custom flat cable assemblies manufacturer

Looking for precision-engineered flat cable assemblies that fit your exact design? We offer fully customized solutions—from pin count and pitch to connector type and cable length. No MOQ, fast samples in 3 days, and expert support. Let’s bring your idea to life—starting now.

Why choose flat cable assemblies from sino-conn

Sino-Conn provides highly customizable flat cable assemblies with rapid sample delivery, no MOQ, and precise engineering. Our solutions ensure space efficiency, superior flexibility, and full compliance with UL, RoHS, and ISO standards—ideal for compact and high-performance electronic systems.

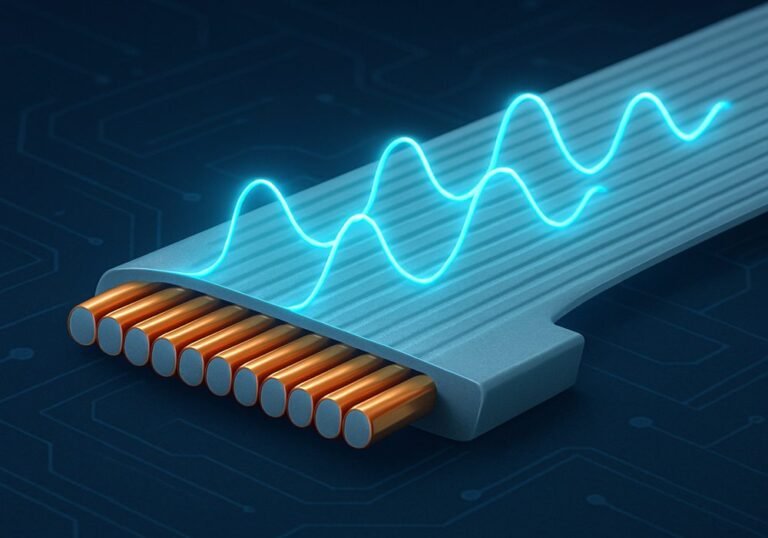

Ultra-Flexible Flat Cable for Compact Routing

Our flat cable assemblies offer exceptional flexibility, making them the perfect solution for compact spaces and tight routing paths in electronic devices. The flat structure ensures minimal cable twisting and consistent signal transmission, even under repeated bending. This is ideal for applications in foldable displays, robotics, printers, or medical devices, where space is limited but performance is critical.

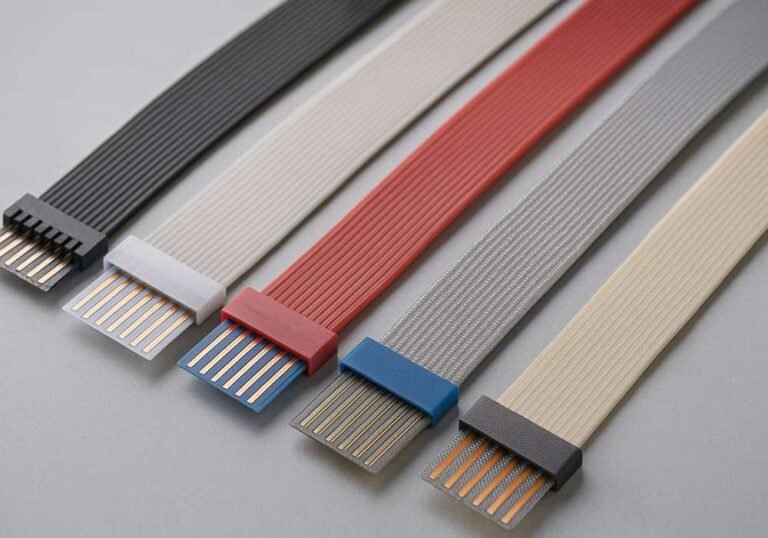

Customizable Configurations for Any Application

Our flat cable assemblies can be tailored in every aspect—pitch, pin count, cable length, connector type, pin-out configuration, insulation material, and shielding. Whether you’re designing for a consumer device, an automotive system, or a medical instrument, we deliver the exact specifications you need. We support small-batch prototypes and high-volume production alike, with CAD drawings ready in hours and rapid sample turnaround within days.

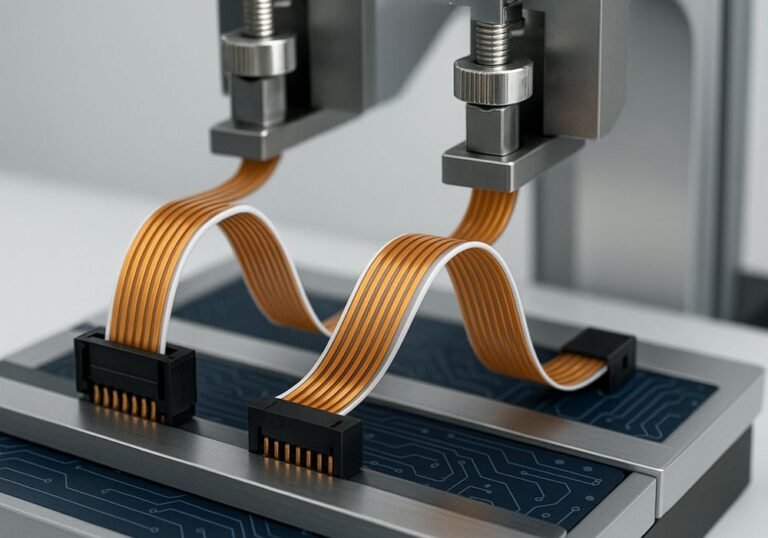

Rapid Prototyping with 30-Minute Drawing Delivery

For urgent design projects, our team provides ultra-fast response with technical drawings ready within just 30 minutes. From CAD to PDF, each flat cable assembly drawing is tailored to your needs and verified by our engineers before production. This dramatically reduces the development cycle, allowing you to move quickly from concept to prototype and into production with zero delays.

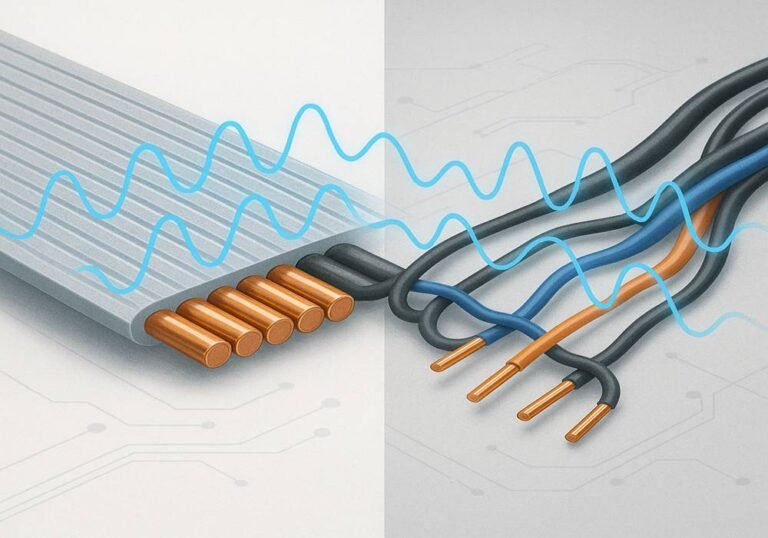

Excellent Signal Integrity and EMI Protection

Our flat cable assemblies are designed with parallel conductor spacing and consistent impedance control to ensure high signal fidelity across all channels. They offer exceptional protection against electromagnetic interference (EMI), making them ideal for high-frequency data transmission in sensitive environments. Whether for industrial controls, medical imaging, or communication equipment, your signal remains stable and protected.

Original or Compatible Connectors Available

We provide both original brand connectors and high-performance compatible alternatives for all flat cable assemblies. Clients can choose based on budget, lead time, or brand preferences. While original connectors ensure maximum compatibility and brand recognition, compatible versions offer faster delivery, stable performance, and better cost efficiency—especially for time-sensitive or small-lot orders.

Zero MOQ, Scalable from 1 Piece to Mass Production

At Shenzhen Sino-conn, we remove barriers to innovation by offering zero MOQ for all flat cable assemblies. Whether you need one prototype or 100,000 pieces for mass deployment, we scale with you. This flexibility supports startups, engineers in R&D, and OEMs alike—providing risk-free development and fast market entry without volume constraints.

Detailed specifications and parameters of flat cable assemblies

At sino-conn, we understand that flat cable assemblies are rarely standardized. Each customer has unique application scenarios, connector preferences, cable structures, and electrical or environmental requirements. That’s why all of our specifications are fully customizable—from pin definitions to jacket materials. Whether you need EMI shielding, flame resistance, or ultra-flexible routing, we can tailor the cable to your exact needs. This level of customization is what sets us apart as a trusted partner for engineers, OEMs, and system integrators worldwide.

| No. | Definition (Pin Configuration) | Connector Model | Cable Spec | Length (mm) | Cable Type | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 1:1 Straight | JST 1.0mm | Custom | Custom | Flat | PVC Sleeve |

| 2 | Cross (Reverse) | FFC ZIF 0.5mm | Custom | Custom | Flat | Teflon Tape |

| 3 | 1:1 Straight | FPC 1.25mm | Custom | Custom | Flat | Conductive Fabric |

| 4 | 1:1 Straight with GND Shield | Molex 2.54mm | Custom | Custom | Formed | Nylon Braid |

| 5 | 1:1 IDC | IDC 2.54mm | Custom | Custom | Flat | Acetate Cloth |

| 6 | 1:1 Twisted Pair | Hirose 1.0mm | Custom | Custom | Round | Teflon Sleeve |

| 7 | Cross | Dupont 2.54mm | Custom | Custom | Flat | PVC Sleeve |

| 8 | 1:1 Shielded | JST 2.0mm | Custom | Custom | Formed | Nano Tape |

| 9 | 1:1 Straight | FFC 1.0mm | Custom | Custom | Flat | Conductive Fabric |

| 10 | 1:1 with Drain Wire | Molex 1.25mm | Custom | Custom | Round | Iron-Fluorine Tape |

Customized flat cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

IDC Ribbon Cable Connectors Flat Cable Assemblies

IDC Ribbon Cable Connector Flat Cable Solutions

IDC Ribbon Cable Assembly with DB9 Connector

IDC Ribbon Cable Assemblies 16 Pin 2.54mm

IDC Flat Ribbon Cable Assemblies 24 Pin

IDC Daisy-Chain Ribbon Cable Assembly

IDC Cable Flat Cable Assemblies Type FC

Flexible Flat Cables IDC Assembly

Flat Flexible Cable Connector Assemblies

Flat Conductor Cable with Latching IDC Connectors

Flat Cable Assembly with D-Sub Connector DB25

Flat Cable Assemblies Type FC IDC Ribbon Cable

Flat Cable Assemblies Type FC 20 Pin IDC

Flat Cable Assemblies IDC Connector Solutions

Custom Ribbon Cable Flat Cable Assemblies

Custom Ribbon Cable Assembly 20 Pin IDC

Custom IDC Cable Ribbon Flat Cable Assembly

Product details display of flat cable assemblies

Explore detailed specifications of our flat cable assemblies, including connector types, pin configurations, cable width, thickness, material options, and temperature resistance. Each product is clearly displayed with close-up photos and technical data to help you make informed customization decisions.

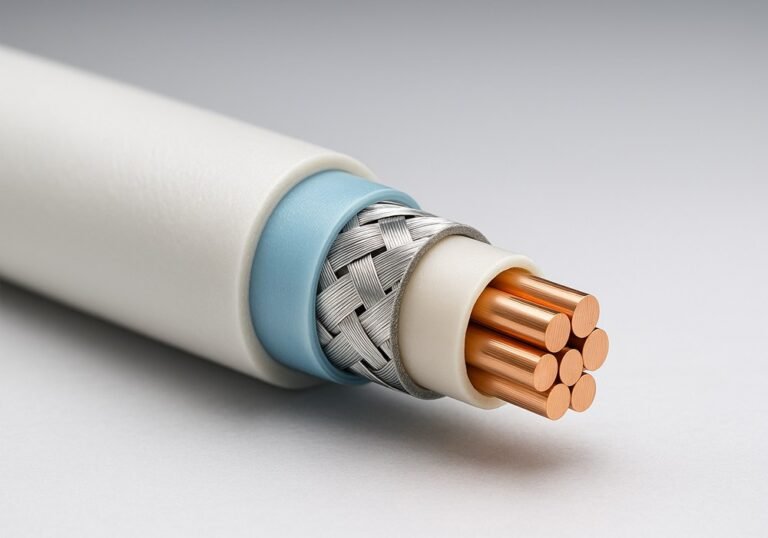

Conductor Alignment & Signal Integrity

The internal structure of flat cable assemblies features tightly aligned and uniformly spaced conductors that play a crucial role in maintaining signal consistency and electrical performance. This configuration brings significant technical advantages:

- Equal Path Lengths: All conductors are aligned in a straight and parallel layout, which ensures that signals travel the same distance, reducing signal skew in high-speed digital applications.

- Controlled Impedance: The parallel spacing allows for precise control over characteristic impedance, critical in maintaining signal integrity in data transmission applications like LVDS, USB, and HDMI.

- Reduced Crosstalk: By maintaining consistent spacing between lines, electromagnetic interference (EMI) and crosstalk are minimized, which is vital for sensitive analog or digital signal lines.

- Predictable Electrical Behavior: Engineers and system integrators benefit from the consistent electrical characteristics, which simplify simulation, PCB layout, and product validation.

This level of consistency makes flat cable assemblies highly suitable for mission-critical applications in medical diagnostics, industrial automation, consumer electronics, and display technologies.

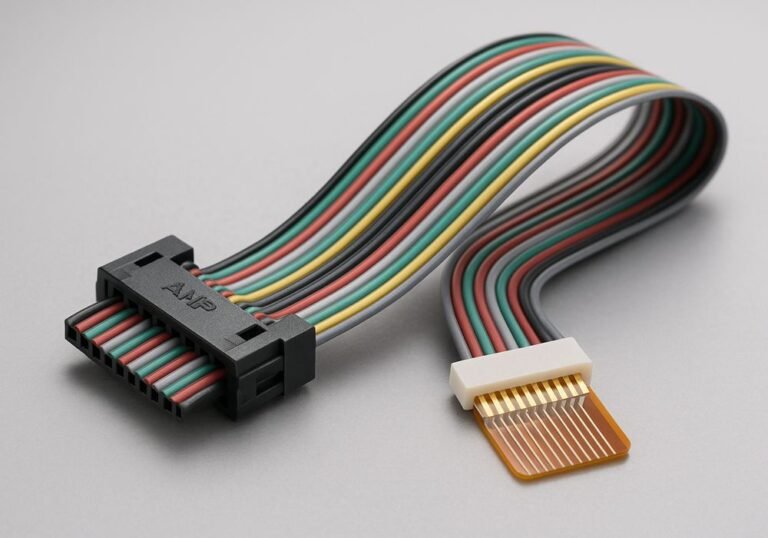

Precision Connector Termination

At Sino-conn, our flat cable assemblies feature expertly terminated connectors using highly controlled soldering or IDC crimping techniques. The connector interface is one of the most critical points in cable reliability, and we ensure optimal performance through the following:

- Connector Compatibility: We offer a wide range of termination options, including IDC, ZIF, FPC, and custom pitch connectors to match your device interface precisely.

- Precision Soldering or Crimping: Our termination process guarantees secure electrical contact, preventing issues like resistance spikes, contact failure, or thermal degradation.

- Connector Alignment: Each connector is mounted with precise positioning tools to ensure accurate orientation and pin mapping, reducing the chance of assembly errors.

- Strain Relief Implementation: Optional strain relief designs prevent mechanical stress at the connector joints, improving durability during repeated mating/unmating.

This meticulous termination process not only enhances the cable’s mechanical strength but also ensures long-term electrical reliability across various applications—whether in industrial controllers, consumer gadgets, or automotive modules.

Flexible & Durable Insulation Structure

The insulation structure of flat cable assemblies is engineered for high flexibility, repeated motion, and extreme environmental resilience. Depending on the use case, we select appropriate insulating materials to meet dynamic or harsh operating conditions:

- Material Options: We offer insulation in PVC, Teflon (PTFE), polyester (PET), or Kapton based on requirements like temperature resistance, chemical resistance, or mechanical strength.

- Flex Life Optimization: Flat cable assemblies are designed to endure thousands of bend cycles in dynamic applications without cracking, delamination, or conductor breakage.

- Temperature & Flame Resistance: Materials like PTFE or high-grade PVC can operate between -40°C to +125°C and offer flame retardancy compliant with UL94 V-0.

- Thin, Lightweight Profile: The overall profile remains compact, which is critical for devices where space constraints matter, such as wearable medical devices, drones, or slim displays.

This insulation structure enables high-performance wiring in robotics, healthcare diagnostics, printing mechanisms, and more—offering flexibility without compromising durability.

Optional Jacket and Shielding Configurations

Flat cable assemblies from Sino-conn can be customized with a variety of outer jacket materials and EMI shielding layers to suit specific usage environments:

- Jacket Material Options: Choose from PVC sleeves, Teflon (PTFE) wrap, nylon braided mesh, nano tape, conductive fabric, and more depending on mechanical, thermal, or chemical exposure.

- EMI Shielding Integration: We offer optional aluminum foil shielding, braided copper mesh, or conductive tapes to minimize electromagnetic interference and maintain signal integrity.

- Environmental Protection: Our jackets can be selected for resistance to oil, UV, chemicals, and high heat to meet standards required in automotive, industrial, or aerospace fields.

- Aesthetic and Mechanical Customization: Jacket color, finish (matte/glossy), and thickness can also be adjusted for visual compatibility with end products or to meet specific handling conditions.

This flexibility allows your flat cable assembly to perform reliably in harsh conditions while aligning with your technical and branding expectations.

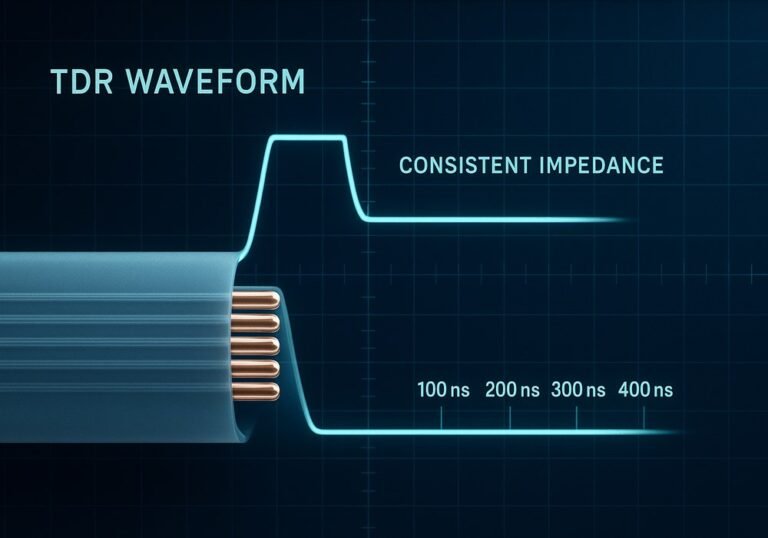

Precise Dimensional Control & Impedance Matching

To ensure optimal signal performance, especially in high-speed digital applications, we apply advanced process control to maintain dimensional precision and impedance consistency across all flat cable assemblies:

- Uniform Conductor Spacing: All conductors are extruded with micron-level spacing tolerance to ensure consistent propagation delay across all channels.

- Consistent Dielectric Thickness: The insulation layer between conductors is tightly controlled to prevent variations that can lead to signal distortion.

- Impedance Matching: For LVDS, USB, HDMI, and other differential signal applications, we design each cable to match the required impedance (typically 50Ω, 75Ω, or 100Ω) to reduce reflection and loss.

- Quality Assurance Testing: Every batch undergoes TDR (Time Domain Reflectometry) and capacitance checks to ensure dimensional accuracy and electrical stability.

This level of precision is particularly important in applications like industrial vision systems, automotive infotainment, and medical diagnostics equipment, where signal integrity is critical to performance.

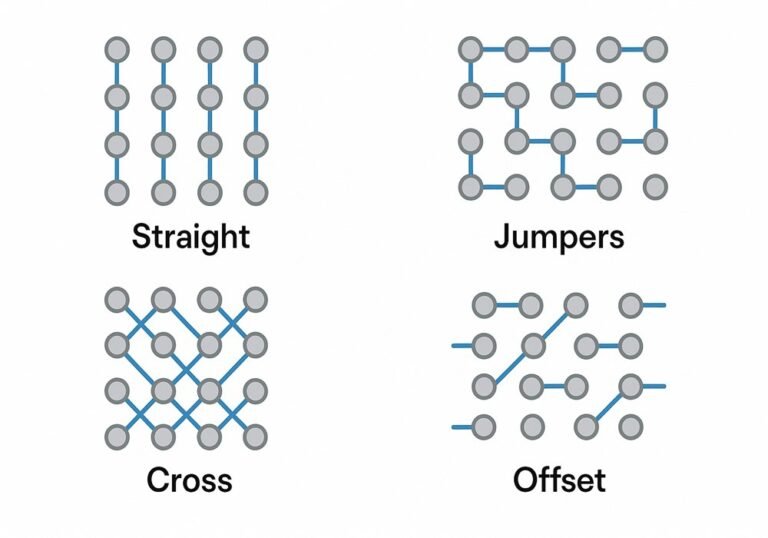

Extreme Customization & Rapid Prototyping Support

One of Sino-conn’s key advantages lies in our ability to support extreme levels of customization and fast prototyping services:

- Custom Pin Mapping: We can accommodate any pin-out logic, including mirrored, crossed, or skipped pin patterns to match your PCB layout or functional requirements.

- Connector Combination: Mixed or asymmetric connector types on each end are supported—perfect for adapters, converters, or system interconnects.

- Non-Standard Arrangements: Flat cables can be folded, formed, or split based on 3D routing requirements, including cable bifurcation or multi-branch structures.

- Labeling & Packaging: Barcode labels, QR codes, traceability tags, or custom logos can be added per batch or unit-level.

- Fast Delivery: We provide accurate CAD-to-PDF drawings within 30 minutes and samples within 2-3 days for urgent R&D projects.

This rapid, flexible capability helps R&D engineers and procurement teams speed up validation cycles and accelerate time-to-market without compromising on technical requirements.

--- Customized Capabilities Services and Processes

Customize your flat cable assemblies

Discover our full range of customized services—from design and prototyping to mass production. We tailor flat cable assemblies to your exact needs in terms of length, pinout, materials, and shielding, backed by fast sampling, professional CAD support, and strict quality control processes.

Customized Capabilities Services and Processes

Customize your flat cable assemblies

At Shenzhen Sino-conn, we specialize in

full-spectrum customization

for flat cable assemblies. Whether you need ultra-fine pitch (0.3mm) FFCs for medical robotics or heavy-duty shielded cables for automotive HDMI, our engineering team tailors every parameter:

Connector Agnostic: Support 200+ connector brands (Molex/JST/Hirose) with OEM/ODM options. Reverse-engineer obsolete parts.

Performance-Driven: Custom impedance (50Ω–100Ω), bend radius (≥5x OD), and operating temps (-40°C to +200°C).

Niche Applications: Acid-resistant jackets for marine systems, PTFE-free cables for EU compliance.

Rapid Iteration: Modify pinouts, lengths, or shielding within24 hoursfor urgent NPI phases.

Cost Optimization: Balance gold-plated contacts vs. tin-plated alternatives without sacrificing signal integrity.

Ultimate Customer Service:

At Sino-conn factory, we don’t just deliver products—we deliver assurance. Our customer service approach is deeply integrated into every stage of your flat cable assembly project.

- Response Speed:CAD drawings delivered within 30 minutes; quotes ready same-day.

- Dedicated Support:One-on-one engineering consultation with real-time video if needed.

- Transparency:Customers receive updates at each step—drawing, prototype, production, shipment.

- Flexibility:Zero MOQ policy, multi-solution pricing, and original/compatible connector options.

- Precision:Every unit is fully inspected three times—during process, after assembly, before shipping.

- Certifications:Full documentation support including UL, ISO, RoHS, REACH, PFAS, COC, COO.

Whether you’re a first-time client or a long-term partner, we ensure that your experience is professional, predictable, and rewarding. We go beyond expectations—because your success is our reputation.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario: Flat ribbon cables for modular PLC system wiring

“Our PLC panels required compact and easily routed flat cable assemblies with varied connector types. Shenzhen Sino-conn quickly adapted to our non-standard pin mapping and even offered solutions for improved EMI performance. Their prototype was delivered in just 2 days, and the documentation—both drawings and test reports—was flawless. Their team is highly responsive, and the price-to-performance ratio is unbeatable.”

Alicia Moreno

Guadalajara, Mexico, Industrial Automation Engineer

Application Scenario: Customized flat cables for touchscreen display integration in smart home systems

“As a buyer in the smart home sector, we often deal with very specific demands—low-profile, ultra-thin flat cables with custom bends and dual connectors. Shenzhen Sino-conn impressed us with their ability to handle 3D-forming requirements and connector asymmetry. The visual sample perfectly matched our product mockup, and their follow-up was top-notch. They’re one of the few suppliers who truly understand small-batch precision production.”

Sophie Dupont

Lyon, France, Senior Buyer

Application Scenario: Customized flat cables for touchscreen display integration in smart home systems

“As a buyer in the smart home sector, we often deal with very specific demands—low-profile, ultra-thin flat cables with custom bends and dual connectors. Sino-conn impressed us with their ability to handle 3D-forming requirements and connector asymmetry. The visual sample perfectly matched our product mockup, and their follow-up was top-notch. They’re one of the few suppliers who truly understand small-batch precision production.”

Sophie Dupont

Lyon, France, Senior Buyer

industry Application of flat cable assemblies

Flat cable assemblies are widely used in automotive electronics, medical devices, industrial equipment, and consumer electronics. Their compact structure, flexibility, and efficient signal transmission make them ideal for space-constrained and high-performance applications across various industries.

Precision Flat Cables for Medical Diagnostics

Application Scenario:

Flat cable assemblies are widely used in medical diagnostic devices that require compact, precise, and low-noise internal wiring—particularly in imaging equipment and wearable health monitors.

Devices & Products:

CT scanners, ultrasound machines, ECG monitors, portable diagnostic tablets, and wearable health patches.

Industry-Specific Requirements:

- Medical equipment requires high signal fidelity and low EMI (electromagnetic interference) to ensure accurate diagnostic output.

- Internal space is often limited, demanding extremely flexible and ultra-thin cabling.

- Materials must be biocompatible, flame-retardant, and certified (ISO, RoHS, REACH, etc.).

- Reliability is critical; cables must withstand repeated movement without signal degradation.

Our Solution:

Shenzhen Sino-conn provides flat cable assemblies with shielded FFC/FFC+foil designs that ensure consistent impedance and minimal EMI. We use high-flex insulation (like Teflon or PET) and medical-grade materials. We offer ultra-slim profiles (0.2mm and up), custom lengths and pin-outs, and pre-formed structures for foldable or wearable use. All cables pass 3-phase inspection and come with RoHS, REACH, and biocompatibility documentation.

Flat Cable Assemblies for Industrial Automation Equipment

Application Scenario:

In industrial automation systems, flat cable assemblies are used for signal transmission between control modules, sensors, HMIs (Human-Machine Interfaces), and motion drivers in PLC cabinets and robotic arms.

Devices & Products:

PLC cabinets, servo controllers, industrial sensors, touch panels, robotic arms, machine vision units.

Industry-Specific Requirements:

- Harsh environments require cables to be oil-resistant, flame-retardant, and resistant to mechanical abrasion.

- Cable routing must be neat, space-efficient, and support high bending cycles in dynamic machinery.

- Connectors must be rugged and customizable to fit different industrial interface layouts.

- EMI shielding is critical to avoid signal interference in high-power equipment.

Our Solution:

We provide flat cable assemblies with customized connector combinations (IDC, JST, Hirose, etc.), reinforced with anti-oil PVC sleeves or braided nylon jackets. For dynamic applications, we offer flex-tested cables with >10 million bending cycles. EMI shielding with aluminum foil or conductive fabric is included as needed. Custom pin-outs and cable shapes (e.g., L-shaped, folded, or multi-branch structures) are supported, and we provide fast drawings and batch-level labeling for easy installation.

Flat Cable Assemblies for Medical Imaging Devices

Application Scenario:

In modern medical imaging systems such as ultrasound machines, endoscopy towers, and portable diagnostic equipment, compact and reliable cable assemblies are critical to ensure stable signal transmission, minimal electromagnetic interference, and user safety.

Devices & Products:

Ultrasound probes, endoscopic control units, patient monitors, portable ECG/EEG machines, handheld diagnostic tools.

Industry-Specific Requirements:

- Space constraints require ultra-thin cable structures with precise routing inside compact housings.

- Materials must comply with medical-grade standards (RoHS, REACH, ISO13485, USP Class VI).

- EMI and RFI shielding are essential to protect sensitive signal lines in high-precision diagnostic equipment.

- Surface finish must be smooth and easy to clean for hygiene and disinfection.

Our Solution:

Shenzhen Sino-conn provides ultra-flat, shielded cable assemblies using Teflon (PTFE) or medical-grade PVC jackets. Cables can be configured with gold-plated micro connectors (such as Hirose or Molex) to ensure signal integrity. We support custom lengths, folding structures, and reduced OD designs for internal routing. Every batch comes with ISO and biocompatibility certificates. We also offer labeling and sterilization-ready packaging for OEM device manufacturers.

Flat Cable Assemblies for Aerospace Cockpit Systems

Application Scenario:

In modern aircraft cockpit and avionics systems, where every millimeter and gram counts, flat cable assemblies offer ideal space-saving solutions while meeting stringent safety and reliability standards.

Devices & Products:

Flight control panels, HUD displays, navigation modules, onboard communication systems, pilot control sticks, instrument clusters.

Industry-Specific Requirements:

- Extremely compact routing space in control panels and behind dashboards.

- Cables must meet aerospace standards for flame retardancy (FAR 25.853), vibration resistance, and operational temperatures (-55°C to 125°C).

- EMI/RFI shielding must comply with MIL-STD-461.

- Reliability under rapid pressure and temperature fluctuations during flight cycles.

Our Solution:

Shenzhen Sino-conn manufactures aerospace-grade flat cable assemblies using flame-retardant PTFE or Kapton tape wrapping, with aluminum foil and braided shielding. Connectors are MIL-spec compliant and vibration tested. We support modular multi-branching designs and edge-connector terminations to suit compact avionics architecture. All assemblies undergo thermal shock, high-G vibration, and EMI chamber validation, and are shipped with full documentation including CoC, FAA/DoD traceability and IPC/WHMA-A-620 Class 3 quality inspection records.

Flat Cable Assemblies for Industrial Inkjet Printers

Application Scenario:

In high-speed industrial inkjet printers used for packaging, textile, or circuit board printing, flat cable assemblies are key to achieving compact design and stable signal control in highly dynamic motion environments.

Devices & Products:

Printhead carriages, motion controllers, print engine modules, driver boards, ink management systems, encoder feedback loops.

Industry-Specific Requirements:

- Repeated flexing during high-speed horizontal motion;

- Strict EMI control to prevent signal distortion affecting droplet accuracy;

- Space optimization in tight mechanical housings;

- Cable must resist ink corrosion, static buildup, and high humidity environments;

- Real-time signal synchronization across multiple printhead modules.

Our Solution:

Sino-conn designs ultra-flexible flat cable assemblies with TPE insulation and reinforced grounding strips. EMI shielding is achieved using double-layer aluminum-mylar foil + copper braid, and anti-ink TPU wraps ensure corrosion resistance. For high-speed signal synchronization, impedance is strictly controlled (<90 ohm differential) and each cable undergoes real-time oscilloscope validation. Our assemblies can be embedded in moving print carriages and support custom connectors (e.g., Hirose, JST, Molex) with secure snap-fit locking, even in high-vibration print environments.

Flat Cable Assemblies for Wearable Medical Devices

Application Scenario:

In the field of wearable healthcare technology, such as smart ECG monitors, wearable insulin pumps, and home-use portable diagnostic tools, flat cable assemblies are used for signal transmission, battery power delivery, and sensor integration—all within ultra-slim, lightweight devices.

Devices & Products:

Wearable ECG patches, glucose monitors, smart thermometers, biosignal sensor arrays, rechargeable battery modules.

Industry-Specific Requirements:

- Ultra-thin cable profile for compact form factors;

- Biocompatibility and skin-contact safety;

- High flexibility and repeated bend resistance (≥100,000 cycles);

- Consistent low-noise signal transmission (especially ECG, EEG, EMG);

- Heat and moisture resistance for long-term skin contact;

- Low weight for user comfort during extended wear.

Our Solution:

Sino-conn provides micro-pitch flat cable assemblies with halogen-free insulation, medical-grade TPU or TPE jackets, and gold-plated fine-pitch connectors (0.5 mm, 0.3 mm). All cables pass skin irritation testing (ISO 10993) and are manufactured in ISO 13485-certified facilities. Shielded twisted-pair internal structures reduce bio-signal interference, while ultra-flex materials ensure durability. Optional breathable mesh overlay helps improve skin adhesion in adhesive-wearable applications.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our personalized flat cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a flat cable assembly, and what is its primary function?

A flat cable assembly (FFC/FPC) is a flexible, flat conductor cable used for high-density signal transmission. Its primary function is to connect devices in tight spaces while ensuring stable signal integrity with minimal interference.

Can you provide CAD drawings before production?

Absolutely. We offer CAD + PDF drawings within 1–3 days for all custom orders, with faster turnaround in 30 minutes when needed.

What are lead times for samples and bulk orders?

Samples: 3 days (expedited) or 2 weeks (standard). Bulk: 2 weeks (urgent) or 3-4 weeks (regular), MOQ 1 piece.

What certifications do you have?

Certifications include UL, RoHS, REACH, ISO 13485 (medical), IEC 61754 (industrial). PFAS/COC/COO docs available upon request.

Are connectors original or compatible alternatives?

Both: Original brands (TE/Molex) have longer leads/higher cost; compatibles offer same performance at 30% lower cost with faster delivery.

What materials do you use for flat cable insulation and jacket?

We offer PVC, Teflon, Silicone, and PE depending on temperature, flexibility, and compliance requirements.

Do you support FFC, FPC, or IDC types in flat cable assemblies?

Yes. We support FFC, FPC, IDC and other flat cable formats with various pitches and connectors.

Can you handle high-flex applications (e.g., robotics)?

Yes. Our cables endure 1M+ bends (tested per IEC 60512-9-3) with patented reinforcement at stress points.

What sheath materials do you commonly use?

We offer PVC, LSZH, PE, Teflon (FEP), nylon braid, and armored jackets — each suited for flexibility, flame resistance, temperature, or outdoor performance.

Do you have stock for any standard overmolded assemblies?

Most of our overmolded assemblies are custom-made. However, we keep samples and materials ready to support rapid prototyping.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China