custom military cable assemblies manufacturer

Tough, tactical, and tailored. Shenzhen Sino-conn customizes military cable assemblies for mission-critical applications—offering original or compatible connectors, rapid design turnaround, and flexible manufacturing from 1 piece to full-scale production.

Why choose military cable assemblies from sino-conn

Sino-Conn provides military-grade cable assemblies designed for demanding applications. Our custom solutions ensure maximum durability, reliability, and compliance with military standards, including resistance to extreme temperatures, EMI shielding, and harsh environments. With a focus on quality, precision, and fast lead times, we deliver cables that meet the high-performance needs of defense and aerospace sectors. Choose Sino-Conn for reliable, high-quality military cable assemblies tailored to your specifications.

Extreme Durability for Harsh Military Environments

Our military cable assemblies are engineered to withstand the most extreme environmental conditions encountered in defense and aerospace applications. From desert heat to arctic cold, and from battlefield vibration to salt fog corrosion, each component is rigorously selected and tested for resistance. With ruggedized jackets, high-flex insulation, and EMI shielding, these cables maintain performance under pressure. Whether deployed in armored vehicles, UAVs, or communication units, they ensure mission reliability where failure is not an option.

Custom Configurations for Mission-Specific Requirements

We provide complete customization of military cable assemblies to match mission-specific demands, whether it’s connector type, cable length, pin-out mapping, or insulation material. Our engineering team collaborates closely with clients to deliver fully tailored designs, often within 30 minutes to 3 days. With no MOQ restrictions and full CAD-to-PDF drawing services, we offer unmatched agility in product configuration. From complex multi-branch looms to hybrid signal-power designs, we adapt to any application scenario.

Rapid Prototyping with 30-Minute Drawings

Time-critical defense projects need speed and precision. Our military cable assemblies come with rapid prototyping support, including 30-minute drawing delivery and 2–3 day urgent sample production. All designs go through a CAD-to-PDF conversion and client confirmation before manufacturing. This workflow allows engineers and procurement teams to quickly verify fit and function, reducing development cycles and securing supply chain readiness. When timing is crucial, our responsiveness makes the difference.

Original and Compatible Connector Options

We offer both original brand connectors (e.g., Amphenol, TE, ITT Cannon) and high-quality compatible alternatives to meet different budget and lead-time needs. While original parts offer guaranteed precision and preferred branding, our compatible versions deliver similar performance with faster delivery and lower cost. All connector options are tested for fit, electrical continuity, and environmental resistance. Whether your priority is compliance or cost-efficiency, we provide the flexibility to optimize your build without compromising reliability.

100% Full Inspection for Guaranteed Reliability

Every military cable assembly undergoes 100% inspection at three key stages: in-process, post-assembly, and pre-shipment. We test electrical continuity, insulation resistance, shielding integrity, and connector torque to eliminate any risk of failure. This full-spectrum quality control ensures each unit meets mission-critical standards and client specifications. With traceable records and documented test reports, our customers gain confidence in both performance and accountability—especially vital for defense and aerospace applications.

No MOQ with Flexible Manufacturing Scale

We support projects from single-piece prototypes to large-volume production, with no minimum order quantity required. Whether you’re testing a new concept, building small batches for field deployment, or launching a full-scale defense program, our manufacturing adapts to your schedule. This flexibility benefits R&D engineers, OEMs, and traders alike—enabling faster validation, lower risk, and reduced upfront cost. You get professional-grade military cable assemblies without limitations on quantity or complexity.

Detailed specifications and parameters of military cable assemblies

The specifications of our military cable assemblies are fully customizable, as each client typically has unique structural, electrical, and environmental requirements. Whether it’s adjusting the pin-out definition, changing the connector brand, selecting specific shielding or jacket materials, or defining exact lengths and form factors, we support complete flexibility. With rich experience in defense-grade wire harnesses, our engineering team can quickly translate your concept or drawing into production-ready solutions, ensuring your exact mission needs are met with precision.

| No. | Pin Definition | Connector Model | Cable Spec | Length (mm) | Cable Form | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 2Pin Power | MIL-DTL-5015 | Custom | Custom | Round | PVC Tubing |

| 2 | 4Pin Data+Power | MIL-DTL-38999 I | Custom | Custom | Round | Nylon Braided Mesh |

| 3 | 8Pin Signal | MIL-DTL-26482 II | Custom | Custom | Molded | Teflon Tape |

| 4 | 6Pin Shielded | Micro-D Connector | Custom | Custom | Flat | Conductive Fabric |

| 5 | 12Pin Hybrid | MIL-DTL-38999 III | Custom | Custom | Round | Teflon Sleeving |

| 6 | 3Pin Ground Loop | Push-Pull Circular | Custom | Custom | Molded | PVC Tubing |

| 7 | 10Pin Data | Nano Circular 1mm | Custom | Custom | Round | Acetate Cloth Tape |

| 8 | 14Pin Mixed Signal | MIL-STD-1553 | Custom | Custom | Flat | Nano Tape |

| 9 | 7Pin EMI Shielded | Circular Thread-Lock | Custom | Custom | Molded | Conductive Cloth |

| 10 | 5Pin Tactical Sync | Amphenol CTV Series | Custom | Custom | Round | Fluoropolymer Tape |

Customized military cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

Military Power Cable with Weatherproof Connectors

Military Grade Electronic Components MIL-DTL-5015 Connector Assembly

Mil Spec Cable Class L Tie-In Power Connector Assembly

Power Cable with Multi-Pin Connectors

Military Cable Assembly Manufacturers Circular Connector Cable Assembly

Mil Spec Cable Military Wire Harness Manufacturers Custom Loom Assembly

Aerospace Cable Assembly Manufacturers Military Spec Wire Harness

Mil Spec Cable Military Cable Connectors 6 Pin Assembly

Mil Spec Cable Coaxial RF Assembly

Military Cable Connectors 4 Pin Power and Signal Assembly

Mil Spec Cable Military Cable Connectors 19 Pin to D-Sub Adapter Assembly

Product details display

Explore the detailed specifications and features of our custom cable assemblies. From material composition and precise dimensions to voltage, current, and shielding options, we offer comprehensive information on each product. Our detailed product display helps you understand the quality, performance, and custom capabilities of our cable assemblies, ensuring they meet your unique requirements and industry standards.

High-Density Gold-Plated Terminal Connectors

Our military cable assemblies utilize high-density connectors with gold-plated terminals to ensure high conductivity, corrosion resistance, and long-term reliability. These connectors are widely used in mission-critical systems that require secure signal transmission in hostile environments, such as tanks, aircraft, and radar systems.

- The terminals follow MIL-DTL-38999 or MIL-DTL-26482 standards and are engineered for tight-fit multi-pin configurations.

- Gold plating reduces contact resistance and improves signal clarity over extended service life.

- Each pin is micro-tested for resistance and coated with high-temperature epoxy for added mechanical stability.

- The connectors are vibration-resistant and moisture-proof, suited for both ground and aerospace platforms.

- Precision-machined housings enhance alignment and ensure seamless mating in repetitive use cycles.

- Suitable for data, power, or hybrid signal transmission under high stress.

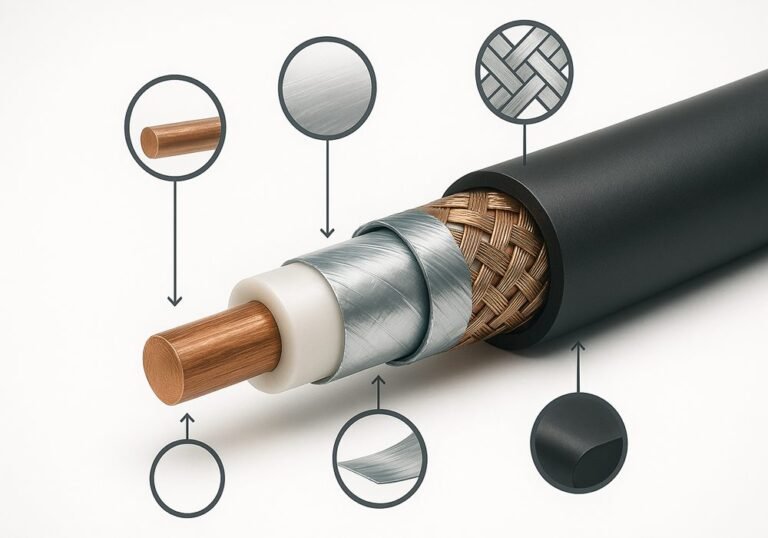

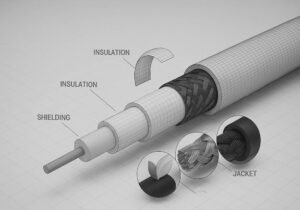

Triple-Layer Shielding Structure Design

Our military cable assemblies feature triple-layer EMI shielding to protect signal integrity in high-interference environments. This structure is essential in defense applications that demand reliable, uninterrupted data flow, especially for navigation, targeting, or real-time control systems.

- Inner layer: Aluminum foil for high-frequency interference rejection.

- Middle layer: Braided copper mesh for low-frequency EMI suppression and added tensile strength.

- Outer layer: Conductive fabric or metalized film jacket to block ambient RF signals.

- Each layer is tested during production to ensure continuity and EMI resistance.

- Shielding supports wide frequency ranges (from kHz to GHz) critical in military radar and communication systems.

- Maintains shielding effectiveness under bending, twisting, and field exposure.

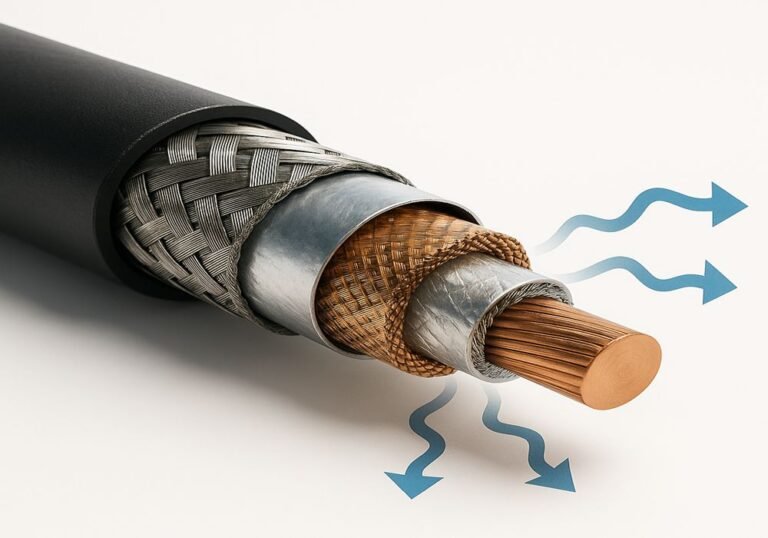

High-Temperature LSZH Jacket for Harsh Environments

To meet safety and durability demands in confined military spaces, we use LSZH (Low Smoke Zero Halogen) outer jackets in our cable assemblies. This jacket type resists fire, emits low smoke, and contains no toxic halogens—ideal for vehicles, aircraft cabins, and submarines.

- LSZH jackets operate in temperatures ranging from -55°C to +200°C.

- Provides resistance against flame, UV radiation, chemicals, oil, and abrasion.

- Material maintains flexibility in both extreme heat and sub-zero cold.

- Smoke emission <0.25m²/g and zero halogen content ensures crew safety in enclosed environments.

- Cable jackets undergo tensile and flammability testing before approval.

- Complies with IEC 60332 and UL 1685 flame standards.

Precision-Machined Shells and Locking Mechanisms

The durability and reliability of military cable assemblies largely depend on the quality of the connector shells and locking mechanisms. At Shenzhen Sino-conn, we use precision-machined connector housings made from corrosion-resistant alloys, often anodized aluminum or stainless steel, to ensure mechanical strength and long-term stability in harsh conditions.

- Connectors are milled with micron-level accuracy for consistent fit and anti-vibration performance.

- Threaded, bayonet, or push-pull locking types are available depending on application needs.

- Locking rings are torque-tested to avoid loosening under shock or movement.

- Special plating (nickel, cadmium-free alternatives) resists chemical exposure and oxidation.

- Ideal for field deployment, aerospace docking panels, and mobile tactical systems.

- Every connector set is visually inspected and mechanically tested prior to cable integration.

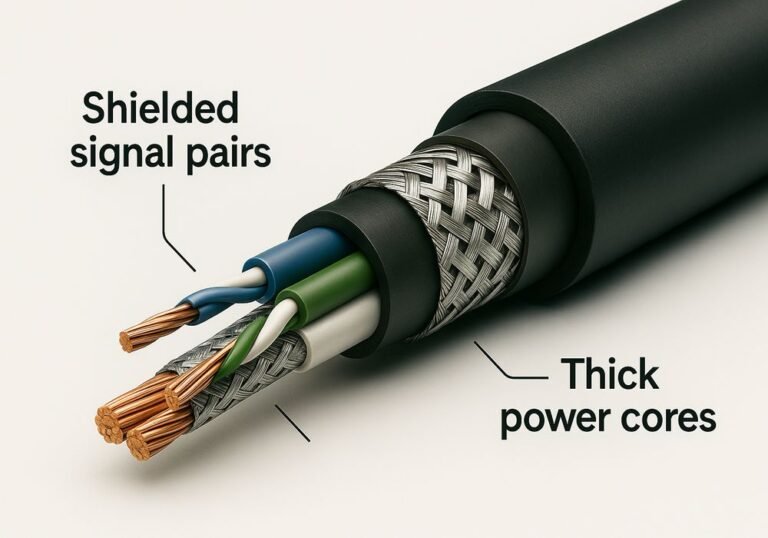

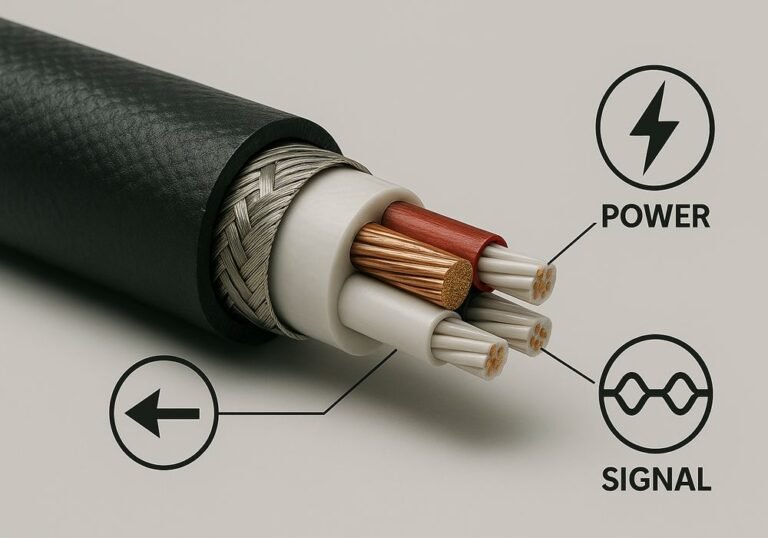

Signal-Power Hybrid Cable Structures

Many modern defense systems require integrated signal and power pathways in a single cable. Our hybrid military cable assemblies combine multi-core signal conductors with power wires in one unified harness, reducing bulk and enhancing efficiency in space-constrained environments like drones, missile systems, or cockpit control panels.

- Signal conductors are shielded independently to avoid cross-talk and interference.

- Power cores are rated for high current (5A–30A) with temperature-resistant insulation.

- Custom pin-outs allow flexible function mapping across mixed systems.

- Internal fillers and separators maintain cable balance and electromagnetic isolation.

- Perfect for integration in compact control modules, rotary turrets, or UAV flight units.

- Each hybrid cable is tested for voltage insulation and cross-channel interference before shipment.

Multi-Layer Environmental Sealing Protection

For military applications exposed to dust, moisture, oil, and extreme temperatures, environmental sealing is essential. Our cable assemblies utilize multiple layers of environmental sealing that include molded strain reliefs, rubber O-rings, heat-shrink boots, and water-resistant epoxies to create a fully sealed interface.

- Molded strain relief prevents cable fatigue at the connector junction.

- O-ring gaskets ensure IP67 or IP68 sealing performance.

- Heat-shrink boots tightly conform to the cable shape, locking out contaminants.

- Epoxy potting compounds are used at critical joints to resist oil, dust, and fluid ingress.

- Tested for submersion, pressure cycling, and thermal shock.

- Designed for outdoor deployment, marine systems, and battlefield electronics.

--- Customized Capabilities Services and Processes

Customize your military cable assemblies

Our custom cable assemblies are designed to meet the specific needs of your industry. We offer tailored solutions for every stage, from product design to final production. With expertise in creating high-quality, specialized cable assemblies, we provide flexible services including CAD design, fast prototyping, and thorough testing. Our streamlined processes ensure precision and reliability, guaranteeing the best results for your unique requirements.

Customized Capabilities Services and Processes

Customize your military cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Shenzhen Sino-conn, customization is at the core of our military cable assembly business. We don’t believe in “one-size-fits-all” solutions—every customer has unique technical, environmental, and operational needs. Our mission is to translate these needs into high-performance, field-proven cable systems.

- We support full customization of cable structure, pin definition, connector type (original or compatible), shielding methods, jacket materials, and signal-power integration.

- Our team can deliver CAD-to-PDF drawings within 30 minutes for urgent projects, enabling rapid design confirmation.

- No MOQ policy allows customers to develop samples without constraints, whether for prototype testing or limited deployment.

- We handle EMI shielding, flame resistance, UV stability, and high-flex builds, based on specific operating conditions.

- Both engineering clients and OEMs benefit from our ability to deliver cables tailored to their internal system architecture.

With end-to-end technical support and fast prototyping, we transform your conceptual requirements into robust, production-ready assemblies. Our flexibility, precision, and engineering depth make us the ideal partner for defense-grade custom cable solutions.

Our Commitment to Outstanding Service

Exceptional service is not an add-on—it’s a fundamental part of how we work with clients. At Sino-conn, we serve as engineering partners, not just suppliers. Our goal is to deliver speed, precision, and trust throughout the customer journey.

- We provide 1-on-1 engineering support via chat, email, and video call, covering technical consultation, connector selection, and custom design guidance.

- Drawing and quotation turnaround takes as little as 30–60 minutes, enabling same-day decision-making.

- Urgent orders benefit from 2–3 day sampling and 2-week bulk production lead time.

- Our three-stage QC process ensures 100% inspection for electrical continuity, shielding, and mechanical durability.

- We also provide all necessary compliance certificates (ISO, UL, RoHS, REACH, COC, COO) and documentation for smooth customs clearance.

What truly defines our service is the level of care and consistency we offer. We listen closely, respond quickly, and take ownership of the problem—not just the product. From prototype to shipment, we aim to make every interaction fast, helpful, and worry-free.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario:

Thomas contacted us during the development phase of a battlefield ground vehicle system requiring heavy-duty, EMI-shielded military cables for reliable sensor-to-processor communication. His team needed a flexible wiring harness that could tolerate shock, dirt, and extended outdoor exposure. Within 3 days, we provided drawings and a hybrid cable sample with MIL-DTL-38999 connectors and triple-layer shielding. After successful testing, it was deployed across 12 armored vehicle prototypes.

“What impressed us most was Sino-conn’s technical speed and flexibility. They understood our complex EMI concerns and adjusted the shielding specs in less than 24 hours. Our engineers trust their work, and we’ll be collaborating again on our UAV line. A responsive, solution-oriented team that gets the job done.”

Thomas Meyer

Berlin, Germany – Lead Systems Engineer

Application Scenario:

Miguel’s OEM factory needed a low-MOQ military cable for avionics system retrofits in light aircraft. The challenge was to match obsolete connector types while integrating LSZH jackets and high-temperature insulation. We reverse-engineered the original connector from a photo and provided a drawing in under 1 hour. Two days later, the client received samples. The first 50 kits were delivered on time with full ISO and RoHS documentation.

“Few suppliers can match this kind of speed and flexibility. We had a vague concept and a photo—Sino-conn turned it into a tested, certified product. Their engineers and support staff are fast, smart, and highly reliable. We’ll be placing larger orders this quarter.”

Miguel Alvarez

Monterrey, Mexico – Procurement Manager

Application Scenario:

Aiden represented a government contractor upgrading field communication stations. The project required waterproof and fire-retardant cable assemblies with MIL-STD-1553 compatibility and IP68-level sealing. We proposed a molded strain-relief design with O-ring sealing and fluoropolymer jacket, tested under submersion. The assembly passed all specs, and production was finalized within three weeks.

“Sino-conn not only met every spec—they went further. Their cable endured heat, water, and abrasion tests beyond what our labs required. It’s rare to find a supplier this thorough and proactive. They’ve now been added to our long-term contract vendor list.”

Aiden Clarke

Canberra, Australia – Defense Contract Specialist

industry Application of military cable assemblies

Military cable assemblies are essential in demanding environments, providing reliable and durable connections for defense applications. These assemblies are designed to withstand harsh conditions such as extreme temperatures, moisture, and physical stress. Used in communication systems, avionics, and tactical equipment, they ensure uninterrupted performance and safety. Our custom military cable assemblies are built to meet stringent military standards, offering high flexibility, corrosion resistance, and superior shielding for optimal protection and functionality.

Solution 1: Military Aircraft Avionics and Navigation Systems

Application Scenario: Military aircraft demand high-reliability cable assemblies to support sensitive avionics and navigation subsystems operating in extreme conditions.

Equipment and Products: Flight control computers, GPS modules, radar units, cockpit displays, interconnect harnesses.

Industry-Specific Requirements (Pain Points):

- Exposure to extreme temperature variations during high-altitude operations.

- Constant exposure to vibration and mechanical stress within aircraft fuselage.

- Electromagnetic interference (EMI) from multiple onboard electronic systems.

Solutions:

- Use of PTFE and cross-linked polyolefin for high-temperature insulation and thermal durability.

- Braided shielding and reinforced jackets to withstand vibration and maintain mechanical integrity.

- EMI shielding with multi-layer foil and braid construction to ensure signal integrity.

Solution 2: Tactical Communication Systems

Application Scenario: Military ground operations rely on real-time tactical communication between command centers, field units, and mobile platforms. High-performance cable assemblies are essential for stable data and power transmission.

Equipment and Products: Field radios, portable communication terminals, encrypted data links, power transmission modules.

Industry-Specific Requirements (Pain Points):

- Outdoor exposure to dust, mud, and moisture in harsh environments.

- Frequent bending and flexing during soldier movement and deployment.

- Need for secure signal transmission under jamming and signal interception threats.

Solutions:

- IP67-rated waterproof and dustproof overmolded connectors and rugged sheathing materials.

- Use of flexible stranded conductors and kink-resistant insulation for repeated motion tolerance.

- Encrypted shielding layers and low-leakage signal paths to ensure secure data integrity.

Solution 3: Unmanned Aerial Vehicle (UAV) Control Systems

Application Scenario: Military-grade UAVs demand ultra-reliable cable assemblies for flight control, camera transmission, and ground command communication, especially under high-altitude and high-speed conditions.

Equipment and Products: Flight control modules, servo motor interfaces, camera modules, data transceivers, GPS antennas.

Industry-Specific Requirements (Pain Points):

- Need for lightweight cabling to minimize payload impact.

- High signal fidelity over long transmission distances during aerial operation.

- Resistance to electromagnetic interference and temperature fluctuation at high altitudes.

Solutions:

- Use of lightweight fluoropolymer jackets and micro-coaxial designs to reduce weight.

- High-speed signal cables with impedance control to minimize signal loss.

- EMI-shielded cables with PTFE insulation to withstand temperature shifts and RF noise.

Solution 4: Naval Combat System Cabling

Application Scenario: Naval vessels such as destroyers and submarines require robust and corrosion-resistant cable assemblies to support radar systems, sonar, and electronic warfare devices in high-humidity, salt-laden environments.

Equipment and Products: Radar interfaces, sonar transceivers, underwater communication cables, control consoles, power converters.

Industry-Specific Requirements (Pain Points):

- High resistance to salt spray corrosion and long-term immersion in seawater.

- Stable transmission under electromagnetic interference from onboard systems.

- Flame retardancy and low-smoke zero-halogen (LSZH) characteristics for enclosed spaces.

Solutions:

- Use of marine-grade materials such as tinned copper braid and fluoropolymer jackets for corrosion resistance.

- Multi-layer shielding structures to isolate and suppress EMI.

- LSZH and flame-retardant sheaths compliant with naval safety standards.

Solution 5: Ground Mobile Command Vehicle Cabling

Application Scenario: Military mobile command vehicles require cable assemblies that can endure frequent movement, rapid deployment, and harsh outdoor exposure. They must maintain stable signal and power delivery while on the move.

Equipment and Products: Onboard communication routers, GPS antennas, surveillance monitors, power distribution units, satellite uplink modules.

Industry-Specific Requirements (Pain Points):

- Abrasion-resistant and flexible cable sheaths for constant reeling and movement.

- Protection against temperature extremes, dust, and water ingress.

- Quick-connect and disconnect interfaces for rapid deployment in tactical operations.

Solutions:

- Employ ruggedized TPE or PUR outer jackets tested for over 1 million flex cycles.

- Integrate IP67/IP68-rated sealing systems and thermal insulation materials.

- Use MIL-DTL-38999 connectors and quick-locking mechanisms for time-sensitive scenarios.

Solution 6: Naval Vessel Radar and Weapon Control Systems

Application Scenario: Military ships require highly reliable cable assemblies for radar signal processing, weapon targeting, and real-time control systems. These cables must withstand continuous vibration, salt fog, and electromagnetic interference.

Equipment and Products: Naval radar antennas, missile control interfaces, communication servers, targeting processors, and fire control panels.

Industry-Specific Requirements (Pain Points):

- Salt fog resistance and corrosion protection in humid marine environments.

- Shielded signal integrity under strong EMI from radar and electronic warfare systems.

- Stability during ship vibration, roll, and shock from weapons discharge.

Solutions:

- Use marine-rated fluoropolymer jackets (e.g., FEP, ETFE) with anti-corrosive braid shielding.

- Apply dual-layer shielding: aluminum-mylar foil + tinned copper braid for maximum EMI suppression.

- Utilize shock-absorbing strain reliefs and MIL-SPEC locking connectors to maintain signal integrity during motion.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our personalized military cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I customize the cable length and terminal type?

Yes, we support full customization including length, terminal types (ring, spade, bullet), and cable routing shapes to meet specific layout requirements.

Do you provide drawings before production?

Yes. We provide CAD drawings (PDF format) for customer confirmation before production. Most drawings are ready within 1–3 days, some in 30 minutes.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

Can your military cables operate in extreme environments?

Yes. Our assemblies withstand temperatures from –55°C to +200°C, high vibration, humidity, oil, UV, and salt spray exposure.

Are your connectors genuine or compatible alternatives?

Both options are available. We can use original branded connectors or high-quality equivalents depending on budget, lead time, and availability.

Can you package and label according to military project specs?

Yes. We follow custom packing guidelines including anti-static bags, MIL-spec boxes, and labeling per project code.

How do you handle requests from customers unfamiliar with technical specs?

We accept images, basic descriptions, or reference samples. Our team will guide the spec design and recommend solutions.

How do you ensure EMI shielding?

Triple-layer shielding: silver-plated braid (95% coverage) + aluminum foil + conductive polymer layer. Tested to MIL-STD-461G, reduces interference by 90dB at 1GHz.

Can your cables support high-speed data transmission?

Yes. We support protocols like USB 3.0, Ethernet, LVDS, HDMI, and other high-frequency signals with stable transmission.

Do you provide EMI/RFI shielding solutions?

Yes, we offer braided copper shields, aluminum foil, or multi-layer composite shielding to meet strict EMI/RFI standards.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China