custom waterproof cable assembly manufacturer

Reliable waterproof cable assemblies for harsh environments. From outdoor security to marine systems, we provide fully sealed, customizable solutions with IP67/IP68 ratings. Built to withstand rain, dust, and corrosion—engineered for your application.

Why choose waterproof cable assembly from sino-conn

Sino-Conn’s waterproof cable assemblies are engineered for reliability in the harshest environments. With customizable specs, IP67/IP68 protection, and rapid prototyping, we help clients across marine, outdoor, medical, and industrial sectors achieve durable, high-performance connectivity. Backed by full certifications and no MOQ, Sino-Conn is your trusted partner for tailored waterproof cable solutions.

Reliable IP67/IP68 Waterproof Protection

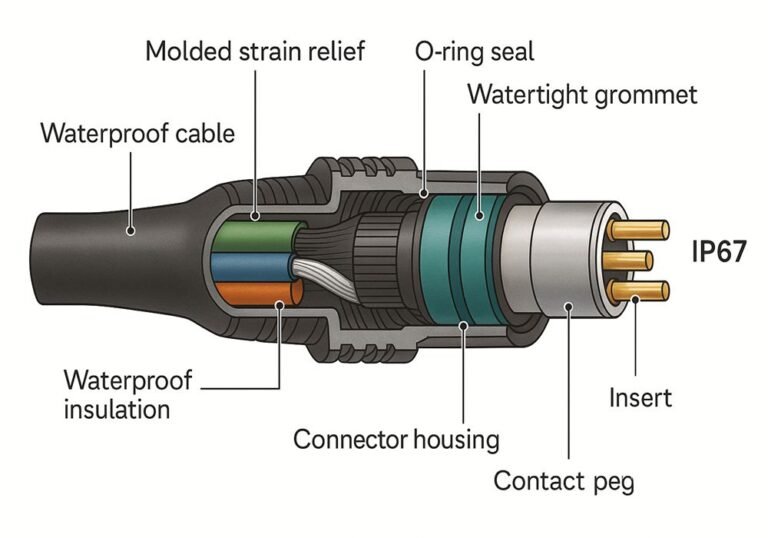

Our waterproof cable assemblies are built to resist water ingress under harsh conditions. With IP67/IP68-rated sealing, they ensure consistent performance in rain, immersion, and humid environments. Ideal for outdoor, marine, and industrial applications. Each connector is tested under pressure and moisture cycles to guarantee long-term reliability.

Fully Customizable Structure and Pinout

We support complete customization of cable length, pin definition, connector type, and outer jacket material. Whether standard or non-standard, we can rapidly turn your design into a manufacturable drawing and sample. OEM, ODM, and hybrid solutions are all supported with full engineering documentation and version control.

Rapid Design Support and Fast Prototyping

Drawings in 30 minutes, samples in 3 days. Our engineering team can quickly respond to customer ideas with CAD-to-production workflow, accelerating product development. We provide both 2D/3D drawings for review and ensure each design meets mechanical, electrical, and sealing standards before sampling.

Wide Range of Connector Options for Diverse Applications

Our waterproof cable assemblies support a wide variety of connector types including circular, M12, RJ45, USB, and custom designs. These options allow seamless integration into automotive, outdoor lighting, and industrial control systems. Each connector interface supports both genuine and compatible options to meet different budget needs.

High Durability Materials for Outdoor and Harsh Environments

We use UV-resistant, flame-retardant, oil-proof, and corrosion-resistant materials in our waterproof cable assemblies. These properties ensure stable performance in rugged field environments, including high temperature, humidity, and mechanical stress. Jackets can be selected based on specific industry standards such as UL, CSA, or MIL-Spec.

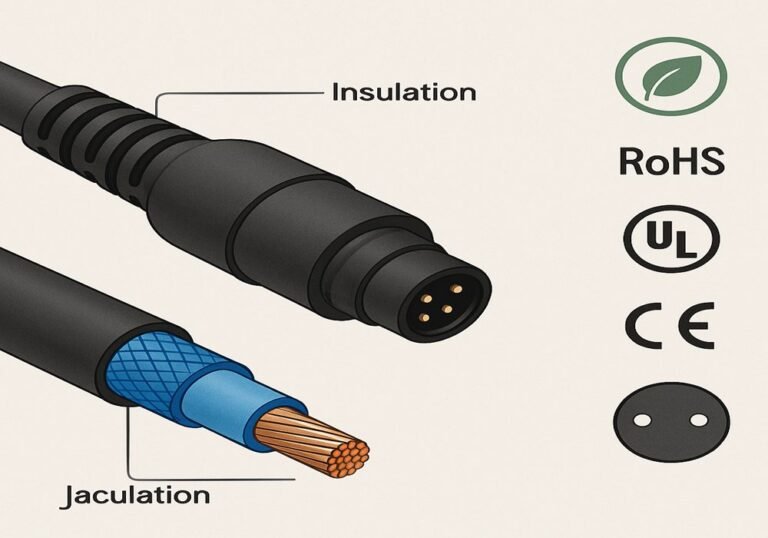

Certified Quality with Full Compliance to Global Standards

All waterproof cable assemblies are produced under ISO management and comply with RoHS, UL, REACH, PFAS, and other global standards. Each unit is fully tested and traceable with 100% inspection protocols. COC/COO documentation is available for shipments, and we support batch testing for PFAS-free compliance.

Detailed specifications and parameters of waterproof cable assembly

| No. | Pin Definition | Connector Type | Cable Spec | Length (mm) | Cable Form | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | USB2.0 A to B | USB A Male to USB B Male | Custom | Custom | Round | PVC Tube |

| 2 | USB2.0 A to Micro-B | USB A Male to Micro-B | Custom | Custom | Round | Nylon Braided Mesh |

| 3 | USB2.0 A to C | USB A Male to USB-C | Custom | Custom | Round | Teflon Jacket |

| 4 | USB3.0 A to C | USB A Male to USB-C 3.0 | Custom | Custom | Round | PVC Tube |

| 5 | USB3.0 C to C | USB-C Male to USB-C Male | Custom | Custom | Round | Teflon Tape |

| 6 | USB-C to Micro-B | USB-C Male to Micro-B | Custom | Custom | Round | Conductive Fabric Tape |

| 7 | USB3.0 A to A | USB A Male to USB A Male | Custom | Custom | Round | Acetate Cloth Tape |

| 8 | USB A to Panel Mount | USB A Male to A Female Panel Mount | Custom | Custom | Molded | Nylon Braided Mesh |

| 9 | USB A to Right Angle C | USB A Male to USB-C Right Angle | Custom | Custom | Round | PVC Tube |

| 10 | Dual USB A to 2x Micro-B | Dual USB A Male to Dual Micro-B | Custom | Custom | Flat | Teflon Jacket |

Due to the diversity of application scenarios and end-user equipment, our USB cable assemblies are highly customized. Each client often requires a different combination of connector type, pin definition, cable length, shielding structure, and jacket material. The examples above are just common configurations. We provide full flexibility in design to meet your specific functional, mechanical, and aesthetic requirements.

Customized waterproof cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

3 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

5 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

6 Pin Waterproof Cable Assembly M20 to JST PHR-6 Outdoor Extension

10 Pin Waterproof Cable Assembly with M20 Connector to JST PHR-10 Outdoor Waterproof Extension Cable

M8 4 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

M12 8 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

M12 4 Pin Waterproof Cable Assembly Outdoor Electrical Wire Conduit

M12 5 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

MC4 2 Pin Waterproof Cable Assembly Outdoor Waterproof Cable Connector

M12 8 Pin X Coded Waterproof Ethernet Cable Outdoor Waterproof Cable Assembly

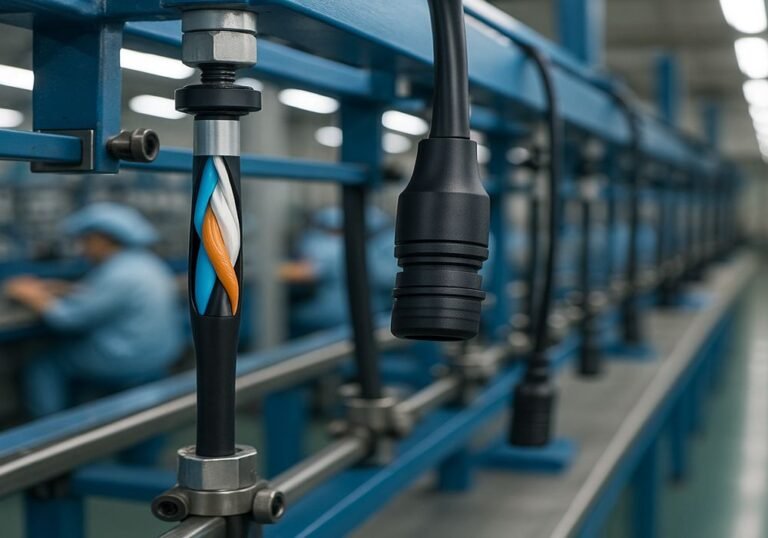

Product details display of waterproof cable assembly

Explore the detailed specifications of Sino-Conn’s waterproof cable assemblies, including connector types, wire gauges, insulation materials, IP ratings, EMI shielding, and flexibility. Our product images highlight both overall structure and fine details, helping you better evaluate the right fit for your application. All assemblies support full customization.

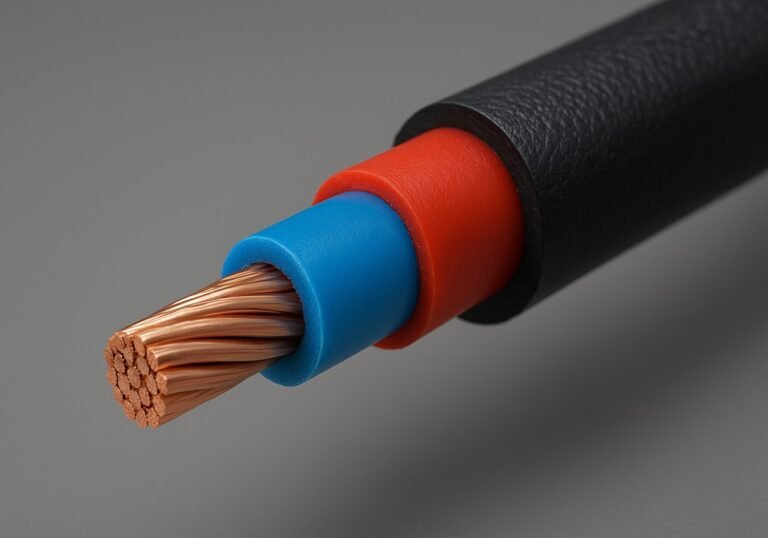

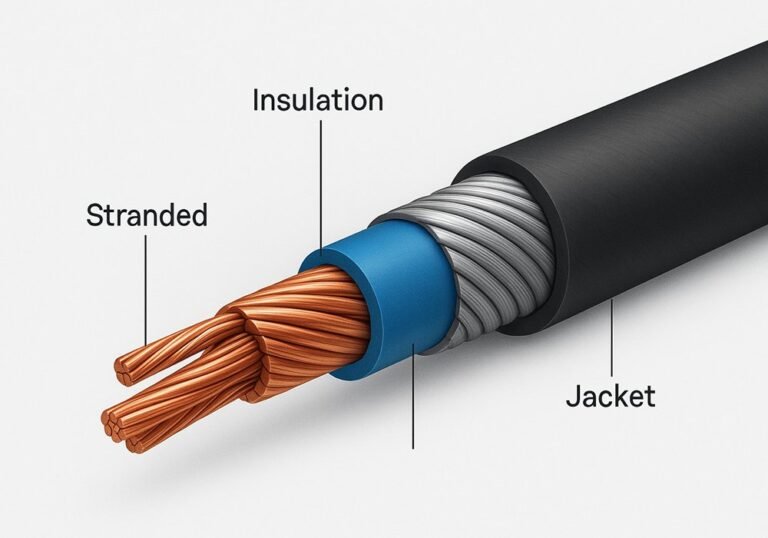

High-Purity Conductors Ensure Signal Stability

The core of any waterproof cable assembly lies in its conductor material. At Sino-conn, we use only high-purity copper or tinned copper conductors that guarantee optimal signal transmission and electrical performance. These conductors are essential for minimizing signal loss, reducing resistance, and maintaining stable current under varying temperatures and environments. Proper conductor selection directly affects the durability, EMI shielding performance, and long-term stability of your product. We offer multiple options to meet different cost-performance needs, from high-flexibility stranded cores to cost-effective solid wires.

- High-Purity Copper Core: Delivers superior conductivity, low resistance, and stable transmission.

- Tinned Copper Option: Offers enhanced oxidation resistance and longer lifespan.

- Stranded vs. Solid Core: Flexible stranded wires for dynamic use; solid core for static environments.

- Optional Silver-Plated Copper: For ultra-high frequency and low-loss environments.

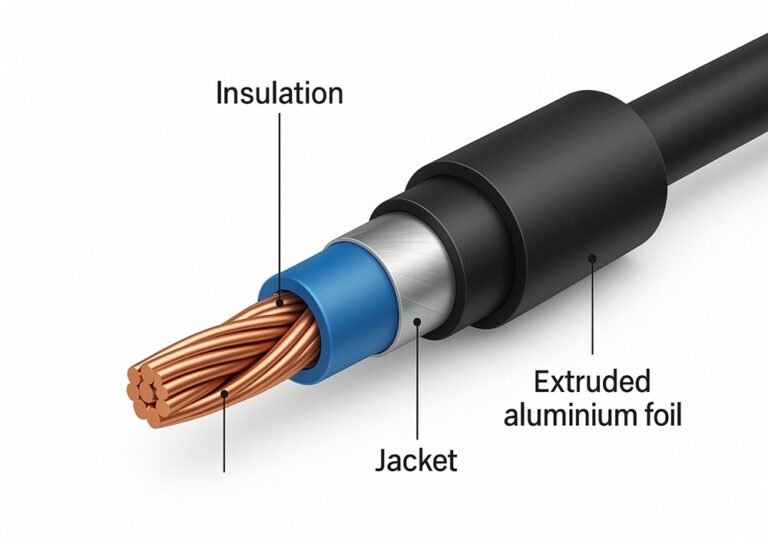

Durable Insulation and Jackets for Extreme Environments

Insulation and outer jacket materials define a cable’s ability to withstand harsh operating conditions. Our waterproof cable assemblies use top-grade materials such as PVC, PE, PUR, and TPE, selected according to the environmental demands of each application. These jackets are engineered to resist UV, oil, corrosion, fire, and extreme temperatures. The insulation layer inside protects signal integrity and ensures safety under voltage load. Whether your cables are exposed to outdoor sun, industrial oil, or require halogen-free composition, we offer fully customizable materials to ensure performance, durability, and compliance with international standards like RoHS, REACH, and UL.

- PVC & PE: Cost-effective options for general indoor/outdoor use with good flame resistance.

- PUR Jacket: Highly resistant to abrasion, oil, and chemicals—ideal for robotics and automation.

- Flexible, halogen-free, and eco-friendly—suitable for sensitive applications.

- UV & Flame Resistance: Ensures longevity in outdoor or high-heat applications.

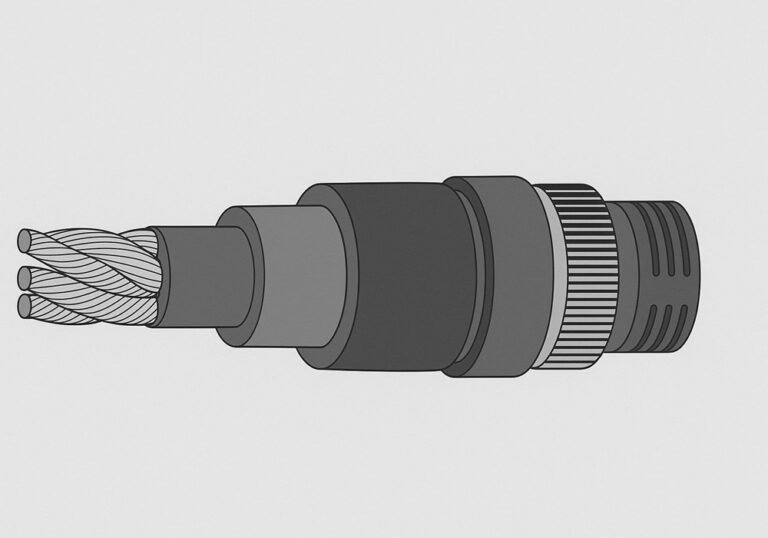

Wide Range of Connector Types & Flexible Customization

Connectors are the critical interface between your device and the outside world. Our waterproof cable assemblies support an extensive selection of connector types, including M8, M12, RJ45, USB, D-sub, circular push-pull, and more. We offer both original (brand-name) and compatible alternatives to suit your project budget, function, and timeline. In addition, Sino-conn provides full customization on connector direction, pinout configuration, housing material, overmolding style, and IP rating. From simple replacements to unique applications with special locking mechanisms, we help you build the exact solution you need—faster, cheaper, and more efficiently.

- Connector Variety: M8, M12, USB, RJ45, D-sub, and circular types are available.

- Pinout Customization: Pin configuration, crossovers, and shielding layout can be fully customized.

- Original vs. Compatible: Offer both genuine brands or compatible alternatives based on customer needs.

- Overmolding & Orientation: Custom right-angle, straight, or Y-branch molds with various jacket colors.

Advanced Waterproofing Technology with IP67/IP68 Protection

The waterproof performance of a cable assembly is critical for ensuring uninterrupted operation in wet, dusty, or outdoor environments. At Sino-conn, we implement advanced sealing technologies such as ultrasonic overmolding, dual-layer sealing rings, and integrated strain relief to meet IP67 and IP68 standards. These techniques guarantee protection against water immersion, high-pressure spray, and particle ingress. Whether used in marine, automotive, or outdoor LED applications, our cables retain full function and reliability. Additionally, each assembly undergoes 100% waterproof testing to validate its performance before shipping, ensuring peace of mind in mission-critical deployments.

- IP67 / IP68 Rated: Withstands immersion in water up to 1 meter (IP67) or continuous submersion (IP68).

- Sealing Technologies: Uses dual-ring seals, hot-melt glue, or molding compound for tight protection.

- Cable-to-Connector Overmolding: Prevents ingress at the weakest point—connector joints.

- 100% Leak Testing: All cables are water-tested before delivery for guaranteed reliability.

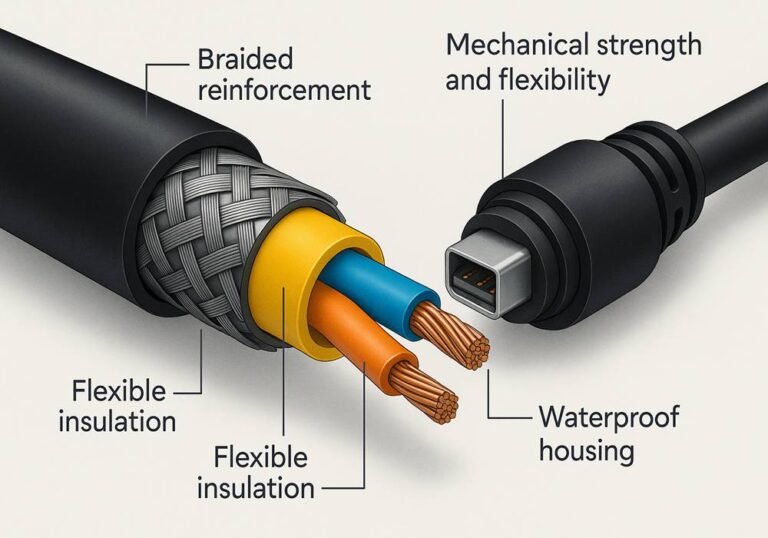

Reinforced Strength and Flexible Construction for Longevity

Mechanical strength and flexibility are key to ensuring that waterproof cable assemblies survive harsh operating conditions like bending, pulling, vibration, and abrasion. At Sino-conn, we design cables with reinforced strain relief, robust outer jackets, and optimized conductor structures to pass over 1 million bending cycles. Our products combine toughness with agility, making them ideal for applications in robotics, automotive harnesses, and outdoor lighting. Whether the cable needs to twist, move, or remain fixed under stress, we engineer it to deliver consistent electrical performance and long mechanical life—no matter how demanding the environment.

- High Flex Life Design: Survives up to 1 million+ bending cycles without fatigue failure.

- Integrated Strain Relief: Reduces tension at connector joints and prevents wire breakage.

- Abrasion-Resistant Jackets: Uses PUR or nylon sheaths to handle rough industrial conditions.

- Flexible Shielding & Core Structure: Ensures consistent signal even during motion.

Certified Compliance with Global Safety & Eco Standards

Compliance with international safety and environmental standards is essential for global distribution and end-user trust. Sino-conn ensures that all waterproof cable assemblies meet rigorous certifications, including UL, ISO9001, ISO14001, RoHS, REACH, COC, COO, and PFAS-Free declarations. Our materials are halogen-free, heavy-metal-free, and manufactured under strict process controls. These certifications not only guarantee the safety and reliability of the product but also support customer approval processes in sectors like medical, automotive, industrial automation, and smart devices. We provide full documentation with every shipment and assist with customer-specific compliance reporting when needed.

UL & ISO Certified: Ensures product safety, process control, and traceable quality.

RoHS & REACH Compliance: No hazardous substances or banned chemicals.

PFAS-Free / Halogen-Free Options: Safe for eco-sensitive and medical applications.

COC, COO, SDS Documents: Provided upon request for seamless import/export.

--- Customized Capabilities Services and Processes

Customize your waterproof cable assembly

Discover Sino-Conn’s customized capabilities, services, and manufacturing processes for waterproof cable assemblies. From fast sampling and detailed CAD drawings to flexible material choices and zero MOQ production, we tailor each solution to meet your exact technical and application needs. Enjoy full design support and rigorous quality control throughout the process.

Customized Capabilities Services and Processes

Customize your waterproof cable assembly

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Tailored Waterproof Cable Assembly to Match Every Detail You Need

At Sino-conn, we understand that every project is unique—so we provide truly flexible and highly engineered customization services for waterproof cable assemblies. Whether your requirement is structural, functional, or environmental, we tailor our solutions from the inside out to ensure perfect fit and performance.

What makes our customization different:

Connector-to-Connector Flexibility

We customize both ends of the cable—different connector types, brands (original or replacement), orientations (straight, angled), and pinouts to match your system.

Cable Construction Personalization

From conductor materials (bare copper, tinned, silver-plated), shielding types (braid, foil), to insulation (PVC, PE, PUR, TPE), every layer can be adapted.

Length, Shape, and Color Customization

Cable length can be defined to the centimeter. Special shapes such as Y-branch, coiled, or panel-mount versions are available. Jacket color can follow your branding or identification needs.

High Performance & Environmental Compatibility

Optional features include UV resistance, flame retardancy, oil resistance, low smoke halogen-free (LSZH), and PFAS-free for medical or industrial requirements.

Rapid Prototyping and Engineering Support

We offer CAD-to-PDF drawings within 30 minutes to 3 days, and support technical refinement throughout development—from samples to production.

Our Commitment to Outstanding Service

At Shenzhen Sino-conn, we don’t just manufacture waterproof cable assemblies—we engineer confidence, efficiency, and peace of mind for every customer. Our end-to-end service process is designed to minimize response time, maximize customization accuracy, and make every step transparent and supportive.

Why our service stands out:

Lightning-Fast Response

Inquiries are answered within hours. For urgent cases, we provide drawings and quotations in as fast as 30 minutes.

Free and Timely Drawing Support

Every customer receives customized CAD + PDF drawings before production. Most drawings are completed within 1–3 working days.

Unlimited Customization Dialogue

Whether you’re a trader or an engineer, we speak your language. Our team communicates clearly across technical, procurement, and business concerns.

No MOQ, No Delay

From one-piece samples to large-volume orders, we guarantee flexible scheduling. Even urgent samples can be produced in 2–3 days.

Video Meetings and Real-Time Support

We offer online meetings with technical staff to review designs, drawings, and even monitor production or testing in real time.

100% Quality Inspection Guarantee

All cables undergo three-stage inspection (in-process, post-assembly, pre-shipping) to ensure absolute reliability.

This is more than service—it’s partnership built on expertise, integrity, and speed.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

“We were developing a new generation of robotic arms for a leading German factory automation line, which required waterproof cable assemblies that could survive continuous bending, exposure to oils, and operate in tight, high-temperature enclosures.

Sino-conn provided far more than just product – they delivered precision engineering. Their team responded to our inquiry within hours, and within 36 hours, we had a complete cable drawing tailored to our specs: double-shielded, PUR jacketed, UL-certified, with custom 90-degree M12 connectors.

We requested urgent samples. They delivered working units in 3 days. Their ability to offer flexibility in connector types, bend radius, and jacket formulation made them stand out.

The end result was a cable that passed 5 million+ bending cycles in our lab without failure. We were impressed.

Their technical support, responsiveness, and quality control gave us absolute confidence. They are now our approved vendor for all waterproof cable needs.”

Lukas Braun,R&D Engineer

Company Location: Stuttgart, Germany

“Our outdoor security systems are installed across U.S. highways, parking lots, and building exteriors. We needed waterproof cable assemblies that could handle extreme sun, rain, snow—and meet UL, RoHS, and REACH certifications.

After being frustrated with our previous supplier’s delays and rigid solutions, we reached out to Sino-conn. From day one, they made it easy. They explained material options like TPE vs. PE, offered drawings in 24 hours, and even joined our engineering meeting via video call.

Their recommendation to use LSZH jackets and PFAS-free insulation met both our environmental compliance and performance needs. We ordered a 500-unit batch. They delivered ahead of schedule.

The cables are now installed in several key projects, and after 6 months of real-world testing—zero issues.

Professional, fast, and flexible. Sino-conn helped us meet tough U.S. standards without compromise.”

Sarah Thompson, Procurement Manager

Company Location: Austin, Texas, USA

“In medical electronics, reliability and precision are non-negotiable. Our latest patient monitoring device required a custom waterproof USB cable—PFAS-free, halogen-free, and with ultra-slim OD to pass through small enclosures.

I reached out to Sino-conn with a 3D STEP file and detailed spec sheet. In just one working day, they returned a clear CAD drawing with suggested improvements. We reviewed and approved it via video call.

The sample arrived in 4 days. The cable was flawless—durable, UL & ISO certified, and the EMI shielding exceeded our test thresholds. Their understanding of medical compliance and ability to customize every layer (from insulation to overmold) was exceptional.

Sino-conn is not just a vendor—they’re a design partner. We trust them fully for future medical projects.”

Hiroshi Tanaka, Senior Engineer

Company Location: Osaka, Japan

industry Application of waterproof cable assembly

Waterproof cable assemblies from Sino-Conn are engineered for reliable performance in demanding environments. Widely used in outdoor electronics, marine equipment, industrial automation, LED lighting, medical devices, and military-grade systems, they ensure stable signal and power transmission even under moisture, dust, and extreme temperature exposure.

Waterproof connectivity for robotic motion control

Application Scenario:

In advanced manufacturing environments such as robotic arms used in automobile production lines, consistent and high-precision motion is critical. These machines operate under high stress, rapid motion, and frequent exposure to dust, lubricants, and sometimes liquid coolant. Cable assemblies must remain secure, sealed, and flexible to maintain uninterrupted signal transmission in this challenging environment.

Equipment & Products

- Articulated robotic arms

- servo motors

- motion controllers

Industry Pain Points:

- Traditional cable assemblies lack flexibility while maintaining waterproof sealing.

- Harsh environmental exposure risks signal degradation and corrosion.

- Continuous motion causes cable fatigue and connector loosening.

Solutions:

- Designed high-flex, IP67-rated waterproof cable assemblies with reinforced strain relief.

- Incorporated PUR sheathing and braided shielding for abrasion, oil, and EMI resistance.

- Custom connector integration with locking mechanisms ensures vibration-resistance.

Outdoor Surveillance Security

Application Scenario:

In modern outdoor security systems, waterproof cable assemblies play a crucial role in connecting surveillance cameras, motion sensors, alarm units, and control panels across wide environmental zones. These systems are installed in residential complexes, industrial parks, and transportation hubs, often exposed to severe weather conditions, UV radiation, and fluctuating temperatures. Waterproof cable assemblies are required not only to maintain consistent signal transmission but also to ensure reliable long-term operation under environmental stress.

Equipment & Products:

- High-definition IP surveillance cameras requiring stable power and data signals.

- PIR (passive infrared) motion detectors and alarm modules for perimeter defense.

- Solar-powered control boxes and wireless access units deployed in remote zones.

Industry Pain Points

- Water intrusion causes corrosion and signal failure, especially in rainy climates.

- Outdoor connectors loosen due to vibration and thermal expansion.

- Compatibility between cables and different brand protocols often causes setup delays.

Solutions:

- Our waterproof cable assemblies use IP67/IP68 rated connectors and UV-resistant jackets.

- Each connection features molded strain relief and locking mechanisms for physical security.

- We tailor cable ends and pin configurations to match major security equipment brands.

Medical-Grade Cable Reliability

Application Scenario:

In hospitals and medical research labs, waterproof cable assemblies are essential for ensuring uninterrupted power and signal transmission in life-saving diagnostic and patient monitoring equipment. These cables must meet the highest standards of safety, cleanliness, and data precision. Exposure to repeated sterilization, disinfection chemicals, and sensitive bioelectrical signals makes ordinary cables unreliable in such demanding environments. Sino-conn’s custom waterproof assemblies are engineered to handle harsh medical conditions while maintaining absolute signal fidelity.

Equipment & Products:

- USB and circular waterproof cables used in patient monitors, defibrillators, and bedside monitoring systems

- Custom cable assemblies for diagnostic probes, imaging sensors, and mobile carts

- Integration into data logging devices, emergency systems, and hospital-grade wearables

Industry Pain Points:

- Toxic material emissions under high-temperature sterilization processes

- Chemical corrosion and degradation from daily cleaning agents

- Signal disruption caused by electromagnetic interference (EMI) and poor shielding

Solutions:

- Use of medical-grade, ROHS/REACH/PFAS-free, and LSZH-compliant cable materials

- Application of TPE, PUR, or silicone jackets to withstand sterilization and chemical exposure

- Multi-layer shielding and impedance-controlled designs to ensure flawless signal transmission

Rugged Connectivity for Critical Surveillance

Application Scenario:

In outdoor security infrastructure—such as parking lots, public parks, smart city projects, and private estates—waterproof cable assemblies play a vital role in maintaining uninterrupted video and power transmission. These environments expose cables to unpredictable weather, UV radiation, moisture, and even vandalism. Installations often span long distances, requiring consistent signal quality without degradation. Sino-conn Technology provides purpose-built waterproof cable solutions that combine environmental durability, stable power delivery, and seamless data transmission for a wide range of security system installations.

Equipment & Products:

- IP67/IP68 waterproof cables for outdoor CCTV cameras, smart access controls, and PTZ camera systems

- Custom-length extension cables with locking connectors for pole or wall-mounted surveillance setups

- Power/data hybrid cable assemblies for solar-powered or PoE-enabled surveillance units

Industry Pain Points:

- Cable degradation from UV exposure, rain, and extreme temperatures

- Unstable signal due to EMI and fluctuating voltage in long-range installations

- Inflexible cable lengths or connector types incompatible with site-specific setups

Solutions:

- UV- and moisture-resistant jackets using PUR or TPE for reliable outdoor longevity

- Enhanced EMI shielding and voltage-stabilized designs for consistent signal and power delivery

- Highly customizable cable length, pinout, and connector configurations for diverse application needs

Corrosion-Resistant Waterproof Cabling for Harsh Marine Conditions

Marine environments—including offshore oil platforms, cargo vessels, coastal patrol boats, and underwater drones—demand waterproof cable assemblies that can survive long-term exposure to salt spray, humidity, vibration, and pressure. Wiring used in shipboard power distribution, sonar systems, navigation equipment, and communication arrays must ensure uninterrupted operation despite corrosive and wet conditions. Sino-conn designs and supplies marine-grade waterproof cables that provide robust sealing, chemical resistance, and durability even under continuous submersion and harsh dynamic loads.

Devices and Products:

- Waterproof cable assemblies for radar, sonar, and navigation terminals

- Hybrid data-power lines for underwater sensors and ROVs (remotely operated vehicles)

- High-flex marine cables for engine rooms, control consoles, and deck machinery

Industry Pain Points:

- Saltwater corrosion and accelerated aging of cable jackets and terminals

- Frequent mechanical stress due to engine vibration, wave impact, or coiling

- Risk of signal attenuation and water ingress at connector joints

Our Solutions:

- Use of marine-grade materials such as tinned copper, fluoropolymer insulation, and TPU jackets

- High-flex and strain-relief designs for dynamic marine motion tolerance

- Double O-ring sealed connectors and molded-overmold solutions for extreme waterproofing

Ruggedized Waterproof Cabling for Outdoor and Urban Systems

Application Scenario:

In smart cities and modern outdoor environments, waterproof cable assemblies play a critical role in ensuring consistent connectivity and power distribution to LED street lights, traffic monitoring cameras, public charging stations, and environmental sensors. These systems must operate reliably across wide temperature swings, rainstorms, UV exposure, and occasional vandalism. Sino-conn provides cable solutions that integrate weather sealing, anti-aging jackets, and modular connector designs to support rapid deployment and long-term stability in municipal infrastructures.

Equipment and Products:

- IP-rated cable assemblies for outdoor LED lighting and traffic signals

- Modular cable harnesses for smart bollards, kiosks, and EV chargers

- UV-resistant and flame-retardant cables for public surveillance systems

Industry Challenges:

- Constant outdoor exposure to moisture, temperature fluctuation, and UV radiation

- Installation complexity in modular and retrofitted street infrastructure

- Downtime risk due to faulty or degraded cables in high-traffic public zones

Our Solutions:

- UV-stabilized TPU or PUR outer jackets and IP68 waterproof sealing technology

- Pre-molded connector ends and plug-and-play cable kits for easy installation

- Triple-stage quality inspection and vibration-resistant assembly methods

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized waterproof cable assembly services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Do you offer customization on both cable ends?

Yes, we can customize both ends with different connectors, pinouts, angles, brands (original or alternatives), and even housing types.

What is your minimum order quantity (MOQ)?

No MOQ. We accept orders starting from 1 piece, including samples and trial runs.

Can you design the cable based on our drawing or specifications?

Absolutely. We can create CAD & PDF drawings based on your specs, often within 30 minutes to 3 days.

Can you match our required brand connectors?

Yes. We offer both original and compatible brand alternatives, depending on your budget and delivery urgency.

Do your cables support UV and oil resistance?

Yes, we offer jackets like PUR and TPE that are resistant to UV, oil, and harsh environments.

How fast can I get a sample?

Urgent samples can be delivered within 2–3 working days. Standard sample lead time is around 2 weeks.

What certifications do your products meet?

Our products meet UL, ISO, RoHS, REACH, PFAS-free, and can provide COC, COO upon request.

Can you provide waterproof connectors with IP67/IP68?

Yes. Most of our waterproof cables use IP67/IP68 rated connectors to ensure long-term durability.

What type of shielding do you offer?

We offer foil, braid, or combination shielding based on your EMI/EMC requirements.

Can I request a PFAS-free solution for medical use?

Yes, we support PFAS-free cable assemblies for medical and environmentally regulated industries.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China