custom power harness cable manufacturer

Power Up with Confidence. Our custom power cable assemblies deliver high current, tight EMI shielding, and flexible configurations to meet your industrial needs. Fast prototyping, full certifications, and zero MOQ—built to perform and scale.

Why choose power harness cable from sino-conn

Sino-Conn offers custom power harness cable assemblies with unmatched flexibility, fast prototyping, and zero MOQ. Our cables are built for durability, high voltage, EMI shielding, and extreme conditions. We support OEM/ODM clients with original or alternative connectors, rapid drawing services, and global certifications like UL, ROHS, and REACH.

Full Customization: From Length to Connector Types

We support full customization of power harness cables, including cable length, connector types, pin definitions, shielding layers, and cable jacket materials. Whether your project requires unique layouts, specific bend radii, or special insulation, our team can deliver quickly with zero MOQ and flexible tooling.

Fast Turnaround: 3 Days for Samples, 2 Weeks for Bulk

With efficient in-house production and engineering support, we offer extremely fast delivery: samples in 2–3 days and bulk orders in 2 weeks or less. For urgent projects, we can deliver drawings within 30 minutes and begin production the same day after customer approval.

Original & Compatible Connector Options Available

We offer both original brand connectors and high-quality compatible alternatives. Customers can choose based on cost, lead time, or application needs. Our compatible options ensure full functionality with better delivery flexibility and price competitiveness.

Reliable Performance in Harsh Industrial Environments

Our power harness cables are built for extreme conditions, offering resistance to oil, UV, high temperature, bending stress, and moisture. Designed for outdoor, automotive, and factory applications, our cables ensure stable current flow and long-term durability even in the toughest settings.

Certified Quality: ISO, UL, RoHS, REACH, PFAS, COC

All our power harness cables meet international compliance standards including ISO, UL, RoHS, REACH, and PFAS. We provide COC and COO upon request. With a 3-stage full inspection system, we ensure top-grade performance, traceability, and safety for critical applications.

No MOQ and Instant Engineering Support

We offer full flexibility with no minimum order quantity. Whether you need 1 piece for prototype or 10,000 for production, we deliver. Our engineering team can provide drawings in 30 minutes and tailored solutions within hours, helping customers launch projects with speed and precision.

Detailed specifications and parameters of power harness cable

| No. | Definition (Pin Connection) | Connector Model | Wire Spec | Length (mm) | Sheathing Type | Sheathing Material |

|---|---|---|---|---|---|---|

| 1 | 4-pin straight | Molex 43025-0400 | Custom | Custom | Round | PVC Sleeve |

| 2 | 6-pin right-angle | JST XH-6A | Custom | Custom | Flat | PTFE Sleeve |

| 3 | 8-pin loopback | TE 1-1773838-8 | Custom | Custom | Molded | Nylon Braid |

| 4 | 2-pin waterproof | Deutsch DT04-2P | Custom | Custom | Round | Conductive Fabric |

| 5 | 12-pin hybrid | Hirose DF12-12P | Custom | Custom | Flat | Acetate Cloth |

| 6 | 3-pin shielded | Amphenol ATS-03 | Custom | Custom | Shielded Tube | Nano Tape |

| 7 | 10-pin high-current | JAE MX40-10S | Custom | Custom | Molded | PTFE Tape |

| 8 | 5-pin automotive | Sumitomo 6189-5 | Custom | Custom | Round | Silicone Sleeve |

| 9 | 7-pin EMI-protected | LEMO FGG.0B.307 | Custom | Custom | Shielded Tube | Copper Foil |

| 10 | 9-pin industrial | Harting 0933 000 901 | Custom | Custom | Flat | Kevlar Braid |

Our power harness cables are fully customized based on the unique requirements of each project. There are no fixed templates. Customers can define the pinout, connector models, wire specs, cable length, shielding method, and jacket material according to their application. We support rapid drawing, flexible engineering, and quick prototyping for all configurations.

Customized power harness cable styles

Trusted by 300+ global brands,1000+ styles have been developed.

SATA to Dual 8 Pin Molex Power Supply Harness Cable

Custom 2.54mm Pitch DC Power Jack Cable Harness

10 Pin Cable Harness Wiring 2.54mm Pitch Power Harness Cable

Custom to Custom 2.54mm Pitch Power Harness Cable

Custom Cable Harness Wiring 2.54mm Pitch Power Harness Cable

Custom Black Wire DC Power Jack Cable Harness

Waterproof Power Harness Cable 2Pin

High Voltage Power Harness Cable with Waterproof Connector for EV Battery

High Output Alternator Power Harness Cable Kit

DC Power Jack Cable Harness with Fuse

Automotive Power Harness Cable 2-Pin Connector with Terminal Leads

Automotive Multi-Circuit Power Harness Cable Heavy-Duty

12V Heavy Gauge Power Supply Harness Cable with Ring Terminals

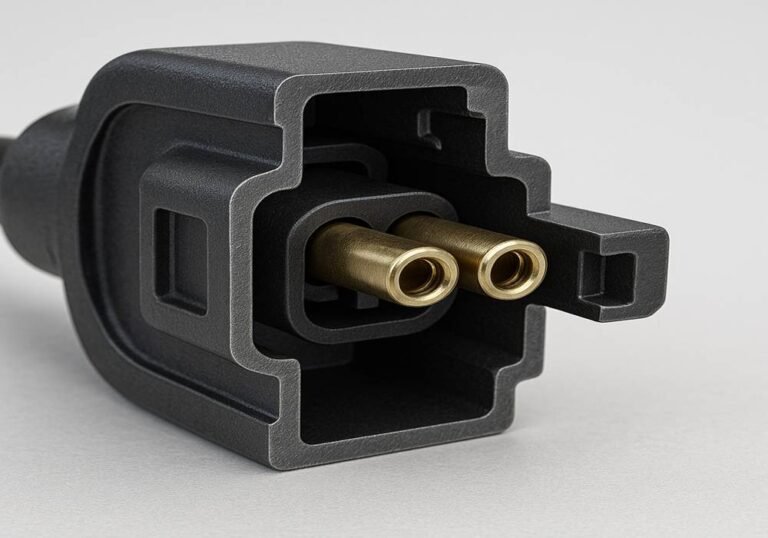

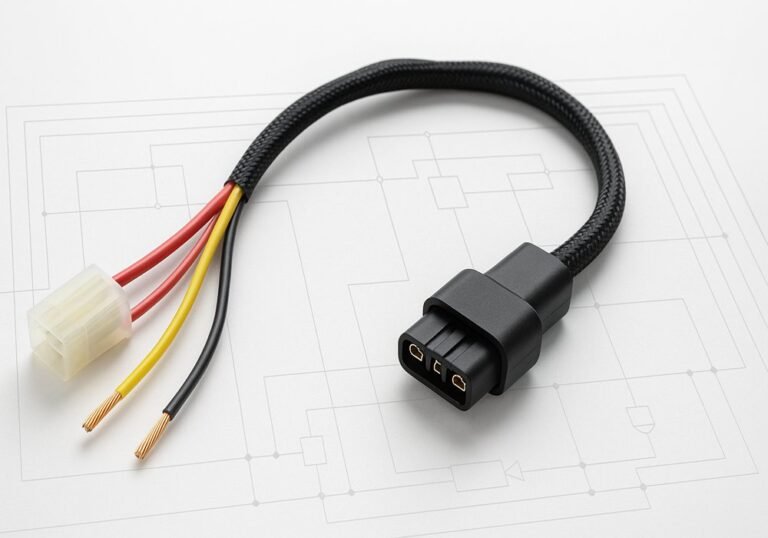

Product details display

Our product display section showcases high-resolution images and detailed technical specifications of custom power harness cables, including connector types, cable structure, voltage ratings, shielding options, and material composition. Explore both macro and close-up views to better understand the build quality, flexibility, and design precision tailored for demanding industrial and OEM applications.

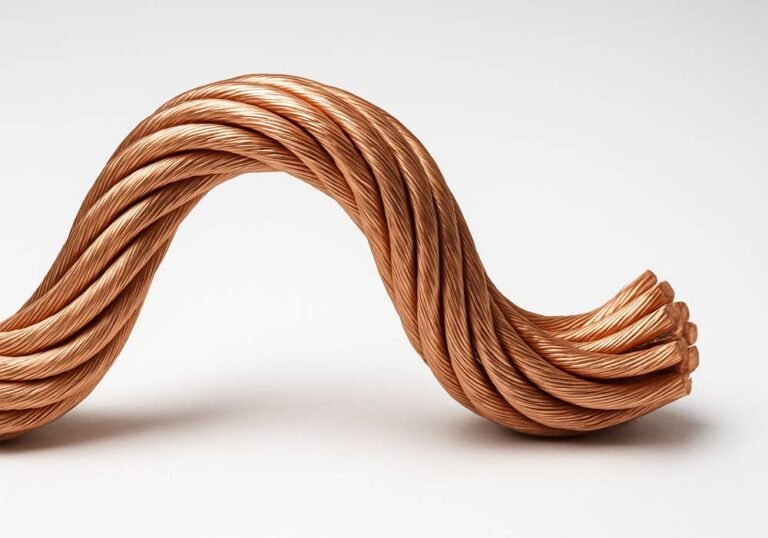

Multi-Strand Tinned Copper Conductors for Stable Power Transmission

Our power harness cables utilize multi-strand tinned copper conductors to guarantee excellent electrical performance. This structure offers lower resistance, higher conductivity, and excellent flexibility. The tin coating protects the copper core from oxidation, especially in outdoor or high-humidity environments. Compared to solid conductors, multi-strand copper is more resilient to bending and vibration, making it a better choice for automotive, robotics, and motion-heavy applications.

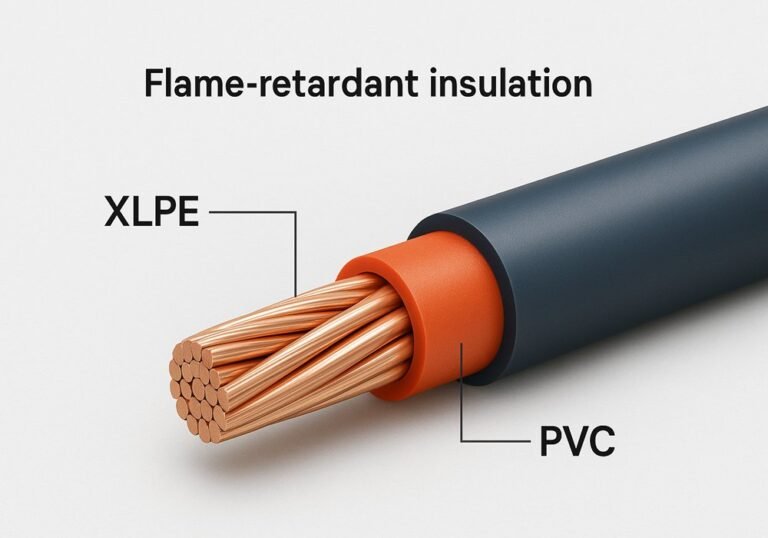

Heat-Resistant and Flame-Retardant Insulation Materials

The insulation layer plays a vital role in both electrical safety and mechanical protection. We use flame-retardant materials like XLPE and fire-rated PVC, ensuring the cable performs reliably even under high-temperature or oily environments. These materials resist cracking, melting, or deformation, offering insulation stability in demanding industrial or vehicle applications. Our cables also comply with UL, RoHS, and REACH certifications.

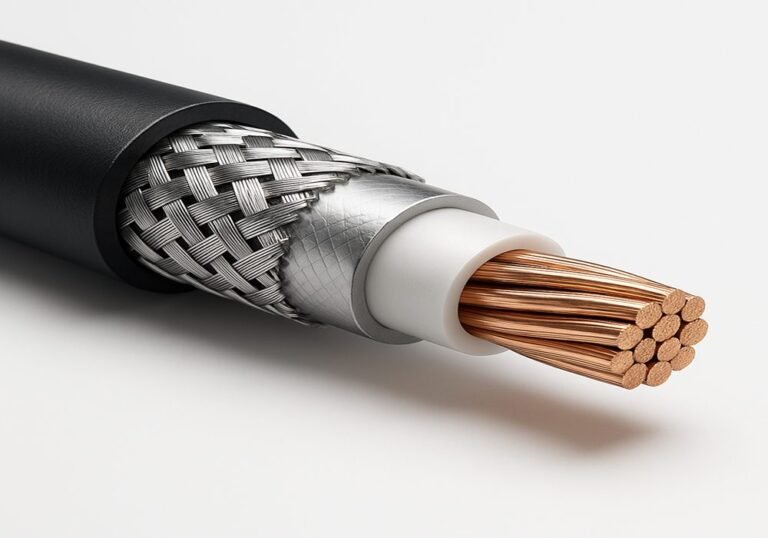

High-Density Braided Shielding for EMI and Signal Integrity

To combat electromagnetic interference (EMI), we use high-density braided shielding made from tinned copper or aluminum alloy. This shielding forms a conductive cage around the inner wires, significantly reducing signal loss and noise intrusion. Especially in communication-critical or power-sensitive environments, our shielding ensures signal clarity, reduced crosstalk, and system stability. Braided shielding coverage typically exceeds 90%.

Precision-Molded Connector Ends for Secure Mating Interface

Connector integrity is essential for power harness reliability. We use precision-molded connector ends that ensure tight tolerance and perfect alignment during mating. Whether it’s latch-lock, screw-lock, or board-to-cable interfaces, our terminals are manufactured to minimize contact resistance and prevent loosening under vibration. Each connector passes through strict inspection for insertion force, mating cycles, and alignment accuracy to guarantee long-term electrical reliability in dynamic environments like automotive and automation systems.

Low MOQ and Rapid Prototyping with CAD Engineering Support

We support projects of all scales with low or no minimum order quantity (MOQ), allowing customers to test and validate harness designs before committing to volume. For prototypes, we provide CAD drawings within 30 minutes and confirm technical specs with the customer before production. Whether it’s a 1-piece test sample or a 10,000-piece batch, our engineering support ensures precision, fast response, and efficient communication throughout the project lifecycle.

Triple Quality Inspection: Process, Final, and Pre-Shipment Checks

To ensure consistent product quality, every power harness cable undergoes a strict three-stage inspection system. This includes process inspection during production, final inspection before packaging, and pre-shipment quality checks. Each cable is tested for electrical continuity, insulation resistance, connector torque, and visual defects. We maintain detailed inspection records and can provide test reports upon request, helping customers reduce quality risks and ensure zero-defect delivery.

--- Customized Capabilities Services and Processes

Customize your power harness cable

Discover our customized capabilities, from tailored cable lengths and unique pinout definitions to material selection and connector configuration. Our engineering team provides rapid CAD drawings within 30 minutes to 3 days, with full client approval before production. We support flexible prototyping, no MOQ requirements, and fast turnaround, ensuring your power harness cable project meets precise functional, environmental, and regulatory requirements.

Customized Capabilities Services and Processes

Customize your power harness cable

At Shenzhen Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, we specialize in delivering end-to-end customization for power harness cables, enabling seamless integration across automotive, industrial, medical, and robotics systems. Every project is tailored from the ground up, ensuring our harnesses meet your exact electrical, mechanical, and environmental requirements.

Flexible Electrical Design

Custom pinouts, voltage ratings, and circuit layouts are designed according to your schematics. We support multi-channel, mixed-signal, and power-signal separation wiring.

Mechanical Adaptability

Cable length, bend radius, and mounting interface are fully configurable. We accommodate tight-space routing, heat zones, and high-vibration applications.

Material and Connector Options

Choose from PVC, XLPE, TPE, nylon mesh, or Teflon insulation. We offer both original and compatible connectors to fit your budget and timeline.

Engineering-Backed Prototyping

We provide 2D/3D CAD drawings, rapid samples within 3 days, and ongoing technical consultation to adapt quickly to evolving project needs.

Our Commitment to Outstanding Service

At Sino-conn, service is more than support—it’s a guarantee of reliability, speed, and accountability throughout your project’s lifecycle. We go beyond expectations to ensure every customer experiences a seamless, transparent, and solution-driven collaboration.

Lightning-Fast Response

Drawings can be delivered in as fast as 30 minutes. Quotes are usually returned within 1 hour, with support for urgent RFQs 24/7.

Real-Time Engineering Support

Our technical team is available for video calls, screen-sharing design reviews, and live troubleshooting for complex builds or changes.

Flexible Commercial Terms

We support NO MOQ, offer payment term options (including 30–60 days for OEMs), and adapt to small-lot needs without delay.

Total Quality Assurance

From raw material incoming inspection to 100% final testing and pre-shipment QC, we provide a 3-stage inspection process with documentation.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Use Case: High-resolution medical imaging device

When Lucas reached out to us, his team was in urgent need of a custom high-voltage power harness for a prototype electric vehicle battery pack. The original European supplier could not meet the specific pin configuration and thermal insulation requirements under tight deadlines. We responded within 30 minutes with a preliminary drawing and quote. After two design iterations and 100% alignment with their CAD specs, our sample passed their lab test within one week.

From first contact to sample delivery, the process was efficient, responsive, and technically accurate. Lucas shared his feedback after receiving the mass production batch:

“As an engineer, I care deeply about every wire’s thermal, mechanical, and EMI properties. What impressed me most was how fast the Sino-conn team understood our spec and delivered a solution that met all safety and endurance targets. Their team worked almost like our internal R&D extension. I now count them among our top three suppliers globally.”

Lucas Schmidt

Lead Electrical Engineer, eMobility Systems GmbH,Germany

Use Case: 5G base station antenna systems

Priya contacted us during the final integration stage of their robotic surgical system, where a specialized low-noise power harness was required to link the central control board with modular servo arms. Their in-house team had already tried three local suppliers but encountered EMI interference and overheating issues. After a 45-minute video call, we proposed a dual-layer shielded harness with PTFE jacketing and tinned copper conductors.

We delivered samples in just 3 working days. Our harness not only met their low-interference expectations but also passed continuous 48-hour robot arm simulation testing without signal loss or temperature spikes. Priya gave her full feedback post-delivery:

“It’s rare to find a vendor who listens, advises, prototypes, and delivers—all within one week. The Sino-conn team impressed us with their detailed documentation, fast responses, and ability to handle small-batch high-spec projects. I trust them with our next-gen designs, and we’ve already started developing with them again.”

Priya Nair

Procurement Manager, Axis Medical Robotics Pvt Ltd, India

Use Case: Robotic arm control systems

Daniel approached us with a time-critical project—his team was building a solar-powered industrial automation unit that required durable outdoor-rated power harnesses capable of withstanding high UV, extreme heat, and regular flexing. Their local supplier quoted 6 weeks with limited flexibility in design. We provided three feasible configurations within 24 hours, each with different jacketing (TPE, PVC, and braided nylon) and detailed bend radius charts.

Daniel selected the TPE-jacketed version with additional UV-blocking layer. We prototyped, tested, and shipped a full sample batch in 5 days. After two months of field use, he shared:

“We work in harsh environments where reliability is everything. Sino-conn’s ability to understand our use case and deliver an outdoor-rated harness that actually lasted through desert temperatures was impressive. The cost-performance ratio beat our expectations, and they’ve become a go-to supplier for all future solar automation builds.”

Daniel Ruiz

Operations Director, Solartec Industrial Solutions,Mexico

industry Application of power harness cable

Power harness cables from Sino-Conn are widely used across various industries including automotive, industrial automation, medical devices, telecommunications, and military equipment. Their durability, high current capacity, and customizability make them ideal for environments requiring reliable power transmission under harsh conditions such as high temperatures, vibrations, and electromagnetic interference.

Solution 1: Heavy-duty power harness cable for safe and efficient high-voltage charging systems

- Application Scenario: With the rapid growth of electric vehicles (EVs), charging stations are being deployed across urban and rural locations. These stations demand reliable, high-current wiring harnesses that can withstand environmental stress, enable efficient energy transfer, and ensure user safety.

- Equipment & Products Involved: DC fast chargers, onboard charging modules, power conversion units, outdoor electrical cabinets

- Industry Pain Points:

- Exposure to outdoor conditions such as rain, dust, and UV radiation leading to cable degradation.

- Heat buildup during high-current fast charging that compromises safety.

- Complexity in installation due to space constraints and various connector standards.

- Solutions:

- We provide UV-resistant, IP-rated cable jackets with flame retardant and anti-corrosion properties to ensure long-term durability.

- Our power harnesses use high-temperature TPE insulation and multi-core copper for superior thermal stability during charging cycles.

- Custom molded ends and flexible routing design reduce space requirements and ensure compatibility with multiple EV charging standards.

Solution 2: Flexible and wear-resistant harnesses for robotic arms and motion control systems

- Application Scenario: Industrial robots operate under continuous motion cycles and require power cables that support repetitive bending, resist oil and abrasion, and maintain consistent performance in factory automation environments.

- Equipment & Products Involved: Robotic arms, CNC machinery, motion controllers, servo drives

- Industry Pain Points:

- Cable fatigue and failure due to repeated bending and flexing.

- Oil and coolant exposure in machining environments causing insulation degradation.

- Signal interference between power and data lines within the same harness.

- Solutions:

- We use finely stranded copper conductors and TPE insulation to achieve high flexibility and bending endurance.

- Outer jackets made of oil-resistant polyurethane and nylon braid extend the cable’s operating life.

- Integrated shielding and separated routing of signal and power lines ensure EMI reduction and reliable data transmission.

Solution 3: Weatherproof, vibration-resistant power harnesses for smart farming equipment

- Application Scenario: Agricultural vehicles such as tractors and combine harvesters increasingly rely on electronic systems for precision farming. These vehicles operate in harsh outdoor conditions, demanding rugged harness solutions.

- Equipment & Products Involved: Tractors, harvesters, GPS units, moisture sensors, control terminals

- Industry Pain Points:

- Constant exposure to mud, dust, and UV rays that wear down standard cables.

- Vibration and shock from uneven terrain leading to wire breakage.

- Requirement for modular and serviceable cable assemblies to reduce downtime.

- Solutions:

- Use of IP67-rated sealed connectors and thick TPE outer jackets ensures environmental sealing and UV resistance.

- Harnesses are built with crimp-locked terminals and vibration-proof clip supports to withstand shocks.

- Modular plug-and-play interface design allows for quick replacement in field service.

Solution 4: EMI-shielded and flexible power harnesses for MRI, CT, and ultrasound systems

- Application Scenario: Medical imaging machines operate in highly sensitive environments that demand zero signal interference and uninterrupted power supply. Power harness cables in these systems must be low-noise, shielded, and maintain high reliability for patient diagnostics.

- Equipment & Products Involved: MRI machines, CT scanners, ultrasound units, control panels

- Industry Pain Points:

- Signal interference from unshielded cables affecting imaging accuracy.

- Need for ultra-flexible routing within confined machine housings.

- Risk of downtime due to harness malfunction impacting hospital operations.

- Solutions:

- Use of multi-layer shielding (aluminum foil + copper braid) ensures minimal EMI and optimal imaging quality.

- Employing ultra-flexible silicone-insulated cables allows easy routing inside tight enclosures.

- 100% electrical and mechanical inspection ensures operational reliability with fast replacement support.

Solution 5: High-density and flame-retardant harness cables for server rack power distribution

- Application Scenario: In modern data centers, efficient power distribution to server racks is critical to maintaining uptime and managing heat. Power harness cables must support high current, comply with strict fire safety standards, and be easily routed in dense environments.

- Equipment & Products Involved: Server racks, PDUs (Power Distribution Units), cooling fans, UPS systems

- Industry Pain Points:

- Cable overheating due to continuous high current loads in confined cabinet spaces.

- Fire risk and regulatory non-compliance from non-rated cables in IT infrastructure.

- Difficulties in maintenance and cable management due to tight routing space.

- Solutions:

- We use UL94-V0 flame-retardant cable jackets and low-smoke, halogen-free insulation to meet global fire safety standards.

- Our power harnesses are built with oxygen-free copper and thermally stable insulation to prevent heat-related failure.

- Color-coded and pre-labeled modular harness kits improve traceability and ease of maintenance.

Solution 6: Vibration-resistant and high-voltage tolerant harnesses for rail traction and onboard electronics

- Application Scenario: Modern railway systems require reliable power distribution and signal control across locomotives, carriages, and auxiliary equipment. Power harness cables must withstand high vibration, voltage fluctuations, and outdoor environmental stress during long-distance operation.

- Equipment & Products Involved: Locomotive control units, braking systems, traction converters, passenger display systems

- Industry Pain Points:

- Continuous mechanical vibration and impact cause connector loosening and wire fatigue over time.

- Exposure to fluctuating temperatures, humidity, and corrosion in outdoor routes affects insulation and performance.

- High voltage surges in traction systems pose insulation breakdown risks without robust protection.

- Solutions:

- Cables use double-crimped sealed terminals, anti-vibration locking housings, and silicone gaskets to ensure stability under motion.

- Harness jackets are made from halogen-free, flame-retardant crosslinked polyolefin with anti-UV additives.

- Multi-layer insulation with high dielectric strength and surge protection components ensures safe performance under variable loads.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized power harness cable services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a power harness cable?

It is a custom cable assembly designed to transmit power in electrical systems, widely used in EVs, industrial machines, and medical equipment.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Can you provide product drawings and specifications?

Yes, we can provide CAD drawings and detailed specs within 1-3 days. PDF versions are included for all quotations and order confirmations.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

Can I use your harness in outdoor or harsh environments?

Yes, we offer IP-rated, UV-resistant, flame-retardant, and oil-proof materials for rugged environments.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China