Custom Receptacle Comnectors manufacturer

Looking for a connector partner who truly understands your design challenges? At Sino-conn, we specialize in high-precision Receptacle Connectors that power next-generation devices with unmatched reliability and customization. Whether you’re an R&D engineer seeking tailored pinouts, or a procurement officer in need of urgent delivery, we’ve got you covered.

Our connectors are trusted across industries from consumer electronics to aerospace, designed for signal integrity, space-saving performance, and seamless assembly. With over 10 years of experience and a library of thousands of models, we deliver more than components—we deliver confidence.

Let us help you bring your ideas to life—fast.

Why choose Receptacle Comnectors from sino-conn

Choose receptacle connectors from Sino-conn for unmatched reliability, precision engineering, and tailored solutions. Our connectors deliver consistent performance across demanding environments, featuring superior durability, EMI shielding, and compliance with global standards. Backed by fast sampling, flexible customization, and strict quality assurance, Sino-conn ensures your projects stay on schedule with products designed to meet exacting specifications.

Ultra-Thin Micro Coaxial Cable for Space-Constrained Electronics

Our micro coaxial cables are engineered with ultra-thin diameters—starting from as low as 0.2mm—making them ideal for space-limited applications like smartphones, medical devices, and aerospace modules. Despite their compact size, these cables ensure stable high-frequency signal transmission with minimal loss. Their flexibility and precision help engineers design smaller, more powerful, and tightly integrated systems without compromising performance.

Fully Customizable Micro Coaxial Cable for Unique Design Requirements

We offer full customization for our micro coaxial cables, including cable length, pin configuration, jacket material, shielding structure, connector type, and layout. Whether you need non-standard pinouts, medical-grade sheathing, or brand-specific connectors like I-PEX or Hirose, we can tailor every detail to fit your product design and application needs—without MOQ. Custom drawings and samples are delivered in as fast as 30 minutes.

High-Frequency, Low-Loss Signal Transmission for Reliable Data Integrity

Our micro coaxial cables support stable high-frequency signal transmission with ultra-low attenuation, making them perfect for applications like 5G modules, medical imaging, and high-resolution video systems. With controlled impedance and superior EMI shielding, our cables ensure reliable signal integrity even in high-noise environments. Engineers can trust our cables for mission-critical performance without compromise.

100% Quality Inspection with Triple Testing Procedures

Every micro coaxial cable we produce undergoes triple-stage quality control: in-process inspection, final assembly testing, and pre-shipment verification. Our professional QC team uses advanced equipment to ensure zero-defect delivery. From electrical performance to physical durability, every cable is thoroughly tested for reliability. Quality assurance isn’t optional—it’s our standard.

Fast Samples and On-Time Delivery for Urgent Projects

We understand time-sensitive projects. That’s why we offer rapid sampling—within 2–3 days—and batch delivery in as fast as 2 weeks. Urgent prototypes? No problem. Our streamlined production and engineering teams are ready to meet tight deadlines with precision and consistency, ensuring your project moves forward without delay.

Supports Multiple Connector Types and Custom Pin Configurations

Our micro coaxial cables are compatible with a wide range of high-frequency board-to-cable connectors. Whether you require standard plug types or custom-tailored pin configurations, we can assemble and test to your exact design. Both original-grade and equivalent-quality connector options are available to match your cost, delivery, and performance requirements—ensuring excellent fit and signal reliability.

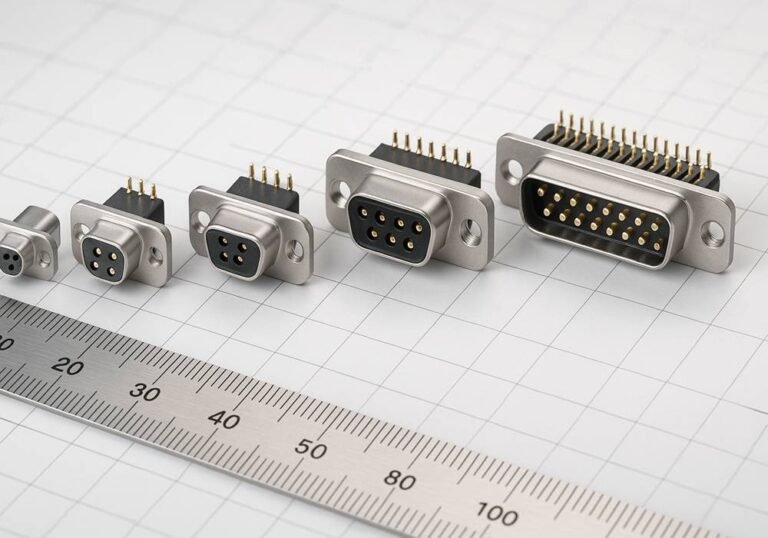

Detailed specifications and parameters of Receptacle Comnectors

| Definition (Pin Configuration) | Connector Model | Cable Spec | Length (mm) | Covering Type | Covering Material | |

|---|---|---|---|---|---|---|

| 1 | 1.0mm Pitch, Single Row | SM-RCP1001 | UL1571 28AWG | 150 | Flat | Conductive Fabric |

| 2 | 0.5mm Pitch, Dual Row | SM-RCP0502 | UL1007 30AWG | 120 | Molded | Teflon Sleeve |

| 3 | 1.25mm Pitch, Single Row | SM-RCP1251 | UL2464 26AWG | 200 | Round | PVC Sleeve |

| 4 | 0.8mm Pitch, Dual Row | SM-RCP0802 | UL20276 32AWG | 180 | Flat | Nano Tape |

| 5 | 1.0mm Pitch, SMT Type | SM-RCP1003-SMT | UL2651 28AWG | 250 | Molded | Nylon Mesh |

| 6 | 2.0mm Pitch, Vertical Type | SM-RCP2001V | UL2517 24AWG | 100 | Round | Acetate Cloth |

| 7 | 0.4mm Pitch, Board-to-Board | SM-RCP0401-B2B | UL1007 30AWG | 80 | Molded | Teflon Tape |

| 8 | 1.27mm Pitch, IDC Type | SM-RCP1271-IDC | UL2651 26AWG | 300 | Flat | Conductive Fabric |

| 9 | 1.5mm Pitch, Right Angle | SM-RCP1501-RA | UL1571 28AWG | 220 | Molded | PVC Sleeve |

| 10 | 0.3mm Pitch, Ultra Fine Pitch | SM-RCP0301-UF | Custom FPC | 90 | Flat | Nano Tape |

Customizable Precision for Every Connection Need

At Sino-conn, we understand that every application has its own unique requirements. While the technical parameters listed above showcase our most commonly produced Receptacle Connector models, we pride ourselves on our unmatched customization capabilities. Whether you need specific pin configurations, uncommon cable types, precise lengths, or special covering materials to meet environmental or mechanical constraints—our engineering team is equipped to tailor every detail to your specification.

From rapid prototyping to full-scale production, we offer CAD drawings within hours and sample delivery in just a few days. We support zero MOQ, offer both original and alternative connector options, and ensure 100% quality inspection throughout the process. If you have an idea, drawing, or requirement—we can turn it into reality.

Customized Receptacle Comnectors styles

Trusted by 300+ global brands,1000+ styles have been developed.

DF13 High Temperature Resistant 125'C Engine Compartment Wiring Harness

HRS DF11-32DEP-2C Circular Connector-32Pin IP67, UL Certifed For industrial Control

DF14 Series SMT Connector-30AWG Tinned Copper, 80'C30V Rating,VW-1 Flameproof

Product details display of Receptacle Comnectors

Discover the product details of Sino-conn receptacle connectors, designed with precision to meet diverse industrial needs. From material composition and dimensions to voltage, current, shielding, and durability, each connector is engineered for high performance and reliability. Explore comprehensive specifications to ensure the perfect fit for your applications.

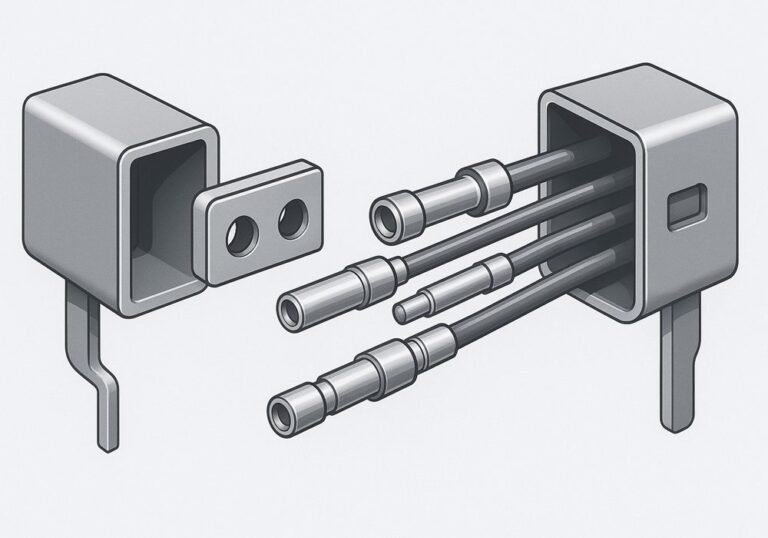

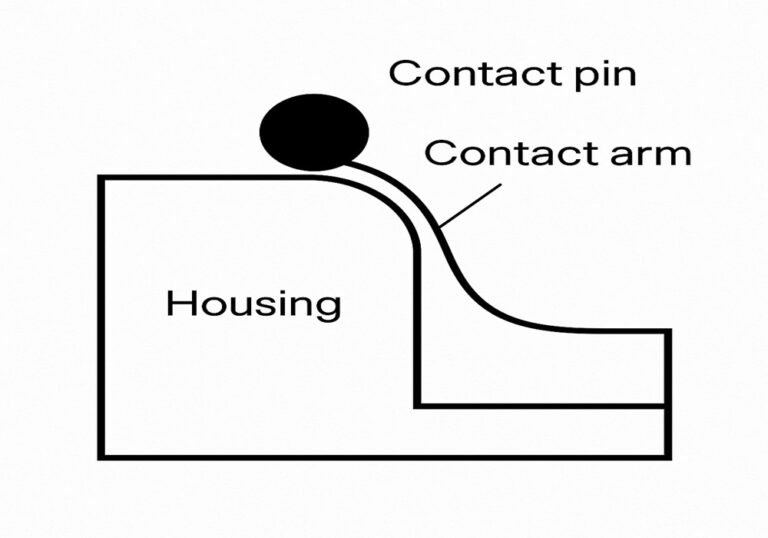

High-Precision Structural Design

Our Receptacle Connectors feature high-precision internal structures designed to ensure perfect mating with their corresponding plugs. Every contact point is crafted using advanced precision engineering to support consistent performance and long-term durability.

- Precision Fit: Each socket is finely tuned for high-accuracy insertion, guaranteeing stable signal transmission and reliable current flow.

- Metallic Contact Elements: The core contact pins are made from corrosion-resistant alloys that enhance longevity and prevent signal loss.

- Anti-Backlash Design: The locking mechanism and internal guiding features eliminate backlash and prevent disconnection under vibration or movement.

- Compact Assembly: Designed to fit tightly in compact equipment layouts, allowing for maximum space efficiency and modular flexibility.

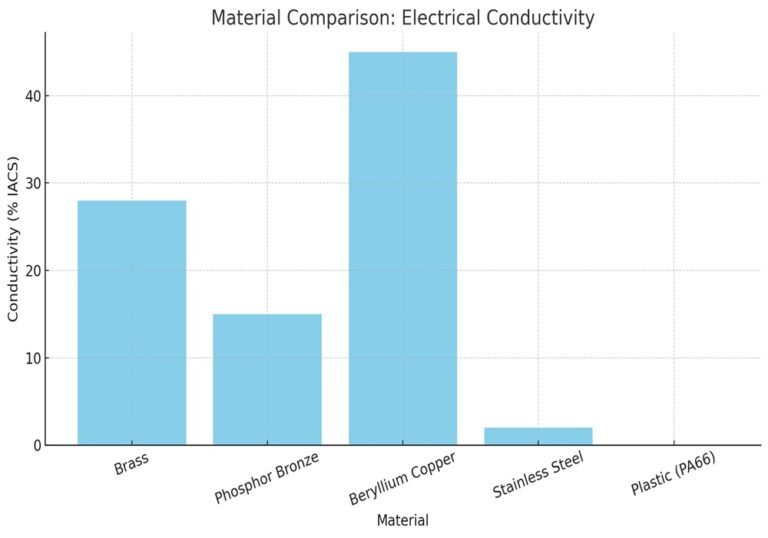

Multi-Material Composition Options

Our Receptacle Connectors offer flexible material options to accommodate a wide range of operating environments and technical demands:

- Contact Materials: Options include phosphor bronze, silver-plated copper, or gold-plated brass to provide excellent conductivity and anti-oxidation resistance.

- Housing Materials: Commonly used housings are made from high-performance engineering plastics such as PBT, PA66, and LCP, known for their durability, flame resistance, and thermal stability.

- Environmental Resistance: Custom materials can be selected to meet specific conditions like UV exposure, oil resistance, flame retardancy (UL94V-0), and high-temperature operation.

- Halogen-Free & PFAS-Free: We support eco-friendly options that meet RoHS, REACH, and other international environmental regulations.

With such versatility, our connectors are ideal for automotive, aerospace, industrial, and consumer electronics applications.

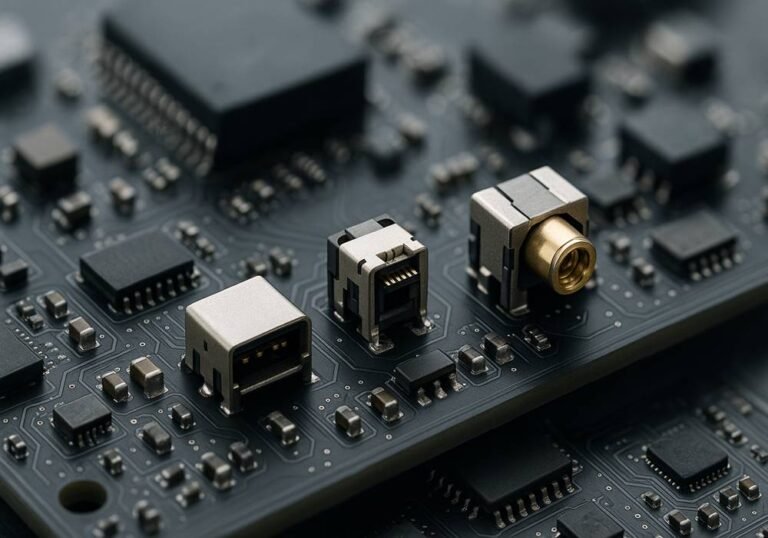

Seamless Integration Performance

Our Receptacle Connectors are engineered for seamless integration into modern electronic systems:

- Standard Interface Matching: Adheres to widely used standards like USB, RJ45, SMA, and D-sub for universal compatibility.

- Modular Assembly: Designed for flexible installation with snap-in, screw-lock, or panel-mount options, reducing time and tooling costs.

- PCB and Cable Compatibility: Supports both direct-to-board and cable-end terminations with minimal signal loss.

- Compact Mounting Footprints: Ideal for dense environments such as handheld devices or compact control systems.

This level of integration simplifies production workflows and ensures faster time-to-market for OEMs and product developers.

Accurate Specs and Comprehensive Options

Every Receptacle Connector we offer is specified with full technical data to meet exact engineering needs:

- Dimensions & Pin Count: Customizable in length, width, and number of poles

- Cable OD & Impedance: OD ranges supported from 2mm to 14mm; matched to 50Ω/75Ω impedance if needed

- EMI Shielding: Multi-layer braided copper shielding optional for critical signal environments

- Flame Resistance & Temperature Tolerance: Supports -40°C to +125°C, UL94V-0 certified materials

- Chemical Resistance: Oil-proof, UV-proof, halogen-free, PFAS-free compliant

You can rely on our detailed specifications to select the ideal solution for your engineering challenge.

Certified to Global Standards

We back every Receptacle Connector with globally recognized certifications:

- UL and ISO9001: Compliant with international safety and quality management standards

- RoHS & REACH: Environmentally responsible and fully compliant with EU directives

- COC (Certificate of Conformance) & COO (Country of Origin): Available for logistics and regulatory transparency

- Optional PFAS & Halogen-Free Declarations: Provided based on project requirements

Certifications ensure product credibility and help customers meet import/export and compliance needs worldwide.

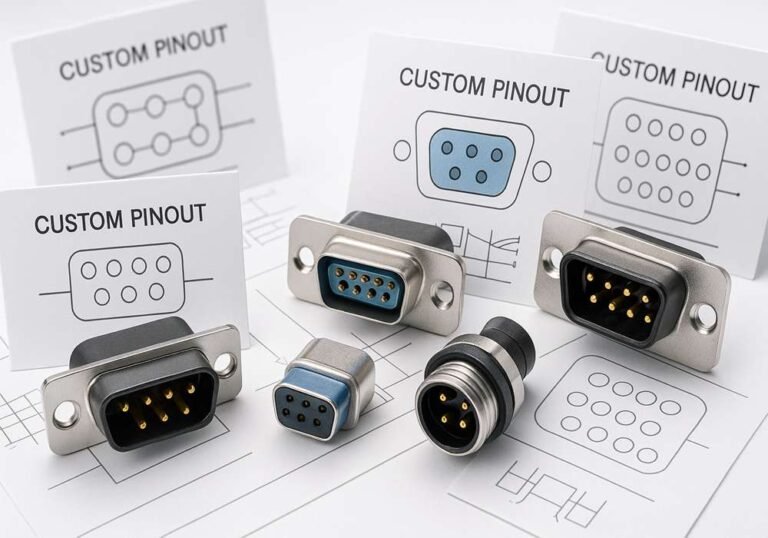

Fully Customizable, Tailored to Fit

Our Receptacle Connectors are designed with full customization capability, supporting unique customer requirements:

- Custom Pinouts: Adjustable pin configurations to meet circuit design needs

- Housing Modifications: Tailored shapes, textures, and materials upon request

- Cable Assembly Options: Flexible connectivity design on both ends, including different connector types

- Length and Orientation: Any cable length, angle, or side-entry/vertical alignment configurations

- Rapid Prototyping Support: Drawings within 30 minutes, with CAD-to-PDF conversion and full client confirmation before production

This flexibility ensures optimal fit for everything from R&D prototyping to mass production scenarios.

--- Customized Capabilities Services and Processes

Customize your Receptacle Comnectors

Sino-conn offers comprehensive customized capabilities, services, and processes to meet your unique connector and cable requirements. From design consultation and material selection to prototyping, mass production, and rigorous testing, we provide end-to-end solutions. Our flexible approach ensures precise specifications, fast turnaround, and reliable performance tailored to your project needs.

Customized Capabilities Services and Processes

Customize your Receptacle Comnectors

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, we pride ourselves on delivering highly customized Receptacle Connector solutions tailored to meet the exact needs of each customer. Whether the requirement involves unique pin-out configurations, specific cable lengths, housing materials, EMI shielding, or orientation adjustments, we can adapt quickly and precisely.

Our engineering team works hand-in-hand with clients from the early inquiry phase through final production. We provide full CAD design services, including 2D and 3D drawings, with rapid turnaround—often within 30 minutes. We also support a wide range of connector types (USB, RJ45, SMA, D-sub, etc.), with full compatibility and mechanical re-engineering available.

Customization options include:

- Pin assignment reconfiguration

- Cable length and routing direction

- Dual-end connector type matching

- Specialized materials (UV-proof, flame-retardant, oil-resistant)

- Overmolding, heat shrink, or braided cable finishing

- Branding options for housing or label printing

Most importantly, there’s no minimum order quantity (MOQ). Whether it’s a one-off prototype or bulk production, we deliver with equal attention to detail. Our flexible design and manufacturing system ensures that even the most unconventional specifications can be realized in 2–4 weeks.

Our Commitment to Outstanding Service

Customer satisfaction is at the core of everything we do. At Sino-conn, we offer industry-leading service levels designed to support our clients every step of the way—from the first inquiry to post-shipment support.

Our technical sales team responds to inquiries within 1 hour and provides professional consultation, helping even less-technical clients understand options and trade-offs. We also offer fast quote and drawing delivery—most within 30 minutes, with complex customization specs returned in under 3 days.

Clients can expect:

- Real-time video support for technical discussions or product demos

- Direct access to engineers for R&D consultation

- Flexible communication via email, chat, Zoom, or WhatsApp

- Transparent order tracking from prototyping to logistics

- Full document support: specification sheets, certificates (UL, RoHS, REACH), COC/COO, and compliance declarations

Our 100% quality inspection process (pre-production, in-process, and final QC) ensures product consistency. Should any issue arise, we offer rapid replacement, technical review, and on-call troubleshooting.

Whether you’re a trading company, OEM, or end-user engineer, we adapt to your workflow and speak your language—technically and professionally. With no MOQ, fast delivery, and a team that truly listens, we’re more than a vendor—we’re your strategic partner.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Case 1 – Automotive BMS Connector

“We had a critical need for a power connector alternative in our BMS control module. The original European supplier was slow, expensive, and unwilling to adapt the pin layout. Sino-conn not only provided a custom layout that fit our PCB perfectly, but also delivered a validated EMC-compliant sample in 2 weeks. Their mass production hit our deadline in under a month. Truly professional and solution-oriented!”

Michael Bauer

Stuttgart, Germany – Automotive Harness R&D Engineer

Case 2 – Railway Signal System

“Our project required ruggedized connectors with flame resistance, low-temperature tolerance to -40°C, and full GOST compliance. Sino-conn quickly tailored the materials and structure to meet all specifications. Even under Russian winter field conditions, the connector’s performance was excellent. Documentation and communication were flawless. We’re now considering them for all future railway interface needs.”

Elena Petrova

Moscow, Russia – Project Buyer, Railway Systems Integrator

Case 3 – Medical Imaging Equipment

“In our MRI development, we needed ultra-low noise, compact receptacle connectors that wouldn’t interfere with signal paths. Sino-conn’s team worked closely with us to fine-tune the shielding and provided gold-plated, EMI-protected designs. Drawings were delivered in 30 minutes, samples in 3 days. Their support was on par with the best U.S. vendors—at half the cost.”

Dr. Ethan Chang

San Jose, USA – Lead System Engineer, Medical Imaging Startup

industry Application of Receptacle Comnectors

Receptacle connectors from Sino-conn are widely applied across industries such as automotive, aerospace, telecommunications, medical devices, and consumer electronics. Engineered for durability, EMI shielding, and secure connectivity, they ensure reliable performance in demanding environments, supporting seamless power and data transmission for critical industrial applications.

Solution 1: High-reliability, vibration-resistant receptacle connectors

Application: Automotive electronics wiring harnesses for ECU, BMS, and infotainment modules

Devices & Products: Engine control units, battery management systems, dashboard infotainment systems, parking sensors

Industry Requirements: Automotive environments demand connectors that can withstand extreme temperatures (-40°C to 125°C), vibrations, and electromagnetic interference. There is also a growing need for miniaturized connectors to reduce vehicle weight.

Our Solution:

Our connectors are designed with snap-lock and vibration-proof structures.

We use UL94V-0 rated flame-retardant materials and provide optional EMI shielding.

Custom layouts are supported for multi-pin configurations.

All units are tested for vibration resistance and signal continuity under harsh conditions.

Solution 2: High-cycle durability receptacle connectors for factory automation

Application: Industrial robotics, sensors, PLC systems, and servo drives

Devices & Products: Robotic arms, conveyor sensors, machine vision systems, PLC cabinets

Industry Requirements: Demands include resistance to repetitive motion stress, oil/chemical exposure, and quick disconnection capability for modularity. Space-saving layouts are also critical in robotic arms.

Our Solution:

Our connectors support >10,000 mating cycles.

Made with oil-resistant TPU jackets and corrosion-proof housing.

Available in compact right-angle and straight configurations.

Fast-release lock designs help during maintenance.

Solution 3: Low-noise, EMI-shielded connectors for signal-sensitive equipment

Application: Imaging and diagnostic machines

Devices & Products: MRI machines, ultrasound devices, portable ECG monitors, surgical robots

Industry Requirements: Must ensure accurate signal transmission with no interference, bio-safe materials, and sterile handling. Compact and lightweight design is also a priority.

Our Solution:

Gold-plated contacts and multi-layer EMI shielding reduce noise.

Medical-grade, biocompatible materials used for housings.

Connectors delivered in ESD-safe and sterile packaging.

Support for fine-pitch, high-density pin configurations.

Solution 4: Lightweight, temperature-stable receptacle connectors for avionics

Application: Avionics systems and drone control interfaces

Devices & Products: Flight control units, drone navigation systems, aerospace data links

Industry Requirements: Requires minimal weight, resistance to wide temperature ranges, and rugged mechanical stability in high-altitude pressure conditions.

Our Solution:

Custom connectors using LCP and aluminum alloy housings

High-altitude pressure testing up to 60,000 feet

Supports MIL-grade environmental sealing

Designed for secure locking under vibration and shock

Solution 5: UV- and corrosion-resistant connectors for outdoor installations

Application: Solar panel strings, wind turbine control boxes, energy storage modules

Devices & Products: Solar inverters, junction boxes, power controllers, battery racks

Industry Requirements: Outdoor conditions with strong UV exposure, rain, humidity, and temperature changes. Also requires safe handling of high-voltage/current lines.

Our Solution:

IP67 waterproof designs and anti-UV plastic compounds

Corrosion-resistant pin plating

Complies with IEC and TUV solar connector standards

Flame-retardant, halogen-free cable jackets optional

Solution 6: Aesthetic, compact, and easy-to-install receptacle connectors

Application: Smart home hubs, consumer electronics, wearable devices

Devices & Products: Smart speakers, IoT gateways, indoor sensors, AR/VR gear

Industry Requirements: Clean design integration, low-profile connectors, safe for indoor consumer use. Rapid assembly and ease of replacement.

Our Solution:

Sleek, matte-finish low-profile housing

Color-matching options for enclosures

Plug-and-play installation with soft-locking features

Optional logo/branding service on connector shell

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized Receptacle Comnectors services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can you customize receptacle connectors based on our drawing or specifications?

Yes, we offer full customization including layout, pinout, materials, and cable structure. Drawings (CAD to PDF) can be delivered in 30 minutes to 3 days depending on complexity.

What certifications do your receptacle connectors support?

We provide UL, ISO, RoHS, REACH, PFAS, COC, and COO upon request. Most standard parts are already certified.

What is the lead time for samples and bulk orders?

Sample lead time is 2 weeks; urgent samples can be ready in 2–3 days. Bulk production takes 3–4 weeks, or as fast as 2 weeks for rush orders.

Do you have a MOQ (Minimum Order Quantity)?

No MOQ. We accept orders starting from just 1 piece.

Can you offer alternative connectors instead of original brands?

Yes. We provide original and replacement solutions. Replacements are lower cost, faster to deliver, and have excellent compatibility.

What materials are used in your connectors?

We use flame-retardant plastics (UL94V-0), brass or phosphor bronze contacts, optional gold plating, and halogen-free cable jackets.

How do you ensure quality?

All products undergo triple inspection: in-process, final inspection, and pre-shipment. 100% are tested for electrical performance.

Can you draw and confirm design before production?

Absolutely. All orders receive a final drawing confirmation before manufacturing begins.

Do you offer OEM or logo branding on connectors?

Yes, we offer OEM services and can add customer logos on connector shells or packaging.

How fast can I get a quote and drawing?

For standard requests, we can quote and send drawings within 30 minutes during working hours.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China