Custom Ribbon Cable Assemblies Designed for Your Industry

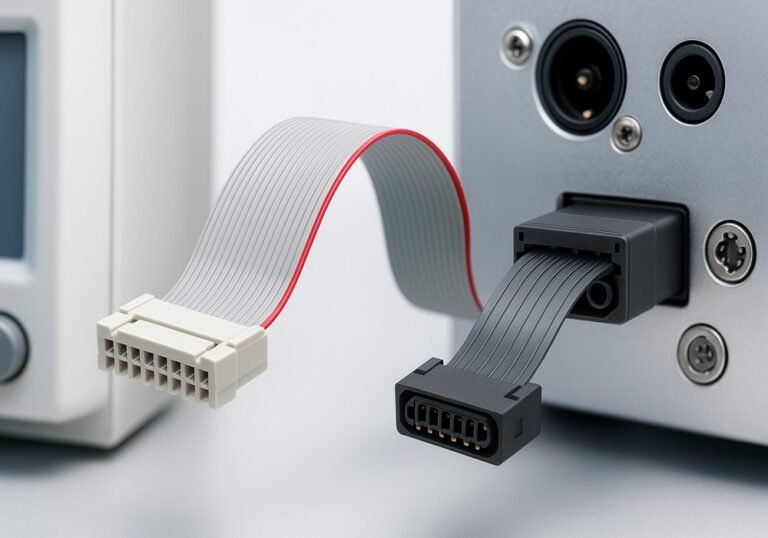

From consumer electronics to industrial controls, we deliver flat cable solutions tailored to your specs — connector types, pinout, pitch, shielding, and more. No MOQ. Drawings ready in 30 minutes.

Why choose ribbon cable assembly from sino-conn

Sino-Conn’s ribbon cable assemblies offer precise pin alignment, compact design, and flexible routing tailored to your specifications. Backed by UL/ISO certifications and fast prototyping, we ensure high-performance solutions for industrial, medical, and electronic applications.

Flexible Customization for Connector, Pitch and Pinout

Our ribbon cable assemblies offer complete customization options including connector type (IDC, FFC, D-sub, etc.), pinout configurations, conductor pitch, cable length, shielding, labeling, and materials. Whether for prototyping or mass production, we can fully tailor the design based on your application needs. From consumer electronics to industrial equipment, flexibility ensures precise integration and performance reliability.

Ultra-Fast Prototyping and Short Lead Times

We understand the urgency of product development. That’s why we offer ultra-fast prototyping — with sample drawings ready in 30 minutes and prototypes delivered in as fast as 2–3 days. For mass production, we support flexible delivery options, usually within 2–3 weeks. Whether it’s a one-off custom design or a large OEM batch, our rapid turnaround helps you stay ahead in time-sensitive projects.

Zero MOQ and Full Support from 1 Piece

Whether you’re an engineer testing a new design or a small business sourcing niche components, we support your project starting from just 1 piece. With zero MOQ, we enable faster project validation, lower initial costs, and reduced procurement barriers. Even for low-volume orders, we provide full engineering support, drawings, customization, and quality inspection — just like we do for large OEM batches.

100% Inspection with Triple Quality Checks

Quality is at the heart of every ribbon cable assembly we deliver. Every unit undergoes a rigorous three-step inspection process: in-process inspection, final product testing, and pre-shipment verification. From conductor integrity to connector alignment, we check every detail to ensure zero defects. This commitment to quality makes us a reliable supplier for high-end applications in medical, automotive, and industrial sectors.

Certified Materials and Compliance with Global Standards

All our ribbon cable assemblies are built using certified materials that comply with global standards such as UL, RoHS, ISO, REACH, PFAS, and more. From flame retardancy to halogen-free options, we provide full documentation to support your technical, environmental, and import compliance needs. Our strict material sourcing ensures safety, reliability, and smooth customs clearance for international shipments.

Wide Application Across Industries and Devices

Our ribbon cable assemblies are used across a wide spectrum of industries including consumer electronics, automotive systems, medical devices, industrial automation, home appliances, and robotics. Whether it’s for compact PCBs, LCD modules, or multi-axis control systems, our cables provide space-efficient, reliable, and customizable interconnections that meet the demands of modern product designs.

Detailed specifications and parameters of ribbon cable assembly

Ribbon cable assemblies are highly versatile and tailored to meet specific application needs. Since every customer has different electrical, mechanical, and integration requirements, each cable we produce is fully customizable — from pin configuration and connector type to cable length, shape, and jacket material. This table provides only a sample of common configurations. In reality, our engineering team works closely with clients to deliver precise solutions for their exact technical demands.

| No. | Definition (Connector Pinout) | Connector Model | Wire Specification | Length (mm) | Sheathing Style | Sheathing Material |

|---|---|---|---|---|---|---|

| 1 | DIP (Dual In-line Package) | JST XH-40 | Custom | Custom | Flat | PVC Tape |

| 2 | ZIF (Zero Insertion Force) | Molex 52589 | Custom | Custom | Flat | Conductive Cloth |

| 3 | IDC (Insulation Displacement Connector) | TE 1-104257-1 | Custom | Custom | Flat | Acetate Cloth |

| 4 | FFC (Flexible Flat Connector) | Hirose FH12-40S | Custom | Custom | Flexible Strip | Nanofiber Tape |

| 5 | D-Sub (High-Density D-Subminiature) | Amphenol 10150-3000 | Custom | Custom | Round | Braided Nylon Sleeve |

| 6 | Wire-to-Board (Standard Pin Header) | JST PH-20 | Custom | Custom | Molded (Right Angle) | PTFE Tape |

| 7 | FPC (Flexible Printed Circuit Connector) | Molex 502578 | Custom | Custom | Flexible Flat | Copper Foil Shielding |

| 8 | Locking (Snap-in Latch Connector) | TE 1734599-1 | Custom | Custom | Flat | Flame-Retardant Sleeving |

| 9 | DIN (Rail-Mountable Connector) | Phoenix 1703632 | Custom | Custom | Round | Silicone Rubber |

| 10 | USB-Type (High-Speed IO Connector) | JAE DX07 | Custom | Custom | Molded (Overmolding) | TPE (Thermoplastic Elastomer) |

Customized ribbon cable assembly styles

Trusted by 300+ global partners,1000+ styles have been developed.

8 Pin Flat Ribbon Cable Assembly IDC Connector 1.27mm Pitch Red Housing

10 Pin Flat Ribbon Cable Assembly IDC Connector 1.27mm Pitch

10 Pin Flat Ribbon Cable Assembly IDC to Pin Header 1.27mm Pitch

15 Pin Flat Ribbon Cable Assembly DB15 Male to IDC Connector 1.27mm Pitch

16 Pin Flat Ribbon Cable Assembly IDC Connectors 1.27mm Pitch Locking Type

16 Pin Flat Ribbon Cable Assembly IDC Locking Connectors 1.27mm Pitch

18 Pin Rainbow Flat Ribbon Cable Assembly IDC Connectors 1.27mm Pitch

18 Pin Flat Ribbon Cable Assembly IDC Male Connectors 2.54mm Pitch Red Housing

20 Pin Flat Ribbon Cable Assembly IDC Connector 1.27mm Pitch Keyed Type

64 Pin Rainbow Flat Ribbon Cable Assembly IDC to PLCC Connector 0.635mm Pitch

16 Pin Flat Ribbon Cable Assembly IDC Connectors 1.27mm Pitch

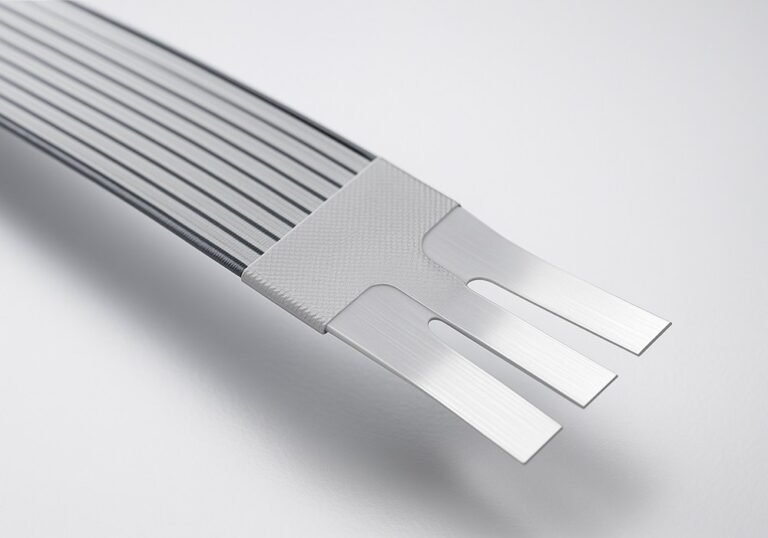

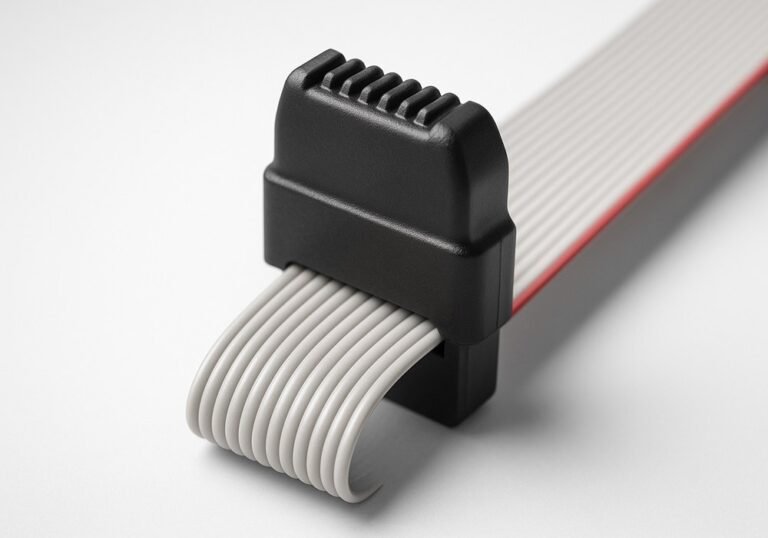

Product details display

Explore detailed product displays of our ribbon cable assemblies, including connector types, cable pitch, conductor count, insulation materials, and customization options. Each product image highlights both overall structure and fine details to help you evaluate compatibility with your specific application needs.

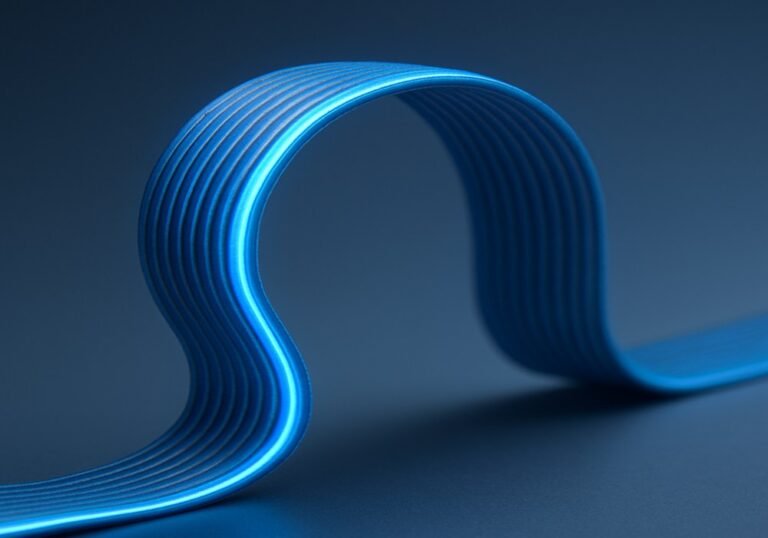

Excellent Cable Flexibility for Dynamic Bending Applications

Our ribbon cable assemblies are designed with high flexibility to accommodate dynamic movement and tight installation paths.

- We use soft PVC or TPE insulation that allows repeated bending without cracking or delamination.

- The flat profile of the ribbon cable naturally supports small bend radii, making it ideal for applications with motion—such as printers, robotics, and folding displays.

- Stranded tinned copper conductors offer better fatigue resistance compared to solid cores.

- Customizable thickness and pitch help reduce mechanical stress while maintaining signal integrity during movement.

- Flex-tested over 10,000 cycles, our cables maintain durability and connectivity under constant mechanical strain.

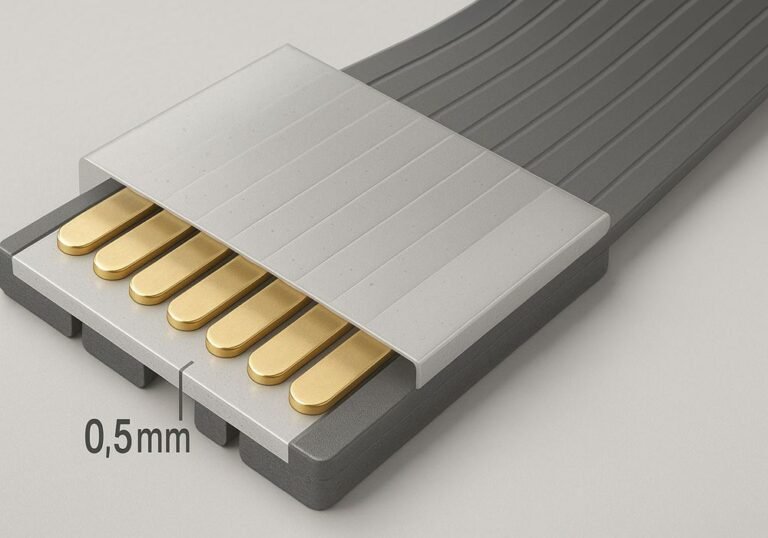

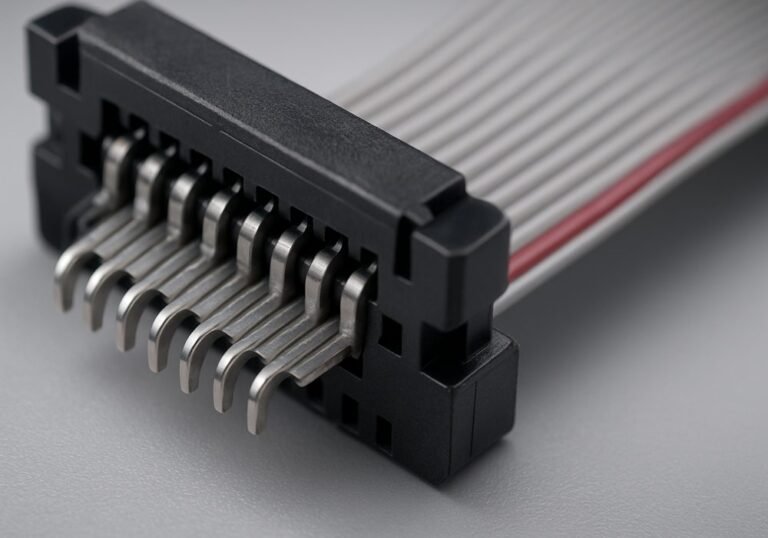

High-Density Multi-Pin Connector Alignment Precision

Our ribbon cable assemblies are built to support high-density connector interfaces with superior alignment precision.

- We support various connector types including IDC (1.27mm, 2.54mm), FFC/FPC (0.5mm–1.0mm pitch), and micro ZIF/LIF connectors.

- Using precision mold tooling and automated crimping machines, each conductor aligns perfectly with its mating pin, even in ultra-fine pitch configurations.

- Proper alignment ensures contact reliability, reduces the risk of short circuits, and improves long-term connection stability.

- These cables are ideal for compact electronic systems such as medical diagnostics, test instrumentation, automotive control modules, and embedded computing boards.

- We offer custom pinouts (1:1, reverse, mirrored, ground-included) to match your exact system architecture.

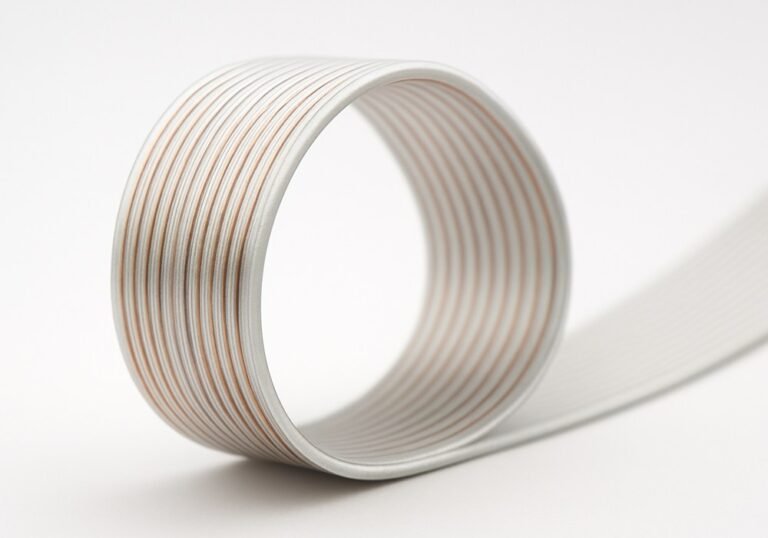

Layered Structure with Uniform Conductor Alignment

The internal build of our ribbon cable assemblies emphasizes stability and consistency in electrical performance.

- Conductors are made of oxygen-free tinned copper and are aligned in a flat parallel layout, reducing signal distortion and impedance mismatch.

- Each conductor is uniformly embedded in a flat PVC or PET insulation layer, with precise spacing to maintain controlled impedance and reduce crosstalk.

- The flat cable structure minimizes vertical thickness while maximizing flexibility and routing efficiency in compact environments.

- Layered construction includes optional foil or braid shielding for EMI protection and improved signal integrity in high-speed applications.

- Custom configurations include options for specific pitch sizes, conductor counts, insulation thicknesses, and jacket colors.

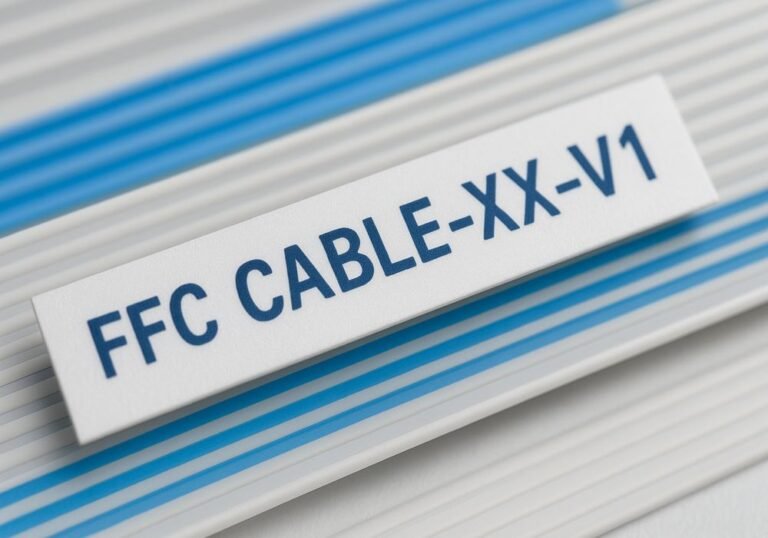

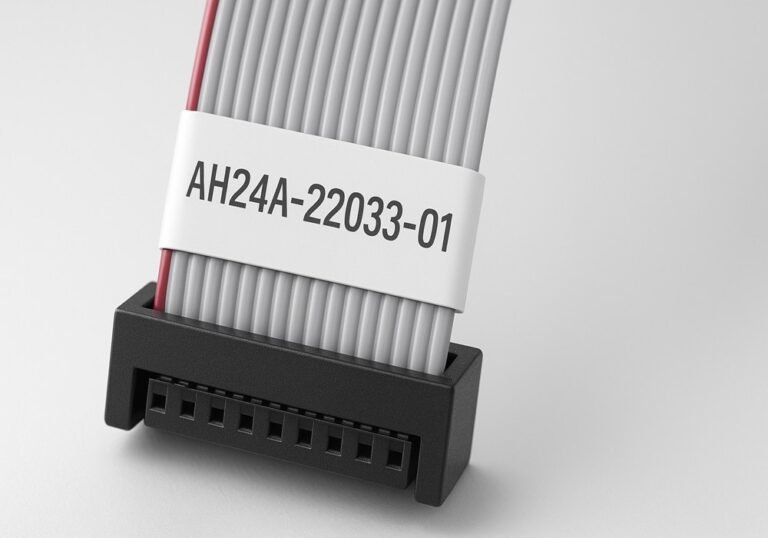

Clear Labeling and ID Tags for Easy Assembly Identification

Every ribbon cable assembly from Sino-conn can be customized with detailed labeling for quick identification and error-free installation.

- We support printing on the insulation layer or adding heat-shrink labels with part numbers, pin mapping, or customer-specific codes.

- Each label is placed in a visible location near connectors or split ends to assist during assembly or maintenance.

- Labels are made from heat-resistant, wear-resistant materials to prevent fading or peeling under harsh conditions.

- Available in color-coded formats, barcodes, or QR codes for advanced traceability in automation environments.

- Ideal for production lines, field maintenance, and OEM assembly where precise wire recognition is crucial.

Multiple Jacket Material Options for Environmental Adaptability

Our ribbon cable assemblies are available with a range of jacket materials to meet diverse environmental and application demands.

- Standard PVC jackets offer good flexibility and cost-efficiency for most consumer electronics and internal device wiring.

- For high-temperature or chemically exposed environments, we offer Teflon (PTFE) or silicone jackets that withstand up to 200°C and resist oils, solvents, and UV radiation.

- EMI-sensitive applications can benefit from conductive fabric wraps or foil-shielded constructions, improving signal integrity in industrial or medical environments.

- Flame-retardant and halogen-free jackets are available for public safety, data centers, and transport applications in accordance with UL, RoHS, and REACH.

- Custom options include heat-shrink tubing, braided nylon mesh, nano-adhesive tape, and multi-layered jackets combining insulation and shielding.

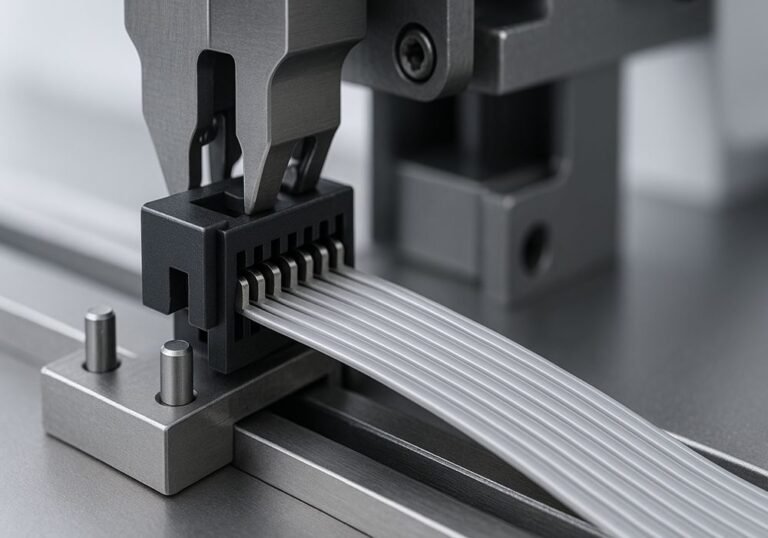

Flexible End-Termination: Split, Crimped, or Molded Options

To match diverse assembly needs, we offer various end termination processes for our ribbon cable assemblies.

- Open-ended split wires allow for multi-point connections or field-terminals, ideal for complex panel wiring.

- IDC or crimped connector terminations ensure reliable, vibration-resistant attachment to headers and sockets.

- Overmolded ends with strain relief reduce mechanical stress and improve cable life in motion-prone applications.

- Heat-shrink or TPE boots are available to enhance protection and prevent wire pull-out during handling.

- All terminations can be configured in Y-branch, daisy chain, T-shape, or single-ended formats based on customer needs.

--- Customized Capabilities Services and Processes

Customize your ribbon cable assembly

Customize your ribbon cable assembly

Customize your ribbon cable assembly with Sino-Conn by selecting cable length, pitch, conductor count, insulation material, connector type, and pin-out definition. Our expert team supports fully tailored solutions to meet diverse industrial and OEM specifications.

Customization capabilities

At Sino-conn, our core strength lies in offering fully customizable ribbon cable assemblies that adapt to the unique needs of each client. Whether you’re prototyping a new medical device, upgrading an industrial control system, or building connectors for automotive sensors, we deliver precision-engineered solutions tailored to your application. Every cable we produce is built with engineering insight, speed, and accuracy to help our clients achieve fast time-to-market and uncompromising reliability.

Key Customization Capabilities

- Connector Versatility: Support a wide range of standard and proprietary connectors such as IDC, FFC, FPC, JST, Molex, Hirose, and more.

- Pin Configuration Options: Straight-through, cross-wired, reversed, or custom-mapped according to circuit requirements.

- Flexible Pitch and Length: Pitch from 0.5mm to 2.54mm, and custom cable lengths from 30mm to several meters.

- Structural Options: Available in flat, folded, overmolded, or split-branch types.

- Shielding Choices: Options include aluminum foil, conductive cloth, braided shielding, or EMI-free.

- Sheath Materials: PVC, PTFE, Teflon, nylon mesh, flame retardant, halogen-free, and other specialized jackets.

- Labeling and Coding: Custom labeling, barcodes, pin numbering, color codes, or customer logo printing.

- Engineering Drawings: 30-minute CAD generation, fast revisions, PDF delivery for confirmation before production.

- Certifications and Compliance: RoHS, REACH, UL, ISO, PFAS, and others available on request.

We believe customization is not a service—it’s a responsibility. With no MOQ, fast prototyping, and deep understanding of your application needs, we become your most reliable and flexible manufacturing partner for any custom ribbon cable project.

Ultimate Service

At Sino-conn, customer service is built into our engineering DNA. Every ribbon cable order receives the same level of technical care, real-time response, and post-sales support—no matter the quantity. Our goal is to make your sourcing process seamless and transparent. From quick response to complete documentation, from drawing validation to 100% inspection, we deliver a service experience that matches your technical expectations.

Our Ultimate Service Includes

- Fast Quote & Drawing: We provide accurate quotes and CAD drawings in 30–60 minutes.

- 1-Piece Sample Welcome: Support for low-volume or R&D stage orders with zero MOQ.

- Real-Time Design Support: Live video meetings, screen sharing, or instant CAD feedback.

- Professional Communication: Sales with technical knowledge and fluent English across time zones.

- Visual Production Tracking: Progress photos from production to inspection and packing stages.

- 3-Stage Quality Check: Full inspection during production, after assembly, and pre-shipment.

- Documentation Pack: BOMs, pinout diagrams, labels, certifications, and logistics tracking.

- Flexible Pricing Models: Different offers for OEMs, end users, and resellers.

- Responsive After-Sales: Fast action on any quality issues, remake requests, or clarifications.

We do more than deliver cables—we build customer confidence. Whether it’s a quick sample or a high-volume batch, our team is here to ensure that every detail is right and every project runs smoothly from start to finish.

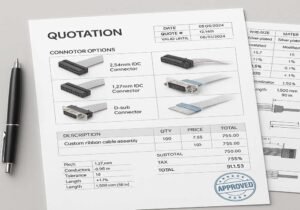

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario: High-Density Signal Transmission for Medical Diagnostic Devices

“As part of our next-generation CT scanner development, we required a highly customized ribbon cable with 80 pins, superior EMI shielding, and flame-retardant insulation. Shenzhen Sino-conn not only provided detailed CAD drawings in just 3 hours, but also helped us optimize the connector pinout for better signal integrity. Their engineering team communicated efficiently and delivered samples in less than a week. The cable passed all our internal reliability and burn-in tests. We’ll definitely continue working with them for future developments.”

Michael Braun

Munich, Germany, Senior R&D Engineer

Application Scenario: Signal and Power Delivery in Industrial Control Panels

“For our programmable logic controller systems, we needed flat ribbon cables with dual-purpose signal and power lines, UL certification, and high-temperature resistance up to 105°C. Shenzhen Sino-con provided a complete turnkey solution—from sample drawing to volume production within just three weeks. Their ability to customize wire gauge combinations and connector orientation exceeded our expectations. They even stocked equivalent connector replacements to help us save cost and lead time. Exceptional supplier with excellent technical support!”

Rahul Mehta

Bangalore, India, OEM Project Manager

Application Scenario: Flexible Interconnection in Medical Diagnostic Equipment

“We were developing a compact medical diagnostic device that required ultra-flat ribbon cable assemblies with precise impedance control and zero halogen compliance. Shenzhen Sino-conn impressed us from the first engineering call. Their team quickly reviewed our 3D model, proposed cable routing improvements, and delivered a pre-tested prototype in just 5 days. The cable’s EMI shielding and bio-safe materials passed all internal validations. Their responsiveness and technical depth make them an outstanding partner for any medical R&D project.”

Anna Müller

Munich, Germany, R&D Engineer

industry Application

Ribbon cable assemblies from Sino-Conn are widely used across industries such as telecommunications, consumer electronics, medical devices, automotive systems, and industrial automation. Their compact design and parallel conductor layout make them ideal for space-constrained environments requiring reliable, organized signal transmission.

High-Speed Data Transmission in Medical Imaging Equipment

Application Scenario:

In advanced medical imaging systems such as MRI and CT scanners, the need for rapid, interference-free transmission of large image data is critical. Ribbon cable assemblies are widely used to connect internal components within these machines, enabling synchronous communication across multiple channels.

Devices and Products:

- MRI scanners mainboard to display control panel

- CT imaging sensor array to processor board

- Ultrasound probe to signal processing unit

Industry Pain Points:

- Need for highly flexible and compact cables that fit tight internal spaces

- High EMI environment requiring robust shielding

- Heat resistance and long operational reliability under continuous use

Our Solutions:

- Provide ultra-flat, high-flex ribbon cables with custom pitch and insulation

- Use aluminum foil + braided shielding to block EMI effectively

- Apply high-temperature rated insulation (e.g., PTFE) for safe, long-term use

Precision Control in Industrial Automation Systems

Application Scenario:

Modern industrial automation systems, such as robotic arms, CNC machines, and smart conveyors, require compact, durable, and flexible cable solutions to connect control units, sensors, and actuators. Ribbon cable assemblies are ideal for such environments due to their organized structure and easy routing through confined equipment spaces.

Devices and Products:

- Robotic arm controller to motor drive unit

- CNC sensor array to control board

- Conveyor system encoder to logic processor

Industry Pain Points:

- Limited internal space for cable routing

- Frequent cable motion causing wear and breakage

- Need for error-free, low-latency signal communication

Our Solutions:

- Provide ultra-thin, multi-conductor ribbon cables with high-flex insulation

- Use high-flex life materials rated for over 5 million bending cycles

- Incorporate EMI shielding and color-coded conductors for signal integrity and easier installation

Data Transmission in Gaming and Consumer Electronics

Application Scenario:

In high-performance gaming laptops, monitors, and entertainment systems, ribbon cable assemblies are essential for connecting high-resolution displays, touch sensors, and control buttons within tight housing. These applications demand precision signal transmission and minimal EMI to ensure seamless user experience and performance.

Devices and Products:

- LVDS cable from motherboard to LCD display

- Flat interconnect for touch screen sensors

- Control panel ribbon for volume and function buttons

Industry Pain Points:

- Need for compact and low-profile cable design

- Interference from nearby high-speed digital components

- Requirement for consistent mass production quality

Our Solutions:

- Use ultra-flat FFC/FPC ribbon cables with precision-aligned conductors

- Apply EMI shielding and ground planes to minimize signal interference

- Implement full-process quality inspection and automatic alignment tooling

Medical Diagnostic Imaging Devices

Application Scenario:

In advanced diagnostic equipment like MRI, CT scanners, and ultrasound systems, internal communication relies heavily on high-density cable assemblies. Ribbon cable assemblies play a critical role in ensuring compact integration, EMI control, and precise data transmission between modules.

Devices & Products:

- MRI control console and signal acquisition board

- CT scan imaging processing unit

- High-frequency ultrasound transducer array

Industry Pain Points:

- High sensitivity to electromagnetic interference that can distort imaging results

- Space limitations inside machines requiring compact, low-profile cabling

- Stringent requirements for flame retardancy, medical-grade materials, and certifications (e.g., UL, ISO 13485)

Solution:

- Provide shielded ribbon cable assemblies with twisted-pair layout and conductive fabric for maximum EMI suppression

- Customize ultra-thin, flexible cable structures with medical-grade Teflon or silicone jackets for minimal space usage

- Deliver full compliance with ROHS, ISO13485, and other medical safety certifications to support hospital-grade use

Consumer Electronics Display Modules

Application Scenario:

In slim-profile consumer electronics such as tablets, ultrabooks, and smart monitors, ribbon cable assemblies are essential for internal data and power transmission between display panels, touch modules, and main logic boards. These cables support high-speed signal transmission while maintaining a flexible, compact form factor required by modern device design.

Devices & Products:

- FFC/FFC cable between LCD display and motherboard

- Ribbon cable connecting touchscreen digitizers

- Backlight power supply cable in LED modules

Industry Pain Points:

- Devices require ultra-slim, lightweight cabling to fit tight housings

- High-speed data transmission prone to EMI or crosstalk

- Aesthetic requirements limit use of bulky or stiff cables

Solution:

- Design ultra-thin, multi-pitch ribbon cable assemblies tailored for micro-spaces

- Apply foil and braided shielding to reduce EMI in high-frequency signal lines

- Use heat-resistant, low-profile insulation materials like PET and polyimide for clean internal layout

Industrial Control Panels & PLC Systems

Application Scenario:

In modern industrial automation systems, ribbon cable assemblies are widely used inside control panels and PLC cabinets to interconnect modules like relays, I/O boards, human-machine interfaces, and power drivers. Their organized structure ensures stable signal flow in harsh, space-constrained environments.

Devices & Products:

- Ribbon cables connecting PLC I/O boards

- Flat cable assemblies for HMI touchscreen interfaces

- Wiring between modular DIN-rail-mounted relays

Industry Pain Points:

- High risk of signal interference and voltage drop in complex, noisy environments

- Limited space inside electrical enclosures

- Need for flame-retardant and chemical-resistant materials in factory environments

Solution:

- Use shielded ribbon cable assemblies with consistent pitch for EMI resistance

- Optimize flat cable layout to reduce wiring congestion and improve heat dissipation

- Apply insulation materials like FR-PVC or UL-rated polyester for factory durability

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

International Certifications

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is your MOQ (Minimum Order Quantity)?

We have no MOQ requirement. You can start with a single sample. We support small batches and mass production based on customer needs.

Can I customize the length, pitch, and connector type of your ribbon cable assembly?

Yes, we offer full customization on length, wire pitch, pinout configuration, and connector type. Just send your specifications or drawings, and we will support you from design to production.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

What certifications do you have?

Certifications include UL, RoHS, REACH, ISO 13485 (medical), IEC 61754 (industrial). PFAS/COC/COO docs available upon request.

Are connectors original or compatible alternatives?

Both: Original brands (TE/Molex) have longer leads/higher cost; compatibles offer same performance at 30% lower cost with faster delivery.

How do you ensure EMI shielding effectiveness?

3-layer shielding: (1) 0.025mm aluminized PET film (2) 85%-cover tinned copper braid (3) conductive ink outer layer. Tested to 70dB attenuation @1GHz.

How do I choose the correct connector for my ribbon cable?

You can send us your application or mating connector model. Our team will recommend a suitable connector from our database or custom options.

Can you handle high-flex applications (e.g., robotics)?

Yes. Our cables endure 1M+ bends (tested per IEC 60512-9-3) with patented reinforcement at stress points.

What materials are used in your cables?

Commonly used materials include FEP, PTFE, PVC, fluoropolymer jackets, and silver-plated copper cores.

Can you provide a specification sheet for my project?

Yes. Once we confirm your requirements, we can generate a full datasheet including materials, dimensions, electrical specs, and drawing reference.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China