custom rf cable assemblies manufacturer

Looking for high-performance RF cable assemblies tailored to your exact specifications? At Shenzhen Sino-conn, we specialize in precision-engineered custom RF cables with guaranteed signal integrity, low VSWR, and fast lead times—even for small quantities. Let’s build your ideal solution.

Why choose rf cable assemblies from sino-conn

Sino-Conn offers fast customization, expert engineering, and full certification for RF cable assemblies. We deliver quick samples, flexible designs, and precise technical support with CAD drawings ready within 30 minutes. Our strict 100% inspection ensures stable quality for every order. Whether you need original or compatible connectors, we provide cost-effective, reliable solutions tailored to your exact specifications and industry requirements.

Flexible Configurations for Custom Requirements

Our RF cable assemblies offer exceptional flexibility in length, pin-out, connector type, and shielding structure. Whether you’re dealing with compact medical devices or high-frequency telecom systems, we can tailor each cable to match your design precisely. This high configurability ensures compatibility, performance, and ease of integration.

30-Minute Drawing Turnaround for Fast Quotation

Time matters. We provide precise CAD-to-PDF drawings within 30 minutes for most RF cable assembly requests. This allows our clients to confirm specifications, communicate internally, and make faster decisions. Whether it’s a sample or mass production, rapid documentation shortens your lead time and speeds up project launch.

Support Both Original and Compatible RF Connectors

We offer both genuine brand RF connectors and high-quality compatible alternatives, giving customers more flexibility in cost, delivery time, and inventory planning. While original connectors meet brand requirements, our alternatives match form, fit, and function—ideal for fast-moving, budget-sensitive, or prototype projects.

Fast Prototyping — 3 Days for Sample Delivery

Speed matters in product development. We can deliver fully functional RF cable assembly samples within just 3 working days. This fast prototyping helps engineers validate designs quickly, reduce iteration cycles, and seize market timing. Even urgent projects can move forward without compromise in quality.

Global Certifications and Full Material Compliance

Our RF cable assemblies are backed by complete certifications including ISO, UL, RoHS, REACH, PFAS, and more. We ensure full material traceability and compliance with global environmental standards. Whether your application requires medical-grade, aerospace, or telecom compliance, we have the documentation ready.

Extreme-Environment RF Cables: -65°C to 250°C & IP68 Rated

Special cables for harsh conditions stay flexible at -65°C, operate at 250°C with PTFE insulation, and resist 500 kgf/cm² crushing. With ozone-resistant rubber or fluoroplastic sheaths and IP68 connectors, they endure salt spray, chemicals, and UV in deep-sea, steel mill, and polar applications, passing 720-hour IEC 60068-2-52 salt spray tests.

Detailed specifications and parameters of rf cable assemblies

At Sino-conn, every RF cable assembly is custom-built based on the client’s unique application requirements. The technical parameters—such as connector combinations, cable length, pinout, jacket style, and materials—are fully configurable. This means there’s no fixed standard; instead, we work closely with engineers, OEMs, and sourcing teams to develop assemblies that perfectly fit their system specifications, compliance needs, and environmental challenges. The above chart reflects just a sample of commonly ordered structures and is a starting point for your tailored solution.

| No. | Configuration | Connector Type | Cable Spec | Length | Jacket Shape | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | Male-Female | SMA-SMA | Custom | Custom | Round | PTFE Sleeve |

| 2 | Male-Male | N-N | Custom | Custom | Flat | Conductive Fabric |

| 3 | Female-Female | MCX-MCX | Custom | Custom | Molded | PVC Sleeve |

| 4 | Male-Board | SMA-SMP | Custom | Custom | Round | Nylon Braid |

| 5 | Male-Reverse Polarity | RP-SMA-SMA | Custom | Custom | Flat | PTFE Tape |

| 6 | Female-Board | MCX-U.FL | Custom | Custom | Molded | Acetate Cloth |

| 7 | Right Angle-Straight | SMA-90°-SMA | Custom | Custom | Round | Nano Tape |

| 8 | Male-Bulkhead | N-Bulkhead | Custom | Custom | Flat | PTFE Sleeve |

| 9 | Waterproof | 7/16 DIN-7/16 DIN | Custom | Custom | Round | Silicone Seal |

| 10 | Ultra-Thin | MMCX-MMCX | Custom | Custom | Molded | Heat Shrink Tubing |

Customized rf cable assemblies styles

Trusted by 300+ global partners,1000+ styles have been developed.

Custom RF Cable Assemblies M12 Hybrid 4+4Pin Shielded

Custom RF Cable Assemblies Socket Contact Size 8

Custom RF Cable Assemblies Spring-Loaded Contact Pin

RF Connector Adapter 2.92mm Male Plug High Frequency

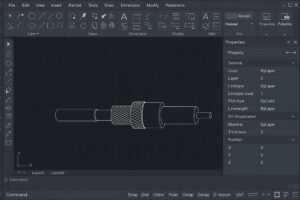

Product details display of rf cable assemblies

Sino-conn factory RF cable assemblies are presented with detailed specifications, including connector models, cable materials, dimensions, voltage, current ratings, EMI shielding, impedance, flexibility, and environmental resistance such as high-temperature, fireproof, oilproof, UV, and corrosion protection. Each product display includes clear overall and close-up images, allowing customers to evaluate design precision. Even when customers provide only photos or partial specifications, our experienced team accurately interprets requirements to ensure correct production. All products are supported by complete certifications like UL, ISO, ROHS, and REACH, ensuring full compliance with industry standards. Comprehensive technical drawings are provided for customer approval before production begins, guaranteeing precise manufacturing.

Impedance Consistency & Low VSWR

For high-frequency RF systems, impedance matching and low return loss are critical. We manufacture cables with tight control over impedance and VSWR.

- Impedance Control: Maintained at 50Ω (±2Ω tolerance) along the full length

- Low VSWR: Typical values ≤1.3, reducing signal reflection and energy loss

- Application Fit: Suitable for 5G, satellite, Wi-Fi, radar, and high-speed RF modules

- Design Simulation: Cable and connector interface are co-simulated for match

- Quality Assurance: Every batch is randomly sampled for VNA testing

Superior Flexibility & Bending Durability

In applications with repeated movement, our RF cables maintain structure and performance even after thousands of flex cycles.

- Minimum Bend Radius: As low as 5×OD depending on construction

- Dynamic Applications: Ideal for robotics, antennas, rotating joints

- Bending Life: Exceeds 10,000 bend cycles without conductor breakage

- Reinforced Terminations: Strain reliefs at connectors prevent cable pull damage

- Material Synergy: Combined use of soft insulation + durable jacket for balance

Wide Frequency Band & Low Insertion Loss

We engineer cables for high-frequency applications with minimal insertion loss and broad bandwidth support.

- Frequency Support: DC to 3GHz, 6GHz, 12GHz, or higher depending on cable type

- Insertion Loss: <0.5dB/m at 1GHz typical (varies by diameter and shielding)

- Signal Purity: Optimized for amplitude and phase stability

- Connector Integration: Matched cable/connector combinations for full-band performance

- Use Cases: RF modules, wireless routers, test equipment, 5G infrastructure

Excellent Shielding Effectiveness (SE ≥ 90dB)

EMI rejection is critical in modern RF systems. Our assemblies are designed with high shielding effectiveness to ensure clean signal transmission.

- SE ≥ 90dB: Certified shielding effectiveness across 1–1000 MHz ranges

- Layered Structure: Braided shield + aluminum foil optional for extreme environments

- Application Fit: Used in military, 5G base stations, EMC labs, medical imaging

- Field-Tested: Validated via TEM cell and GTEM chamber testing

- Customizable: Shielding structure can be tuned for your EMI scenario

Connector Impedance Precision

Connector impedance mismatch can cause signal reflections. We maintain tight mechanical and electrical tolerance at the connector level.

- 50Ω or 75Ω Matching: Depending on application (e.g., telecom vs video)

- Gold-Plated Contacts: Ensure consistent electrical properties over time

- Low VSWR: Typically ≤1.2 for entire cable assembly

- CNC-Machined Housing: Ensures precise mating diameter and contact geometry

- Application-Specific Matching: Especially useful for test equipment, filters, and antennas

Low Crosstalk Structural Design

In multi-line RF assemblies, internal crosstalk can corrupt signals. Our design addresses this via optimized internal layout and shielding.

- Signal Pair Separation: Physical spacing to reduce capacitive coupling

- Individual Shielding: Optional per-pair foil or braid shields

- Twisted Pair Balancing: Maintains symmetry and phase for differential lines

- EM Simulation Verified: Layouts validated via ANSYS HFSS or CST

- Use Cases: MIMO antennas, phased arrays, multi-channel data transmission

--- Customized Capabilities Services and Processes

Customize your rf cable assemblies

Customize your rf cable assemblies

Our RF cable assemblies offer fully customized solutions tailored to each client’s technical requirements. We support adjustments in length, pin configurations, connector types, materials, and shielding structures to meet specific performance needs. With advanced CAD capabilities, we provide accurate drawings within 30 minutes to 3 days for customer approval before production. Our team is experienced in interpreting client-supplied images or incomplete specifications, ensuring correct design and manufacturing. Whether customers require original brand connectors or cost-effective alternatives, we offer flexible options without compromising compatibility or function.

Customization capabilities

At Shenzhen Sino-conn, customization isn’t a feature—it’s our foundation. Every RF cable assembly we produce is tailor-made to meet the exact requirements of your system, no matter how standard or specialized. Whether you are developing a cutting-edge medical device, a high-frequency wireless system, or a rugged outdoor antenna unit, we configure the cable structure, length, pin definition, shielding layers, connector types, and jacket material specifically for your application.

- 100% custom pinouts based on electrical schematics

- Wide connector compatibility, from IPEX-compatible to branded SMA/N-type

- Custom cable lengths and bend radius for flexible integration

- Choice of shielding & insulation materials, including Teflon, FEP, PVC, and nylon braid

- Overmolding, labeling, and color coding available upon request

- No MOQ, from 1 pcs prototype to mass production

We support our clients through every stage of design, simulation, prototyping, testing, and delivery. What you get is not just a cable—but a cable engineered for your idea.

Ultimate Service

We don’t just sell cables—we deliver certainty. From the moment you share your idea to the final shipment, our team ensures fast, accurate, and transparent communication. We reply to most RF cable inquiries within 2 hours. Urgent drawings? We deliver within 30 minutes. Need a video meeting? We’ll show you the product, process, and sample in real time.

- 30-minute CAD drawings & quotations for most custom cables

- 3-day sample delivery for urgent prototyping

- Full engineering support, including connector suggestions and pinout logic guidance

- Responsive customer service, available via email, phone, or video call

- Flexible solutions—whether you want branded connectors or low-cost alternatives

- Visual inspection reports, VNA test records, and photo documentation upon request

We treat every inquiry like a project, and every client like a partner. Our mission is not only to deliver a cable—but to eliminate your uncertainty.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

We encountered phase drift problems when deploying millimeter wave 5G base stations – the original supplier’s cables had a phase difference of ±5° in the 28GHz band. Sino-conn provided a PTFE silver-plated low-loss solution within 48 hours, and controlled the difference within ±1° through 3 iterations of optimization. The first batch of 500 sets has passed the German TÜV certification and is now our exclusive supplier.

“Phase consistency outperforms Rosenberger at 60% cost. Lightning response & free TDR reports sealed the deal!”

Markus Schneider

CTO of TelekomTech GmbH

The fourth axis cabling of the da Vinci surgical robot needs to withstand ethylene oxide sterilization and have a bending radius of less than 15mm. Sino-conn developed a double-shielded PUR cable that passed 10,000 dynamic tests without signal attenuation. What’s even more surprising is that they proactively provided a delivery time that is 30% shorter than the original manufacturer (2 weeks for batch delivery).

“Perfect halogen-free solution! 72hrs from CAD approval to FDA documentation.”

Dr. Sarah Chen

Lead Engineer of SurgiBot Inc.

The extreme desert environment causes oxidation failure of ordinary cable connectors. Sino-conn’s gold-plated stainless steel connector + double-layer EMI shielding solution passed the 55℃/95%RH salt spray test and is equipped with a military quick-plug interface. The first batch of 2,000 sets has zero failures in 18 months on the front line in Kabul.

“Only Chinese supplier meeting MIL−STD−810G.Custom SCAD Aadapters save dus 120k R&D cost!”

Majid Al-Farsi

Procurement Director of DesertShield Defense

industry Application of rf cable assemblies

RF cable assemblies play a critical role across multiple industries due to their high performance, precision, and customization flexibility. In medical fields, they ensure stable signal transmission in diagnostic equipment and monitoring systems, where EMI shielding and durability are essential. The military and aerospace sectors rely on these assemblies for their superior temperature resistance, corrosion protection, and reliable performance in extreme environments. Telecommunication companies use them extensively in antennas, base stations, and network infrastructure to guarantee consistent high-frequency data transmission. Industrial automation benefits from their flexibility and signal integrity in robotic systems and control units. Additionally, OEM manufacturers across various sectors require customized RF cable solutions that meet specific technical drawings and standards. Backed by global certifications like UL, ISO, ROHS, and REACH, these assemblies are designed to meet the stringent demands of diverse markets while ensuring long-term reliability and consistent quality.

5G mmWave Phase-Synchronized Cables

Application scenarios:The deployment of millimeter wave micro base stations in densely populated urban areas requires phase consistency of multi-antenna MIMO systems to avoid signal interference.

Equipment and products:

– Equipment: AAU (active antenna unit), DAS system

– Products: PTFE silver-plated phase matching cable (±1°@28GHz, SMA/4.3-10 connector)

Industry pain points:

1. Phase drift in high frequency bands causes beamforming failure

2. The impedance fluctuation of traditional cables when the temperature changes is >5Ω

3. The limited space on the top of the base station tower requires a small bending radius (≤5 times OD)

Solution:

– Use gas injection foam insulation layer to reduce the dielectric constant to 1.38

– Triple self-compensating shielding structure to offset thermal expansion and contraction deformation

– Pass the TDR full inspection process to ensure that each batch has an impedance of 50Ω±0.5Ω

Surgical Robot Dynamic Cables

Application scenarios:

The seventh axis wiring of the Da Vinci surgical robot arm needs to achieve lossless transmission of high-frequency signals in a limited space.

Equipment and products:

– Equipment: laparoscopic robot arm, electrosurgery generator

– Product: PUR outer sheath 180° twisted cable (ROHS halogen-free, IP68 waterproof)

Industry pain points:

1. Ethylene oxide sterilization causes cracking of ordinary wires

2. The robot arm is prone to fatigue when bent more than 3,000 times a day

3. RF leakage in the human body needs to be <1mW/cm²

Solution:

– Spiral winding shielding layer to achieve 100,000 bending lifespans

– Medical grade silicone-filled joints, resistant to 134℃ autoclave sterilization

– Ensure local SAR values meet standards through 3D field strength scanning

Military Radar EMP-Shielded Cablesxainc

Application scenarios:

Stable signal transmission of vehicle-mounted phased array radar in desert/polar environments.

Equipment and products:

– Equipment: AESA radar, tactical data link

– Product: Armored fluoroplastic composite cable (MIL-DTL-17 standard)

Industry pain points:

1. Electromagnetic pulse (EMP) causes system downtime

2. Dust intrusion causes connector wear

3. Sudden increase in attenuation under 40℃~125℃ working conditions

Solution:

– Double-layer gold-plated stainless steel braided layer, shielding effectiveness 120dB@10GHz

– Self-cleaning bayonet connector, compliant with MIL-STD-810G

– Low-temperature flexible conductor, ensuring VSWR<1.5 at -55℃

Ultra-Compact RF Cable Assemblies for IoT Wireless Modules and Security Devices

Application Scenario: Smart Security Systems / LoRa & NB-IoT Modules / Consumer & Industrial IoT

IoT and security systems require ultra-miniature RF connections for antenna and module integration. These cables must support multi-band signals, provide EMI protection, and remain reliable in long-term deployments with limited space.

Devices & Products Involved: LoRa modules, NB-IoT chipsets, smart cameras, smart locks, wireless meters, gateway hubs

Industry-Specific Requirements:

Ultra-thin cable OD (≤1.3mm) for dense installation

EMI shielding for crowded radio environments

Universal micro RF connectors (U.FL, IPEX) with long mating life

Frequency range: 2.4GHz, 5.8GHz, 868/915MHz compatible

Our Solution (Point-by-Point):

Micro Coax Structure: 0.81mm OD, 7/0.08mm copper core, FEP insulated, with triple-shielding (foil + braid + conductive wrap)

Full Band Compatibility: VSWR <1.2, Insertion Loss <0.5dB/m, suitable for NB-IoT, LoRa, WiFi, and Bluetooth

EMI Protection: Dual-ended ground bonding and layered shielding to minimize signal drop and interference

Connector Options: IPEX1 to IPEX4, U.FL, Hirose micro-RF series available for most mainstream module interfaces

Mass Production Quality: Fully automated terminal crimping + 100% RF testing ensure consistency in bulk production

Automotive-Grade RF Cable Assemblies for V2X and Connected Vehicle Antenna Systems

Application Scenario: Smart Transportation / TCU & ADAS Modules / Vehicle Antenna Integration

RF cable assemblies are essential for connecting antennas and communication modules in modern vehicles, supporting V2X, GNSS, UWB, and 5G. These environments demand high EMI resistance, ruggedized builds, and compact interface design.

Devices & Products Involved: TCU, 5G/4G modules, UWB radar, GPS antennas, ADAS camera/radar units

Industry-Specific Requirements:

Micro RF connectors (U.FL, Fakra, HSC) with precise pin mapping

Frequency support up to 6GHz, -40~+105°C operating temperature

Minimum 50,000 flex cycles, anti-vibration & shock-proofing

UV-resistant, oil-resistant, moisture-proof for outdoor use

Our Solution (Point-by-Point):

Custom Signal Mapping: Multichannel RF signal combinations available (e.g., 5G + GNSS + UWB)

Automotive-Grade Materials: Outer jacket using TPU/PVC hybrid, compliant with ISO 6722 & flame/aging tests

Signal Integrity Design: Triple shielding (foil + braid + conductive cloth) ensures clean transmission in high-EMI zones

Connector Options: U.FL, Fakra, HSC automotive-specific interfaces available with locking mechanisms

Mechanical Adaptability: Molded overmolds and bracket support for embedded or angled installation in constrained automotive spaces

Low-Loss, Lightweight RF Cable Assemblies for Aerospace & Satellite Communication

Application Scenario: Satellite Uplink Systems / Avionics Boards / Radar Modules

Aerospace RF signal paths must be ultra-reliable, support high frequency, endure vibrations, and remain lightweight. These requirements are critical for applications like telemetry, radar, in-flight communication, and navigation.

Devices & Products Involved: Satellite modems, radar antenna modules, flight control units, telemetry boards, airborne navigation systems

Industry-Specific Requirements:

High-frequency operation (>12GHz), low insertion loss

Strict weight control (<10g per cable assembly)

Shock/vibration resistance and thermal stability in extreme altitudes

Connector compatibility with SMA, SSMB, MMCX, etc.

Our Solution (Point-by-Point):

High-Frequency Performance: Using 0.81mm/1.13mm coax cores with VSWR <1.15 and IL <0.4dB/m, supporting up to 18GHz

Weight Optimization: FEP insulation, aluminum braid, and ultra-thin outer jackets keep total cable weight under 10g

Vibration Protection: Epoxy reinforcement at connector joints and flexible overmolds absorb in-flight micro-vibrations

Environmental Durability: Material rated for -55°C to +125°C, passed salt spray and humidity testing

Connector Integration: Precision SMA, SSMB, and MMCX connector assemblies aligned to aerospace interface standards

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

International Certifications

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a custom RF cable assembly, and how does it differ from standard cables?

A custom RF cable assembly is a tailored coaxial cable solution with specific connectors, lengths, shielding, and impedance to meet unique application needs. Unlike standard cables, they are engineered for precise frequency, durability, and environmental resistance in industries like telecom, military, and medical.

What materials are used in your RF cables?

We use PTFE (Teflon), PE, PUR, and FEP for insulation, with bare copper/copper-clad steel conductors. Shielding options include braided, foil, or spiral wraps for EMI protection. Outer jackets can be PVC, LSZH, or silicone for flexibility/fire resistance.

Can you provide UL/ISO/RoHS certifications?

Yes! We hold UL, ISO 9001, RoHS, REACH, and MIL-STD certifications. Certificates are available upon request, and we conduct third-party testing for compliance.

What’s your turnaround time for samples and bulk orders?

Samples: 3-5 days (express), 2 weeks (standard) // Bulk: 2-3 weeks. Rush options (72h samples, 10-day bulk) are available for urgent needs.

Do you support custom connector configurations (e.g., SMA to N-type)?

Absolutely! We customize connector types, genders, pinouts, and cable lengths. Provide drawings or specs, and we’ll confirm feasibility within 24 hours.

How do you ensure signal integrity in high-frequency applications?

We optimize impedance matching (50/75Ω±1%), use low-loss dielectrics, and apply triple shielding to minimize attenuation and EMI up to 40GHz.

Do your cables support high-frequency applications like 6GHz or higher?

Yes, we offer RF cables with low insertion loss and stable VSWR for frequencies up to 18GHz. Please let us know your specific bandwidth and signal integrity needs.

What’s your MOQ? Do you accept small prototype orders?

No MOQ! Prototypes start at 1 piece, with free design review and 3D drawings before production.

What are your payment terms and shipping methods?

We support T/T, PayPal, and Alibaba Trade Assurance. Shipping options include DHL, FedEx, UPS, or your appointed forwarder. Terms like EXW, FOB, DDP are available.

Can you sign NDAs for proprietary designs?

Yes! We protect IP via NDAs and secure data protocols. All tooling/modifications are client-owned.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China