/Molex) have longer leads/higher cost; compatibles offer same performance at 30% lower cost with faster delivery.

Can your harnesses resist high temperatures and oils?

Yes. We offer heat-resistant (up to 150°C) and oil-resistant jackets such as XLPE, Teflon, or PVC.

Can your harnesses operate in high-temperature environments?

Yes. With Teflon, silicone, or cross-linked insulation, our harnesses can operate up to 125°C–200°C depending on application.

Can you make angled or right-angle overmolded connectors?

Yes. We support 90-degree, 45-degree, or custom-angle overmold shapes to accommodate tight installation spaces.

What sheath materials do you commonly use?

We offer PVC, LSZH, PE, Teflon (FEP), nylon braid, and armored jackets — each suited for flexibility, flame resistance, temperature, or outdoor performance.

Do you have stock for any standard overmolded assemblies?

Most of our overmolded assemblies are custom-made. However, we keep samples and materials ready to support rapid prototyping.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China