custom spiral cable assembly manufacturer

Sino-conn spiral cable assemblies offer unmatched flexibility and precise coil memory for motion-intensive environments. Customize length, coil size, and connector type to suit robotics, medical, and automation needs. We support rapid prototyping, zero MOQ, and 3-day sample delivery — engineered for movement, built for reliability.

Why choose spiral cable assembly from sino-conn

Sino-Conn’s spiral cable assemblies are engineered for high flexibility, durability, and space efficiency in dynamic environments. With UL, ROHS, and ISO certifications, our coiled cables withstand oil, flame, UV, and high temperatures. We offer zero MOQ, fast prototyping, and full customization in length, coil diameter, and connector options—making them ideal for automation, robotics, and medical equipment.

Highly Flexible Design for Repeated Extension and Retraction

Our spiral cable assemblies are engineered for high-frequency motion applications, providing excellent extension and retraction performance. The coiled structure ensures tangle-free routing and reliable memory return even under continuous use. Ideal for environments where cables need to stretch and retract repeatedly — such as robotics, medical carts, and handheld devices — our cables retain elasticity over time and reduce mechanical wear. Built for motion, they stay compact when idle and extend smoothly when needed.

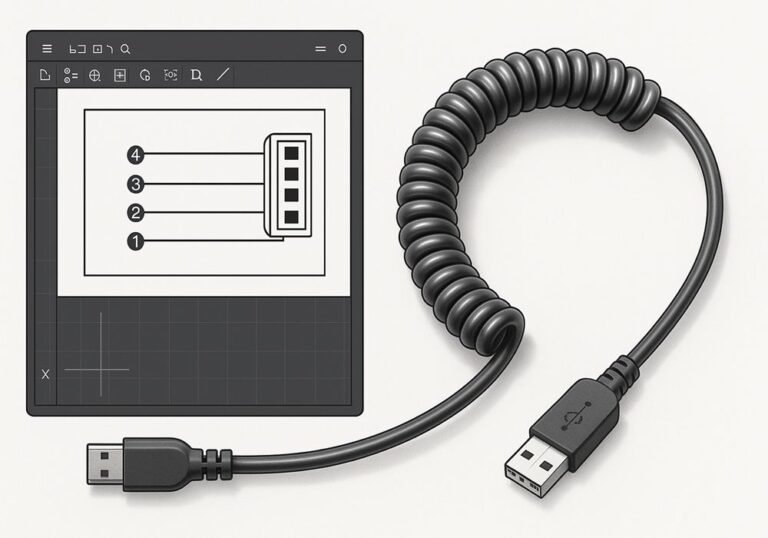

Customizable Coil Length, Diameter, and Connector Options

Our spiral cable assemblies offer full customization to meet your exact project requirements. You can choose the coil length, outer diameter, wire gauge, number of conductors, and connector types. Whether you’re designing for medical devices, test equipment, or automotive control units, we adapt to your design. We support both brand-name and cost-effective connectors. Flexible design, fast CAD drawing service, and engineering support — all help you get the right cable assembly for your system.

Zero MOQ with Rapid Prototyping and Mass Production Support

No matter your order size, we support you from concept to production. We offer zero MOQ and deliver samples within 3 days. Whether you need 1 prototype or 10,000 units, our flexible production process adapts quickly. Our factory is optimized for both rapid small batch output and scalable mass production, helping you speed up development while reducing cost and risk.

Triple Quality Inspection to Ensure Long-Term Reliability

Each spiral cable assembly goes through a strict three-stage inspection: in-process inspection during assembly, post-production quality control, and final pre-shipment verification. We ensure every unit is free from defects and meets design specifications before delivery. This comprehensive quality control process reduces failure rates and improves product lifespan — giving engineers and OEMs long-term confidence in performance and durability, even in demanding environments.

Supports Both Genuine and Cost-Effective Connector Solutions

We offer flexibility in connector selection — from genuine brand-name components to compatible, cost-effective alternatives. Clients can choose based on budget, lead time, or project requirements. Genuine connectors ensure full compatibility and high reliability, especially for volume orders. For urgent or low-volume needs, alternative options offer faster delivery and better pricing. We maintain stock for both options, ensuring quick turnaround and tailored solutions for every application scenario.

Fast Response with CAD Drawing in as Little as 30 Minutes

We understand that speed matters. That’s why our engineering team can provide custom spiral cable assembly drawings within just 30 minutes. Whether you need a 2D layout or 3D CAD for approval, we support fast technical communication and modifications. All orders come with production-ready drawings for client confirmation. This service significantly shortens development cycles and helps R&D engineers or OEM customers accelerate project launches with minimal delays.

Detailed specifications and parameters of spiral cable assembly

| No. | Pinout Definition | Connector Model | Cable Spec | Length (mm) | Jacket Shape | Jacket Material |

|---|---|---|---|---|---|---|

| 1 | 1:1 straight | USB-A to USB-B | Custom | Custom | Round | PVC tubing |

| 2 | Crossed TX/RX | DB9 to DB9 | Custom | Custom | Coiled round | Nylon braid |

| 3 | 1:1 straight | DC5.5 to DC5.5 | Custom | Custom | Molded round | Teflon tape |

| 4 | GND-only | JST to bare wire | Custom | Custom | Flat coiled | Conductive fabric |

| 5 | Power + GND | XT30 to XT60 | Custom | Custom | Round | PVC tubing |

| 6 | Differential pair | RJ45 to RJ45 | Custom | Custom | Spiral pair | Nylon braid |

| 7 | 1:1 straight | USB-C to USB-C | Custom | Custom | Round | Teflon sleeve |

| 8 | Open end | Molex to open | Custom | Custom | Molded round | Acetate cloth |

| 9 | 1:1 shielded | HDMI to HDMI | Custom | Custom | Spiral round | Aluminum foil wrap |

| 10 | I²C (SDA/SCL) | PH2.0 to PH2.0 | Custom | Custom | Coiled flat | PVC tubing |

Each spiral cable assembly is uniquely built based on the customer’s technical requirements. From pin definitions and connector models to jacket style and shielding materials, everything can be tailored. The table above illustrates just a few of our common configurations. In reality, over 90% of our spiral cables are custom-made — designed to solve specific problems in motion control, space constraints, or EMI interference in our client’s applications.

Customized spiral cable assembly styles

Trusted by 300+ global brands,1000+ styles have been developed.

Spiral Cable Assembly USB + DB9 + DC Multi-Function

Spiral Cable Assembly RJ45 Ethernet

Spiral Cable Assembly High Current Anderson Plug Coiled Cable

Spiral Cable Assembly DC Power Cable 2C

Spiral Cable Assembly DB9 to PH2.0 Coiled Wire Harness

Spiral Cable Assembly DB9 to Custom Wire Harness

Spiral Cable Assembly DB9 RS232 9 Pin Coiled Cable

Spiral Cable Assembly Automotive Connector

Spiral Cable Assembly 7 Pin Automotive Charging Cable

7 Pin Spiral Cable Assembly Automotive Trailer

Heavy Duty Spiral Cable Assembly Industrial Power

Product details display of spiral cable assembly

The detailed specifications of Sino-Conn’s spiral cable assemblies, including wire gauge, coil diameter, extension length, voltage rating, insulation material, connector type, and environmental resistance. Clear product photos and technical diagrams are provided to help buyers understand structure, flexibility, and durability for customized applications.

Precision-Coiled Geometry for Consistent Retraction and Extension

The coiling geometry of our spiral cable assemblies is precisely engineered to maintain consistent shape, memory, and elasticity. Using advanced tension control and forming techniques, each cable is manufactured with uniform coil spacing and diameter to ensure stable retraction and smooth extension over time. This controlled coiling process prevents tangling, enhances fatigue resistance, and improves long-term usability in dynamic applications. From robotics to portable electronics, our spiral cables return to their coiled shape without losing tension, providing both compact storage and flexibility during operation — a perfect blend of mechanical design and user functionality.

- Uniform Coil Spacing: Each spiral maintains consistent pitch to avoid irregular spring force or unbalanced tension during retraction.

- Long-Term Elasticity: Engineered to recover original coiled shape after thousands of extension cycles without deformation.

- Anti-Tangle Structure: Precision-wound geometry minimizes overlaps or entanglement during active use.

- Application-Oriented Tension: Coiling density can be adjusted to match retraction force needs for robotics, automotive, or handheld tools.

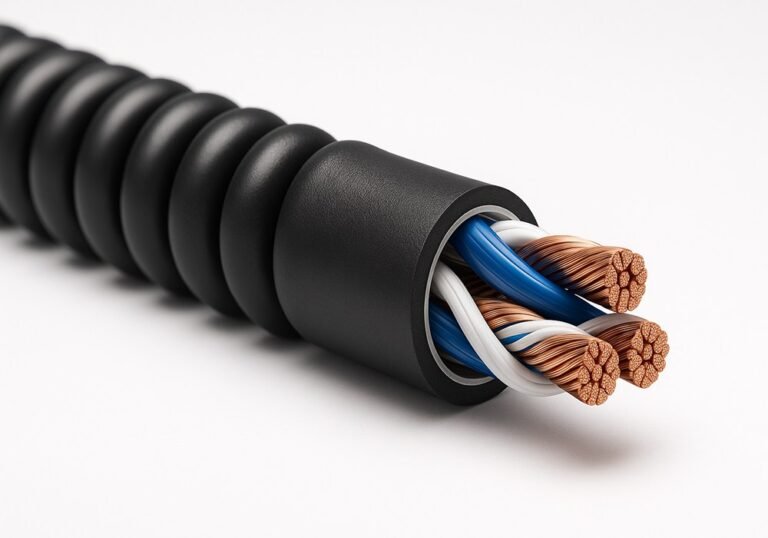

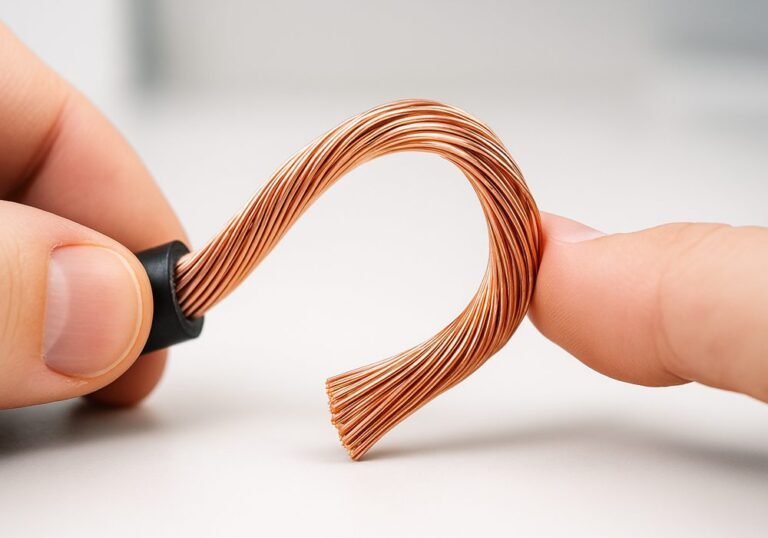

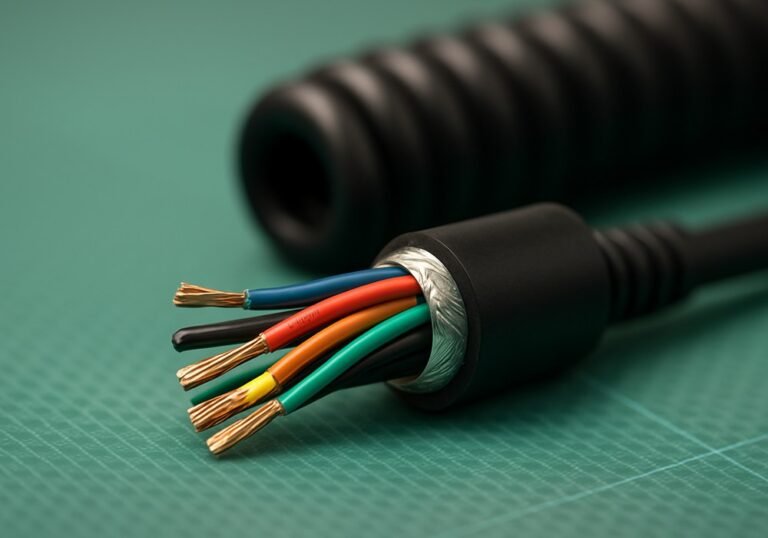

High-Flex Copper Strands with Optimized Conductor Layout

At the core of each spiral cable lies high-flexible copper conductors, made from finely stranded oxygen-free copper. These conductors offer superior conductivity, mechanical flexibility, and fatigue resistance — making them ideal for repeated bending and dynamic applications. The conductor layout is fully customizable, supporting multiple signal types including power, data, and control. Whether you need twisted pairs for EMI reduction or parallel wiring for power delivery, our design team will adjust the internal structure to fit. Combined with precision extrusion, the cable core ensures stable signal integrity and minimal resistance over long-term use.

- Ultra-Fine Copper Strands: Use of 0.05mm–0.08mm diameter strands increases flexibility and bending cycles.

- Custom Pin Configurations: Power, signal, and shielding layouts can be tailored to project needs.

- Twisted Pair Integration: Twisted pair layouts available for noise-sensitive applications like sensors or control lines.

- Oxygen-Free Copper: Ensures low resistance, excellent conductivity, and corrosion resistance even in harsh environments.

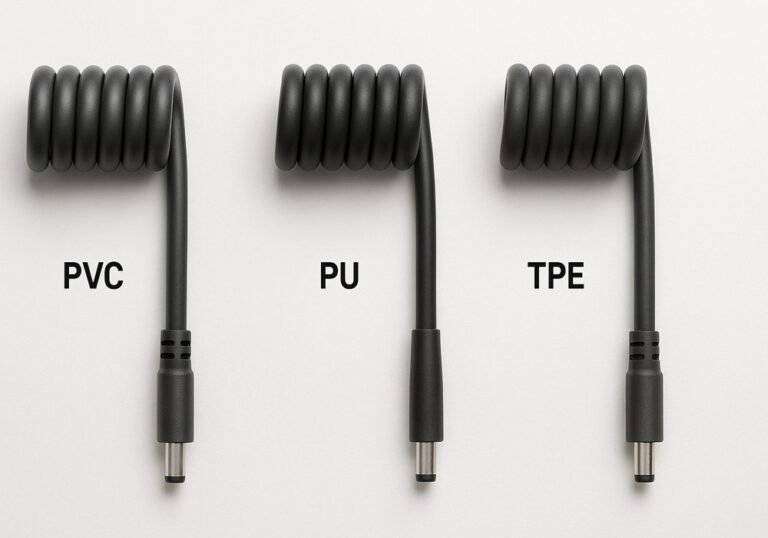

Abrasion-Resistant Outer Jacket for Rugged Applications

Our spiral cable assemblies are built to endure harsh industrial environments, thanks to their abrasion-resistant outer jackets. These jackets are made from high-grade materials such as PVC, PU, or TPE — each chosen based on flexibility, tensile strength, and environmental resistance. The outer sheath protects the inner conductors from mechanical wear, dragging friction, or chemical exposure. Whether you’re using the cable in factory automation, automotive diagnostics, or mobile testing systems, the jacket maintains its integrity under continuous bending, pulling, or surface contact. This ensures longer cable lifespan and reduced maintenance costs in mission-critical operations.

- Durable Materials: Options include PVC for economy, PU for elasticity, and TPE for outdoor-grade resistance.

- Scratch and Drag Resistant: Jacket surface withstands repeated sliding across metal or rough surfaces.

- Oil and Chemical Protection: Special compounds available to resist grease, solvents, and industrial fluids.

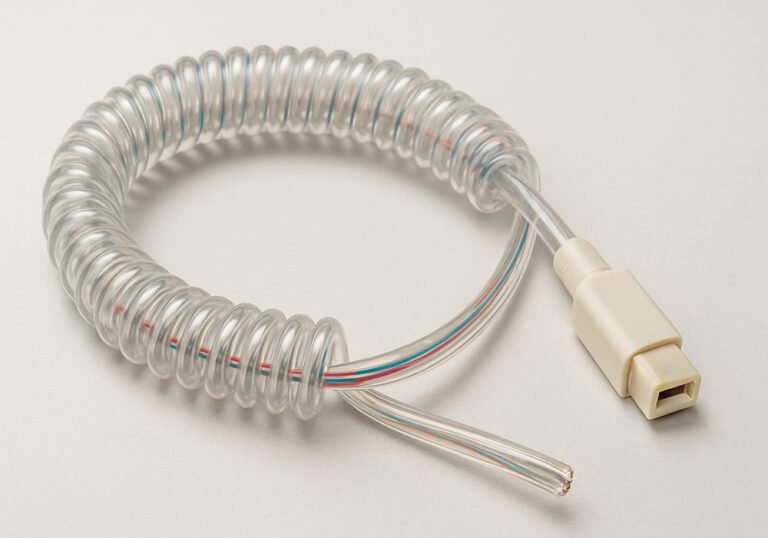

- Color-Coded or Transparent Jackets: Outer layer can be customized for identification, safety, or visual inspection of inner conductors.

Customizable End Connector Configurations and Pin Mapping

Our spiral cable assemblies support a wide range of connector types and pin mapping configurations. Whether your design calls for USB, RJ45, D-sub, circular industrial connectors, or customized hybrid connectors, we can integrate them seamlessly. Additionally, we support various pinouts including power/signal separation, differential pairs, or shielding layers for EMI protection. This flexibility allows engineers to specify exactly how the cable connects to their systems, reducing the need for adapters or extra components. With rapid drawing service and compatibility checks, we ensure that every connector is properly configured to meet mechanical and electrical demands.

- Wide Connector Options: USB, HDMI, Molex, JST, aviation plugs, and more are available.

- Custom Pin Mapping: Assign any pin-to-wire configuration based on schematic or usage logic.

- Shielding and Drain Wire Integration: EMI-sensitive applications can add braided shields and dedicated grounding lines.

- Mixed-Signal Interfaces: We support combining power, data, and signal lines in a single multi-pin connector.

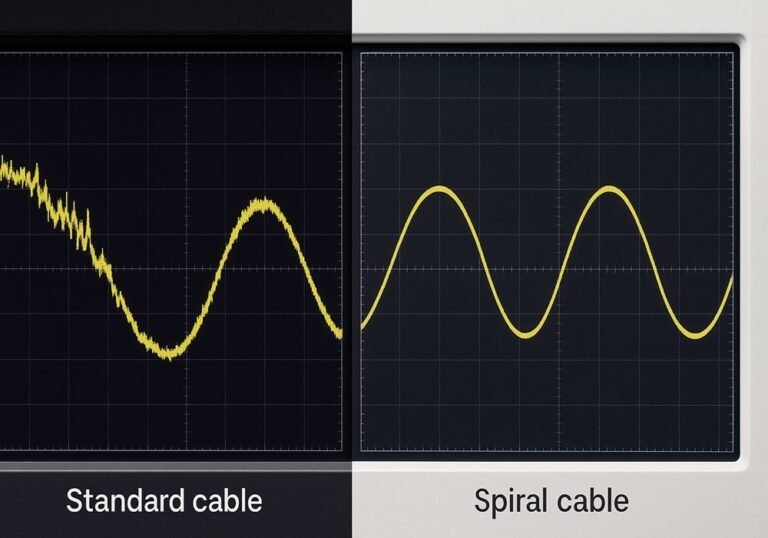

Stable Signal Transmission Under Dynamic Movement

Spiral cable assemblies are often used in applications with constant motion, such as robotic arms, vehicle diagnostic tools, and wearable test devices. Our cables are engineered to maintain signal stability even under high-frequency bending, twisting, and stretching. Through optimized conductor insulation, precise shielding techniques, and controlled impedance design, we ensure minimal signal loss, excellent EMI suppression, and low crosstalk. The spiral form helps absorb movement stress while maintaining cable geometry — this combination allows data, power, and control signals to travel smoothly in unstable environments without degradation or interruptions.

- Dynamic Flex-Tested Design: Each cable passes high-cycle bend and torsion tests for reliability.

- Impedance-Controlled Structure: Balanced cable geometry reduces reflections and data corruption.

- EMI Shielding Layers: Braided or foil shielding minimizes electromagnetic interference during operation.

- Consistent Signal Integrity: Low crosstalk and low attenuation ensure clear signal paths in motion-heavy systems.

Environmental Resistance for Outdoor and Industrial Use

Our spiral cable assemblies are designed to operate reliably in harsh outdoor and industrial environments. With options for waterproof sheathing, UV-resistant jackets, flame-retardant materials, and wide operating temperature ranges, they’re ideal for exposed applications. These cables are used in mobile field equipment, outdoor monitoring systems, and industrial robots — where exposure to heat, cold, moisture, and sunlight is common. Material options like TPE, silicone, or ruggedized PU allow cables to remain flexible while resisting cracking, aging, and deformation. Whether you need cables for marine, automotive, or open-air control systems, we provide tailored protection for maximum durability and performance.

- Wide Temperature Range: Operational from -40°C to +105°C for cold and high-heat applications.

- Water and Moisture Resistance: Optional sealed jackets prevent moisture ingress in outdoor use.

- UV and Flame Protection: Specialized compounds withstand prolonged sunlight exposure and meet UL flame ratings.

- Material Options for Tough Conditions: TPE and silicone maintain flexibility in freezing temperatures or oily environments.

--- Customized Capabilities Services and Processes

Customize your spiral cable assembly

Explore Sino-Conn’s customized capabilities for spiral cable assemblies, including length, coiling tension, connector configuration, material selection, and shielding options. From rapid 2D/3D drawing support to flexible sampling and small-batch production, we tailor every process to your technical requirements—ensuring precision, fast lead time, and complete compliance with global standards.

Customized Capabilities Services and Processes

Customize your spiral cable assembly

At Sino-conn, customization is not just a service—it’s our core strength. From the moment a customer submits an inquiry, our team moves into action to provide tailored solutions for every cable assembly request. We support full customization in:

Customization Capabilities

Custom Engineering to Match Every Industrial Need

At Sino-conn, we specialize in designing and manufacturing fully customized spiral cable assemblies tailored to meet each customer’s specific application needs. From initial concept to final production, our engineering team works closely with clients to transform functional requirements into reliable, production-ready solutions. No matter the complexity, volume, or timeline, we deliver precision, speed, and flexibility with every custom project.

- Connector Flexibility: Choose from USB, HDMI, RJ45, aviation plugs, D-sub, JST, or fully custom-designed interfaces.

- Wire Structure & Pinout: Customize conductor count, shielding layout, and exact pin-to-function mapping based on electrical schematics.

- Jacket Material Options: Select PVC, PU, TPE, silicone, or hybrid materials based on environmental resistance, softness, and durability.

- Mechanical Design: Adjust coil diameter, pitch, extension length, and retraction strength to fit your mechanical constraints.

- Color & Labeling: We support color-coded jackets, printing, or barcode labeling for identification and traceability.

- Low MOQ & Rapid Prototyping: No minimum order quantity. Samples delivered in as fast as 3 days.

- Compliance Ready: We support UL, ISO, RoHS, REACH, COC, PFAS, and country-of-origin documentation.

Our Commitment to Outstanding Service

At Sino-conn, our service goes far beyond basic manufacturing — we deliver a high-efficiency, engineer-level support experience that reduces lead time, minimizes communication friction, and ensures every spiral cable assembly matches the customer’s needs exactly.

- Engineer-Direct Support: Clients communicate directly with experienced engineers who understand both structure and application, ensuring fast, technical solutions with no information loss.

- Rapid Quotation and Drawing: We provide detailed quotations and CAD drawings within 30 minutes for most requests. This speed helps customers accelerate their development cycles.

- Full-Cycle Visualization: From drawing approval to final inspection, we involve customers in every key milestone, supported by real-time updates, sample photos, and video calls.

- Flexible Solutions: Whether customers request original brand connectors or cost-effective alternatives, or require adjustments in length, coiling ratio, or pinout — we support all variants.

- Strict Quality Assurance: All cables undergo triple inspection (in-process, final, and pre-shipment), with full documentation for compliance and traceability.

- No MOQ Commitment: Even for one piece, we offer the same service experience as large-volume clients.

| Items | Alternative | Original |

| Price | Cost sensitive project | Value Oriented Project |

| Lead Time | Delivery within 3-4 weeks | Delivery within 4-8 weeks |

| Performance | Commonly used in consumer Products | Widely used in Commerical and Industrial Field |

client Projects

300+ global clients trust sino-conn’ premium service

I manage procurement for a U.S.-based medical diagnostics company. We needed spiral cable assemblies for portable ECG devices — compact, lightweight, and biocompatible. Our challenge was tight lead time and strict FDA compliance. Other vendors quoted 5–6 weeks just for samples, which didn’t work for our clinical pilot deadlines.

A colleague recommended Shenzhen Sino-conn. I emailed them on a Friday afternoon and received a response within 2 hours. Their engineer understood our spec sheet immediately — we discussed connector types, material certifications, and coiling ratios over a video call that same day.

What amazed me was how quickly they delivered: 3 working days for a fully customized, FDA-ready cable. The white outer jacket was soft but durable, the pinout matched perfectly, and they even helped us add a color-coded strain relief for ease of assembly.

“They move fast without cutting corners. Their responsiveness and technical accuracy made them our go-to supplier for medical cabling.”

Lisa Thompson

Procurement Manager, United States

I’m an engineer at a robotics company in Germany. We were developing a new robotic arm and needed a spiral cable assembly that could endure continuous stretching without signal loss. Our key challenges were EMI interference and poor durability with previous suppliers — the coils would deform after 30,000 cycles.

When I reached out to Sino-conn, I was surprised how quickly they responded. I sent them our functional drawing and explained our testing goals. In less than 48 hours, I had a CAD diagram and two connector options — both OEM and cost-saving alternatives. They even offered to simulate cycle fatigue in their lab.

What really impressed me was their attitude. They weren’t just quoting a product, they were solving a real-world issue with technical precision. The first sample arrived in 4 days. It passed 500,000 cycles with no degradation. It was also easier to integrate due to their customized coiling and precise pin mapping.

“They proved they can handle highly engineered projects with urgency and care. I’m confident they’ll be a long-term partner.”

Andreas Müller

Senior Engineer, Germany

I lead product development at a smart agriculture startup in Japan. For our autonomous field sensor units, we needed spiral cable assemblies that could stretch outdoors, resist UV, moisture, and hold stable signal in low temperatures. Off-the-shelf solutions always failed after two months in the field.

I contacted Shenzhen Sino-conn after seeing a post on LinkedIn. Their response was immediate. I sent field photos and our target specs. Their team proposed a PU-jacketed spiral cable with waterproof connectors, EMI shielding, and a special tension-reducing coil pitch — all within 72 hours.

We received samples within 5 days. Field installation was easy, and even after a month of rain, mud, and cold nights, everything performed flawlessly. The custom coil diameter also made cable routing easier on our pole-mounted units.

“They understood the environmental challenges and engineered the solution to fit — not just to sell. That makes them rare and reliable.”

Takeshi Yamamoto

Product Development Lead, Japan

industry Application of spiral cable assembly

Spiral cable assemblies from Sino-Conn are widely used in industries that require retractable, flexible power and signal transmission—such as medical equipment, robotics, automotive, industrial automation, and consumer electronics. Their ability to extend and retract without tangling makes them ideal for dynamic environments where mobility, space efficiency, and durability are critical.

Solution 1: Automated Robot Arms in Assembly Lines

Application Scenario:

In modern automated assembly lines, robot arms are deployed for tasks such as welding, picking, sorting, and placement. These arms often require power and data transmission through cables that flex repeatedly, rotate with the joints, and endure thousands of stretch cycles per day. Spiral cable assemblies are the preferred choice due to their compact design, retractable form, and resistance to constant motion and mechanical stress. However, the challenge lies in maintaining stable electrical performance despite prolonged exposure to vibration, torsion, and dynamic bending. In environments such as automotive component factories or electronics assembly plants, failure of cables can halt production, causing losses in both time and cost. Our spiral cable assemblies are customized to meet these demanding conditions with high flexibility, reliable insulation, and strong resistance to EMI and abrasion.

Equipment & Products:

Robotic arms

CNC welding stations

Pick-and-place robots

Industry Pain Points:

- Frequent cable fatigue due to continuous flexing and twisting.

- EMI interference in high-frequency data transmission.

- Limited installation space requiring compact cable structure.

Solutions:

- Use of high-flex polyurethane sheath and stranded copper conductors for enhanced mechanical durability.

- Integrated EMI shielding with multi-layer foil and braid to ensure stable signal transmission.

- Custom coil pitch and OD to fit narrow cable routes and tight rotary joints.

Solution 2:Medical Imaging Equipment Cable Management

Application Scenario:

Medical imaging equipment, such as mobile X-ray machines, CT scanners, and portable ultrasound devices, requires reliable cable assemblies that can handle constant movement, tight routing, and sensitive signal transmission. These devices are often wheeled between rooms, rotated at multiple angles, and used intensively in clinical settings. Spiral cable assemblies are ideal due to their retractability, small footprint, and ability to maintain structural integrity under repeated flexing. Moreover, these applications require excellent shielding to prevent EMI, which can affect diagnostic imaging results. With stringent hygiene and space constraints, any cable solution must also be resistant to disinfectants, easy to clean, and compact enough to not hinder hospital workflows.Sino-conn’s spiral cable assemblies are built for these needs with bio-compatible sheathing, precision shielding, and custom pinout options.

Equipment & Products:

- Mobile X-ray units

- CT & MRI imaging devices

- Portable ultrasound carts

Industry Pain Points

- EMI interference affecting diagnostic accuracy in sensitive devices.

- Space-limited routing paths in mobile medical machines.

- Surface wear from frequent sterilization using alcohol or disinfectants.

Solutions:

- Shielded cable with high-frequency blocking foil to minimize EMI during imaging.

- Spiral structure with optimized coil memory and diameter for space-saving installation.

- Medical-grade PU jacket with alcohol and chemical resistance for long-term hygiene.

solution 3: Spiral Cables in Automated Warehouse Robots

Application Scenario:

In large-scale automated warehouses, AGVs (Automated Guided Vehicles) and robotic arms play a critical role in material handling, picking, and shelf repositioning. These systems operate around the clock, requiring highly flexible, retractable, and durable cable assemblies to connect sensors, power modules, and control units. Traditional straight cables often tangle, wear out, or obstruct mechanical movement. Spiral cable assemblies provide a compact, self-retracting solution that accommodates tight bending radii and constant motion. In dusty and high-speed operating environments, EMI shielding and abrasion resistance are essential to ensure data integrity and longevity. Sino-conn’s spiral cable assemblies are engineered with reinforced copper cores, anti-friction sheathing, and customizable ends to adapt to a wide range of automated systems.

Equipment & Products:

- Automated Guided Vehicles (AGVs)

- Robotic picking arms

- Mobile storage and conveyor robots

Industry Pain Points:

- Cable entanglement causing robotic arm jamming or AGV stalling.

- High mechanical fatigue from repetitive movements and short-radius turns.

- EMI interference disrupting sensor signal and wireless communication.

Solutions:

- Spiral cable shape with optimized memory coil to eliminate slack and tangles.

- Flexible core conductor with 1 million+ bending cycles for long service life.

- Multi-layer EMI shielding for signal stability in noisy environments.

solution 4: Spiral Cable Assemblies in Medical Imaging Systems

Application Scenario:

Modern medical imaging systems such as MRI scanners, CT machines, and digital X-ray devices require dynamic and precise cable management, especially in moving components like rotating gantries or articulating arms. Traditional cable setups are prone to wear, kinking, and interference due to the repetitive movements and electromagnetic environments. Spiral cable assemblies offer a compact and retractable structure, allowing smooth extension and retraction during scanning procedures. They prevent entanglement and minimize mechanical stress on connectors. In addition, their shielding capabilities help reduce electromagnetic interference, ensuring clean image signals. Shenzhen Sino-conn customizes medical-grade spiral cables with bio-compatible sheathing, flame resistance, and EMI layers, supporting stable performance in high-frequency, high-precision imaging scenarios.

Equipment & Products:

- MRI and CT scanners

- Digital X-ray arms

- Diagnostic ultrasound consoles with movable probes

Industry Pain Points:

- Cable damage from repeated motion and equipment articulation.

- Image distortion caused by EMI interference.

- Sterilization requirements and compliance with medical safety standards.

Solutions:

- Spiral-shaped structure reduces wear during movement and retracts cleanly.

- Multi-layer shielding resists EMI for clearer image transmission.

- Medical-grade materials ensure flame resistance, low toxicity, and sterilization compatibility.

solution 5: Spiral Cable Assemblies in Robotic Automation Systems

Application Scenario:

In robotic automation, cables face extreme stress from constant twisting, rotating, and retracting movements in confined spaces. Industrial robotic arms—used in assembly lines, welding, packaging, and material handling—require flexible, durable cable assemblies that can follow complex trajectories without failure. Conventional cables often snag, stretch excessively, or break due to continuous torsional loads. Spiral cable assemblies, however, offer compact coil designs that extend and retract in sync with robotic movement, eliminating cable slack and reducing tangling. Shenzhen Sino-conn designs custom spiral cable solutions with wear-resistant insulation, multi-axis bending capability, and tight-tolerance shielding. These features enhance signal reliability, extend service life, and ensure compatibility with high-speed industrial protocols such as EtherCAT and CANopen.

Devices and Products:

- Industrial robotic arms

- Automated guided vehicles (AGVs)

- Collaborative robots (cobots) in smart factories

Industry Pain Points:

- Cable fatigue and failure due to repetitive multi-directional motion.

- Signal noise and data loss caused by industrial EMI.

- Limited space for routing cables along articulated joints.

Our Solutions:

- Spiral form factor allows retraction and extension without strain.

- Shielded spiral cables ensure signal integrity under EMI exposure.

- Custom bending radius designs fit compact robotic enclosures.

solution 6: Spiral Cable Assemblies in Elevator and Automatic Door Control

Application Scenario:

In modern buildings and public infrastructure, elevator cabins and automatic doors demand highly reliable, space-efficient cable management systems. These systems require continuous electrical and signal connection during vertical movement or door actuation cycles. Traditional straight cables may wear out quickly or restrict movement due to limited flex cycles. Spiral cable assemblies provide a coiled structure that stretches and contracts smoothly with movement, allowing uninterrupted transmission of power, control, and sensor signals. Shenzhen Sino-conn provides spiral cable solutions with flame-retardant, UV-resistant jackets, high-flex copper conductors, and noise-reducing shielding. These cables are installed in door headers, elevator car tops, and control panels to ensure silent operation, user safety, and extended product lifecycle.

Equipment and Products:

- Elevator control panels

- Automatic sliding and revolving doors

- Vertical lift platforms in commercial buildings

Industry Challenges:

- Cable wear due to repeated opening and closing motion.

- Limited installation space in narrow tracks or lift shafts.

- Need for reliable signal and power delivery in continuous cycles.

Our Solutions:

- Spiral structure supports frequent flexing without fatigue.

- Slim-profile cables fit tight channels and moving assemblies.

- Shielded and fire-retardant designs ensure long-term safety and performance.

Ask Us About Free Samples

Hey, don’t hesitate to try & feel the FREE SAMPLES before making up your decision

--- A reliable manufacturer with competitive price and Quality Assurance

Price and delivery

Flexible Pricing: Based on connector brand (original or equivalent), cable material, and customization level.

Industry-Based Pricing: Higher for medical, military, and end-users; more competitive for OEM factories, assemblers, and traders.

Regional Price Variations: U.S. and Western Europe have higher pricing; Asia and Eastern Europe are more cost-effective.

No MOQ: Orders start from 1 piece, fully supporting small batch or prototype needs.

Customization Scope: Length, pinout, connector type, materials, and special designs are fully customizable.

Rapid Quotation & Drawing: 30 minutes for technical drawings and price offers, ensuring fast response.

Fast Lead Time: Samples in 3 days; standard bulk production within 2-4 weeks; urgent orders supported.

Certified Quality: UL, ISO, ROHS, REACH, PFAS, COC, COO certifications with 100% full inspection (in-process + final).

Quality Assurance

At Sino-Conn, quality assurance is at the core of our cable assemblies manufacturing process, ensuring every product meets strict international standards and customer specifications.

Comprehensive Inspection: Every assembly undergoes 100% inspection at multiple stages—process inspection, final inspection, and pre-shipment inspection—ensuring flawless product quality.

Certifications: All products are fully certified with UL, ISO, ROHS, REACH, PFAS, COC, and COO, meeting global regulatory and environmental standards.

Detailed Specifications: Each product is manufactured according to precise technical parameters including dimensions, voltage, current, EMI shielding, impedance, flexibility, and resistance to heat, fire, oil, UV, and corrosion.

Accurate Engineering Drawings: We provide CAD to PDF drawings within 30 minutes to 3 days for customer confirmation, guaranteeing accuracy before production.

Material & Connector Authenticity: Both original and equivalent connectors are available, carefully selected to ensure compatibility and performance consistency.

Professional Team: Our engineers and sales team deeply understand product design, materials, production processes, and international market requirements, allowing us to deliver customized solutions with stable and repeatable quality.

Flexible Production Control: From small samples to full-scale production, we maintain consistent quality regardless of order size.

With Sino-Conn’s strict quality assurance system, customers receive highly reliable cable assemblies that perform consistently in demanding applications.

Frequently Asked Questions

Here you’ll find answers to the most frequently asked questions about our customized spiral cable assembly services. From product certifications and customization options to order processing and after-sales support, this section covers everything you need to know. If you have a specific inquiry that isn’t listed, feel free to contact our team—we’re available 7 days a week to assist you.

What is a spiral cable assembly?

A spiral cable assembly is a coiled electrical cable designed to extend and retract without tangling. It’s ideal for dynamic applications where mobility and flexibility are key.

What is your lead time for samples and bulk orders?

Samples: 2 weeks standard, 2-3 days for urgent.

Bulk: 3-4 weeks standard, 2 weeks for urgent bulk orders.

What connectors can be used with spiral cable assemblies?

We support various connector types: circular, rectangular, waterproof, signal, and power connectors — all customizable.

Are your connectors original or compatible alternatives?

We offer both original and cost-effective alternatives. Clients can choose based on budget, lead time, or preferred brand.

Do your Ethernet cable assemblies comply with certifications like UL, RoHS, and REACH?

Yes, all our assemblies can be manufactured with UL, ISO, RoHS, REACH, PFAS-free, and other certifications upon request.

Is there a minimum order quantity (MOQ)?

No MOQ required. We support 1 piece orders to help customers with samples or small-volume customization.

How do I confirm the product before mass production?

We provide full drawings, material lists, and test reports for confirmation before starting mass production.

Can spiral cables be flame-retardant or UV-resistant?

Yes, we offer flame-retardant, UV-resistant, waterproof, oil-proof, and halogen-free options.

Do you support online video meetings to discuss technical requirements?

Yes, our sales and engineering team can communicate via Zoom, Teams, or Google Meet.

What kind of testing do you perform before shipping?

We perform 100% full inspection including appearance, continuity, insulation resistance, pinout, and EMI shielding tests.

- Our team will answer your inquiries within 12 hours.

- Your information will be kept strictly confidential.

Drop us a line now, and you will get the free sample soon.

We would love to hear about your project and discuss how we can help. To schedule a meeting with our team, simply fill out the form in this section.

- (+86)13924649075

- info@sino-conn.com

- Southeast Industry and Trade Building, #1021 Houhai Avenue, Shekou, Nanshan District, Shenzhen, China