Custom Micro coaxial cable manufacturer

At Sino-Conn, we specialize in custom Micro Coaxial Cables designed for cutting-edge electronics. Whether you’re building next-gen medical devices, aerospace systems, or compact consumer gadgets, our ultra-thin, high-performance cables provide unmatched flexibility, signal integrity, and design versatility. With rapid prototyping, no MOQ, full certifications (UL, ROHS, REACH), and guaranteed compatibility with I-PEX, Hirose, JAE, and more—we empower your innovations to go further.

Let us turn your concept into reality—fast samples, full customization, and expert engineering support.

Partner with a manufacturer that delivers more than just cables—deliver confidence.

Why choose Micro coaxial cable from sino-conn

Choosing micro coaxial cables from Sino-Conn means partnering with a manufacturer that offers unmatched customization, fast prototyping, and engineering precision. With no MOQ, rapid 30-minute drawings, and full compliance with UL, ROHS, and ISO standards, Sino-Conn delivers flexible, high-performance solutions trusted across medical, military, and consumer electronics industries.

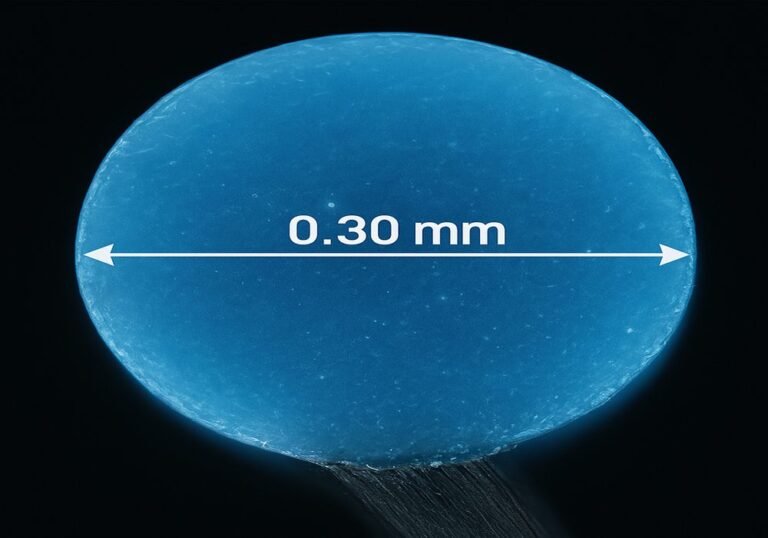

Ultra-Thin Micro Coaxial Cable for Space-Constrained Electronics

Our micro coaxial cables are engineered with ultra-thin diameters—starting from as low as 0.2mm—making them ideal for space-limited applications like smartphones, medical devices, and aerospace modules. Despite their compact size, these cables ensure stable high-frequency signal transmission with minimal loss. Their flexibility and precision help engineers design smaller, more powerful, and tightly integrated systems without compromising performance.

Fully Customizable Micro Coaxial Cable for Unique Design Requirements

We offer full customization for our micro coaxial cables, including cable length, pin configuration, jacket material, shielding structure, connector type, and layout. Whether you need non-standard pinouts, medical-grade sheathing, or brand-specific connectors like I-PEX or Hirose, we can tailor every detail to fit your product design and application needs—without MOQ. Custom drawings and samples are delivered in as fast as 30 minutes.

High-Frequency, Low-Loss Signal Transmission for Reliable Data Integrity

Our micro coaxial cables support stable high-frequency signal transmission with ultra-low attenuation, making them perfect for applications like 5G modules, medical imaging, and high-resolution video systems. With controlled impedance and superior EMI shielding, our cables ensure reliable signal integrity even in high-noise environments. Engineers can trust our cables for mission-critical performance without compromise.

100% Quality Inspection with Triple Testing Procedures

Every micro coaxial cable we produce undergoes triple-stage quality control: in-process inspection, final assembly testing, and pre-shipment verification. Our professional QC team uses advanced equipment to ensure zero-defect delivery. From electrical performance to physical durability, every cable is thoroughly tested for reliability. Quality assurance isn’t optional—it’s our standard.

Fast Samples and On-Time Delivery for Urgent Projects

We understand time-sensitive projects. That’s why we offer rapid sampling—within 2–3 days—and batch delivery in as fast as 2 weeks. Urgent prototypes? No problem. Our streamlined production and engineering teams are ready to meet tight deadlines with precision and consistency, ensuring your project moves forward without delay.

Supports Multiple Connector Types and Custom Pin Configurations

Our micro coaxial cables are compatible with a wide range of high-frequency board-to-cable connectors. Whether you require standard plug types or custom-tailored pin configurations, we can assemble and test to your exact design. Both original-grade and equivalent-quality connector options are available to match your cost, delivery, and performance requirements—ensuring excellent fit and signal reliability.

Detailed specifications and parameters of Micro coaxial cable

| No. | Pin Configuration Definition | Connector Model | Cable Specification | Length (mm) | Structure Type | Wrapping Material |

|---|---|---|---|---|---|---|

| 1 | End A 1.0mm Pitch 4Pin to End B same pinout | 20453-040T | 32AWG*1C + AL + Drain | 300 | Round | PTFE Tape |

| 2 | End A soldered, End B with connector | IPEX 20373-040T | 36AWG*4C + Shield | 500 | Molded | Acetate Cloth |

| 3 | Both ends same connector, cross pinout | Hirose DF36 | 38AWG*2C | 150 | Flat | Nylon Braided Mesh |

| 4 | One end shielded, one end bare wire | Custom Header | 34AWG*4C + AL + Mylar | 250 | Molded | Conductive Fabric |

| 5 | One end soldered with marker sleeve | 20453-030T | 40AWG*1C | 200 | Round | PVC Sleeve |

| 6 | End A 1.0mm connector, End B 1.25mm plug | Mixed (A+B types) | 36AWG*5C + Shield | 450 | Flat | FEP Tube |

| 7 | End A connector, End B PCB socket | Board Socket | 38AWG*3C + Shield | 600 | Molded | Nano Tape |

| 8 | Both ends with customized connectors | Customized | 32AWG*1P + Mylar + Foil | 100 | Round | Acetate + PTFE Combo |

| 9 | End A with connector, End B with pin header | 20347-030T | 36AWG*2P | 180 | Flat | Conductive + PVC Layer |

| 10 | Fully shielded medical-grade assembly | Medical-Grade | 34AWG*4C + Shield + Drain | 350 | Molded | PTFE + Nylon Braided Mesh |

Micro coaxial cables are not standardized components—they are custom-engineered solutions tailored to each customer’s specific application. Variations in cable length, pinout configuration, shielding level, flexibility, connector compatibility, and space constraints require adaptable design.

Our experienced engineering team can quickly translate customer drawings, specifications, or functional needs into precise cable assemblies. We provide full technical support from drawing confirmation to prototyping, ensuring a smooth transition from concept to production. Whether it’s a standard configuration or a highly customized request, we deliver professional solutions with fast turnaround.

Customized Micro coaxial cable styles

Trusted by 300+ global brands,1000+ styles have been developed.

BNC to MCX Micro Coaxial Cable Assembly

Custom I-PEX Micro Coaxial Cable Assembly

I-PEX Micro Coaxial LVDS Cable Assembly

Mini Coax Micro Coaxial Cable Assembly

Multi-core Micro Coaxial Cable Assembly

SMA to Mini RF Micro Coaxial Cable Assembly

SMA to N-Type Micro Coaxial Cable Assembly

Product details display of Micro coaxial cable

Explore detailed specifications of our custom Micro Coaxial Cables, including conductor material, insulation type, shielding structure, OD, voltage, flexibility, flame resistance, and more. Each cable is engineered for precision signal transmission in compact applications, with options for EMI shielding, halogen-free materials, and custom pin-outs.

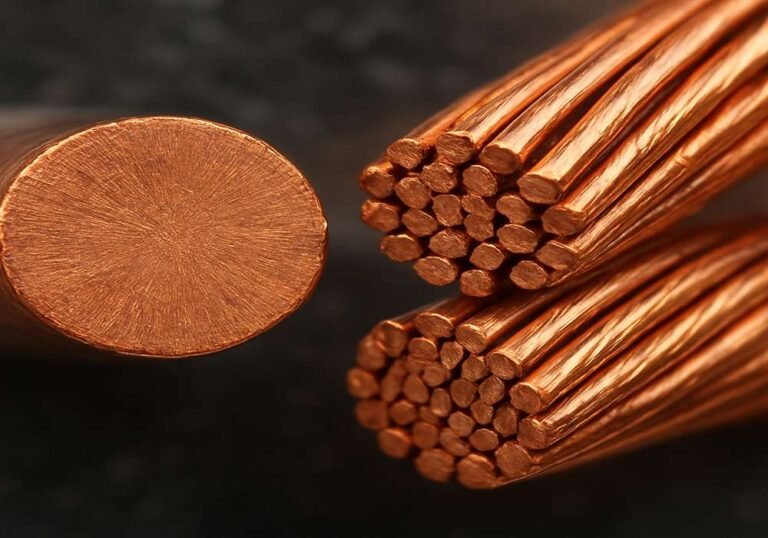

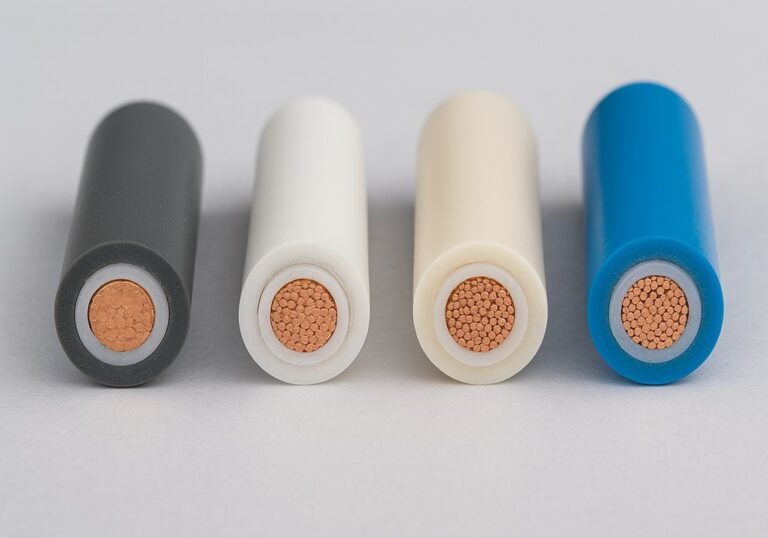

Inner Conductor Structure

The inner conductor is the signal backbone of a micro coaxial cable and plays a critical role in determining transmission speed, signal integrity, and electrical stability. We offer a wide range of conductor materials and constructions, tailored for different project needs.

- Material Options: We typically use high-conductivity materials such as silver-plated copper, bare copper, and tin-plated copper. These materials offer varying levels of conductivity, oxidation resistance, and mechanical properties.

- Conductor Type:

- Single core: Ideal for high-frequency, low-loss transmission.

- Stranded: Offers higher flexibility, suitable for moving or folding installations.

- Conductor Diameter: Ranges from 0.05mm to 0.12mm, depending on gauge and mechanical flexibility.

- Customization: Depending on customer requirements (e.g., camera module vs. medical device), we can adjust the conductor type and size to match specific design and performance needs.

The inner conductor is the foundation of a reliable cable. Choosing the right type ensures stable signal performance and extends the product’s lifecycle under demanding conditions.

High-Flex Copper Strands with Optimized Conductor Layout

The insulation layer serves as the critical dielectric barrier between the inner conductor and the shielding layer. It is one of the most important components affecting the characteristic impedance, signal attenuation, and dielectric strength of a micro coaxial cable. We offer a range of premium insulation materials and precise manufacturing control:

Material Selection:

- FEP (Fluorinated Ethylene Propylene): Excellent dielectric properties, high heat resistance, low friction.

- PFA (Perfluoroalkoxy): Enhanced chemical resistance and higher mechanical strength.

- ETFE: Strong, lightweight, with good abrasion resistance.

- PE: Cost-effective option with stable insulation performance.

Thickness Precision:

- Advanced extrusion equipment ensures ±0.01mm tolerance in insulation thickness.

- Uniform wall thickness enhances signal stability and impedance control.

Dielectric Properties:

- Low dielectric constants (typically 2.1–2.3) help maintain high signal integrity, even at gigahertz-level frequencies.

Customization Support:

- We tailor insulation material and thickness according to the specific demands of high-speed data transmission, compact mechanical routing, or thermal performance.

High-quality insulation ensures consistent electrical performance and mechanical protection, even in space-constrained, high-frequency applications.

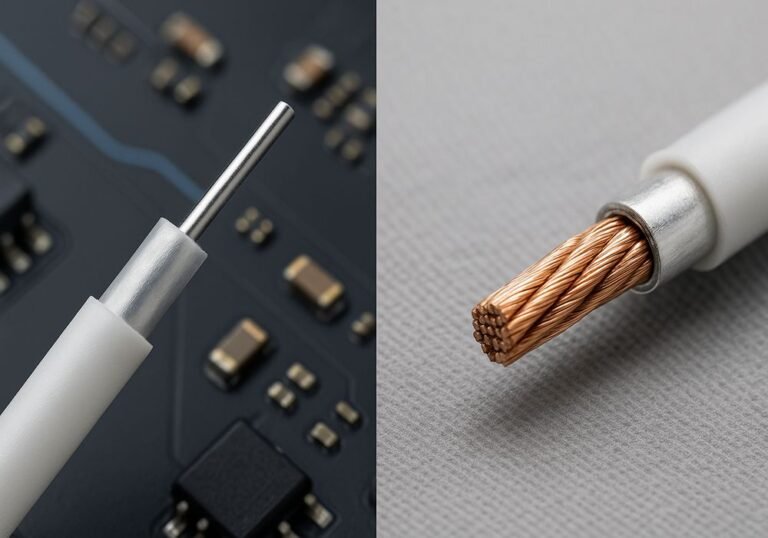

Multi-Layer Shielding Structure Design

The shielding structure in a micro coaxial cable is a vital component for protecting signal integrity against external electromagnetic interference (EMI) and radio frequency interference (RFI). We offer versatile multi-layer shielding solutions tailored to meet diverse performance requirements:

Shielding Composition Options:

- Aluminum Foil + Tinned Copper Braid: Common for high EMI-sensitive environments.

- Metalized Polyester Film: Lightweight, flexible, ideal for space-limited assemblies.

- Dual-layer Braiding: For enhanced shielding efficiency over longer transmission distances.

Performance Customization:

- Shielding coverage can be tailored between 90% to 98% depending on project sensitivity.

- Braid direction and wire density can be customized for flexibility or rigidity.

- We support 1 to 3-layer shielding designs for mission-critical applications.

Application Scenarios:

- High-definition camera modules.

- Industrial automation lines with motor interference.

- Medical signal cables requiring ultra-clean signals.

Quality Assurance:

- Every shielded assembly is tested for continuity, shielding integrity, and impedance.

- Reports can be provided upon request for electromagnetic compliance.

Proper shielding ensures clean, stable, and interference-free signal transmission, especially critical in high-frequency or noisy electrical environments.

Outer Jacket Material & Environmental Resistance

The outer jacket of a micro coaxial cable serves as the first line of defense against mechanical, thermal, and environmental stress. Choosing the right jacket material is critical to ensure product longevity, safety, and stable field performance. We offer a wide range of jacket options for diverse environments:

Material Options:

- PVC Sleeve: Cost-effective and flexible, suitable for standard indoor use.

- FEP Jacket: High-temperature resistance, chemical inertness, and low friction.

- Halogen-Free Flame Retardant: For safety-critical, low-smoke environments like public spaces or transportation.

- Nylon Braided Mesh: Enhances abrasion resistance and aesthetics.

- Anti-Corrosive Tape: Suitable for harsh industrial or outdoor conditions.

Environmental Properties:

- Heat Resistance: From –60°C to +200°C.

- UV Resistance: Prevents degradation under prolonged sunlight.

- Oil, Flame, and Water Resistance: Meets standards like UL VW-1, IP67, etc.

- Chemical Tolerance: For use in laboratories or chemical plants.

Customization:

- Jacket color, texture, and shape can be customized to match product design and brand identity.

- We also support double-layer or reinforced jackets for rugged applications.

A properly selected outer jacket ensures the cable is not only electrically sound but also physically resilient in demanding real-world conditions.

Connector Termination & Soldering Process Control

Connector termination is a critical aspect of micro coaxial cable assemblies, as it directly affects the electrical reliability and mechanical stability of the final connection. At Sino-Conn, we offer a broad range of connector options and highly controlled soldering techniques to meet even the most demanding customer applications.

Connector Types Supported:

- Crimp-type connectors: Ideal for mechanical retention and mass production.

- SMT (Surface Mount): Suitable for compact PCBs and automated assembly.

- Through-hole / wire soldered types: Flexible for customized or prototype builds.

- Common pitch options: 0.4mm, 0.5mm, 1.0mm, 1.25mm.

Soldering Precision:

- All soldering is performed under temperature-controlled environments.

- Visual magnification inspection ensures correct solder depth and pin alignment.

- We follow IPC-A-610 Class II/III standards where required.

Pinout Customization:

- Flexible routing based on customer specifications, including:

- Crossed layouts

- Ground/signal isolation

- Reverse or mirrored pinouts

- Dual-head and asymmetrical assemblies

Reliability Testing:

- All assemblies undergo solder joint pull-force testing.

- 100% continuity and pin-to-pin verification before shipment.

By maintaining strict process control and offering pin-level customization, we ensure each connector termination meets both electrical performance and mechanical endurance requirements

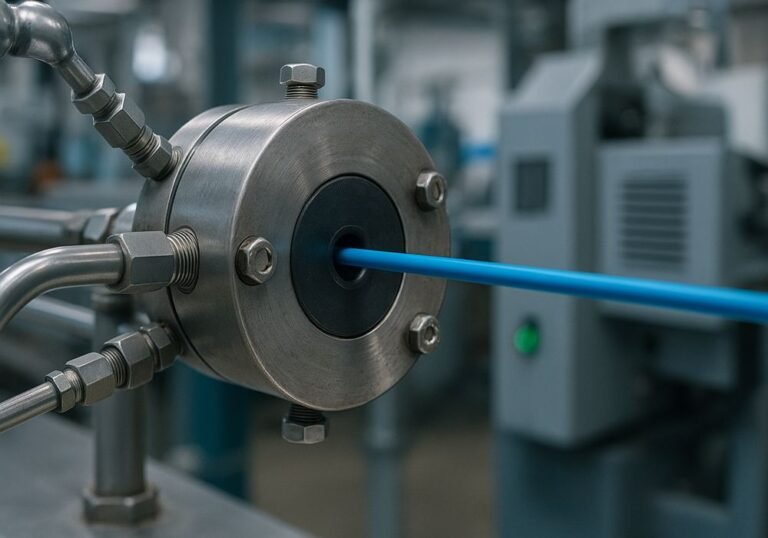

Rapid Customization & Drawing Confirmation Workflow

Given the custom nature of micro coaxial cable assemblies, we offer a streamlined and highly responsive customization process. This ensures that your requirements—no matter how specific—are quickly and accurately translated into manufacturable designs.

Flexible Input Channels:

- We accept drawings, part numbers, pinout tables, sample units, or verbal descriptions.

Fast Design Turnaround:

- Preliminary drawings can be generated within 30 minutes.

- Standard output formats include CAD and PDF with detailed annotations.

Drawing Details Included:

- Cable length, pinout mapping, connector orientation, jacket structure.

- Bending radius, insulation OD, shield layout, and electrical path definition.

Pre-Production Approval Workflow:

- No order is sent to production without client-signed drawing confirmation.

- Drawings are tailored per customer feedback to ensure full accuracy.

Engineering Support:

- We provide real-time communication (email, video call, live demo).

- Our engineers collaborate directly with your R&D or project team.

This rapid and precise engineering workflow reduces lead times, prevents rework, and builds trust in long-term cooperation—especially for R&D and small-batch OEM clients..

--- Customized Capabilities Services and Processes

Customize your Micro coaxial cable

Discover our full-spectrum customized capabilities for Micro Coaxial Cable assemblies, from connector selection and cable length to pin definition, shielding, and material customization. We offer rapid CAD-to-PDF drawing services, 30-minute quoting, flexible prototyping, and full-scale production—all backed by ISO, UL, and RoHS compliance to meet your industry’s exact standards.

Customized Capabilities Services and Processes

Customize your Micro coaxial cable

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-Conn, customization is at the core of our micro coaxial cable solutions. We understand that each customer has unique application scenarios and technical requirements, and we are fully equipped to transform your ideas into functional, high-performance cable assemblies.

We support fully tailored configurations, from cable length, wire gauge, and pin-out assignments to shielding types and connector orientation. Whether you require I-PEX, Hirose, JAE, or other specialized connectors, we offer both original and equivalent options to meet your design and budget needs.

Our engineering team can quickly deliver precise CAD + PDF drawings within 30 minutes to 3 days, ensuring design clarity and fast iteration. No minimum order quantity (MOQ) is required — whether it’s a single prototype or full-scale production, we deliver with the same level of attention.

We also offer a wide range of materials such as FEP, PVC, TPE, and fluoropolymers, with flexible overmolding and sheathing options including nylon mesh, conductive fabric, and heat-shrink tubes. With complete EMI shielding design, temperature resistance, and structural adaptation, our custom cables are ideal for industries like medical devices, automotive, robotics, and aerospace.

From concept to cable — we build what you envision.

Our Commitment to Outstanding Service

At Sino-Conn, we don’t just provide products — we deliver peace of mind. From the moment a customer reaches out, our service process is designed to ensure transparency, responsiveness, and reliability at every stage.

- Rapid Response: Inquiries receive a reply within 1 hour. Urgent RFQs are quoted within 30 minutes, and drawings can be delivered the same day.

- Tailored Communication: Our sales engineers understand both technical specs and client pain points, offering proactive advice and clear answers in fluent English — via email, video meetings, or instant messaging.

- Technical Assurance: Every project is supported by our in-house engineering team who provides drawings (CAD to PDF), technical advice, and layout suggestions.

- Zero MOQ, Full Attention: Whether it’s 1 piece or 10,000, every order gets full attention.

- Pre-Production Confirmation: All drawings are confirmed with the customer before production to avoid misunderstandings or errors.

- Reliable Lead Time: Samples in as fast as 3 days; mass production within 2 weeks for most projects.

- Global Logistics Coordination: We work with DHL, FedEx, UPS, and freight forwarders to ensure fast and traceable delivery.

- After-Sales Support: 100% inspection, warranty support, and responsive follow-up services for any concerns.

We are not just a cable supplier — we are your reliable, solution-driven partner.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

Application Scenario: Robotic Arm Control System for Smart Manufacturing

“We were upgrading our automation line and needed ultra-flexible micro coaxial cables that could endure over 10,000 bend cycles without signal loss. Sino-Conn delivered an ideal solution with nylon-braided jackets and molded strain reliefs, plus lifetime testing and full reports. Communication was smooth, pricing was fair, and even our in-house QC team gave a rare ‘no comment’ stamp of approval. They are now our go-to supplier for motion control applications.”

Keiko Tanaka

Osaka, Japan – Procurement Manager

Application Scenario: Embedded Medical Imaging Device (Portable Ultrasound)

“We were developing a new portable ultrasound device and needed ultra-thin, low-loss micro coaxial cables for signal integrity within compact enclosures. Sino-Conn customized a solution with 38AWG ultra-fine cable, EMI shielding, and mini I-PEX connectors. They delivered samples in just 3 days, and even helped revise our CAD files to optimize routing. The flexibility, durability, and quality were beyond expectations. It’s rare to find a supplier this professional and responsive.”

Michael Schmidt

Munich, Germany – R&D Engineer

Application Scenario: Automotive Infotainment System Harness Integration

“Our automotive infotainment system required high-frequency signal transmission with strict EMI shielding within confined dashboard areas. Sino-Conn offered a custom micro coaxial cable with multi-layer shielding, tight bend radius, and flame-retardant jacket—all tailored to our layout. They provided full certification documents including UL and ROHS, along with detailed wiring drawings in just two days. Their ability to align with our OEM production timelines and quality standards is impressive. We’re planning long-term collaboration.”

Lucas Hernández

Guadalajara, Mexico – OEM Production Manager

industry Application of Micro coaxial cable

Micro coaxial cables are widely used in industries requiring compact, high-speed, and low-interference signal transmission. Common applications include medical imaging devices, industrial cameras, automotive sensors, consumer electronics, robotics, and aerospace systems. Their small diameter and excellent EMI shielding make them ideal for precision and space-constrained environments.

Medical Imaging Equipment

Solution 1: Customized low-loss, high-flexibility fiber cable

Application Scenario: Medical imaging systems (CT, MRI, endoscopes)

Devices and Products: High-speed data fiber cable, terminal connectors, medical-grade outer jackets

Industry Needs:

Ultra-low latency and loss in data transmission

Biocompatible, antibacterial, and flame-retardant cable materials

Tight space wiring requiring ultra-flexible routing

Our Solution:

Custom medical-grade fiber cables with antibacterial and non-toxic coatings

Ultra-bendable cable design for compact systems

Full certifications: ISO13485, ROHS, REACH

Support all types of connectors and device interfaces

Industrial Automation & Robotics

Solution 2: Bend-resistant, EMI-shielded fiber cable for industrial use

Application Scenario: Automated production lines, robotic arms, sensor networks

Devices and Products: Kevlar-reinforced fiber cables, PLC cabinet cables, multi-axis robot fiber harnesses

Industry Needs:

High bending endurance due to repetitive robot arm movements

Strong electromagnetic interference in factory environments

Long-distance, high-speed stable data communication

Our Solution:

Kevlar core and flexible outer jacket for bend/tension resistance

Multi-layer shielding and inherent EMI immunity of fiber

Full customization of cable length, bend radius, and connector type

Drag chain approved designs for repetitive dynamic motion

Fiber Cable Deployment in 5G/Telecom Base Stations

Solution 3: Low-loss, high-protection fiber cabling for indoor and outdoor telecom use

Application Scenario: 5G base stations, mobile cell towers, FTTA (Fiber to the Antenna) systems

Devices and Products: ODN cables, pre-terminated fiber assemblies, waterproof splitter cables

Industry Needs:

Harsh outdoor conditions requiring waterproofing, UV and corrosion resistance

Stable performance in extreme temperatures

Flexible customization of length, branching, and connector types

Our Solution:

PE sheathing + stainless steel armor for IP68-level outdoor protection

Use of G657A1/A2 low-loss fibers suitable for tight-bend installations

Customizable SC/LC/MPO connectors and precise length configuration

Full technical support with drawings and 72-hour rapid production lead time

High-Precision Fiber Optic Cable Solutions for Medical Devices

Solution 4: Custom low-loss and precision fiber cables for imaging, diagnostics, and surgical applications

Application Scenario: Operating rooms, IVD analyzers, endoscopy systems, laser surgery equipment

Devices and Products: Medical-grade endoscopic cables, laser delivery fiber assemblies, FC/PC or ST patch cords, multimode/single-mode cables

Industry Challenges:

Demands for extreme precision, low signal loss, and biocompatibility

Compact cable routing in high-humidity, high-temperature environments

Compliance with ISO 13485, ROHS, halogen-free, REACH and other medical standards

Our Solution:

Certified medical-grade materials aligned with ISO 13485 for safety and bio-compatibility

Precision UPC/APC polished end-faces to ensure low insertion loss and reliable signal integrity

Custom designs for high-temperature (up to 200°C) and tight-bend flexible cable structures

Complete 3D drawings and integration support for easy device design and testing

High-Durability Fiber Optic Cabling for Industrial Automation

Solution 5: Bend-resistant, oil-resistant fiber cable solutions tailored for dynamic industrial settings

Application Scenario: Factory automation, robotic arms, CNC machines, industrial machine vision

Devices and Products: Industrial patch cords (MTP/MPO, LC, SC), drag chain fiber cables, flexible fiber assemblies, heavy-duty outdoor fiber

Industry Challenges:

Constant vibration and repetitive bending leading to fiber breakage

Harsh environments with oil, dust, and wide temperature variations

Limited routing space in drag chain systems, requiring ultra-thin, tensile-resistant cables

Our Solution:

Reinforced aramid yarn structures for superior pull and bend strength

PUR and TPU jacket options for oil resistance and mechanical protection

Custom OD down to 1.2mm and fatigue-resistant designs for drag chains

Each cable undergoes rigorous bend, tensile, and aging tests before shipment

Ruggedized Fiber Optic Systems for Defense Applications

Solution 6: Tactical fiber cable solutions with high EMI shielding, corrosion resistance, and IP68+ protection

Application Scenario: Battlefield communication, radar base cabling, internal networks in military vehicles and aircraft

Devices and Products: Tactical field cables (TFOCA-II, HMA), single-mode/multi-mode MIL-grade fiber assemblies, shipborne/airborne cable solutions

Industry Challenges:

Intense EMI environments demand top-level interference shielding

Harsh conditions: moisture, salt fog, high vibration, large temperature swings

Field deployment requires plug-and-play rapid connection and retrieval

Extremely low communication failure rates, long MTBF expected

Our Solution:

Low-loss MIL-SPEC optical fibers for high-bandwidth transmission

Jacket options with steel armor + PUR sheath for wear resistance and pressure protection

IP68-rated connectors and enclosure systems to resist extreme field conditions

Quick-deploy interface with tactical reels and dustproof caps for mobile missions

Conformity to MIL-PRF-85045, MIL-DTL-83526, and other military standards

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized Micro coaxial cable services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

Can I customize the cable length, connector type, and pin assignment?

Yes, we support full customization including cable length, connector model, pinout configuration, and molding design according to your requirements.

What is your typical lead time for samples and bulk orders?

Sample lead time is normally 2 weeks, urgent samples in 2–3 days; bulk orders take 3–4 weeks, urgent orders can ship in 2 weeks.

Can I get drawings or CAD files before placing the order?

Absolutely. We provide technical drawings (PDF + CAD) within 3 days, or within 30 minutes for urgent requests.

Do you offer brand-name (original) or compatible connectors?

We provide both original and compatible versions. Original is expensive with longer lead time; compatible offers fast delivery and similar performance.

What technical data can you provide for the cables?

We offer full specs: OD, impedance, EMI shielding, temperature resistance, flexibility, bend radius, voltage/current rating, and more.

Do your cables meet safety and environmental certifications?

Yes, our cables can comply with UL, ISO, ROHS, REACH, PFAS-free, COC, COO, and more based on your request.

Can you help me redesign an existing cable structure?

Yes, our engineering team can optimize your existing cable design or provide alternatives tailored to your usage scenario.

What is your MOQ?

No MOQ. We support 1-piece prototype orders and flexible small batch manufacturing.

Can I request online video meetings to discuss my project?

Yes, we support online calls with engineers or sales to discuss drawings, technical specs, or project planning.

How do you guarantee product quality?

We implement 100% inspection—during production, after assembly, and pre-shipment. Full QC reports are available.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China