Custom idc cable assembly manufacturer

Fast, flexible, and ready for custom builds—our IDC cable assemblies are engineered for reliable signal and power delivery. With full material traceability, RoHS compliance, and 100% inspection, we ensure peace of mind from prototype to volume. No MOQ. Fast response. Let’s start building your solution today.

Why choose idc cable assembly from sino-conn

Sino-Conn delivers high-precision IDC cable assemblies tailored to your specs, with fast sampling, no MOQ, and expert engineering support. Choose us for quality, speed, and unmatched customization flexibility.

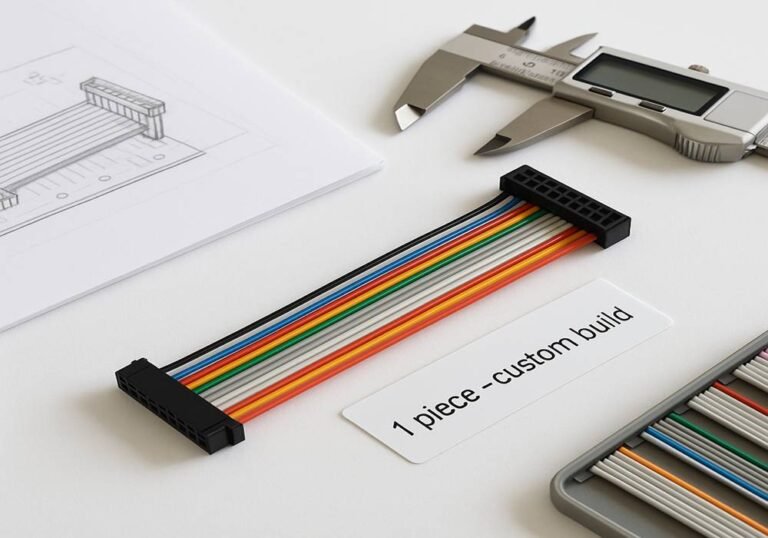

Rapid Customization with No Minimum Order Quantity

We support full customization of IDC cable assemblies—length, pinout, connectors, and routing—with absolutely no MOQ. Whether it’s for a one-piece prototype or a full batch run, we respond fast and deliver accurately. This flexibility allows engineers and OEMs to validate concepts or scale up production with ease.

Full Drawing Support within 30 Minutes

We offer complete 2D and 3D drawings (CAD to PDF) for all IDC cable projects, typically within 30 minutes. Every design is confirmed with the customer before production begins. This ensures the final product perfectly matches your needs, accelerates sampling, and avoids rework.

Support Both Original and Alternative Connectors

We support both original branded IDC connectors and cost-effective alternatives. All options are compatible and tested for performance. Original connectors suit high-end applications; alternatives provide shorter lead times and lower cost. Clients can choose flexibly based on budget, delivery, and usage scenario.

Ultra-Fast Sample Delivery Within 3 Days

We commit to delivering IDC cable assembly samples within 2–3 working days, even for complex customizations. With strong in-house prototyping capacity and priority support, we help customers validate designs quickly and move faster to production. Ideal for engineering verification and urgent trial projects.

Certified for Global Industrial Standards

Our IDC cable assemblies are manufactured with full compliance to international standards including UL, RoHS, REACH, ISO9001, and PFAS control. Every product comes with detailed certificates, test reports, and can be provided with COC/COO upon request. We ensure product trust and smooth customs clearance.

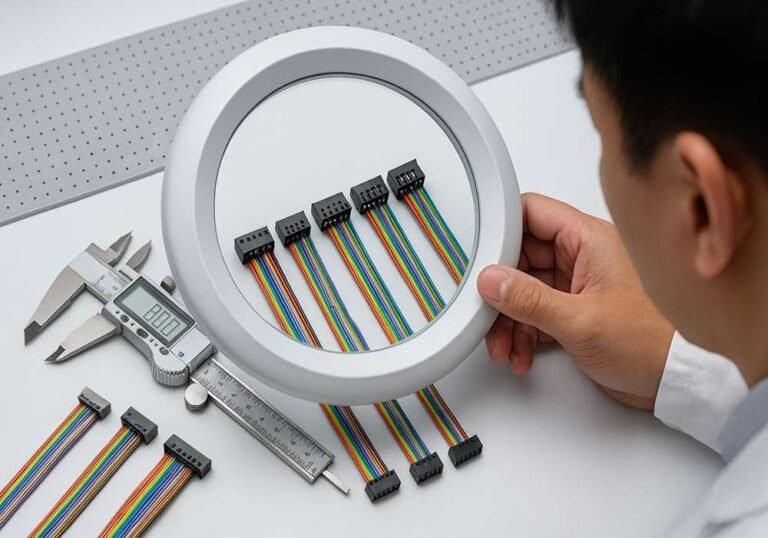

Three-Stage 100% Quality Inspection Process

Every IDC cable assembly undergoes triple inspection: in-process, post-assembly, and pre-shipment. We use continuity testing, pinout verification, and visual checks to ensure zero defect delivery. This process helps minimize failure rate and boosts customer satisfaction in every batch.

Detailed specifications and parameters of idc cable assembly

| No. | Definition (Pinout Type) | Connector Model | Cable Spec | Length (mm) | Jacket Form | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 1:1 Straight Through | 2.54mm 10P Box Header | Custom | Custom | Flat | PVC Tube |

| 2 | Crossed Wiring | 2.0mm 20P IDC Female | Custom | Custom | Flat | Nylon Braided Mesh |

| 3 | Reversed Pinout | 1.27mm 40P Dual Row | Custom | Custom | Flat | Conductive Fabric |

| 4 | Split Cable with Dual End | 2.54mm 16P to 2×8P | Custom | Custom | Formed | Teflon Tape |

| 5 | Ground Pin in Center | 2.54mm 14P IDC Male | Custom | Custom | Flat | Iron-Fluorine Tube |

| 6 | Shielded Grounded Assembly | 2.0mm 26P Box Header | Custom | Custom | Flat | Aluminum Foil + PVC Wrap |

| 7 | IDC to DIP Socket | 2.54mm 10P to DIP-10 | Custom | Custom | Flat | Acetate Cloth |

| 8 | One-to-Many Split Type | 2.54mm 16P to 8×2P | Custom | Custom | Formed | Nano Tape |

| 9 | 1:1 IDC to Edge Card | 2.0mm 30P to Gold Finger | Custom | Custom | Flat | Nylon Braided Mesh |

| 10 | IDC to D-Sub Adapter Cable | 2.54mm 20P to DB25 | Custom | Custom | Round | Teflon Jacket |

Our IDC cable assemblies are highly customizable. The specifications shown above represent typical builds, but every project can vary based on connector type, pinout definition, cable form, or environmental requirements. Whether your application demands special grounding, shielding, or unusual mechanical layout, we can deliver tailor-made assemblies that meet exact needs and standards.

Customized idc cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

10 Pin IDC Ribbon Cable Female to Female 2.54mm Connector

40 Pin 1.0mm Pitch IDC Cable Assembly with UL20276 28AWG Wire

50 Pin IDC Ribbon Cable 2.54mm Pitch Flat Gray UL2651

idc cable connector 26 Pin to D-sub 25 Pin with Color Ribbon Cable

Product details display of idc cable assembly

Explore the detailed specifications of our IDC cable assemblies, including connector types, pin configurations, wire gauges, shielding options, and material properties. Each assembly is engineered for durability, flexibility, and precise signal transmission to meet the needs of your custom applications.

Rapid Customization with No Minimum Order Quantity

We support full customization of IDC cable assemblies—length, pinout, connectors, and routing—with absolutely no MOQ. Whether it’s for a one-piece prototype or a full batch run, we respond fast and deliver accurately. This flexibility allows engineers and OEMs to validate concepts or scale up production with ease.

- Custom pinouts and cable routing available for any configuration

- Connector compatibility includes 1.27mm, 2.0mm, and 2.54mm pitch types

- Flexible options for insulation and sheath materials

- Ideal for rapid prototyping and small-batch trials

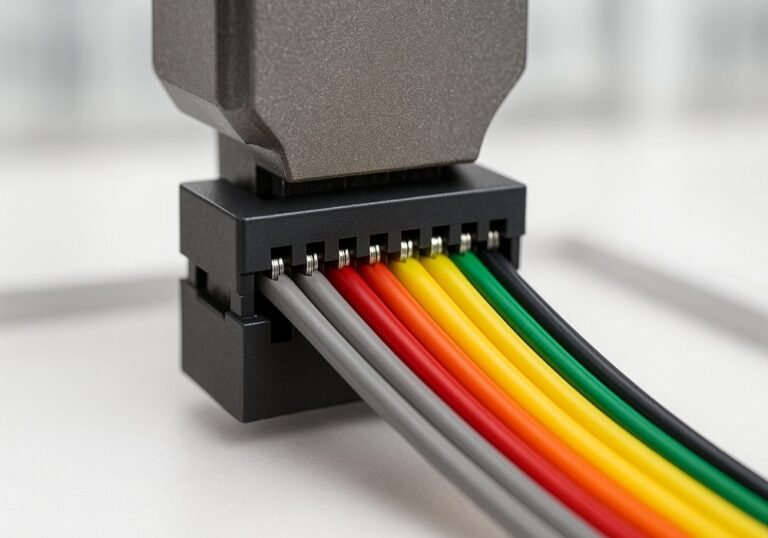

High-Precision Connector Termination Process

Our IDC cable assemblies are produced using high-precision semi-automatic termination machines. This process ensures that each conductor is evenly pressed and perfectly aligned within the connector teeth, maintaining strong contact and consistent electrical performance. By tightly controlling pressure, pitch, and angle during termination, we ensure zero dislocation and maximum conductivity for signal integrity in high-density applications.

- Termination pitch tolerance controlled within ±0.05mm

- Suitable for 1.27mm, 2.0mm, 2.54mm connector pitch

- No soldering required, reducing thermal damage

- Supports 10P to 64P multi-pin assemblies

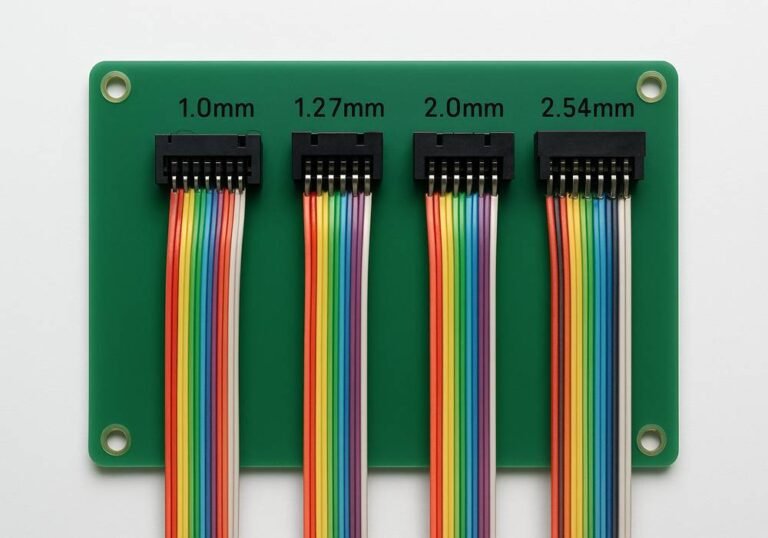

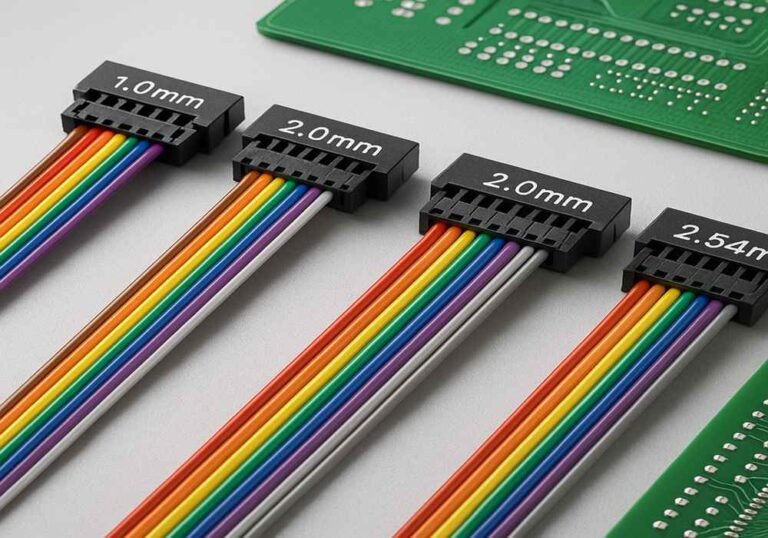

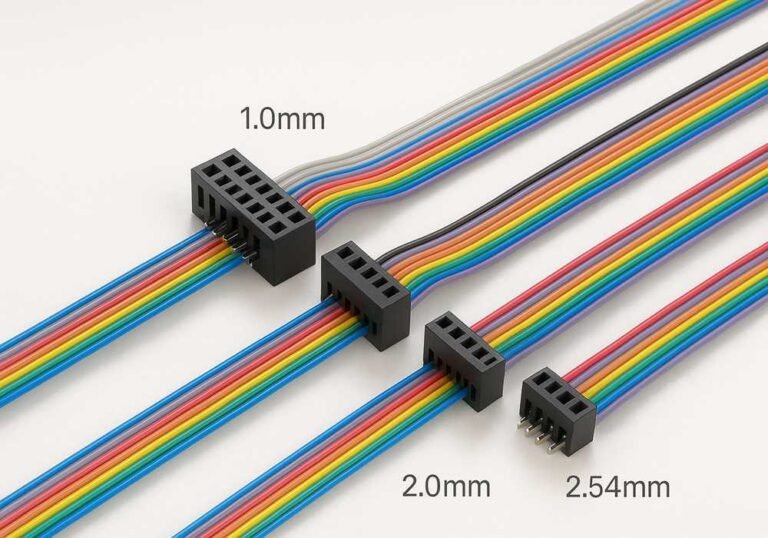

Multi-Pitch Connector Compatibility Design

Our IDC cable assemblies are fully compatible with a wide range of connector pitches, including 1.0mm, 1.27mm, 2.0mm, and 2.54mm. This compatibility ensures integration across diverse systems, from compact embedded devices to large-scale industrial controls. Our engineering team selects the optimal pitch based on signal density, mechanical limits, and mating interface. This flexibility allows us to deliver solutions that precisely meet the mechanical and electrical needs of your device.

- Compatible with multiple IDC connector standards and brands

- Ideal for space-constrained and high-density board layouts

- Offers high mating reliability across different interface types

- Supports pitch-specific impedance and EMI optimization

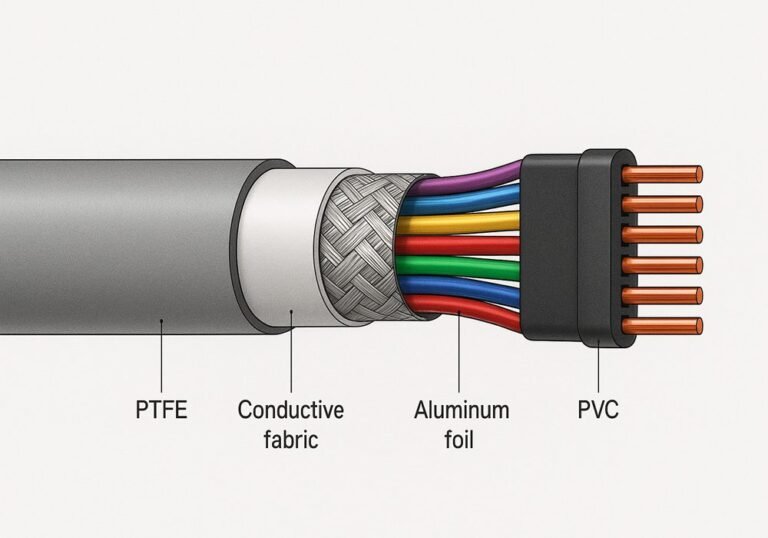

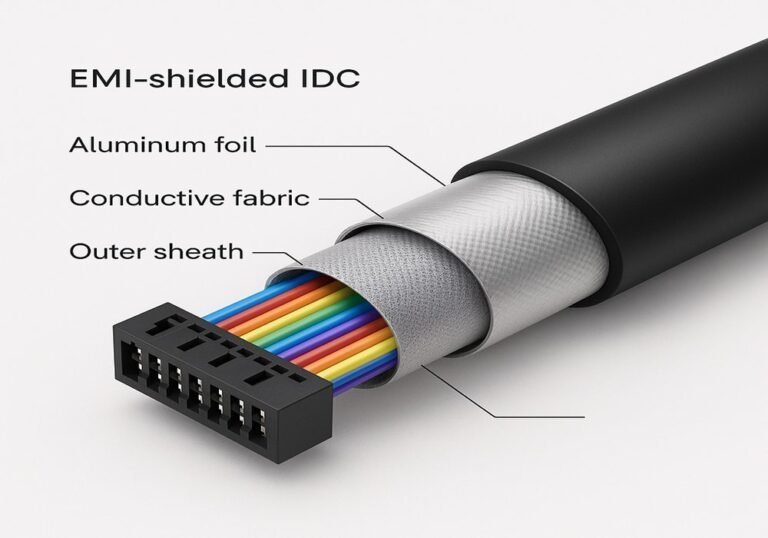

EMI Shielding and Insulation Layer Options

Our IDC cable assemblies offer multiple shielding and insulation options to meet the demands of EMI-sensitive environments. From conductive fabric and aluminum foil to Teflon and PVC jackets, we tailor the structure to specific industry applications. Whether you’re designing for industrial automation or consumer electronics, we ensure the cable performs with minimal interference and maximum durability.

- Shielding options include aluminum foil, conductive fabric, and copper braid

- Insulation available in Teflon, PVC, and halogen-free materials

- Outer jackets withstand oil, UV, and abrasion

- Ideal for medical, industrial, and telecom environments

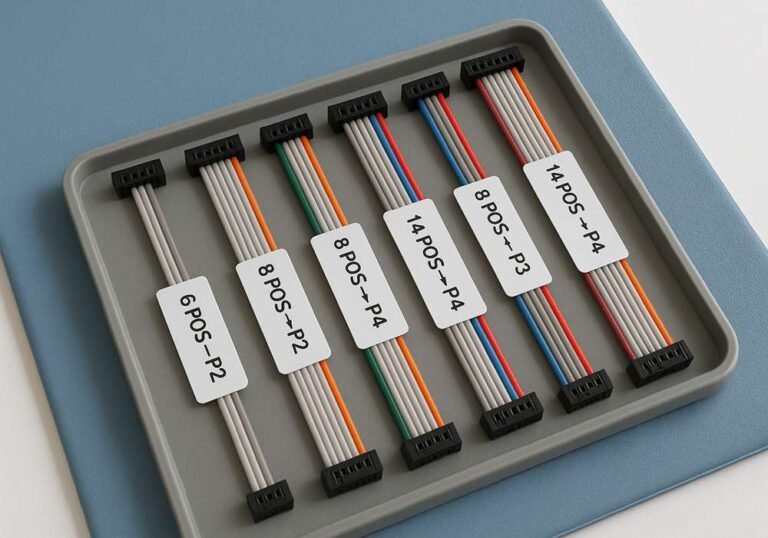

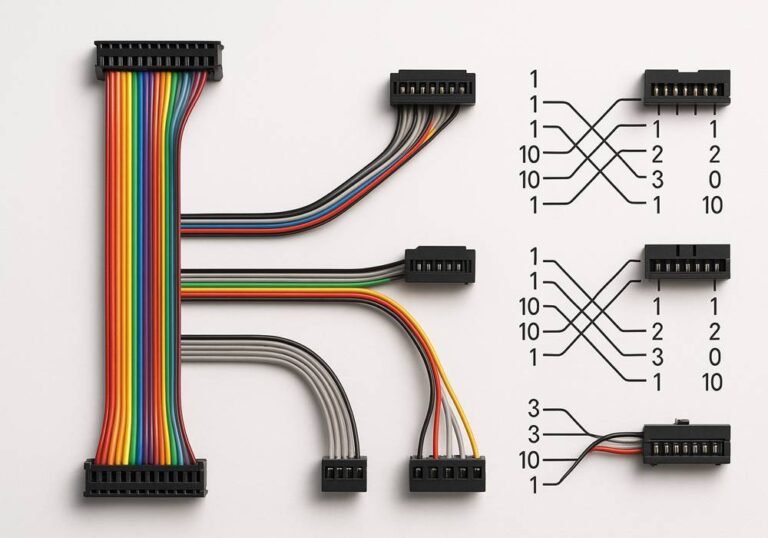

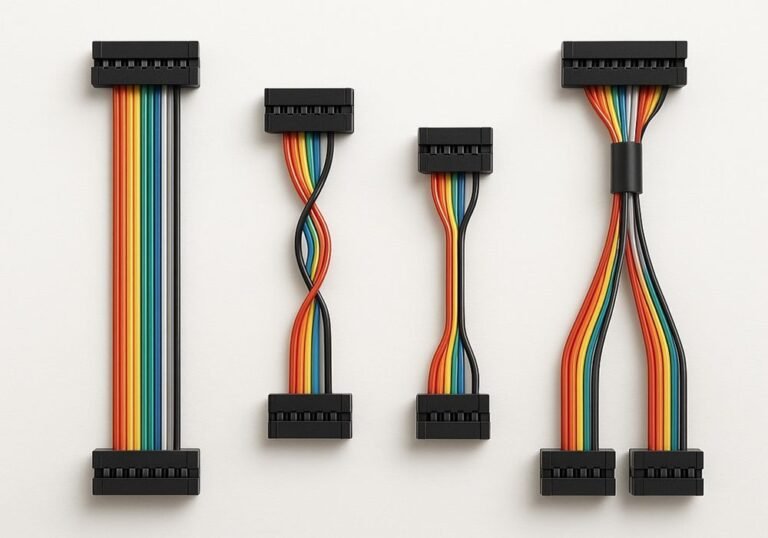

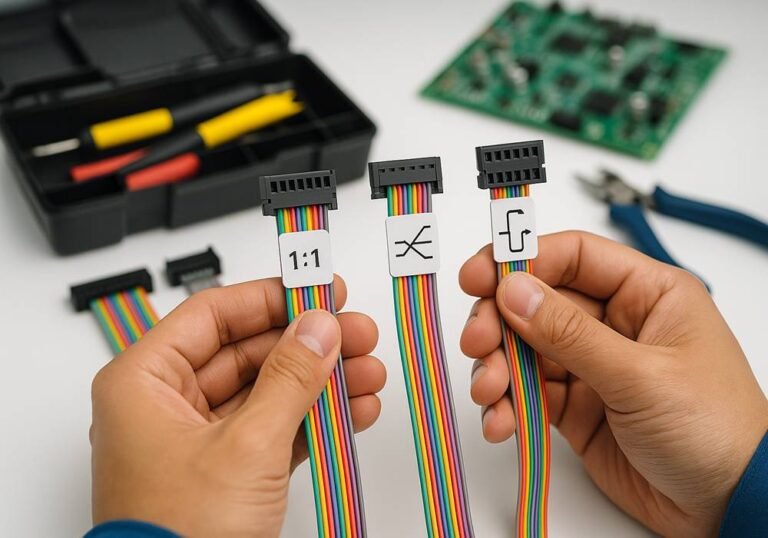

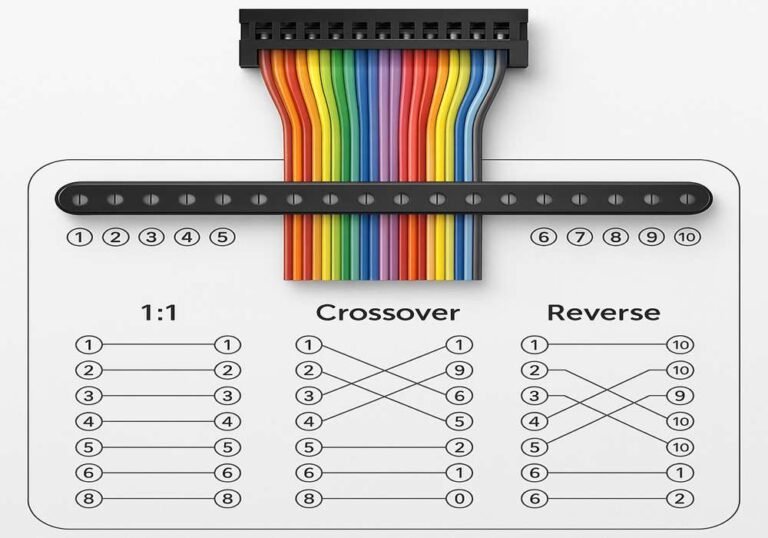

Versatile Output Configurations and Pin Mapping

Our IDC cable assemblies support a wide variety of output formats and pin mapping styles, from straight-through 1:1 types to custom crossover and reversed configurations. We also offer split-ends, multi-branch outputs, and mixed-gender interfaces. This versatility enables engineers to adapt our assemblies to complex PCB layouts, control modules, and multi-board systems with ease.

- Supports 1:1, crossover, reverse, and split configurations

- Mixed connectors (male to female, IDC to DIP, etc.) available

- Custom pin mapping with labeled wiring diagrams provided

- Suitable for prototyping and system-level integration

Triple Quality Control for Every Cable

Each IDC cable assembly undergoes a rigorous 3-stage inspection process to ensure zero-defect delivery. Our QC protocol includes in-process inspection, post-assembly visual and electrical tests, and final outgoing checks. This guarantees every unit meets strict quality, functional, and cosmetic standards before it reaches the customer. Combined with traceable batch records and test data, our process secures confidence for both small-volume and mass production orders.

- 100% tested for continuity, polarity, and pin accuracy

- Visual check for correct connector alignment and cable finish

- Test records and batch traceability stored digitally

- Supports special inspection protocols (e.g. MIL-STD, IPC)

--- Customized Capabilities Services and Processes

Customize your idc cable assembly

Discover our customized capabilities, services, and processes tailored for IDC cable assembly production. From flexible length and pinout definitions to specialized materials and connector options, we offer rapid prototyping, 30-minute drawing turnarounds, and full engineering support. Every order includes precision CAD documentation, 100% quality inspection, and flexible MOQ starting from 1 piece—ensuring your custom cable requirements are met with speed, accuracy, and reliability.

Customized Capabilities Services and Processes

Customize your idc cable assembly

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

At Sino-conn, we offer end-to-end customization for IDC cable assemblies that address a wide spectrum of application-specific challenges. From signal integrity optimization to unconventional pinouts and form factors, we help engineers realize their exact design intent with precision.

Our custom capabilities span multiple dimensions:

- Pin-to-pin mapping based on client-provided diagrams or concepts

- Connector combinations (IDC to DIP, IDC to FFC, mixed pitch)

- Shielding and insulation structures adapted to EMI or high-flex needs

- Labeling, marking, and multi-end splitting for traceability and modular integration

- Full 2D/3D CAD support with rapid drawing turnaround (as fast as 30 minutes)

- Small-batch and prototype-ready with no MOQ limitations

- Tailored packaging, compliance documentation, and bulk order flexibility

Whether for medical devices, industrial PLCs, or embedded control boards, we provide not only cable production but system-level connectivity insight. Our customization service is not just about cables—it’s about solving your engineering problem.

Our Commitment to Outstanding Service

We believe that exceptional service is the foundation of long-term cooperation. At Sino-conn, every IDC cable assembly order is managed with speed, accuracy, and engineering-level support from start to finish.

We serve you with:

- Lightning-fast response: initial quotes and feasibility checks delivered within hours

- Dedicated engineering consultation: our technical team provides design feedback and optimization suggestions at no charge

- Real-time communication: video calls, file sharing, and progress updates keep you informed

- Drawing transparency: all projects receive CAD/PDF diagrams pre-production for approval

- Proactive delivery support: we accommodate urgent sampling (2–3 days) and adjust schedules for rush bulk orders

- 100% inspection: each unit undergoes multi-step QC before dispatch

- Flexible collaboration: from 1-piece samples to 10,000-unit bulk runs, we support your scale

Our goal is not just delivering cables, but helping you build better, faster, and more confidently.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

High-Speed Data Rack Optimization – Compact IDC Harness for Network OEM

As a server OEM, we needed high-density IDC cable assemblies to streamline internal wiring in our new 2U data rack systems. The challenge was balancing space constraints, signal integrity, and ease of mass production—all under a tight 6-week development cycle.

We contacted Sino-conn with a rough layout and pin-out structure. Their engineer responded in under an hour with a refined drawing and recommended a 2.54mm pitch 40-pin IDC-to-IDC design, using flame-retardant flat ribbon cable and reinforced strain relief at both ends. They even accounted for our airflow path when suggesting cable shaping.

Prototypes arrived in just 3 days. All cables passed impedance and continuity tests at 500 Mbps without signal degradation. They helped us customize the connector latch for tool-free installation. RoHS and REACH certifications were included by default.

The smooth communication and ability to handle small-batch customization impressed us deeply. We’ve since placed 4 repeat orders and plan to use Sino-conn for all our future IDC harness needs.

“Sino-conn’s speed and engineering clarity helped us meet a nearly impossible launch deadline.”

Michael Chen

Lead Hardware Engineer

Location: Taipei, Taiwan

Medical Imaging Console Upgrade – EMI-Safe IDC Cables for Signal Clarity

Our hospital’s imaging department was upgrading CT scan consoles, requiring precise signal cable assemblies to connect interface boards to display processors. These needed to be compact, shielded against EMI, and ISO13485-ready.

After disappointing delays with a local supplier, we found Sino-conn. Their team reviewed our diagrams and suggested a 26AWG IDC-to-board cable assembly with aluminum foil wrap, mylar insulation, and a PVC sleeve—all medically rated. They also modified connector positions to match our enclosure layout.

Prototypes were delivered in 5 days. Each unit passed our ISO 10993 compliance test for biocompatibility and met Class B EMI shielding. Signal jitter dropped by 40% compared to our previous assemblies.

Thanks to Sino-conn’s detailed engineering feedback, we minimized board layout changes. We’ve since rolled out the same design across 12 hospitals nationwide.

“They delivered speed, safety, and stability. Our medical upgrade succeeded because of Sino-conn.”

Dr. Laura Bennett

System Integration Lead

Location: Boston, USA

Automotive HVAC Control Unit – Custom IDC Solution with Fast Prototyping

For a new HVAC control unit in our electric SUV model, we needed compact IDC cables to link the climate touch panel with the control MCU. Space was tight, and we had limited EMI shielding headroom due to shared signal paths with CAN lines.

Sino-conn provided a rapid solution. Within a day, we had a full CAD drawing featuring a folded ribbon cable layout with staggered 20-pin IDC connectors and built-in ferrite cores. The cable’s sheath used halogen-free, heat-resistant material that met our auto-grade specs.

Samples arrived in 4 days and worked flawlessly through thermal cycling tests from -40°C to +85°C. Pin-out matching was perfect, and installation time dropped by 20% thanks to their keyed connector design.

Their team also provided DVP (Design Validation Plan) templates for our internal approval, saving us extra time. This was our first project with Sino-conn, but it certainly won’t be the last.

“Impressed by their agility and technical know-how. They think like a partner, not just a vendor.”

Rajiv Verma

Product Manager

Location: Pune, India

industry Application of idc cable assembly

IDC cable assemblies are widely used across industries such as telecommunications, consumer electronics, medical devices, automotive systems, and industrial automation. Their compact design and reliable performance make them ideal for internal connections in PCB-based equipment, control panels, and data systems. Sino-Conn provides tailored IDC solutions that meet the specific technical and environmental demands of each application, ensuring durability, signal integrity, and long-term reliability in critical systems.

Solution 1: Industrial Automation Control Systems

Application Scenario: IDC cable assemblies are widely utilized in industrial automation control systems, especially within PLCs, HMIs, and sensor hubs. In high-speed manufacturing lines, rapid and reliable signal transmission is critical for coordinating robotics, actuators, and safety interlocks. IDC cables facilitate compact, high-density connections between control boards and distributed modules. Their flat design enables easy routing through confined control panels and enclosures, ensuring fast response times with minimal EMI interference.

Devices & Products:

- PLC controllers, HMI screens

- Signal distribution units, I/O modules

- Machine vision systems, servo drives

Industry-Specific Requirements:

- Tight panel space constraints require thin, foldable cables.

- High signal integrity with low EMI crosstalk for critical control signals.

- Need for rapid custom configurations (pinout, length, termination).

Solutions:

- Use of ultra-flat ribbon IDC cables that bend easily in tight spaces.

- Shielded IDC options and customized grounding improve EMI performance.

- Fast prototype support: custom pinouts and lengths within 3–5 days.

Solution 2: Medical Diagnostic Equipment

Application Scenario: In the medical industry, diagnostic equipment like blood analyzers and ultrasound machines demand highly reliable and compact internal cabling. IDC cable assemblies are ideal for connecting internal PCBs and modules due to their compact form and stable contact points. These cables ensure accurate signal transfer between control boards, sensors, and displays, even in mobile or vibration-sensitive environments. Their precise assembly supports high pin counts and low failure rates essential in life-critical applications.

Devices & Products:

- Blood analyzers, ultrasound machines

- ECG modules, portable diagnostic tools

- Embedded computing units

Industry-Specific Requirements:

- Strict reliability and low failure rate under continuous operation.

- Biocompatibility and compliance with ISO/ROHS medical certifications.

- Stable electrical transmission in compact and moving devices.

Solutions:

- 100% inspection with ISO13485-compliant production processes.

- Medical-grade insulation materials, halogen-free and RoHS-certified.

- Custom EMI-reduced IDC assemblies with secure latching for vibration.

Solution 3: Consumer Electronics and Set-Top Boxes

Application Scenario: IDC cable assemblies are commonly used in consumer electronics such as smart TVs, game consoles, and set-top boxes. Inside these devices, flat IDC cables connect logic boards, display modules, and peripheral interfaces. With limited internal space and high production volumes, manufacturers need cost-effective, compact cabling that guarantees consistent performance. IDC connectors allow for fast and tool-free assembly, supporting automated production lines and efficient repairs or replacements.

Devices & Products:

- Set-top boxes, smart TVs

- Gaming consoles, home entertainment hubs

- Media players, Wi-Fi routers

Industry-Specific Requirements:

- Mass production requires standardized, quick-connect solutions.

- Heat resistance and long-term reliability within compact enclosures.

- Flexible supply for varied OEM designs and seasonal demand peaks.

Solutions:

- IDC assemblies with pre-set pinouts for plug-and-play production.

- UL-certified heat-resistant insulation for 85°C+ operating environments.

- Rolling stock production with MOQ=1 policy and flexible lead times.

Solution 4: Data Center Server Backplane Wiring

Application Scenario:

In modern data centers, high-density server racks rely on efficient internal wiring systems to maintain high-speed data transmission, cooling efficiency, and quick maintenance. IDC cable assemblies are used for connecting hard disk backplanes, control panels, and internal interface modules due to their compact form, customizable pinouts, and secure press-fit connection. These assemblies help reduce airflow obstruction, improve signal stability, and allow for rapid replacement during system upgrades. Their use is critical in storage clusters, edge computing nodes, and rackmount servers where reliability and ease of service are paramount.

Devices & Products:

- Rack-mounted servers and disk arrays

- Server backplane boards and interface panels

- Storage nodes in HPC and edge computing systems

Industry-Specific Pain Points:

- Dense environments lead to airflow restrictions and overheating.

- Limited space for connectors and cables in 1U/2U servers.

- Need for precise, tool-less, and service-friendly cable replacements.

Our Solutions:

- Use of ultra-flat ribbon IDC cables with minimal bend radius.

- Offer low-profile connectors and press-fit headers designed for tight server bays.

- Provide custom color-coding and tagging for rapid identification during servicing.

Solution 5: ATM & Self-Service Equipment Connectivity

Application Scenario:

ATM machines, self-checkout kiosks, and ticketing terminals heavily depend on reliable internal wiring systems. IDC cable assemblies are ideal for connecting printer modules, display interfaces, button arrays, and power distribution boards in these compact enclosures. Their press-fit reliability and ability to maintain signal integrity over repeated use make them especially suited for these machines, which operate 24/7 and often in unmanned environments. IDC cables reduce the footprint while allowing for flexible routing within narrow internal chambers.

Devices & Products:

- ATM machines and self-service kiosks

- Thermal printers, keypads, and card reader modules

- Industrial PCBs and backplane interfaces

Industry-Specific Pain Points:

- Limited space and rigid internal architecture.

- High cycle rates with frequent mechanical movement.

- Need for tamper-proof and reliable connections.

Our Solutions:

- Use of shielded IDC cables with low-profile press headers.

- Reinforced strain relief and vibration-resistant locking clips.

- Rapid prototyping based on client chassis dimensions and routing maps.

Solution 6: Security Alarm and Control Panels

Application Scenario:

IDC cable assemblies are widely adopted in fire alarm systems, home security hubs, and industrial access control panels. These systems rely on stable interconnections between PCBs, power modules, sensor terminals, and communication boards. The compact, color-coded ribbon cable structure and strong connector retention help installers wire quickly and maintenance teams identify faults efficiently. The IDC interface supports multi-channel low-voltage signal and power distribution in tight wall-mounted enclosures.

Devices & Products:

- Fire alarm panels and burglar systems

- Home and industrial security control hubs

- Door access interfaces and sensor arrays

Industry-Specific Pain Points:

- Space-constrained wall-mounted enclosures.

- Risk of wiring mistakes during on-site installation.

- Low-voltage signal degradation in bundled wire environments.

Our Solutions:

- Flat, color-coded IDC ribbon cables with keyed connectors.

- Factory-terminated assemblies reduce on-site crimping errors.

- Signal integrity verified via pre-shipment testing and full inspection.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized idc cable assembly services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is an IDC cable assembly?

An IDC (Insulation Displacement Connector) cable assembly is a type of flat ribbon cable terminated with connectors that pierce insulation to form secure electrical contacts, used widely in data, signal, and power transmission within electronic devices.

What types of IDC connectors can you offer?

We offer a wide range of IDC connectors, including 1.27mm, 2.0mm, 2.54mm pitches, box headers, D-sub IDC, card edge connectors, and custom configurations.

Can IDC cables be customized in length and pinout?

Yes, we support full customization of cable length, pinout mapping, connector type, and labeling according to customer drawings or samples.

What is your minimum order quantity (MOQ)?

We have no MOQ. We accept orders starting from 1 piece for samples or trial use.

Do you offer samples?

Yes, sample orders are welcome. Standard lead time is 2 weeks, but urgent samples can be delivered in 2–3 days.

Can you design the IDC cable based on our application?

Absolutely. Our engineers can create drawings within 30 minutes to 3 days based on your specifications.

Are your IDC connectors original or compatible alternatives?

Both are available. Original parts ensure brand compatibility; alternatives offer better flexibility, faster delivery, and cost advantages.

What certifications do your IDC cable assemblies have?

Our assemblies can meet UL, ISO, RoHS, REACH, PFAS, COC, and COO certifications upon request.

What kind of EMI protection can you provide?

We offer shielded IDC cables with aluminum foil, braided shielding, and EMI ferrite filters based on your EMI control needs.

How fast can you deliver bulk orders?

Standard bulk lead time is 3–4 weeks. Urgent orders can be completed within 2 weeks.

Can you provide a product drawing for approval before production?

Yes, all orders come with detailed drawings (CAD+PDF) for confirmation before production starts.

What kind of conductors and insulation do you use?

We use pure copper conductors with PVC, PE, or TPE insulation materials depending on flexibility, flame resistance, or cost.

Can your IDC assemblies be used in automotive applications?

Yes, we offer automotive-grade IDC cable assemblies with high vibration resistance and temperature stability.

Do you support UL wire traceability?

Yes, we use UL-certified wires with full traceability and support for UL harness labeling if required.

What industries use IDC cable assemblies?

Common industries include computers, servers, ATMs, medical devices, security systems, consumer electronics, and test equipment.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China