Medical Cables in Hospitals: Uses, Types, and Safety Standards

- andy

In today’s hospitals, life-saving information flows through an invisible network — not Wi-Fi, not cloud servers, but physical connections. Medical cables are the unsung heroes behind the vital signs on monitors, the clear images from MRI scans, and the smooth functioning of surgical robots. Without them, critical data would be lost, diagnoses delayed, and patient safety compromised.

Medical cables are specialized electrical or fiber-optic assemblies designed for hospital use, transmitting power, data, or signals between medical devices. Built for biocompatibility, flexibility, and reliability, they connect patient monitors, imaging systems, surgical tools, and life-support equipment. Meeting strict standards like IEC 60601 and ISO 13485, these cables ensure safe, interference-free performance in critical care environments.

Imagine a neonatal intensive care unit (NICU). A baby’s heartbeats are picked up by ECG electrodes, travel through a soft, shielded cable, and reach a monitor that alerts staff in milliseconds. That cable isn’t just hardware — it’s the lifeline linking patient and caregiver. In this article, we’ll uncover what medical cables do, why their design matters, and how Sino-conn turns them into precision tools that keep hospitals running and patients safe.

What is a Medical Cable?

A medical cable is a purpose-built cable assembly for healthcare applications, used to transmit electrical power, data, or optical signals between medical devices. Designed to be safe, hygienic, and durable, they withstand frequent sterilization and bending, and meet regulatory standards for hospital use.

Medical cables differ from ordinary industrial cables in almost every way. They use medical-grade materials like silicone or TPU for outer jackets, preventing skin irritation and resisting bacteria. Conductors may be silver-plated copper for optimal signal clarity, and shielding prevents electromagnetic interference from nearby hospital equipment.

In hospital settings, cables often operate 24/7 under physical stress. A patient monitor cable may be plugged in and unplugged dozens of times a day, twisted during patient movement, and cleaned after each use. Ordinary cables would degrade quickly under such treatment; medical cables are tested for tens of thousands of flex cycles and exposure to harsh disinfectants.

For Sino-conn, defining a “medical cable” goes beyond technical specs. It’s about ensuring uninterrupted data flow in environments where even a second of downtime could impact patient outcomes. This is why Sino-conn designs every cable with application-specific safety margins — not just to pass compliance tests, but to exceed them in real-world conditions.

Role of Medical Cables in Patient Monitoring Systems

In patient monitoring, medical cables link sensors like ECG, SpO₂, and blood pressure cuffs to monitors, transmitting accurate vital data in real time. Their reliability ensures clinicians can respond instantly to changes in patient condition, preventing delays in treatment and improving safety outcomes.

Patient monitoring systems are the heartbeat of modern hospitals. From intensive care units to general wards, they provide a continuous stream of life-critical information. Medical cables serve as the physical bridge between the patient and the monitoring device, carrying sensitive signals that must arrive instantly and without distortion.

Key Monitoring Applications:

| Sensor Type | Purpose | Cable Requirements |

|---|---|---|

| ECG/EKG Leads | Measures heart’s electrical activity | High EMI shielding, ultra-flexible, skin-safe jackets |

| SpO₂ Probes | Measures oxygen saturation in blood | Optical signal clarity, antimicrobial surface |

| NiBP Cuffs | Measures blood pressure | Integrated tubing + cable, kink resistance |

| Temperature Probes | Tracks patient body temperature | Small diameter, patient comfort, accuracy |

Technical Specifications – Common Patient Monitoring Cables

| Cable Type | Outer Diameter (OD) | Min. Bending Radius | Operating Temp. Range | Sterilization Method(s) | Compliance Standards |

|---|---|---|---|---|---|

| ECG/EKG Leads | 2.0–3.5 mm | ≥ 10 × OD | -20°C to +80°C | Wipe-down, ETO, Autoclave | IEC 60601, ISO 13485, RoHS |

| SpO₂ Probe Cables | 2.5–4.0 mm | ≥ 8 × OD | -15°C to +70°C | Wipe-down, ETO | IEC 60601, ISO 10993 |

| NiBP Cuff Cables | 4.0–5.5 mm | ≥ 12 × OD | -10°C to +60°C | Wipe-down | IEC 60601, REACH |

| Temperature Probes | 1.8–3.0 mm | ≥ 8 × OD | -30°C to +85°C | Wipe-down, Autoclave | IEC 60601, ISO 13485 |

Notes:

- OD and bending radius values may vary depending on customization.

- Sino-conn offers both single-use and reusable designs with tailored sterilization compatibility.

- All models undergo 100% inspection for electrical continuity, insulation resistance, and mechanical durability before shipment.

Why Cable Quality Matters

- Accuracy: ECG signals are in microvolts — even small interference can distort readings. Sino-conn uses silver-plated copper conductors and multi-layer shielding to maintain signal purity.

- Patient Comfort: Prolonged monitoring requires cables that are soft, lightweight, and flexible to prevent skin irritation. Medical-grade silicone or TPU ensures comfort even during extended use.

- Durability: In a typical ICU, a cable may be repositioned over 10,000 times in a month. Sino-conn’s designs are tested for over 1 million flex cycles to ensure longevity.

Real-World Example

In one European hospital, replacing generic ECG cables with Sino-conn’s high-flex, antimicrobial models reduced cable replacement frequency by 40% and false alarms by 18% over six months. The hospital estimated annual savings of €25,000 in cable costs and staff time.

Design Innovations from Sino-conn

- Color-Coded Leads – Reduces setup errors during emergencies.

- Quick-Disconnect Mechanisms – Allows for rapid patient transfers without cable tangling.

- Low-Noise Shielding – Maintains clean waveforms even in high-EMI environments like operating rooms.

- Custom Pin-Outs – Matches specific patient monitors, avoiding compatibility issues.

By engineering cables that balance signal integrity, patient comfort, and durability, Sino-conn ensures that monitoring systems work seamlessly — because in hospitals, a reliable signal can save a life.

What are the Three Basic Types of Cables?

The three basic types of medical cables are patient monitoring cables, diagnostic imaging cables, and surgical or therapeutic device cables. Each type is engineered for its specific hospital application, with unique design, shielding, and sterilization requirements.

- Patient Monitoring Cables – For ECG, SpO₂, NiBP, and temperature probes. Must be flexible, biocompatible, and resistant to daily cleaning.

- Diagnostic Imaging Cables – For MRI, CT, ultrasound, and PET systems. Require low-loss transmission and EMI immunity.

- Surgical & Therapeutic Cables – For electrosurgical units, endoscopes, and laser devices. Need heat resistance and high electrical safety margins.

Sino-conn tailors each cable category to its environment. Imaging cables, for example, may include multiple coaxial and twisted-pair elements for high-definition signal transmission. Surgical cables are reinforced for mechanical stress and insulated to prevent heat transfer. By matching materials, shielding, and connectors to each category’s needs, Sino-conn delivers performance that generic suppliers can’t match.

Connectivity Solutions for Diagnostic Imaging Equipment

Diagnostic imaging relies on cables that transmit large amounts of data without interference. MRI cables must be non-ferromagnetic, ultrasound cables require multi-core shielding, and CT/PET cables need low-loss performance for accurate images.

MRI machines operate in magnetic fields up to 3 Tesla, which can attract ferrous materials with dangerous force. Sino-conn uses non-ferromagnetic alloys and fiber optics to eliminate risk. For ultrasound, where images depend on high-frequency sound waves, cables integrate precision-matched impedance lines to preserve signal integrity.

CT and PET scanners require split-second image capture. Low-loss coaxial cables ensure image data reaches processing units without delay or distortion. In one hospital upgrade project, replacing legacy cables with Sino-conn assemblies improved scan clarity by 15% and reduced repeat scans, saving both patient time and hospital costs.

What is Medical Wire Used For?

Medical wire is used to transmit electrical power, data, or control signals in medical devices. It can also carry optical signals in fiber-optic form for high-speed data transfer.

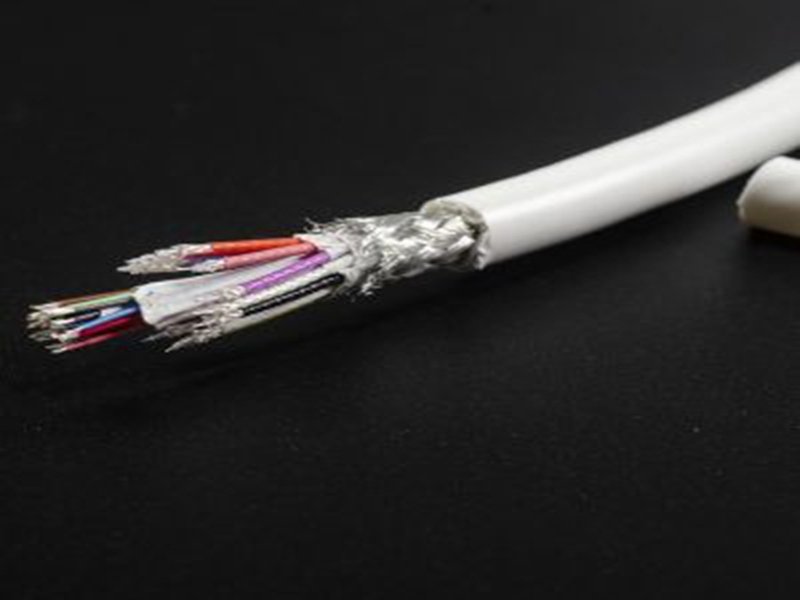

Inside every medical cable is the medical wire — the actual conductor of electricity or light. Depending on the application, it may be ultra-fine stranded copper for flexibility, silver-plated for conductivity, or fiber optic for speed and immunity to EMI.

Applications range from powering infusion pumps to delivering sensor signals in endoscopes. Sino-conn selects wire gauge and plating based on both electrical needs and mechanical durability, ensuring optimal performance for years of hospital service.

What is a Medical Connector?

A medical connector is the interface that joins a medical cable to a device or another cable. It must be durable, easy to sterilize, and designed for secure, repeatable connections in hospital environments.

Connectors can be push-pull, bayonet, or threaded, and may be original manufacturer (OEM) or compatible designs. Sino-conn offers both, advising customers on the trade-offs between cost, lead time, and customization. For example, OEM connectors may have longer lead times but offer brand-matched compatibility; compatible connectors can be customized faster and more affordably without sacrificing performance.

Customization and Regulatory Compliance for Hospital-Grade Medical Cables

Hospital-grade cables can be customized in length, connector type, shielding, and materials, while meeting regulations like IEC 60601, UL, and ISO 13485.

Customization is key for fitting cables into specific hospital workflows. Sino-conn produces CAD drawings within hours, samples in days, and final production in 2–4 weeks. Compliance isn’t optional — it’s proof the cable is safe. Every product comes with full certification, and quality control includes 3-stage inspections: in-process, final assembly, and pre-shipment.

Safety, Hygiene, and Cable Management in Clinical Environments

Hospital cables use antimicrobial jackets, smooth surfaces, and organized routing to ensure hygiene and safety, reducing infection and tripping hazards.

Infection control teams love Sino-conn’s smooth silicone and TPU jackets, which resist bacterial growth and stand up to harsh cleaning. Disposable cables are available for high-risk environments. Cable routing solutions, like color coding and quick disconnects, keep wards tidy and safe.

In hospitals, every second counts — and every connection matters. Sino-conn’s medical cables combine reliability, compliance, and customization to meet the toughest demands of modern healthcare. Whether you need a high-flex ECG lead, an MRI-compatible imaging cable, or a custom connector assembly, Sino-conn can deliver — fast, certified, and built to last.

Contact Szoneier today to discuss your requirements, get expert advice, and receive a custom quote with no minimum order quantity.

Related Keywords :medical cables, hospital equipment cables, patient monitoring, diagnostic imaging, medical wire, medical connectors, custom medical cables, IEC 60601 compliance, cable hygiene, Sino-conn

With over 18 years of OEM/ODM cable assemblies industry experience, I would be happy to share with you the valuable knowledge related to leather products from the perspective of a leading supplier in China.

manufacturer catalogue

Custom Micro Coaxial Cable →

Custom RF Coaxial Cable Assembly →

Custom FFC(Flat Flexible Cable) →

Custom Patch Cable →

Custom Circular Connector Cables →

Custom D-Sub Analog Cable →

Custom Power Cord →

Custom Fiber Optical Transceiver →

Custom Receptacle Connectors →

Get A Sample Now From Factory→

Latest blogs

Here, developing your OEM/ODM custom cable assemblies collection is no longer a challenge—it’s an excellent opportunity to bring your creative vision to life.