custom coaxial cable assemblies manufacturer

At Sino-conn, we specialize in precision-engineered cable solutions tailored to your needs—whether you’re developing cutting-edge electronics, assembling OEM equipment, or solving EMI and impedance challenges. With no MOQ, rapid prototyping in as fast as 3 days, and a full range of certifications (UL, ISO, RoHS, REACH, PFAS), we ensure unmatched flexibility, quality, and speed. Our expert team is ready to support your project with custom drawings, fast response times, and scalable production. Let us turn your concepts into reality—one cable at a time.

Why choose coaxial cable assemblies from sino-conn

Choose Sino-Conn for coaxial cable assemblies to ensure high-frequency signal stability, precise customization, and global certifications. We offer no MOQ, rapid sampling, and expert support from drawing to delivery—perfect for OEMs, R&D, and industrial applications.

Extreme Customization for Any Specification

We support ultimate customization of any parameters. We can flexibly adjust the cable length, connector type, PIN pin definition, sheath material, shielding structure, etc. according to customer needs to meet various application scenarios from medical, communication, industrial equipment to automotive electronics. Whether it is complex technical specifications or unconventional design requirements, we can accurately achieve them.

Rapid Prototyping and Scalable Production

Fast prototyping and scalable mass production capabilities. Samples can be delivered in as fast as 3 days, and batches can be shipped in as fast as 2 weeks, adapting to the full process requirements from engineering verification to large-scale supply. We have standardized processes, flexible production lines and strong material integration capabilities, and can provide stable and reliable production and delivery guarantees for OEM factories, terminal brands and R&D engineers.

Certified Materials, Full Compliance Guaranteed

We use internationally certified materials to ensure that our products comply with global mainstream regulations and environmental standards such as UL, RoHS, ISO, REACH, PFAS, etc. Each batch of products can provide COC, COO, and quality inspection reports to meet the strict requirements of European and American customers for factory inspection, quality control, and traceability. It is a reliable choice for high-demand industries such as medical, military, and automotive.

No MOQ, Flexible for Any Order Size

We support orders starting from 1pc, with no minimum order quantity limit. Whether you are doing proofing, R&D small batch testing, or batch delivery production, we can flexibly meet your needs. Start-up projects and high-frequency iteration customers can start supply cooperation with zero threshold, reduce trial and error costs, and accelerate product launch cycle.

High-Precision Engineering and Drawing Support

We provide engineering support services from concept to drawing. We can complete CAD drawing within 30 minutes and provide PDF version for customer confirmation. All orders must be approved by customer drawings before production to ensure that each cable 100% matches customer structure and function requirements. We are the preferred partner for R&D engineers and technology procurement.

100% Quality Inspection with Full Traceability

Three quality inspection procedures: full inspection during the process, full inspection after completion, and full inspection before shipment to ensure stable product performance and consistent quality. Each cable can be traced back to the production batch and material source, which meets the audit requirements of high-standard industries. We have won the trust of European and American customers with our extremely rigorous quality control system, supporting long-term cooperation and brand delivery.

Detailed specifications and parameters of coaxial cable assemblies

Explore the full specifications of our coaxial cable assemblies, including impedance, shielding, voltage rating, bending radius, jacket material, temperature resistance, and OD tolerance. Designed for precision performance in RF, medical, and industrial applications.

| # | Definition | Connector Model | Cable Spec | Length (mm) | Shaping | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | SMA Male to SMA Male | SMA-JK-SM-50 | RG174 | 500 | Round | PTFE Tubing |

| 2 | BNC Male to N Male | BNC-C4-NM-75 | RG58 | 1000 | Round | PVC Shrink Tube |

| 3 | TNC Female to SMA Female | TNC-FD-SF-25 | RG316 | 300 | Flat Ribbon | Conductive Fabric |

| 4 | N Male to N Male | N-MLC-NM-60 | LMR400 | 1500 | Round | Braided Nylon |

| 5 | SMA Male to MCX Female | SMA-JK-MXF-40 | RG188 | 200 | Molded | FEP Sleeve |

| 6 | RP-SMA to SMA Reverse Polarity | RP-SMA-K-SM-30 | RG178 | 600 | Round | Acetate Cloth |

| 7 | BNC Male to BNC Male | BNC-C4-C4-80 | RG213 | 1200 | Flat | Teflon Tape |

| 8 | FME Female to SMA Male | FME-FD-SM-35 | RG142 | 800 | Molded | Silicone Coating |

| 9 | SMB Male to SMB Male | SMB-JK-JK-45 | RG223 | 400 | Round | PE Mesh |

| 10 | N Male to TNC Female | N-MLC-TNF-70 | RG62 | 900 | Round | ETFE Wrap |

Customized coaxial cable assemblies styles

Trusted by 300+ global brands,1000+ styles have been developed.

Radio Frequency BNC Male to BNC Male Black Cable

Radio Frequency BNC Male to BNC Male Black Coaxial Cable 75Ω

Radio Frequency N Male to SMA Male Black Cable

Radio Frequency BNC Male to RCA Male Black Cable

Radio Frequency Right Angle SMA to SMA Connector Blue Cable

Radio Frequency SMA Female Bulkhead to IPEX Cable OD1.13

Cable Assembly Radio Frequency SMA Female Bulkhead to IPEX Cable OD1.13

Radio Frequency U.FL to SMA Connector

RF Coax Cable Assembly N Male to SMA Male

RF Cable Assemblies N-Type Panel Mount Connector with RG142 Coax Cable

Custom Coax Cables N Male to N Male RG8X Premade Coax Cable

Coax Jumper Cable Assembly BNC Male to BNC Male

Product details display of coaxial cable assemblies

Discover the product details of our coaxial cable assemblies, including connector types, cable structure, shielding layers, and real-shot images. Visual clarity and technical precision ensure you fully understand each product’s features and build quality before customization or purchase.

Authentic or Cost-Effective Alternatives

- Offer both OEM-grade (Amphenol/Rosenberger) and high-performance compatible connectors

- Key differences: Original connectors (longer lead time, 8-12 weeks) vs. alternatives (3-day samples, 2-week bulk)

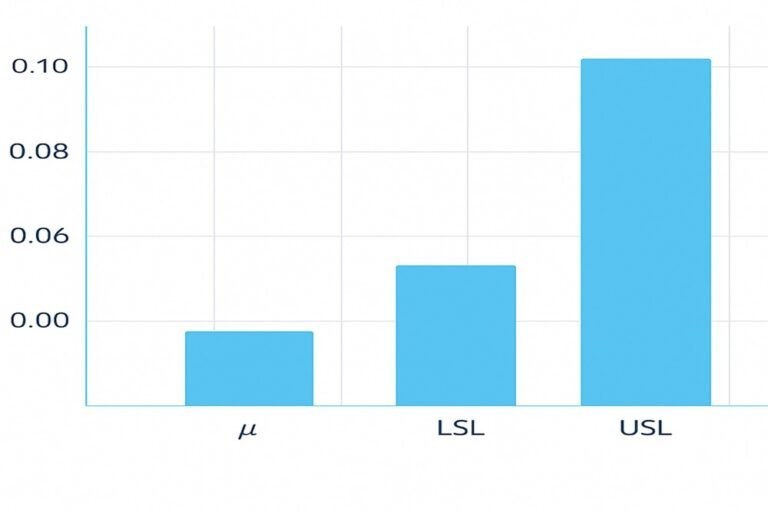

Impedance-Matched Designs

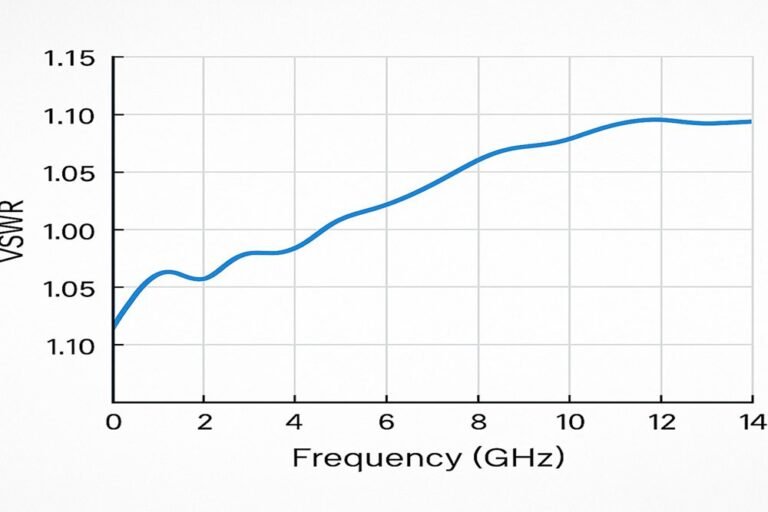

- Standard 50Ω/75Ω options with ±0.1Ω tolerance for RF-sensitive applications

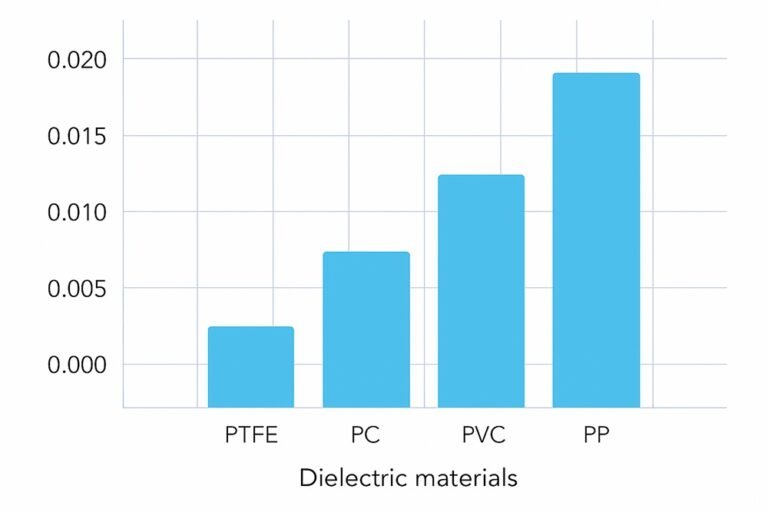

- Custom dielectric materials (PTFE/PE) to minimize VSWR (<1.2 up to 40GHz)

Military-Spec Durability

- Self-locking mechanisms (TNC/SMA) withstand 500+ mating cycles

- Salt spray resistance per MIL-STD-202G for marine/offshore use

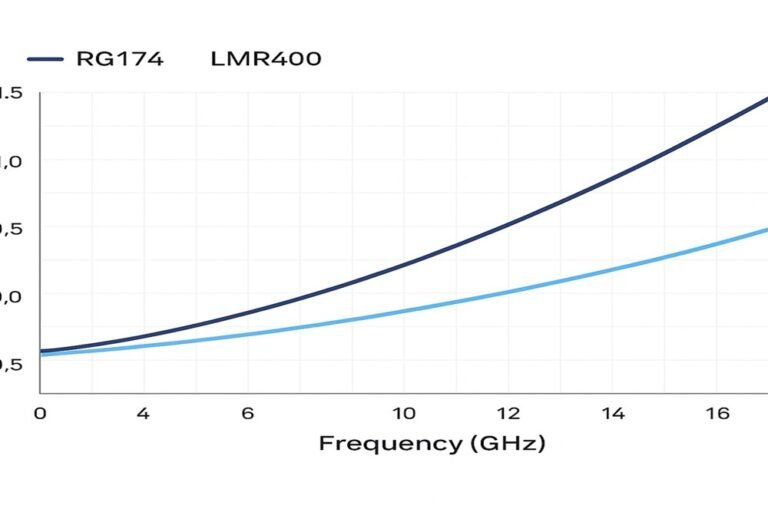

Low-Loss Signal Transmission

- RG316 (0.42dB/m @6GHz) to ultra-low-loss LMR600 (0.07dB/m @6GHz)

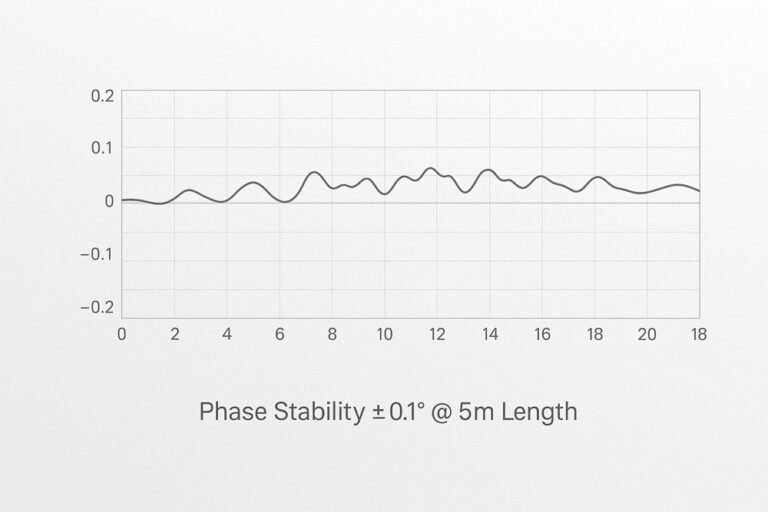

- Phase-stabilized designs (±0.1mm length tolerance) for phased arrays

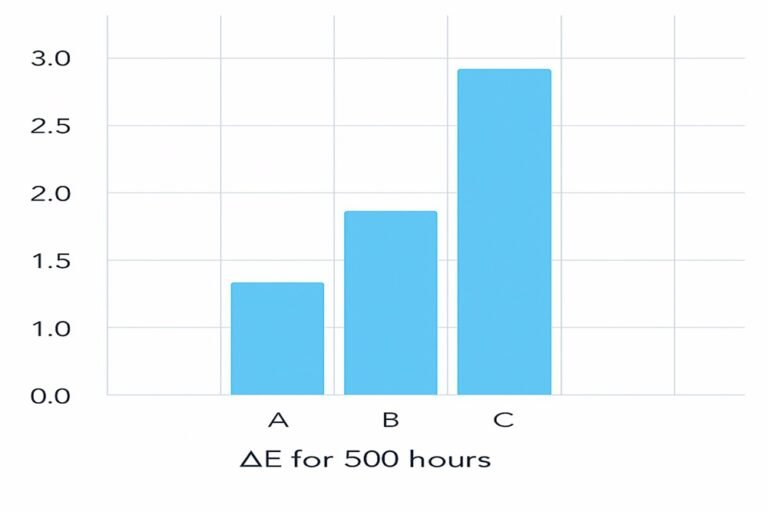

Environmental Resilience

- 200℃~260℃ operating range with FEP/PTFE jackets

- UV-resistant outer sleeves pass 1000hrs QUV accelerated aging

Flexibility & Shielding

- Minimum bend radius down to 3x OD (5mm for RG178)

- Triple-layer shielding (foil+braid+conductive polymer) for 90dB EMI rejection

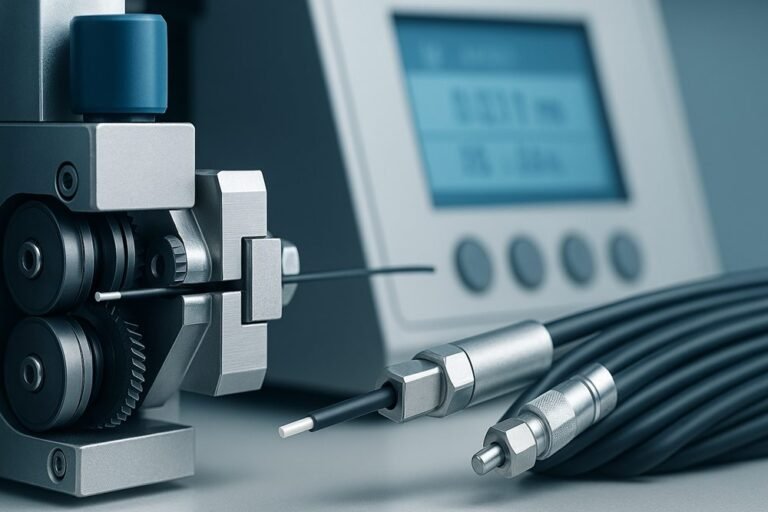

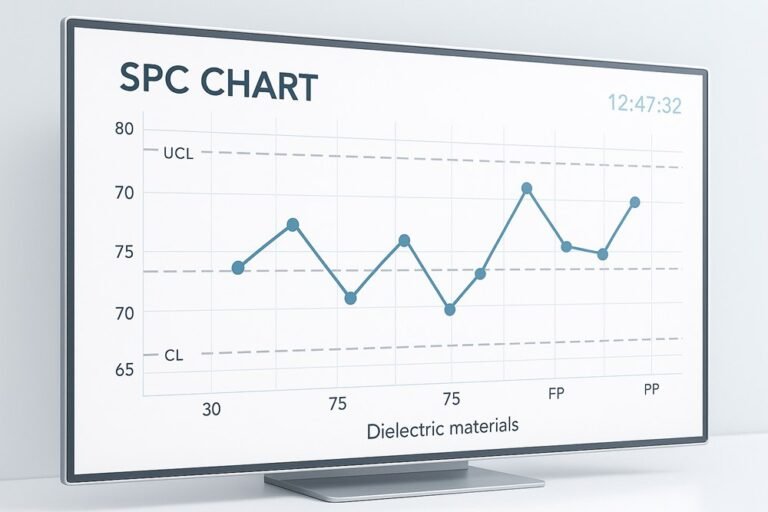

Impedance Control

- 50Ω/75Ω precision machining (±0.5Ω tolerance via TDR verification)

- Continuous impedance monitoring during extrusion (sampling rate: 1000pts/meter)

Signal Integrity

- VSWR ≤1.15 up to 40GHz (PTFE dielectric, air-spaced designs)

- Group delay variation <1ps/m @6GHz for phased array systems

Material Science

- Dielectric constant (εr): 1.13-2.3 (Foam PE/PTFE/Solid Teflon options)

- Velocity factor: 82%~96% (adjustable via foaming ratio control)

Process Verification

- Continuous impedance monitoring (Sampling: 100% at 1GHz/5GHz/18GHz)

- Center conductor concentricity: Automated vision inspection @0.005mm resolution

Clean Room Standards

- Class 10000 assembly area for medical/aerospace orders

- Particle count <5 per liter (ISO 14644-1 Class 5)

Traceability

- Laser marking: Lot number + date code + test operator ID

- Raw material batch records preserved for 15 years

Shield Architecture

Triple-layer:

- Inner: 100% coverage aluminum foil (overlap width ≥ 5mm)

- Middle: 96 braided tinned copper wire mesh (density ≥ 95%)

- Outer: Conductive nylon anti-friction layer

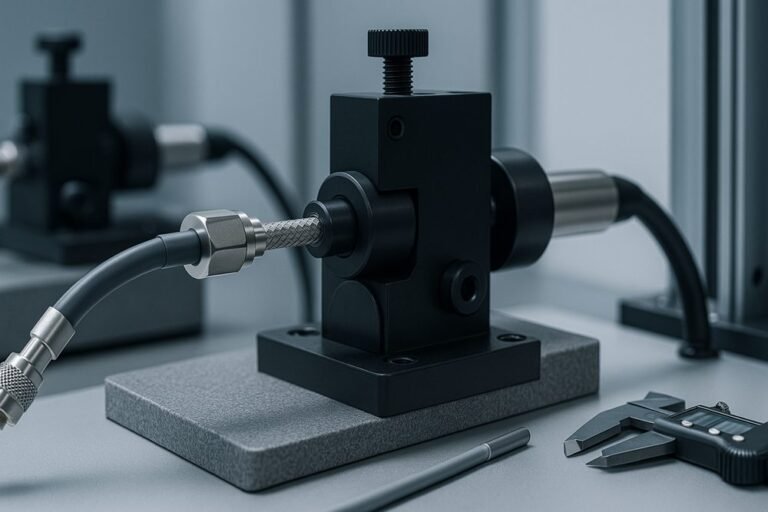

Precision Tolerancing

- Concentricity ≤85%(Laser micrometer controlled)

- Outer diameter consistency: ±0.02mm over 100m length

Termination Methods

- Center conductor: Laser welding (Rj≤0.015mm)

- Connector interfaces: Thread locking with retention forces ≥50N

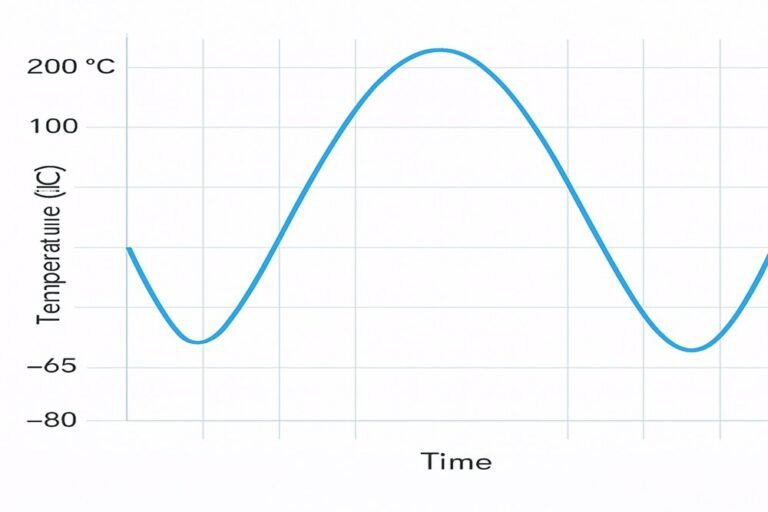

Extreme Temperature

- Operating range: -200℃~+260℃ (Custom alloy center conductors)

- Thermal cycling stability: Δα≤0.1dB/cycle @-55℃↔+125℃

Chemical Resistance

- Hydrocarbon immersion test: No swelling after 24hrs in ASTM#3 oil

- Hydrolysis resistance: ≤0.5% length change @85℃/85% RH x1000hrs

Flame Performance

- Smoke density: <15% (NFPA 262 plenum rating)

- Halogen-free: Acid gas generation ≤0.1% (IEC 60754-1)

--- Customized Capabilities Services and Processes

Customize your coaxial cable assemblies

Explore our customized capabilities, services, and processes for coaxial cable assemblies — from flexible length and connector configurations to EMI shielding, labeling, and unique material selections. Our engineering team provides rapid CAD drawings, prototyping, and end-to-end support to ensure your design is manufactured with precision, speed, and scalability.

Customized Capabilities Services and Processes

Customize your coaxial cable assemblies

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

- Connector Selection: SMA, BNC, U.FL, MCX, N-Type, TNC, QMA, and other RF types are available with original or alternative brands, depending on your price/performance preference.

- Pinout Mapping & Structure: Whether it’s 1-to-1, mirrored, cross-wired, or a multi-branch breakout cable, we can realize any logical wiring configuration, with or without shielding layers.

- Cable Specifications: We support coax types like RG174, RG316, RG58, and LMR-series, with 50Ω/75Ω impedance options, flexible OD, and multiple shielding layers (foil + braid).

- Length, Shape & Jacket: From 50mm to 5000mm+, round or flat form, and jacket materials like Teflon, PVC, nano-tape, braided mesh, flame-retardant or halogen-free.

- Rapid Prototyping: We offer 2–3 day sample delivery (for urgent needs), with full CAD drawings and customer approval before production.

- No MOQ: We support orders starting from just 1 unit, perfect for engineering validation and urgent sample needs.

We don’t just adapt to your design—we help optimize it, communicate clearly, and deliver professionally. That’s what makes us a trusted custom cable partner.

Our Commitment to Outstanding Service

What differentiates Shenzhen Sino-Media is our obsession with service quality throughout the entire custom coaxial cable lifecycle. Every step is engineered to reduce customer risk, increase clarity, and deliver faster than expected.

- Fast Response: Inquiries are answered within hours, and we can deliver drawings or formal quotations in as little as 30 minutes.

- Integrated Sales & Engineering Support: Sales staff understand technical concepts and work closely with our engineers to ensure smooth communication with both technical and non-technical buyers.

- Sample & Drawing Turnaround: We provide CAD-to-PDF drawings in 30 minutes to 1 day, and samples within 2–3 working days if needed urgently.

- Pre-production Confirmation: Every cable goes into production only after formal customer drawing approval—minimizing costly mistakes.

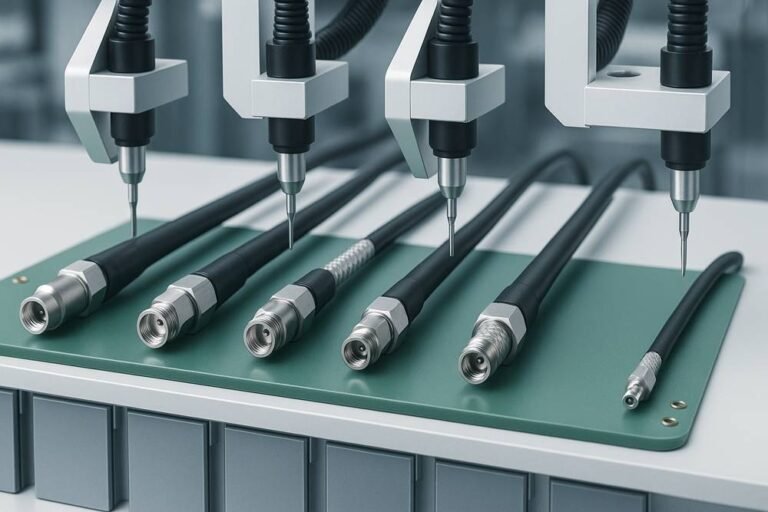

- Full Inspection Process: We run 100% inspection on dimensions, pin mapping, continuity, impedance, and labeling. All results are documented.

- Compliance Ready: We supply UL, ISO, RoHS, REACH, PFAS-free declarations, COC, and COO as needed.

- Flexible Fulfillment: Custom packaging, barcodes, labeling, and even video inspections before shipment can be arranged.

From your first email to the moment your shipment arrives, we focus on communication, precision, and consistency. That’s why our customers come back—project after project.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Use Case: High-resolution medical imaging device

“We needed ultra-low-loss coaxial assemblies with extremely tight impedance control for our new MRI imaging unit. Our previous supplier couldn’t handle custom pinouts with hybrid connectors. After contacting Shenzhen Sino-Media, I was amazed by how quickly their team responded. Within one day, I received full CAD drawings and impedance testing plans. Samples arrived in 3 days—fully passed our lab test. The quality was impeccable. Their technical know-how, flexibility, and communication were far beyond expectation. We’ve now moved them to our Tier 1 supplier list for all new imaging systems.”

Dr. Markus Reiter

Head of R&D, Munich, Germany

Use Case: 5G base station antenna systems

“We were under a tight rollout schedule for a new set of outdoor 5G antenna arrays. The coaxial cables needed to be weather-resistant, UL and RoHS certified, and built with exact pinouts for field technicians. Sino-Media was the only vendor who offered flexible MOQ and could provide both original-brand connectors and performance-equivalent alternates. Their sample turnaround was just 4 days, and the drawings were spot-on. Even our field installers commented on how easy these cables were to work with.”

Michael Foster

Sourcing Director, Houston, USA

Use Case: Robotic arm control systems

“We needed ultra-low-loss coaxial assemblies with extremely tight impedance control for our new MRI imaging unit. Our previous supplier couldn’t handle custom pinouts with hybrid connectors. After contacting Shenzhen Sino-Media, I was amazed by how quickly their team responded. Within one day, I received full CAD drawings and impedance testing plans. Samples arrived in 3 days—fully passed our lab test. The quality was impeccable. Their technical know-how, flexibility, and communication were far beyond expectation. We’ve now moved them to our Tier 1 supplier list for all new imaging systems.”

Keiko Tanaka

Procurement Manager, Osaka, Japan

industry Application of coaxial cable assemblies

Coaxial cable assemblies from Sino-Conn are widely used across industries such as telecommunications, medical equipment, aerospace, automotive electronics, military defense, and industrial automation. Their reliable signal transmission, EMI shielding, and durability make them ideal for high-frequency, high-precision applications where performance and stability are critical.

1.Liquid helium temperature zone coaxial assembly for deep space environments

Application scenarios: deep space detectors, radio astronomy feeders, quantum communication payloads

Equipment and products:

– Superconducting niobium-titanium alloy coaxial inner conductor (working in 4K temperature range)

– Multilayer aluminum foil-nano aerogel composite insulation layer

– Vacuum sealed feedthrough interface (leakage rate <1×10^-9 Pa·m³/s)

Industry pain points:

– Conventional cable brittle fracture near absolute zero

– Cosmic ray-induced dielectric polarization loss

– Contact resistance fluctuation in microgravity environment

Solution:

– Superconducting critical current optimization technology: attenuation at 77K is only 0.02dB/m @10GHz

– Radiation hardened material: passed NASA JEDEC 101F galactic cosmic ray test

– Zero expansion coefficient design: thermal cycle (4K-300K) impedance change <0.3Ω

2.Radiation-hardened millimeter-wave phased array dedicated feeder assembly

Application scenarios: GEO satellite communication payload, intersatellite laser relay system

Equipment and products:

– Gold-copper composite stripline (DC-60GHz ultra-flat loss)

– Yttrium iron garnet (YIG) adjustable phase shifter integrated interface

– Graphene heat dissipation substrate (thermal resistance <0.5℃/W)

Industry pain points:

– Single particle effect leads to phase consistency degradation

– Orbital thermal cycle causes weld cracking

– Multi-channel crosstalk>-40dB

Solution:

– Self-healing radiation protection coating: 90% performance is restored within 24 hours after ionizing radiation damage

– Nanosilver sintering process: 1500 thermal cycles (-80°C~+120°C) without failure

– Heterogeneous electromagnetic bandgap structure: channel isolation is improved to -65dB

3.Battlefield-Grade Coax Assemblies for Secure Tactical Networks

Application scenarios: Stratospheric airships, hypersonic aircraft black box return

Equipment and products:

– Fluoropolymer air gap insulation jumper (withstand voltage 30kV @35km altitude)

– Magnetorheological damping anti-flutter connector

– Plasma sheath penetrating RF window

Industry pain points:

– Thin atmosphere discharge breaks down the insulation layer

– Aerodynamic heating causes deformation when Mach number > 5

– Turbulence causes Doppler frequency shift > 500Hz

Solution:

– Adaptive dielectric composite technology: Dynamically adjust insulation density according to air pressure

– Superelastic nickel-titanium alloy outer conductor: Attenuation increase < 15% at 800°C

– Real-time frequency deviation compensation circuit: integrated in the connector head (compensation accuracy 0.1ppm)

4.Ultra-Low Loss Coax Assemblies for Satellite Signal Integrity

Application scenarios: 6U cubic satellite laser relay, distributed aperture radar

Equipment and products:

– Titanium alloy micro SMP connector (weight <3g/port)

– Atomic clock synchronization compensation transmission line

– Zero exhaust silicon-based dielectric bracket

Industry pain points:

– Microsatellite jitter introduces >2ps delay jitter

– Space limitation leads to bending radius <3mm

– Solar flare induces material outgassing

Solution:

– Optical-RF hybrid timing technology: delay stability ±0.3ps/orbital period

– Topology optimized three-dimensional wiring: π-shaped bending lossless transmission can be achieved

– Molecular sieve getter integration: meet ECSS-Q-ST-70-01C outgassing standard

5.High-Reliability Coax Assemblies for Smart Factory Systems

Application scenarios: Polar imaging satellites, glacier thickness monitoring radar

Equipment and products:

– Liquid-cooled double-shielded coaxial assembly (peak power 1kW CW)

– Faraday rotation polarization compensator

– Hydrogen embrittlement-resistant molybdenum-plated center conductor

Industry pain points:

– Polarization mismatch caused by aurora disturbance

– Metal embrittlement caused by hydrogen atom penetration

– Echo signal dynamic range>80dB

Solution:

– Real-time polarization calibration algorithm: DSP chip integrated in connector (response time <50μs)

– Hydrogen capture molecular sieve coating: permeability reduced to 10^-6 g/m²/day

– Aluminum nitride heat dissipation tooth array: node temperature rise controlled within Δ15℃

6.High-Flex Coax Assemblies for In-Vehicle Signal Stability

Application scenarios: Reusable rocket telemetry, emergency communication in blackout areas

Equipment and products:

– Ceramic-metal composite ablation-resistant outer conductor

– Memory alloy strain relief ring (100% reset after 20 plastic deformations)

– Embedded overload sensor (range ±50G)

Industry pain points:

– Heat flux density in the reentry phase >500kW/m²

– Landing impact acceleration >40G

– Insertion loss change after multiple reuses >30%

Solution:

– Gradient ceramic coating technology: Maintain VSWR <1.3 at 2300℃

– Dynamic simulation pre-deformation design: verified by SpaceX recovery measurement

– Self-diagnosis ferrule wear detection: RFID tag records the number of reuses

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assemblies and wire harness services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I get a datasheet or specification file for your coaxial assemblies?

Yes. We provide full technical datasheets including dimensions, impedance, shielding, jacket type, and connector specs upon request.

What cable types and connectors do you support?

We support RG174, RG316, RG58, LMR, semi-rigid, and more, with SMA, BNC, N-Type, Fakra, MCX, IPEX, and other RF connectors.

Do you accept custom designs with specific pinouts or wiring schemes?

Absolutely. We fully support custom pinouts, lengths, connector types, and cable routing, based on your drawing or requirements.

Can you provide drawings before we place an order?

Yes. We offer free CAD-to-PDF drawings for confirmation before production. Most drawings are ready within 1 working day.

How fast can I get samples or production batches?

Urgent samples in 2–3 days. Regular samples in 7–14 days. Bulk production takes 2–4 weeks depending on order size.

Is there a minimum order quantity (MOQ)?

No MOQ. We support orders from just 1 piece, ideal for prototypes, samples, and low-volume projects.

Can I choose between original and compatible connectors?

Yes. We offer both original-brand and high-quality compatible alternatives based on your preference and budget.

Are your products certified for international compliance?

Yes. We provide UL, ISO9001, RoHS, REACH, PFAS-free declarations, and can supply COC/COO upon request.

How do you ensure product quality and testing?

Every assembly is 100% inspected: in-process, final assembly, and pre-shipment, including continuity, impedance, and labeling.

Can I request a quotation based on my own part number or image?

Yes. Just send us your drawing, photo, or part number—we’ll evaluate and provide a detailed quote accordingly.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China