Choosing the correct LVDS connector for your display can mean the difference between a reliable device or a costly failure. Whether you’re designing consumer electronics, industrial instrumentation, in-vehicle displays, or medical interfaces, selecting the right connector type is essential for signal integrity, EMI control, mechanical fit, and manufacturing reliability. In this guide, we explain how LVDS connectors work, which types are commonly used, how to evaluate compatibility, industry-specific considerations, and when to choose custom assemblies with Sino-conn.

What Is an LVDS Connector and How Does It Work?

LVDS (Low-Voltage Differential Signaling) connectors are widely used for high-speed, low-power signal transmission. They use differential signal pairs to transmit data with minimal electromagnetic interference (EMI), making them ideal for connecting display panels in devices like laptops, industrial monitors, and medical displays.

What makes LVDS special is how it handles data: it uses a very small voltage swing (around ±350 mV) between two wires to represent digital signals. Because both wires carry opposite signals, they naturally cancel out external noise. This means you get clean, fast data transmission even in environments with lots of electrical noise.

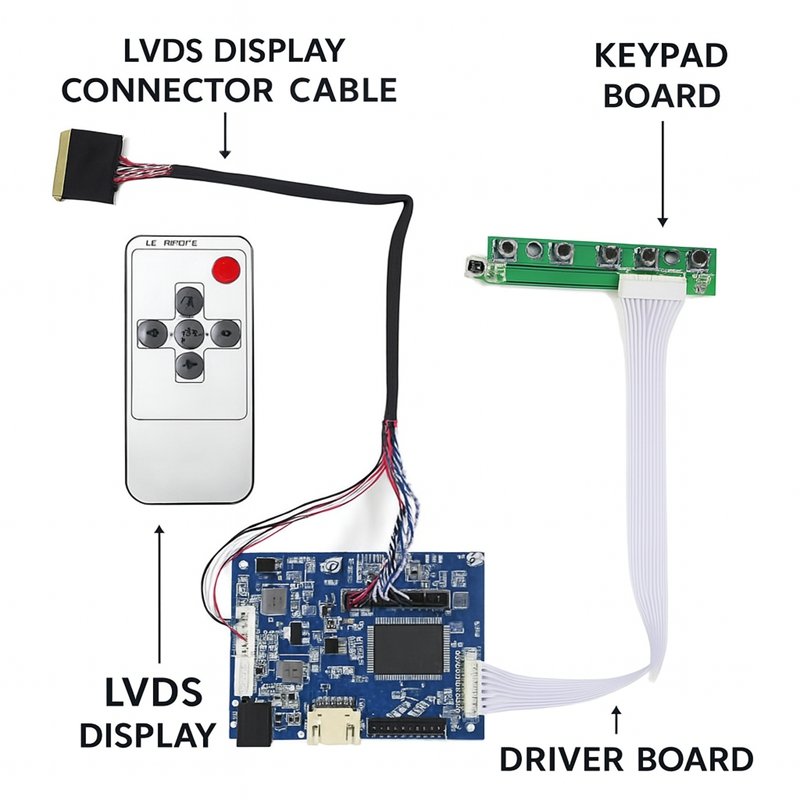

An LVDS connector acts as the link between the display and the controller board. It physically holds the cable in place and ensures correct alignment of signal pins. With the right connector, your display performs reliably under different conditions—whether it’s in a slim tablet or a rugged factory control unit.

Which LVDS Connector Types Are Commonly Used Today?

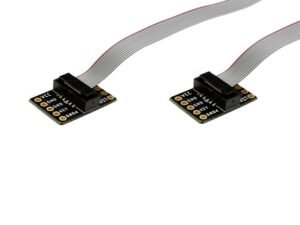

LVDS connectors come in various forms, each designed for specific applications and environments. Some of the most widely used types include JST, Molex, Hirose, DF14, and DF9.

JST connectors are known for being compact and cost-effective, perfect for thin consumer devices like tablets. However, they typically support fewer mating cycles, making them less ideal for industrial use.

Molex connectors are versatile and durable, often used in both consumer and industrial settings. They come with friction or micro-latch mechanisms, offering solid retention without complex locking hardware.

Hirose connectors are engineered for robustness and reliability. Their secure latching systems and durable materials make them a favorite for automotive, robotics, and harsh environment applications.

Panasonic DF14 and DF9 connectors are commonly pre-installed on LCD panels. DF14 is a 1.0 mm pitch connector, while DF9 has a much finer 0.5 mm pitch, ideal for ultra-thin designs.

Choosing the right connector type means considering factors like pitch (distance between pins), number of pins, locking mechanism, and intended application.

Below is a comparison table of the most commonly used LVDS connector types:

| Connector Type | Pitch (mm) | Lock Style | Typical Use Cases | Mating Cycles |

|---|---|---|---|---|

| JST | 0.8–1.0 | Friction latch | Slim laptops, tablets, low-cost devices | ~30 |

| Molex | 0.8–1.25 | Friction / micro-latch | Consumer, industrial, medical | ~50–75 |

| Hirose | 1.25 | Secure latch | Automotive, robotics, harsh environments | 100+ |

| Panasonic DF14 | 1.0 | Friction latch | Standard LCD panel connections | ~40 |

| Panasonic DF9 | 0.5 | Micro latch | Ultra-compact or ultra-thin panel modules | ~20–30 |

How to Identify the Right Connector for Your Display

Finding the right LVDS connector starts with your display’s datasheet. This document provides essential specifications: pin count, pitch, connector orientation, and even part number references. If the datasheet suggests a specific connector series (like Hirose DF14-30P), you’re already halfway there.

Next, match the connector on the controller or driver board. Often, each end of an LVDS cable requires a different type of connector. One side might use a Hirose, the other a Molex. Verifying both ends is key to avoiding mismatches.

Environmental considerations also matter. For applications exposed to EMI or harsh conditions, choose connectors with shielding or grounded metal shells. Sino-conn offers custom shielding options to help mitigate interference and improve signal integrity.

Lastly, consider the mechanical aspects. Think about how the cable routes through your device, how many times it will be plugged and unplugged, and whether space constraints require a low-profile or right-angle connector.

Here is a simple decision matrix to help guide connector selection:

| Criteria | Questions to Ask | Sino-conn Support |

|---|---|---|

| Display datasheet match | What pitch and pinout are specified? | We extract and verify datasheet specs |

| Controller compatibility | What connector is used on the board? | Support for cross-end matching |

| EMI/environmental requirements | Is shielding or flame retardant needed? | Custom shielding and halogen-free materials |

| Mechanical fit | What are the space and durability constraints? | Low-profile, right-angle, and reinforced options |

| Prototyping and validation | Can a sample be tested before bulk order? | 3-day CAD + fast sample support |

Do LVDS Connectors Vary by Industry or Use Case?

Absolutely. Different industries require LVDS connectors that meet their specific needs.

In consumer electronics, where thin and lightweight designs are critical, compact connectors like JST or DF9 are often used. These connectors support sleek form factors but are not built for high durability.

For industrial equipment, durability and resistance to environmental factors are essential. Connectors need to handle temperature changes, vibration, and long-term reliability. Molex and Hirose connectors are typically chosen for these scenarios.

Automotive applications demand connectors with strong locking mechanisms and resistance to vibration and EMI. High mating cycles and secure retention are standard requirements.

In the medical field, compliance with standards like UL94 V-0 and RoHS/REACH is important. Connectors should be cleanroom-compatible and flame-retardant, often requiring specialized materials or coatings.

Sino-conn supports industry-specific customization, ensuring that our LVDS solutions meet both technical and regulatory standards.

Are All LVDS Cables and Connectors Interchangeable?

They may look alike, but LVDS cables and connectors are not universally interchangeable. Even slight differences in pitch, housing type, pin configuration, or shielding can make parts incompatible.

One of the biggest misconceptions is assuming any 30-pin cable will work with any 30-pin connector. But pin pitch, mating height, entry direction, and locking mechanisms vary. For example, a Molex 1.0 mm connector won’t mate properly with a Hirose 1.0 mm connector, despite having the same pitch.

Original parts are ideal for high-performance or regulated environments, but lead times and costs can be challenging. High-quality compatible alternatives can offer similar performance at lower prices and with faster delivery. At Sino-conn, we vet all compatible parts for reliability before recommending them to clients.

Using the wrong connector can lead to EMI issues, poor fit, and even physical damage to the display or board. That’s why custom cable assemblies are often the best option. Sino-conn provides drawings within three days, samples within 3–5 days, and full production in as fast as two weeks—with no MOQ.

Whether you need a flexible flat cable with EMI shielding, a mixed connector solution, or flame-retardant materials for medical applications, we help you build it right the first time.

Ready to Build the Right LVDS Cable for Your Display?

At Sino-conn, we specialize in high-performance LVDS cable assemblies tailored to your exact needs. From one-off prototypes to mass production, we deliver:

- Custom connector matching based on display and board specs

- CAD drawings in 3 days, fast sample delivery

- Support for original and compatible connector options

- Full certifications: UL, RoHS, REACH, PFAS, COC

- No minimum order quantity—start from 1 piece

We believe in fast communication, technical accuracy, and flexible pricing. Tell us your display model or send us a photo or diagram—we’ll do the rest. Contact Sino-conn today to get a quote or start your custom project.