Custom cable assembly manufacturer

Custom cable assemblies built for precision, durability, and flexibility. From one-piece prototypes to large-scale production, we deliver exactly what your application demands—with zero MOQ and full engineering support.

Why choose cable assembly from sino-conn

Sino-Conn offers tailored cable assembly solutions with unmatched flexibility, fast lead times, and global certification standards. From 30-minute drawing delivery to EMI shielding and no MOQ requirements, we ensure your custom designs are realized with precision, speed, and cost-efficiency. Choose us for expert support and scalable production.

Full Customization on Connector Type, Pinout, and Cable Structure

We support complete customization for every cable assembly, including connector brand/model, pin assignment, cable structure, and outer sheath. Whether it’s angled USB, waterproof M12, or ultra-thin FPC, we tailor the cable to your design needs—ensuring mechanical fit, electrical specs, and compliance.

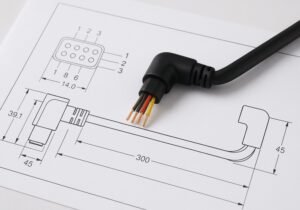

Fast Drawing and Quotation Within 30 Minutes for Engineers

Our engineering team can deliver precise cable drawings and quotations within 30 minutes. Whether you’re an R&D engineer or OEM buyer, we provide CAD-to-PDF layouts tailored to your specs. Quick response means faster decisions and faster go-to-market.

No MOQ Policy and Rapid Sample Delivery Within 3 Days

We accept orders starting from just 1 piece, ideal for R&D and trial runs. Sample cables can be shipped within 2–3 days, even for custom types. This zero-MOQ flexibility makes it easy to validate designs before scaling up.

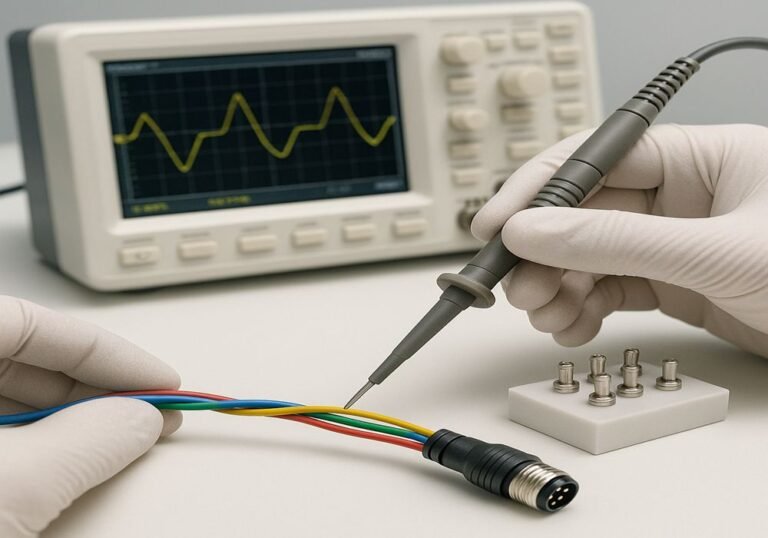

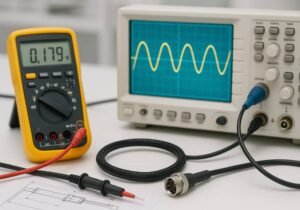

100% Full Inspection—Three-Stage Quality Control Process

Each cable assembly undergoes a rigorous three-stage inspection process: in-process inspection, post-assembly inspection, and pre-shipment inspection. This guarantees electrical continuity, pinout correctness, and flawless appearance before delivery.

Support Both Genuine and Compatible Connector Options

We offer both original brand connectors and cost-effective compatible alternatives. Choose according to your budget, lead time, or inventory availability. All versions are tested for compatibility and performance equivalence.

Multi-Certification Compliance: UL, RoHS, REACH, ISO, PFAS

All cable assemblies are manufactured in compliance with international standards, including UL, RoHS, ISO 9001, REACH, and PFAS restrictions. This ensures safety, environmental protection, and global market acceptance.

Detailed specifications and parameters of cable assembly

| No. | Pinout Definition | Connector Type | Cable Specification | Length (mm) | Cable Profile | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 1:1 Straight | USB-A Male to JST XH | Custom | Custom | Round | PVC Sleeve |

| 2 | Crossed (Tx-Rx) | DB9 Female to DB9 Male | Custom | Custom | Round | Nylon Braided Mesh |

| 3 | Ground Shared | Molex 51021 to Open End | Custom | Custom | Flat | Teflon Tape |

| 4 | 1:N Split | DC5521 to 4x 2.54 Dupont | Custom | Custom | Round | Conductive Fabric Wrap |

| 5 | Shielded Twisted Pair | HDMI Male to Male | Custom | Custom | Round | Aluminum Foil + PVC |

| 6 | Power + Signal | XT60 to 3-pin Fan Header | Custom | Custom | Round | Heat Shrink + Nylon Net |

| 7 | Differential Pair | RJ45 to 8-pin Terminal | Custom | Custom | Round | PVC + Braided Shield |

| 8 | 1:2 Split Sync | USB-C to 2x Micro-USB | Custom | Custom | Molded | Silicone Overmold |

| 9 | Parallel Output | 2.54mm 10P to IDC Header | Custom | Custom | Flat | Acetate Cloth Wrap |

| 10 | Isolated Ground Lines | SMA to U.FL Coaxial | Custom | Custom | Round | FEP (Teflon) Jacket |

Each cable assembly is uniquely tailored to meet the customer’s specific design, electrical, and environmental requirements. Due to the wide range of connector types, pinout schemes, cable profiles, and jacket materials, we do not offer a one-size-fits-all solution. Instead, we collaborate closely with engineers, OEMs, and traders to define custom configurations that perfectly match their systems and standards.

Customized cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

Special Purpose Multi-Core Electrical Cable Assembly

Industrial Shielded Cable Assembly

High-Density D-sub 50 Pin Cable Assembly

9 Pin Waterproof Connector Cable Harness

8 Pin Pitch 1.25mm IDC Connector Cable Assembly

6 Pin Waterproof Cable Harness Assembly

3 Pin Pitch 2.54mm Power Cable Assembly

2-6 Pin Mixed Pitch 2.54mm4.2mm Electrical Cable Harness

Multi-Wire Pitch 1.25mm Wire Harness Assembly

6 Pin Pitch 1.25mm Rainbow Flat Cable Assembly

6 Pin Pitch 2.0mm Flat Cable Assembly

6 Pin Automotive Cable Harness Assembly

5 Pin Pitch 4.2mm Power Cable Harness Assembly

2 Pin Pitch 2.54mm Red Black Wire Harness

6 Pin Pitch 1.25mm Black Wire Harness Connector

6 Pin Pitch 2.54mm Electrical Cable Assembly

2 Pin Power Cable Assembly

custom coax cable assembly SMA to U.FL

Custom Cable Manufacturing Circular 30Pin Assembly

Custom Cable Manufacturers Industrial Connector Cable

Custom Cable Harness 30Pin IDC Connector

custom cable assembly USB RS422 to RJ45

custom coax cable assembly SMA to U.FL

Custom Cable Assemblies FFC 20Pin Flat Ribbon Cable

Small Coaxial Cable with SMA Male to Female Connector

Product details display of cable assembly

Explore detailed visuals and technical insights of our custom cable assemblies, including connector types, wire specs, shielding options, and precise pin definitions. Each product display showcases high-resolution close-ups, dimensions, materials, and layout structures—helping you evaluate compatibility, flexibility, and quality before ordering.

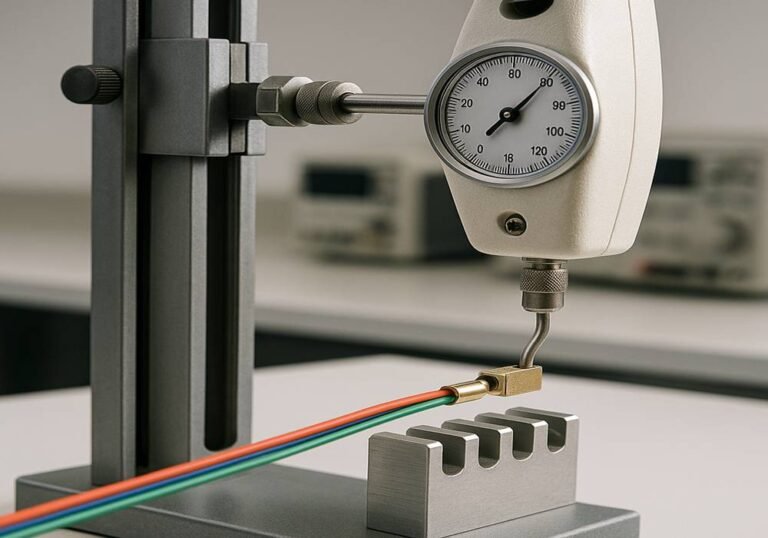

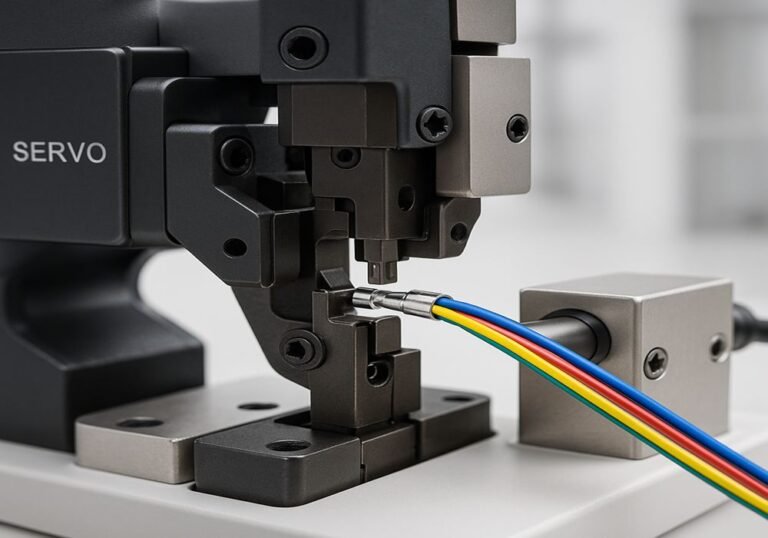

High-Precision Connector Crimping Technology

Our cable assemblies utilize high-precision crimping technology to ensure secure, consistent, and low-resistance connections. Using pneumatic or servo-controlled machines, every crimp is monitored for force, depth, and alignment to match IPC/WHMA-A-620 standards. This level of detail ensures not only mechanical strength but also electrical performance across various applications. Whether it’s JST, Molex, or RF connectors, we validate every joint with pull-force testing and microscopy inspection to ensure durability and reliability in real-world environments.

- Servo or pneumatic crimping machines for stable force and precision

- 100% pull-force and resistance testing on all joints

- IPC/WHMA-A-620 standard compliance for crimp quality

- Optional microscope QC for micro coax and RF connectors

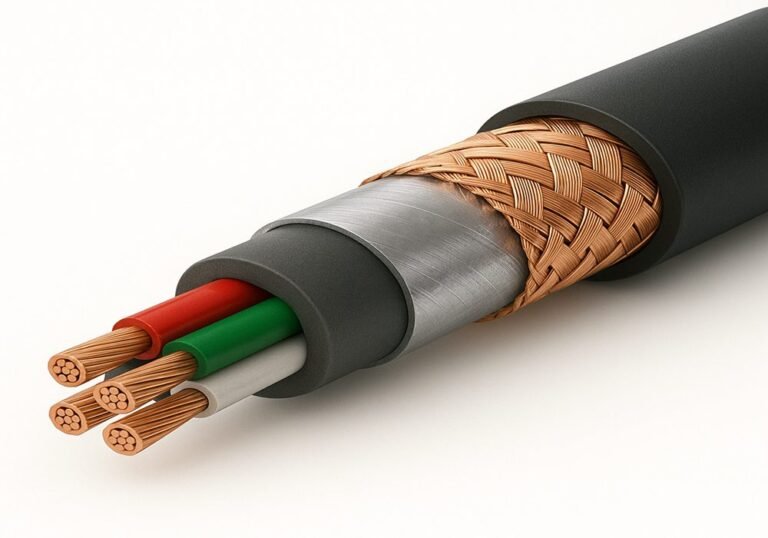

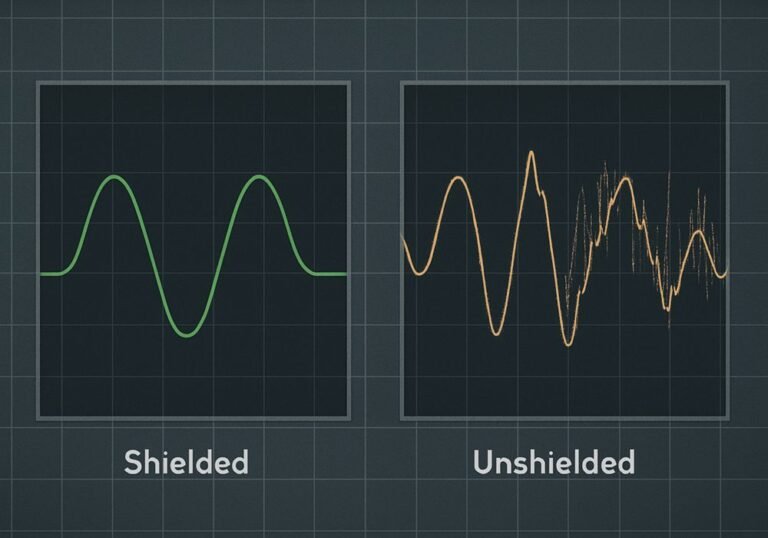

Multi-Layer EMI Shielding Structure Design

Our cable assemblies feature multi-layer shielding to ensure optimal EMI protection in high-frequency and noise-sensitive environments. We combine aluminum foil, braided copper mesh, and conductive tapes to minimize signal interference. These layered structures are critical in applications such as RF communication, industrial automation, and medical imaging. The shielding coverage rate exceeds 95%, verified by oscilloscope and signal integrity testing. Customization options include dual shielding, floating shields, or directional ground referencing depending on system requirements.

- Multi-layer design: foil + braid + conductive tape

- Shielding effectiveness rated >95% coverage

- Applicable for RF, Ethernet, and EMI-critical systems

- Optional drain wire or separate ground lead shielding

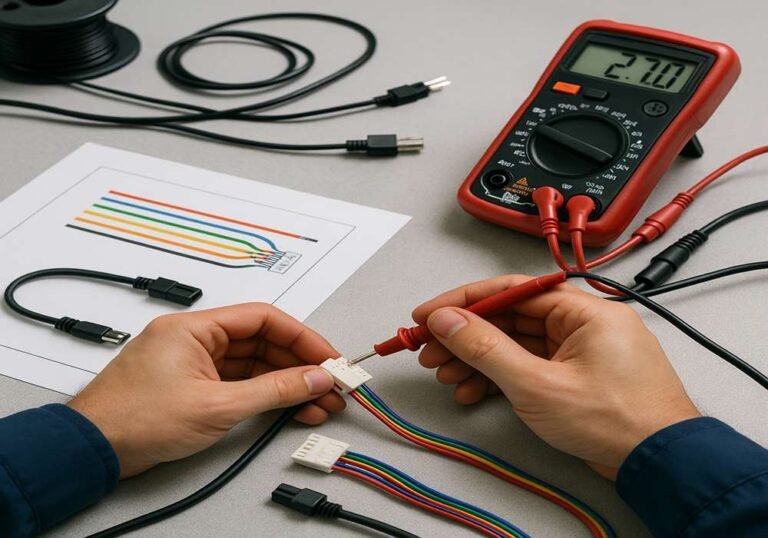

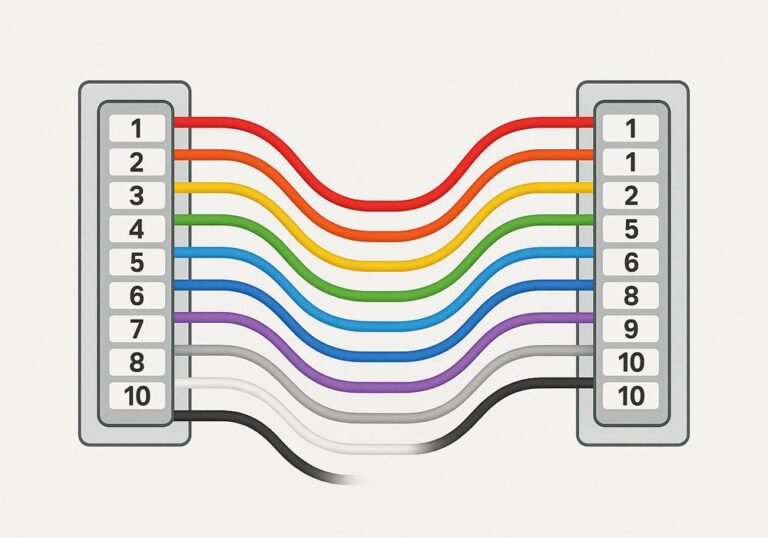

Custom Pinout Configuration for Any Application

Every cable assembly we produce supports full customization of the pinout layout, tailored to the unique interface and functional requirements of your device. Whether it’s mirrored pinouts, crossed Tx/Rx pairs, differential pair mapping, or power-signal separation, our engineers define and verify each connection based on schematics or sample cables. We support standard, non-standard, and reversed pin assignments with high accuracy and traceability. This flexibility ensures perfect compatibility with mating devices, reducing commissioning errors and improving plug-and-play usability.

- Support for 1:1, mirrored, cross-pair, and custom signal mapping

- Engineers verify with schematic, sample, or customer diagram

- Compatibility ensured for multi-protocol, multi-interface systems

- Pin map labels, color codes, and documentation included

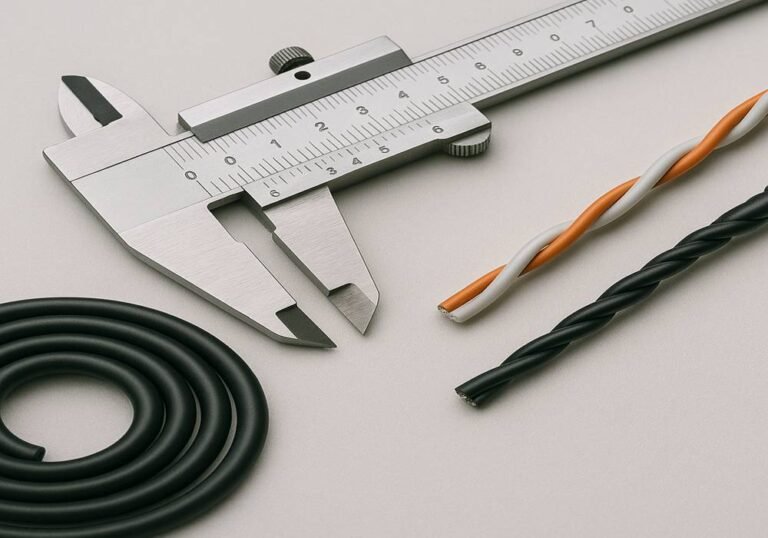

Flexible Jacket and Routing Structure Options

Cable routing can be complex—especially in compact devices or dynamic mechanical environments. We offer flexible jacket structures including round, flat, twisted, spiral, and branched harness types. Each is optimized for space-saving, heat resistance, flexibility, or motion compliance. Jacket materials include PVC, FEP, silicone, woven mesh, and overmolded rubber. Our expertise in routing optimization helps engineers reduce signal crosstalk and mechanical stress points, especially in devices with tight internal layouts.

- Round, flat, spiral, twisted, or branched configurations

- Jacket materials: PVC, silicone, braided, Teflon, etc.

- Designed for tight spaces or repeated motion

- Supports routing through hinges, guides, and cable trays

Labeling, Traceability, and Visual Identification

Our cable assemblies feature robust identification systems for traceability and assembly accuracy. We apply custom-printed heat shrink labels, laser marking, color-coded sleeves, and barcode or QR tags on each cable or branch. These labels help users during installation, maintenance, and system audits. For OEM and export customers, we can apply customer logos, part numbers, and packaging trace codes. Label materials are abrasion-resistant and temperature-stable for harsh environments.

- Heat-shrink, laser, color-ring, and barcode labels

- Support for custom logo, part ID, and QR traceability

- Label placement per customer drawing or spec

- Durable under oil, heat, or abrasion conditions

Certifications and Environmental Compliance Readiness

All our cable assemblies comply with major international standards such as UL, RoHS, ISO 9001, REACH, and PFAS restrictions. We provide test reports and material declarations for every order, including COC, COO, and traceability documents. Our materials are halogen-free, lead-free, and meet fire-retardant or medical-grade options where required. From EV to medical to telecom—our cables are accepted in all certified environments. This makes compliance audits, customs clearance, and system approvals faster and easier.

- UL, ISO, RoHS, REACH, PFAS, COC/COO support

- Material safety data and batch trace reports

- Fire-resistant, halogen-free, and medical-grade options

- Global compliance ready for customs or audits

--- Customized Capabilities Services and Processes

Customize your cable assembly

Discover our customized capabilities and streamlined services, from rapid prototyping and flexible design modifications to detailed CAD drawings and 100% quality inspection. We tailor every cable assembly to meet your exact specifications—length, material, pinout, shielding, and more—with fast turnaround, no MOQ, and full engineering support throughout the process.

Customized Capabilities Services and Processes

Customize your cable assembly

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-Conn, our cable assembly customization capabilities are engineered to support diverse industries including automotive electronics, medical equipment, consumer devices, and industrial automation systems.

- We offer full customization on connector types, pinout logic, cable jacket material, shielding structure, and cable profile (flat, round, spiral, etc.), ensuring every cable meets your exact application needs.

- Our engineering team accommodates both standard and non-standard interface layouts, solving challenges like tight space routing, multi-signal wiring, or high-flex requirements.

- Whether you provide a schematic, a sample, or just a concept, we deliver professional CAD drawings within 24–72 hours, enabling fast alignment and approvals.

- Customers can choose between original-brand or compatible connectors, optimizing for budget, lead time, or brand specification.

- With our no-MOQ policy, we support quick sampling and early-stage prototyping—even for just 1 unit—before full-scale production.

By aligning design with real-world conditions, we deliver cable assemblies that fit precisely, function stably, and scale easily with your system.

Our Commitment to Outstanding Service

At Sino-Conn, we believe delivering a cable assembly is only part of the job—what matters more is how we support your project from first inquiry to final shipment.

- We reply to inquiries quickly and offer drawings or quotations within 30–60 minutes, ensuring fast decision-making for urgent projects.

- Our team includes both sales professionals and technical engineers, allowing us to communicate fluently in both business and technical terms.

- We support live video meetings, sample reviews via camera, and real-time feedback to help customers confirm key details before production.

- Every order is tracked with full documentation, including BOM, drawings, QC reports, COC/COO, and material certifications (UL, RoHS, REACH, etc.).

- From 1-piece samples to high-volume batches, our flexible production system and global logistics support ensure consistent quality and on-time delivery.

We don’t just build cables—we build confidence and long-term cooperation by exceeding customer expectations at every step.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Compact Cable Assembly for Robotics – Precision and Flexibility in Tight Spaces

Our robotics division was launching a compact six-axis robotic arm for precision manufacturing. The biggest challenge was internal wiring: we needed ultra-flexible cable assemblies that could handle constant motion, fit into extremely tight internal passages, and maintain signal integrity over time.

After reviewing multiple suppliers, we partnered with Sino-Conn due to their expertise in micro cable assemblies with custom pinouts, flexible jackets, and tight-bend routing. Their team quickly provided samples using silicone jackets and high-flex stranded copper cores, combined with miniature I/O connectors.

The cables passed over 1 million bending cycles in lab tests and showed no degradation in signal performance. What impressed us most was the pre-labeled harnesses and how each unit came coiled, tested, and plug-ready for our assembly line. They even adjusted the overmold shape to avoid interference with a rotating joint—something our local vendors couldn’t do.

“Sino-Conn’s engineering support was surgical—every modification we requested was delivered precisely. They are now our preferred cable partner for motion applications.”

Kenji Takahashi, Lead Mechanical Engineer

Location: Osaka, Japan

Reliable Cable Assembly for Smart EV Charging Infrastructure – Built for Outdoor Performance

Our team was developing a next-gen EV wall charging station for both residential and commercial markets. One of our biggest technical obstacles was sourcing an outdoor-rated cable assembly that could handle both power and CAN signal, while resisting UV, moisture, and temperature fluctuations common in European climates.

After a thorough supplier screening, we selected Sino-Conn because they offered high-IP rated cable assemblies with dual-layer insulation, tinned copper cores, and automotive-grade connectors. We sent a wiring schematic on Monday, and by Thursday, we received a complete 2D + 3D drawing set with full pinout documentation.

Sino-Conn also suggested using a corrugated PVC jacket with UV-stabilized nylon mesh, which performed exceptionally well in our outdoor simulation chamber. Their engineering team proactively included drain wires and customized the molding shape to fit our enclosure’s mounting slot.

“Their understanding of EV architecture and real environmental needs is outstanding. We’ve made them our official harness supplier for our charging division.”

David Müller, Senior Systems Engineer

Location: Stuttgart, Germany

High-Precision Cable Assemblies for Surgical Imaging Equipment – Zero Signal Drift in Critical Procedures

We manufacture advanced laparoscopic imaging systems used in minimally invasive surgeries. Our newest upgrade required shielded cable assemblies with tight impedance control and biocompatible outer jackets. These cables would transmit high-resolution video and power inside compact medical consoles, and even the slightest signal deviation could risk patient safety.

Sino-Conn demonstrated exceptional technical expertise. They designed a micro coaxial assembly with medical-grade TPU jacket, 95% braid shielding, and custom-molded micro push-pull connectors. We received full IPC-compliant drawings, dielectric test reports, and sterilization compatibility confirmation within 3 days.

Their product passed EMI/ESD tests and worked flawlessly in our 72-hour stress test simulation. Their team also helped us revise our assembly method, reducing final integration time by 20%. Their responsiveness, cleanroom production, and low MOQ made them stand out among Asian suppliers.

“Precision, speed, and service—Sino-Conn delivered all three. They made our surgical upgrade seamless.”

Ayaka Tanaka, Procurement Manager

Location: Osaka, Japan

industry Application of cable assembly

Cable assemblies from Sino-Conn are widely used across industries such as automotive, medical, industrial automation, aerospace, telecommunications, and consumer electronics. Designed for performance, durability, and EMI protection, our assemblies meet strict industry standards and offer flexible customization to suit diverse application environments, including harsh and mission-critical conditions.

Automotive Powertrain Systems – Engineered for Heat, Vibration & Signal Integrity

Application Scenario:

Cable assemblies in automotive powertrain systems must withstand harsh thermal, mechanical, and electrical conditions. These include engine sensors, ECU control lines, and transmission harnesses, which require high-temperature materials, vibration resistance, and stable signal performance.

Devices & Products:

- Engine Control Unit (ECU) Harnesses

- Oxygen Sensor Cable Assemblies

- Transmission Solenoid Connectors

Industry Challenges:

- High temperatures (up to 150–200°C) around engine compartments

- Continuous mechanical vibration and movement

- EMI interference from ignition and motor systems

Our Cable Assembly Solution:

- Use of high-temp fluoropolymers (FEP, Tefzel) and heat-resistant jacketing

- Strain relief structures and crimp reinforcement to prevent fatigue failures

- Multi-layer shielding (aluminum foil + copper braid) to ensure signal fidelity

Medical Diagnostic Devices – Precision Signal Cable Assemblies in Compact Spaces

Application Scenario:

Medical devices such as ultrasound machines, ECG monitors, and imaging scanners require cable assemblies that are compact, biocompatible, and EMI-protected. These cables must also maintain accurate signal transmission in highly sensitive environments.

Devices & Products:

- Ultrasound Probe Cable Assemblies

- ECG Lead Wire Harnesses

- CT Scanner Internal Harnessing

Industry Challenges:

- Must be biocompatible and sterilizable

- Fit into limited internal space with high routing density

- Prevent any signal distortion or noise in diagnostic output

Our Cable Assembly Solution:

- Use of soft medical-grade TPE and silicone jackets

- Flexible, high-pin-count micro-coaxial or shielded twisted pairs

- RoHS/REACH/ISO13485-compliant production with 100% inspection

Industrial Robotics & Motion Control – Durable Cable Assemblies for Dynamic Bending

Application Scenario:

Industrial robots and CNC systems rely on cable assemblies for servo motor control, sensor feedback, and power distribution. These cables must endure continuous movement, high EMI, and chemical exposure in manufacturing environments.

Devices & Products:

- Servo Motor Feedback Cable

- Robot Arm Control Harness

- CNC Machine Sensor Cabling

Industry Challenges:

- Repeated dynamic flexing and drag chain usage

- Exposure to oils, coolants, and abrasives

- Precise signal transfer to maintain motion control accuracy

Our Cable Assembly Solution:

- Use of highly flexible PUR or TPE jacketed cables with >5 million bend cycles

- Shielding with braid + foil, low-capacitance pairs for signal clarity

- Custom overmolded or grommeted designs to protect strain points

Renewable Energy Equipment – Weatherproof Cable Assemblies for Harsh Outdoor Use

Application Scenario:

Solar and wind systems require cable assemblies that can handle UV, humidity, salt fog, and wide temperature ranges. These systems use custom cables for power transfer, inverter connection, and control modules.

Devices & Products:

- Solar Tracker Positioning Harness

- Wind Turbine Control Cables

- Inverter Signal Assemblies

Industry Challenges:

- Must resist UV, ozone, and temperature fluctuations (-40 to +90°C)

- Waterproof sealing against rain, ice, and salt corrosion

- Long lifespan of 20+ years in field deployments

Our Cable Assembly Solution:

- UV-rated XLPE jackets and IP67/IP68 waterproof connectors

- Silicone or TPE sealing boots and potting for long-term protection

- Salt-spray tested and certified to IEC 60529 & UL standards

Data Center & Server Systems – High-Speed Cable Assemblies for Network Backbone

Application Scenario:

Modern data centers need custom cable assemblies for signal and power distribution in high-density server racks. These include high-speed interconnects like SFP/QSFP, shielded DC power cables, and management bus wiring.

Devices & Products:

- QSFP+ High-Speed Cable Assemblies

- DC Busbar Harnesses

- BMC/Management Bus Lines

Industry Challenges:

- Must support 10–100 Gbps signal integrity in short distances

- High cable density requires compact, thermally stable designs

- EMI containment to avoid cross-talk in tight spaces

Our Cable Assembly Solution:

- Low-loss twinaxial and shielded differential pairs with impedance control

- Overmolded locking connectors and heat-resistant TPE jackets

- 100% eye diagram testing and TDR verification on all batches

Aerospace Avionics Systems – Lightweight & EMI-Shielded Cable Assemblies for Flight Electronics

Application Scenario:

In modern aircraft, cable assemblies are used in avionics systems including navigation, communication, and sensor integration. These must be lightweight, flame-retardant, and EMI-shielded, while meeting rigorous certifications.

Devices & Products:

- Cockpit Display Control Cables

- Flight Control Sensor Harnesses

- RF Communication Module Assemblies

Industry Challenges:

- Strict weight limitations demand ultra-light designs

- Compliance with AS9100, FAR 25.853, MIL-STD EMI standards

- Zero tolerance for in-flight failures

Our Cable Assembly Solution:

- Use of PTFE, FEP, and PEEK for weight and flame rating

- Multi-layer EMI shielding with foil and braid

- AS/ISO certified production and 100% testing for reliability

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized cable assembly services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I request a fully custom cable assembly based on my design?

Yes. We support 100% customization including connectors, pinouts, cable jacket, shielding, and length.

Do you have a minimum order quantity (MOQ)?

No MOQ. We support 1pcs for sampling and prototyping.

How fast can you deliver samples?

Standard samples take 7–14 days. Urgent ones can ship within 2–3 days.

Can you provide drawings before production?

Yes. We offer CAD + PDF drawings for approval before mass production.

What certifications can you provide?

We offer ISO, UL, RoHS, REACH, PFAS, COC, COO and more on request.

Can I use original brand connectors in my assembly?

Yes. We offer both original and alternative connectors based on your budget and lead time.

Can I change the pin definition of the cable?

Yes. You can specify pin-to-pin wiring, which we will confirm with drawings.

Do you offer shielded and EMI-resistant designs?

Yes. We support EMI shielding with braided, foil, or conductive fabric options.

Can you match specific connector brands or models?

Yes. Just share the part number or reference image, and we’ll match it.

How do you guarantee product quality?

100% full inspection at three stages: during production, post-assembly, and before shipment.

Do you accept urgent orders?

Yes. We prioritize urgent samples and small-volume orders with flexible scheduling.

Can you help design the cable if I only have functional requirements?

Yes. Our engineers can propose a solution and draw it for confirmation.

What are your standard payment terms?

T/T is standard. Net 30/60/90 days available for large OEMs after credit approval.

Can I get pricing for different volumes?

Sure. We provide tiered pricing for 1pcs, 100pcs, 1K pcs and more.

How do I get a quote quickly?

Send your drawing, part number, or sample photo. We’ll respond in 30–60 minutes.

What cable types do you support?

We support coaxial, ribbon, LVDS, twisted pair, flat flex, PVC, Teflon, and more.

What jacket materials do you offer?

Options include PVC, TPE, nylon braid, FEP, silicone, and more.

Can you handle waterproof cable assemblies?

Yes. We support IP67/IP68 waterproof designs using overmolded or sealed connectors.

How do you handle confidential designs?

We sign NDAs and store your files securely in encrypted systems.

Do you support online meetings to discuss my project?

Absolutely. We offer video calls with engineers to support real-time discussions.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China