custom semi rigid cable assemblies manufacturer

Precision-engineered semi rigid cable assemblies designed for high-frequency signal stability and EMI protection. Available in SMA, SMP, and custom connectors, with rapid prototyping and 100% inspection. Perfect for aerospace, test systems, and advanced RF applications.

Why choose semi rigid cable assemblies from sino-conn

Choose semi rigid cable assemblies from Sino-Conn for unmatched precision, superior EMI shielding, and full customization flexibility. Whether you require high-frequency performance, tight bending radii, or military-grade durability, our assemblies are engineered to meet the most demanding requirements. Backed by fast prototyping, no MOQ, and comprehensive certifications, Sino-Conn is your trusted partner for quality and reliability in critical signal transmission applications.

Exceptional EMI Shielding with Solid Copper Outer Conductor

Our semi rigid cable assemblies feature a seamless solid copper outer conductor, offering unmatched EMI shielding and superior RF performance. The rigid structure prevents signal leakage, minimizes interference, and is ideal for high-frequency applications where signal integrity is paramount—such as radar, aerospace, and precision test systems.

Custom Pre-Bending for Precise Routing in Tight Spaces

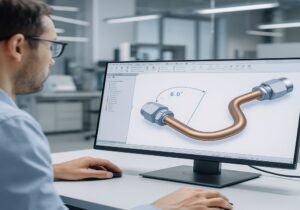

Our semi rigid cable assemblies can be pre-bent to exact shapes according to your CAD drawings or design specifications. This allows for precise installation in compact or high-density environments such as aerospace payloads, RF modules, or test instruments, eliminating the need for post-installation adjustments and improving system reliability.

High Frequency Performance up to 110GHz Applications

Built for demanding RF and microwave environments, our semi rigid cable assemblies support frequencies up to 110GHz, depending on the cable diameter and connector type. Ideal for mmWave, radar, satellite, and 5G testing systems, these cables ensure minimal insertion loss, consistent impedance, and signal clarity in ultra-high frequency transmission.

Flexible Connector Options: Original Brands or Cost-Effective Equivalents

We provide both genuine branded connectors and reliable equivalent alternatives based on your needs. Original parts ensure maximum compatibility for high-volume projects, while alternatives offer cost savings and faster lead times. Our team will guide you to the best choice—balancing performance, budget, and availability—so you never face production delays or supply risks.

Rapid Prototyping: Drawings and Samples Ready in 3 Days

We understand time is critical. That’s why we offer 30-minute CAD drawings and 3-day sample turnaround for most semi rigid cable assembly projects. Whether you need revisions, PDF documentation, or custom routing plans, our team works fast without compromising precision—ideal for engineers, R&D teams, and urgent project timelines.

Strict Quality Control: Triple Inspection Before Shipment

Every semi rigid cable assembly we deliver undergoes three rounds of 100% inspection—during production, after assembly, and before shipment. We check for electrical performance, connector integrity, bend accuracy, and visual quality. This ensures each product meets our high standards and arrives ready for critical applications in aerospace, telecom, and defense systems.

Detailed specifications and parameters of semi rigid cable assemblies

| No. | Definition (Pin Mapping) | Connector Model | Cable Spec | Length (mm) | Jacket Form | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | SMA male to SMA male | SMA(M)-SMA(M) | Custom | Custom | Round | Teflon tubing |

| 2 | SMP female to SMP female | SMP(F)-SMP(F) | Custom | Custom | Round | PVC sleeve |

| 3 | SMA male to 2.92mm male | SMA(M)-2.92(M) | Custom | Custom | Round | Nylon braided mesh |

| 4 | Right angle SMA to SMA | SMA(M)-SMA(M) RA | Custom | Custom | Molded | Conductive fabric |

| 5 | N-type male to SMA female | N(M)-SMA(F) | Custom | Custom | Round | Teflon tape |

| 6 | SMPM male to SMPM male | SMPM(M)-SMPM(M) | Custom | Custom | Flat | PVC tubing |

| 7 | MCX male to SMA male | MCX(M)-SMA(M) | Custom | Custom | Round | Acetate cloth |

| 8 | SMA female to 2.4mm male | SMA(F)-2.4(M) | Custom | Custom | Round | Nano adhesive wrap |

| 9 | QMA male to QMA male | QMA(M)-QMA(M) | Custom | Custom | Molded | Teflon sleeve |

| 10 | SMP female to 3.5mm male | SMP(F)-3.5(M) | Custom | Custom | Round | Shielded fabric tape |

The specifications listed above are just a small part of our semi rigid cable assembly portfolio. In reality, over 90% of our orders are custom-made based on unique customer requirements. Whether it’s a specific connector combination, a precise cable routing angle, or special shielding materials, we tailor each cable to your application environment and engineering goals. Our flexibility and engineering support make us a trusted partner for R&D teams, OEMs, and global integrators.

Customized semi rigid cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

Semi Rigid RF Cable Assembly U-Shape SMA Male to SMA Male 086 Coax

Semi Rigid RF Cable Assembly SMA to SMP

Semi Rigid RF Cable Assemblies U.FL Male to Male

Semi Rigid RF Cable Assemblies SMA Male Straight to SMA Male Right Angle

Semi Rigid Coax Cable SMA Male to SMA Male – Semi Rigid Cable Assemblies

Semi Rigid Coax Cable Assembly SMA Male to SMA Male Red 141 Coax

Semi Rigid Coax Cable Assemblies SMA Female Bulkhead to SMA Male Right Angle

Semi Rigid Coax Assemblies SMA Male to IPEX Micro Coax Connector

High Power RF Semi Rigid Cable Assemblies SMA Male to N-Type Male

086 Semi Rigid Coaxial Cable SMA Male to SMA Male – Semi Rigid Cable Assemblies

086 Semi Rigid Coaxial Cable SMA Male to Male

086 Semi Rigid Coax Cable SMA Male to Right Angle Assembly

086 Semi Rigid Coax Cable Assembly BNC Male to Male

Product details display of semi rigid cable assemblies

Our product details display of semi rigid cable assemblies offers a clear overview of key specifications including connector types, cable diameter, impedance, shielding structure, and bend radius. Each product is shown with high-resolution images, dimension drawings, and material options to help you evaluate performance and compatibility for RF, microwave, or high-frequency signal applications.

Solid Copper Outer Conductor Shielding

The semi rigid cable assemblies from Shenzhen Sino-conn use a solid copper outer conductor to provide unmatched EMI shielding and mechanical strength. This rigid shielding layer is essential in high-frequency applications where signal clarity is critical. The solid copper construction not only ensures consistent impedance but also acts as a mechanical backbone to maintain shape and resist damage. As a result, the cable performs reliably even in environments with severe electromagnetic interference, such as aerospace modules, radar systems, or high-speed test instruments.

- Provides superior EMI and RFI shielding for clean signal transmission.

- Maintains cable shape and mechanical integrity under stress or vibration.

- Improves insertion loss and VSWR stability across frequency bands.

- Ensures long-term reliability in aerospace and defense systems.

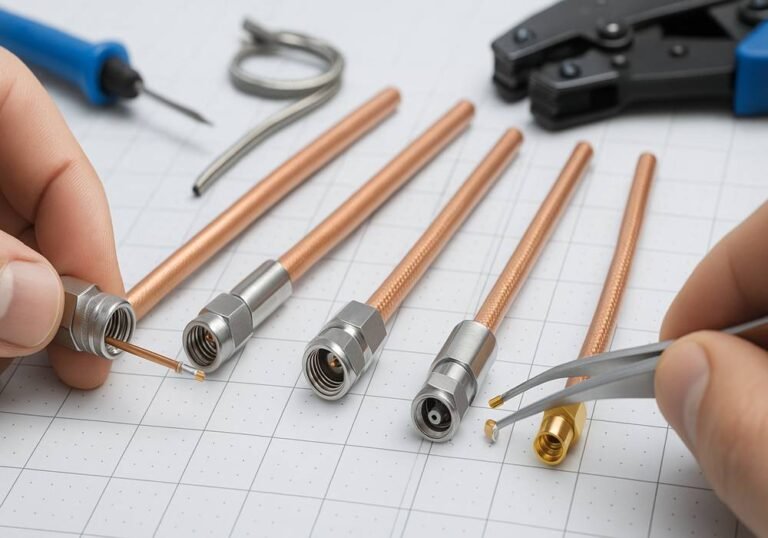

Precision-Bent Cable Geometry Control

Our semi rigid cable assemblies are custom-bent to exact specifications based on your CAD files or mechanical layout. This precision-controlled geometry is critical for installations in high-density or confined environments, such as RF modules, radar subsystems, or aerospace payloads. Each bend is accurately programmed and formed using CNC-controlled tooling to eliminate on-site guesswork and ensure reliable signal alignment. The result is a clean, repeatable layout that saves time, improves signal performance, and ensures system reliability.

- CNC pre-bending ensures tight and consistent bend radius.

- Supports multi-axis routing inside compact modules.

- Reduces manual errors during installation or retrofitting.

- Perfect for aerospace, defense, and satellite enclosures.

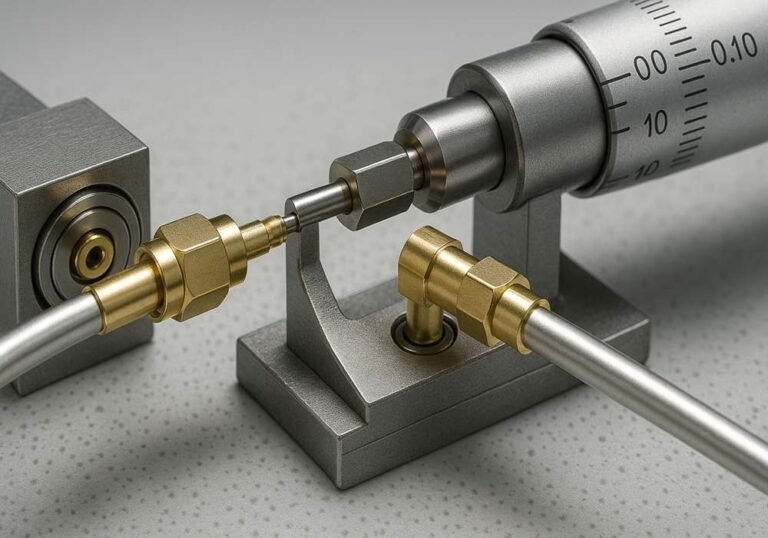

Connector Interface Options and Tolerances

Our semi rigid cable assemblies are compatible with a wide variety of RF connectors, including SMA, SMP, 2.92mm, MCX, and QMA types. Each connector is professionally terminated using high-precision crimping or soldering methods that guarantee excellent electrical continuity and mechanical integrity. We support both original-brand and equivalent connectors to meet varying project needs. Tolerances are tightly controlled to ensure impedance consistency and optimal VSWR performance, even under repeated mating cycles in demanding applications like defense, aerospace, and high-frequency lab test systems.

- Compatible with standard and custom RF connector types.

- Tight mechanical tolerance ensures repeatable mating accuracy.

- Low VSWR and insertion loss at critical junction points.

- Available with original or cost-efficient equivalent connectors.

High Frequency Range up to 110GHz

Our semi rigid cable assemblies are engineered to support ultra-high frequencies—up to 110GHz depending on the connector and cable type. This makes them ideal for mmWave, radar, satellite, and 5G test systems where signal loss and phase stability are critical. We use low-loss dielectrics and ultra-precise conductors to minimize insertion loss and maintain consistent impedance throughout the signal path. Every high-frequency assembly is tested with vector network analyzers to ensure reliable VSWR and return loss at specified frequencies.

- Supports DC to 110GHz transmission with stable performance.

- Perfect for mmWave, VNA, 5G, radar, and RF test systems.

- Low insertion loss and superior phase stability.

- Verified with full-spectrum S-parameter test reports.

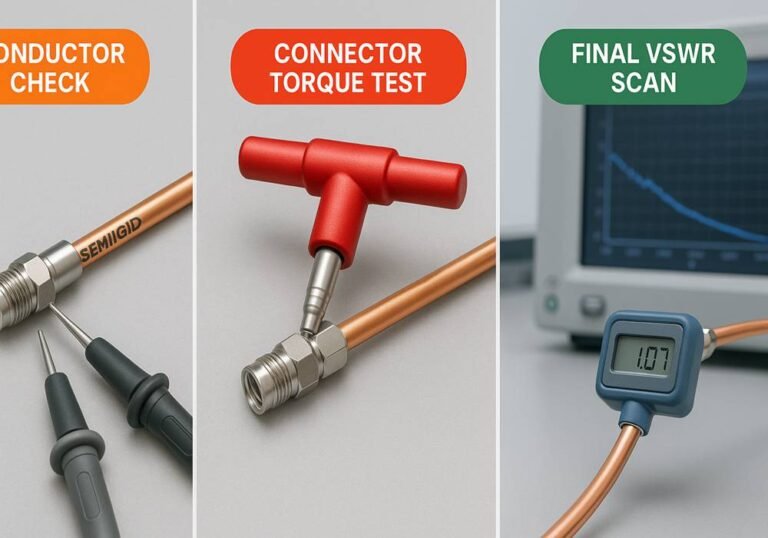

Triple Quality Inspections Before Shipping

Every semi rigid cable assembly we produce undergoes three full stages of quality inspection to ensure perfect performance and consistency. From raw cable and conductor validation, through connector assembly testing, to final VSWR and appearance checks, each step is documented and traceable. Our technicians use calibrated instruments to verify electrical characteristics, mechanical strength, and visual conformity. With serialized inspection records provided, our customers are assured that each product shipped has passed stringent quality control protocols for mission-critical RF systems.ility.

- Initial inspection of cable and shielding continuity.

- Mid-process check of connector installation and torque.

- Final full test for VSWR, insertion loss, and appearance.

- Each assembly is traceable with a unique inspection code.

Flexible Jacket and Coating Material Options

While semi rigid cables are inherently shielded by their solid metal construction, we offer a wide selection of optional outer jackets and coating materials. These include Teflon tubing, PVC sleeves, nylon braided mesh, conductive fabric, and nano adhesive tape. Such coatings not only enhance environmental resistance but also assist with color coding, abrasion protection, and routing identification. Whether you need flame retardant, UV-resistant, oil-proof, or high-temperature materials, we tailor the jacket type to your exact application environment—without compromising electrical performance or form factor.

- Available materials: Teflon, PVC, acetate, nano tape, braided nylon.

- Supports round, flat, or molded jacket forms.

- Adds mechanical protection and visual routing clarity.

- Helps meet UL94, RoHS, REACH, or customer-specific standards.

--- Customized Capabilities Services and Processes

Customize your semi rigid cable assemblies

Explore our customized capabilities, services, and processes designed for precision semi rigid cable assemblies. From connector selection, cable routing, and EMI shielding to high-frequency optimization, we provide tailored engineering support, fast prototyping (as quick as 2–3 days), and detailed CAD drawings. Our end-to-end service ensures full control over material, length, pinout, and performance—meeting exact requirements with zero MOQ and strict quality inspection at every stage.

Customized Capabilities Services and Processes

Customize your semi rigid cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, customization is not an extra service—it’s our core strength. For every semi rigid cable assembly we produce, our goal is to meet the exact technical and structural requirements of each client, no matter how complex or specific.

- Connector Flexibility: We support a wide range of connector types and brands, including SMA, SMP, QMA, 2.92mm, and more. We can mix interfaces, customize pin-outs, or match incompatible models with high precision.

- Structure Customization: From cable length to bend angle, from shielding type to coating material, every assembly can be uniquely tailored using CAD drawings and CNC equipment.

- Material & Compliance: We offer full material traceability and support RoHS, REACH, ISO9001, UL, and COC/COO certification based on request.

- Engineering Support: Clients can receive technical drawings within 30 minutes, and 3D simulation before sampling. We also support technical feedback during design iterations.

- Quantity Flexibility: Whether you need 1 prototype or 10,000 units, we support no MOQ and provide consistent quality from sample to mass production.

With deep RF experience and a flexible manufacturing system, we don’t just build cables—we deliver solutions. Our custom assemblies are engineered to solve your problems, not just fit your specs.

Our Commitment to Outstanding Service

At Sino-conn, we believe that excellent service is just as important as product performance. Our clients work on high-stakes, precision-driven projects—and we treat their needs with equal urgency and dedication.

- Speed First: We deliver 2D drawings in as fast as 30 minutes, provide quotes within hours, and offer sample production in just 3 working days.

- Zero MOQ & High Flexibility: Whether it’s one cable or ten thousand, we treat every project seriously. From R&D prototypes to urgent field replacements, we respond quickly.

- Communication Transparency: We support real-time updates, video calls, collaborative CAD revisions, and multilingual communication (EN/DE/JP).

- Professional Documentation: Each project is tracked with full inspection reports, CAD files, RoHS/REACH/UL documentation, and S-parameter test data.

- Full Lifecycle Support: From the first inquiry to after-sales technical consultation, we provide one-on-one service, always fast and responsive.

We don’t just sell semi rigid cable assemblies—we build trust, reduce risk, and deliver confidence. That’s what true service means to us, and what you can expect from Sino-conn.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Aerospace Radar System – Precision with Zero Signal Drift

We were developing a phased-array radar system for aerospace testing, which required ultra-stable signal performance under extreme mechanical and thermal stress. The core challenge was sourcing a semi-rigid cable assembly that could maintain phase integrity across variable frequencies while surviving 200+ thermal cycles from -55°C to +125°C.

Sino-conn impressed us from the very first interaction. Their technical team not only offered a low-loss semi-rigid solution with solid copper outer shielding and PTFE dielectric, but also matched our required length tolerances to within ±0.1 mm. We received full CAD drawings within hours, and they even simulated signal attenuation across our custom routing layout.

After testing, their assemblies showed less than 0.05 dB deviation across the frequency range. Assembly-to-assembly consistency was remarkable. We quickly approved the design and received samples in 5 days. This level of precision and engineering support is rare.

“Sino-conn delivers aerospace-grade precision with incredible responsiveness. They are a true partner in RF integrity.”

Erik Schneider, RF Systems Engineer

Location: Munich, Germany

U.S. Aerospace Lab – 110GHz Microwave Testing

Our lab specializes in next-gen satellite payload testing, which demands coaxial assemblies that maintain low insertion loss and stable impedance up to 110GHz. We struggled for months to find a supplier who could deliver real performance above 90GHz, with consistent phase matching.

Working with Sino-conn was a breakthrough. Their semi-rigid assemblies featured silver-plated copper tubing and 1.0mm connectors rated for 110GHz. They reviewed our layout and proposed a routing plan that reduced bends by 40%.

We received the first batch of cables within 10 days. They performed excellently in thermal vacuum testing and met our phase stability targets. The documentation was complete with S-parameter plots and material certs.

What impressed me most was their ability to customize connector orientation and housing material on short notice. It gave us flexibility without compromising signal integrity.

“At these frequencies, every detail matters. Sino-conn nailed it.”

Dr. Rachel Kim, RF Systems Engineer

Location: San Jose, United States

Japanese Defense Integrator – Compact Radar Modules

Our team was sourcing semi-rigid cable assemblies for a compact radar unit used in unmanned surface vehicles. These cables had to meet stringent military specs: MIL-STD shielding, tight tolerance on phase delay, and must be pre-formed to precise 3D shapes due to space constraints.

We had approached multiple suppliers before, but none could meet both the mechanical precision and electrical specs. Sino-conn quickly stood out. Their engineers worked directly with our CAD files and provided pre-bent prototypes with ±0.3mm tolerance. They even helped revise our connector mating depth to improve return loss.

What truly impressed me was their full-process traceability and 100% inspection policy. Each cable came with serialized labels, 3D test fitting photos, and full test reports. The assemblies fit perfectly into our compact housing, and signal performance exceeded our previous benchmarks.

Sino-conn’s ability to blend engineering accuracy with responsive service made them our preferred vendor for future military-grade projects.

“Their attention to detail and precision is exactly what our defense projects need.”

Hiroshi Sato, Procurement Manager

Location: Yokohama, Japan

industry Application of semi rigid cable assemblies

Semi rigid cable assemblies are widely used across industries that demand high-frequency performance and minimal signal loss, including aerospace, military, medical devices, telecommunications, and RF testing. Their durable, bendable yet stable design makes them ideal for confined or precision-sensitive environments. Whether in satellite communication or advanced diagnostic equipment, semi rigid cables ensure reliable signal integrity under extreme conditions.

Precision RF Transmission in Aerospace

Application Scenario: Semi-rigid cable assemblies play a critical role in modern aerospace navigation systems, especially in aircraft avionics and satellite positioning modules. These environments demand extreme stability and signal fidelity under harsh conditions such as high altitude, vibration, and thermal cycling. Within avionics, RF modules must maintain impedance consistency for accurate transmission of data between radar, GPS, and control units. Semi-rigid cables provide mechanical rigidity and shielding integrity, essential for preventing signal loss and interference during flight maneuvers or reentry heat exposure.

Equipment & Products:

- Avionics radar units

- GPS signal transceivers

- Aerospace-grade connectors

Industry Challenges:

- Need for minimal signal loss under thermal and mechanical stress.

- Demands for consistent impedance (e.g., 50 ohms) across long-term deployment.

- Weight and size restrictions in tightly packed aerospace modules.

Our Solutions:

- Use of solid copper or copper-tin outer sheath for excellent shielding and thermal conductivity.

- Laser-welded and custom-bent assemblies for exact fit and consistent impedance.

- Lightweight PTFE dielectric and compact connector design to meet aerospace weight specs.

High-Frequency Stability for Outdoor 5G Systems

Application Scenario:

In 5G outdoor macro base stations, the backbone RF interconnects require cable assemblies that ensure minimal loss, phase stability, and excellent shielding in a compact layout. Semi-rigid cable assemblies are often deployed between RF filters, power amplifiers, and remote radio units. These environments feature continuous signal transmission at high frequencies (typically 3.5 GHz and above) with exposure to temperature swings, rain, UV, and wind-induced vibration. System integrators rely on robust semi-rigid solutions for VSWR-sensitive nodes and long-term reliability.

Equipment & Products:

- Remote Radio Units (RRUs)

- High-frequency bandpass filters

- Outdoor-rated RF connectors

Industry Challenges:

- Environmental stress (temperature, UV, moisture) impacts phase and VSWR.

- Requirement for minimal return loss and shielding leakage in high-density panels.

- Difficult-to-route positions in outdoor enclosures requiring custom shaping.

Our Solutions:

- Use of PTFE-insulated, solid copper jacketed semi-rigid coax with soldered interfaces.

- Each cable pre-tested for VSWR < 1.2 and insertion loss compliance.

- Customized bending and layout support for fast deployment and secure routing.

Ultra-Low Signal Loss in Cryogenic RF Transmission

Application Scenario:

In quantum computing environments, signal integrity must be preserved even at cryogenic temperatures approaching absolute zero. Semi-rigid cable assemblies are used to transmit microwave signals to and from superconducting qubits and resonator arrays inside dilution refrigerators. These cables must deliver consistent impedance, minimal insertion loss, and zero phase drift in the face of thermal contraction and vibration. Traditional flexible cables fail under these conditions, while semi-rigid options with solid copper jackets and silver-plated interiors maintain stability at milliKelvin ranges.

Equipment & Products:

- Dilution refrigerators

- Superconducting microwave resonators

- Cryo-compatible SMA connectors

Industry Challenges:

- RF signal degradation due to extreme low temperatures and contraction.

- Connector failure from repeated thermal cycles and micro-movements.

- Shielding inefficiency causing qubit decoherence in test runs.

Our Solutions:

- Use of silver-plated, solid copper semi-rigid coax with cryo-rated PTFE insulation.

- Precision-form bending with pre-thermal cycle stress analysis.

- Hermetically sealed connectors with screw lock for mechanical integrity.

Space-Rated Semi-Rigid Cabling for Orbital Reliability

Application Scenario:

In satellite payload systems, every gram and every signal matters. RF modules in satellites require high-frequency, low-loss, and thermally stable connections that can endure vacuum, radiation, and temperature cycling. Semi-rigid cable assemblies are favored for their bendable yet fixed shape, allowing precise routing in confined satellite interiors. They also maintain performance across intense launch vibrations and the deep-space environment, making them ideal for payload-to-antenna or transceiver links.

Equipment & Products:

- Satellite transceiver modules

- Miniature RF switches and filters

- Space-grade SMA and SMP connectors

Industry Challenges:

- Need for radiation-resistant and vacuum-compatible materials.

- Limited space for routing while avoiding signal crosstalk.

- Performance retention across wide thermal ranges (-150°C to +150°C).

Our Solutions:

- Use of silver-plated copper outer shield and PTFE dielectric for space stability.

- Custom-formed cable geometries with 3D model support.

- Outgassing-compliant materials with MIL-STD-202 qualification.

Mission-Critical RF Cabling for Defense Applications

Application Scenario:

In military radar systems and electronic warfare (EW) platforms, signal reliability under shock, EMI, and extreme climate is non-negotiable. Semi-rigid cable assemblies are widely adopted in mobile radar trailers, vehicle-mounted jamming equipment, and missile tracking systems. Their rigid yet formable construction ensures consistent impedance and high shielding effectiveness, crucial for distinguishing friendly vs. hostile signals and preventing electronic disruption in battlefield conditions.

Equipment & Products:

- Mobile radar transceiver units

- Vehicle-based EW jamming modules

- MIL-SPEC-rated SMA/N connectors

Industry Challenges:

- Intense vibration, thermal shock, and salt fog exposure

- Demands for high shielding to prevent interception or interference

- Compatibility with MIL-STD connectors and space-constrained panels

Our Solutions:

- Copper-tin outer jacket with triple-layer EMI shielding

- Customized bends for secure routing in tactical enclosures

- Use of halogen-free, corrosion-resistant materials compliant with MIL-STD-810

Low-Loss RF Pathways for Quantum Cryogenic Systems

Application Scenario:

Quantum computing platforms often operate at cryogenic temperatures near absolute zero, where even minor thermal disturbance or EMI can collapse qubit stability. Semi-rigid cable assemblies are the preferred choice for routing microwave and RF signals from room temperature down to dilution refrigerators. Their solid metal sheath and PTFE dielectric deliver phase-stable, ultra-low-loss transmission that is crucial for qubit control and readout channels.

Equipment & Products:

- Dilution refrigerator RF ports

- Qubit microwave control lines

- Cryo-compatible SMA/2.92mm connectors

Industry Challenges:

- Preventing thermal leakage in multi-stage cryostats

- Preserving signal phase and amplitude across temperature gradients

- Ensuring materials are cryo-compatible and vacuum-rated

Our Solutions:

- Solid copper or stainless steel tubing to minimize thermal conductivity

- Ultra-low-loss PTFE and silver-plated center conductor for stable performance

- Vacuum-suitable soldering and material screening to meet cryo-system specs

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized semi rigid cable assemblies services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a semi-rigid cable assembly?

A semi-rigid cable assembly features a solid metal outer conductor, typically copper or stainless steel, offering excellent shielding and phase stability. It’s ideal for high-frequency RF signal transmission.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

Can I customize the cable length and connector types?

Yes. We support full customization, including cable length, connector model, pin-out configuration, and shape.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

Are your cables bendable or completely rigid?

They are semi-rigid—bendable once during installation, holding shape thereafter.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China