BMW’s decision to use LVDS cables rather than HDMI is far more than just a hardware preference—it’s a calculated choice grounded in automotive-grade reliability, electromagnetic compatibility, and long-term integration. Imagine driving at high speeds with multiple screens, cameras, and infotainment modules working in unison. A single HDMI line might deliver high-resolution video, but can it survive the temperature swings of a desert, the vibrations of rough roads, or the electromagnetic interference from engine control units? LVDS cables, with their low‑voltage differential signaling and twisted‑pair shielding, are built precisely for this environment.

BMW uses LVDS cables over HDMI for superior EMI resistance, automotive‑grade durability, and flexible custom wiring. LVDS supports low‑power, high‑speed video transmission in harsh car environments while HDMI lacks automotive shielding and thermal resilience.

Picture this: a late model 5 Series weaving through desert heat, sand swirling around, infotainment, ADAS cameras, HUD—all running flawlessly. We’ll explore why LVDS makes BMW’s sleek display experience resilient—and why HDMI just can’t cut it in the automotive world. Read on to discover technical insights, real BMW use‑cases, and how Sino‑conn supports custom solutions that OEMs, engineers, and resellers trust.

What Is an LVDS Cable and How Does It Work?

An LVDS cable is a low‑voltage differential signaling link using twisted‑pair copper to transmit high-speed video with outstanding EMI suppression and low power consumption. It forms the physical layer in BMW infotainment and ADAS—combining tight impedance control, shielding, and automotive-rated insulation to deliver stable image quality in demanding vehicle environments.

Low‑Voltage Differential Signaling (LVDS), standardized under ANSI/TIA/EIA‑644, operates by transmitting data as the voltage difference between two wires, rather than relative to ground This differential approach reduces electromagnetic interference and ground‑bounce, critical in the dense electrical environment of automobiles. A constant current driver (~3.5 mA) produces a differential swing of ~350 mV, consuming minimal power (~8‑9 mW) even at 2.5 V supply .

LVDS is purely a physical layer standard, meaning data encoding (8b/10b, embedded clock techniques) is handled above it. This ensures wide compatibility with various video protocols—most notably FPD‑Link II/III variants used in automotive contexts .

Key Electrical and Structural Characteristics:

- Voltage & Impedance: Typical differential impedance is 100‑120 Ω, tightly controlled to minimize reflections.

- Cable Geometry: Outer diameter (OD) ranges from 1.0 mm to 3.0 mm depending on shield and conductor count. Bend radius often ≥10× OD to maintain reliability.

- Shielding & Flexibility: Many cables combine foil + braid shielding to block EMI, while maintaining flexibility for tight routing—a necessity in dashboards and A-pillars.

Materials:

- Conductors: Tin-plated or bare copper, with stranded or solid wires. Automotive-grade purity ensures low resistance and high flexibility.

- Insulation: Options include PE, FEP, PUR, TPU—each offering resistance to high heat (up to 150 °C), oil, UV, fire, and halogen‑free compliance.

- Shielding: Foil + tinned copper braid with ≥85% coverage, often grounded to connector shell for electrostatic discharge protection.

LVDS design allows full-HD video at 1‑3 Gbit/s per differential pair, with combined use of multiple pairs or serializers (FPD‑Link II) to reach higher resolutions or embed clock signals in a single pair.

For automotive OEMs like BMW, LVDS meets stringent AEC‑Q100 reliability spec, supports long‑term thermal cycles, and offers ergonomic installations. HDMI does not meet these rugged criteria.

Which BMW Systems Use LVDS Cables?

BMW uses LVDS cables across numerous systems: the central infotainment iDrive display, digital instrument cluster, head‑up display (HUD), 360° cameras, rear‑seat media, and ADAS vision modules. Modern models like the G30, X5 (G05), iX and i4 rely on LVDS to stream crisp, low‑latency video across multiple internal screens and sensors.

.jpg)

BMW’s cockpit integrates multiple dynamic displays and cameras—each demanding stable video over harsh conditions. LVDS cables are used extensively in:

- Central iDrive displays: The infotainment controller (CIC/NBT) communicates with 8.8″ or 10.2″ screens via LVDS. BMW uses 6‑pin round LVDS connectors on many models from F‑series and E‑series to G‑series

- Instrument clusters: Digital gauges in recent 5, 7, and X models rely on LVDS links for high refresh rate, glitch‑free rendering.

- Head-Up Display (HUD): LVDS delivers the HUD imagery from control modules to the windshield projection unit with zero latency.

- 360° camera and ADAS feeds: Surround‑view, night‑vision, and lane‑keeping cameras stream via LVDS to central display or cluster.

- Rear‑seat entertainment systems: Some higher-end BMWs include rear displays connected via LVDS to media sources.

Model Examples:

- 5 Series (G30), 7 Series (G70): LVDS cables feed the main display and instrument cluster; camera systems synchronize seamlessly.

- X5 (G05), iX electric model: LVDS is integral for large infotainment canvas and advanced vision sensors.

- BMW i4: LVDS used for multiple high‑res data channels splitting display between screen and cluster.

BVMS’ operating system—BMW OS 8/9—relies on robust video pipelines that use LVDS signaling to guarantee responsiveness under high data rates. Unlike HDMI, LVDS easily integrates into BMW’s internal wiring harnesses and is fully compliant with their OEM connector standards (FAKRA, HSD, 4‑/6‑pin round connectors)

When aftermarket interface modules inject HDMI input, they typically convert it internally back into LVDS to drive OEM screens. HDMI input alone cannot drive native dashboards—confirming BMW’s reliance on LVDS as the final display layer

This means whether it’s OEM or aftermarket, LVDS is the “native language” of BMW displays—HDMI must be adapted, adding latency, complexity, and often incompatibility.

Why Not HDMI? LVDS vs HDMI in Automotive Use

HDMI cables are designed for home entertainment—not for cars. LVDS provides better EMI protection, thermal resistance, connector flexibility, and ruggedness. BMW selects LVDS over HDMI to ensure signal stability, low latency, and mechanical reliability in challenging automotive environments.

Technical Comparison: Signal Type, EMI, Flexibility

Signal Integrity: HDMI uses single‑ended TMDS signaling with fixed‑rate or FRL modes—sensitive to noise and ground potential changes. By contrast, LVDS’ differential pairs cancel common‑mode interference and maintain signal fidelity in electrically noisy automotive harnesses .

Cable Flexibility: HDMI cables and connectors are stiff, bulky and have large plug bodies. LVDS assemblies are thin, flexible, and can follow tight paths behind dashboards, through hinges, or around sharp corners.

EMI Resistance: LVDS’s shielded twisted‑pair plus constant‐current driver design offers high immunity against external electromagnetic interference. HDMI cables, designed for consumer electronics, lack automotive‑grade shielding, and may cause or suffer interference when near ECUs, ignition systems, or wireless modules.

To make this comparison clearer, here’s a detailed breakdown of LVDS vs HDMI in automotive environments:

LVDS vs HDMI Technical Comparison

| Parameter | LVDS (Used by BMW) | HDMI (Consumer Standard) |

|---|---|---|

| Signaling Type | Differential | Single-ended (TMDS) |

| EMI Immunity | High (twisted pairs + shielding) | Low (susceptible to interference) |

| Temperature Resistance | −40°C to +125°C (automotive-grade) | 0°C to 70°C (consumer-grade) |

| Connector Design | Locking, compact (FAKRA, HSD, round) | Large, no locking, prone to disconnection |

| Cable Flexibility | High (thin, bendable, shielded) | Low (rigid, bulky) |

| Licensing Requirement | No | Yes (royalty fees required) |

| Real-time Performance | Near-zero latency | Higher latency due to encoding |

| Suitable for Automotive? | Yes | No |

Automotive-grade Durability and Thermal Resistance

Thermal Range: Automotive cables must endure −40 °C to +125 °C or higher. LVDS cables built with FEP, TPE or halogen‑free materials sustain these conditions. Consumer HDMI cables generally fail above 70 °C or are not rated for UV or engine‑bay oil exposure.

Mechanical Robustness: Frequent vibration, shock, flex fatigue demand automotive‑qualified cables. LVDS assemblies meet AEC‑Q100 or supplier reliability specs; HDMI cables do not. HDMI connectors lack retention latches suited for vehicle conditions.

EMI Shielding: Why HDMI Fails in Harsh Car Environments

Vehicles generate diverse EMI: switching regulators, alternators, ignition, CAN bus pulses. LVDS differential signaling cancels this noise; shielding confines radiated emissions. HDMI lacks differential wiring in the cable bundle—making it prone to degraded data or visible artifacts when installed near interference sources.

By using LVDS, BMW can guarantee display performance and avoid potential electromagnetic non‑compliance, critical in regulated automotive markets (CE, FCC, E‑mark).

Cost & Licensing Considerations

HDMI requires licensing from HDMI Licensing Administrator, with royalty costs, compliance testing, and logo certification. LVDS and FPD‑Link II are open standards free from these constraints. For high‑volume BMW integration, LVDS keeps costs predictable and avoids licensing hurdles that HDMI entails

Overall, HDMI simply falls short of the automotive demands in EMI immunity, rugged environmental resistance, compact flexibility, connector ergonomics, and cost predictability—whereas LVDS meets or exceeds all these requirements, rendering HDMI unsuitable for OEM-level applications in BMW.

How Does LVDS Improve Safety, Speed, and Integration?

LVDS supports real‑time streaming for safety cam views, enables minimal latency, and integrates cleanly with BMW’s network buses (CAN, FlexRay). It provides reliable high-speed video, low-power consumption, and smooth synchronization across infotainment and ADAS systems—enhancing both safety and user experience.

Stable high-speed data transmission for real-time video

With data rates typically between 1–3 Gbit/s per pair, LVDS enables full HD (1920×1080) resolution at 60 Hz or greater, with low latency. This is critical for image‑based ADAS functions—rear‑view, surround‑view, night‑vision—where real-time responsiveness saves lives. In multi‑screen configurations, LVDS ensures data consistency and refresh uniformity across cluster, HUD, and infotainment.

For parking assist or emergency brake camera images, even a millisecond delay can disrupt the human‑machine interaction. LVDS minimizes skew and jitter, especially with serializers like FPD‑Link II/III embedding clock in data stream

Enhanced safety in ADAS systems and backup cameras

Latency and signal glitches are unacceptable in ADAS. LVDS’s deterministic differential signaling means predictable delay and consistent image integrity—even under vibration or temperature drift. This feed into algorithms for obstacle detection, lane‑keeping, and predictive braking is crucial. In extreme environments—cold winters or desert heat—LVDS cables maintain consistent performance.

Integration with CAN/FlexRay and infotainment systems

BMW vehicles use a modular electronics architecture: infotainment control unit, ADAS sensors, climate control, instrument clusters, all linked by CAN, FlexRay, MOST, or Ethernet backbones. LVDS fits seamlessly into this structure: the physical LVDS cable connects modules directly, while CAN or FlexRay handles logic. Synchronization of video and sensor data is achieved with deterministic timing, essential for features like HUD overlay, driver assistance warnings, and split-screen display.

LVDS’s low power usage also minimizes strain on vehicle power buses. HDMI may draw more power, complicating thermal design and causing potential ground loops.

Critical thinking and multi-angle view

While alternatives like V‑by‑One HS offer higher bandwidth over fewer pairs—and are gaining traction in consumer electronics—they are newer and not yet widely adopted in automotive OEM systems. Implementing V‑by‑One would require system redesign, connector and harness changes, and retraining; BMW continues to rely on proven LVDS/FPD‑Link II for backward compatibility and reliability.

In R&D-focused EV models, future transitions may happen—but as of today, LVDS remains the field‑proven standard. The trade‑off: HDMI ≠ LVDS—HDMI’s strength lies in audio/video consumer devices where manufacturing conditions differ.

Do All BMW Models Use the Same LVDS Cable?

No, LVDS cables vary by BMW model and function: lengths, pinouts, conductor pairs, shielding, connector types (6‑pin round, FAKRA, HSD) differ across infotainment, instrument cluster, camera, and HUD systems. Custom LVDS assemblies must match BMW OEM specs or adapt for aftermarket needs with flexible configuration.

Custom cable requirements by model or function

BMW models—and even trim or production year—dictate specific LVDS configurations. For example, earlier F‑series models use 6‑pin round LVDS connectors for CIC/NBT screens. Newer G‑series may use flat ribbon or HSD connectors. Cable lengths vary depending on dashboard layout; pinouts differ for camera vs display signals. Impedance tuning and pair count must match OEM spec to avoid display artifacts or sync issues.

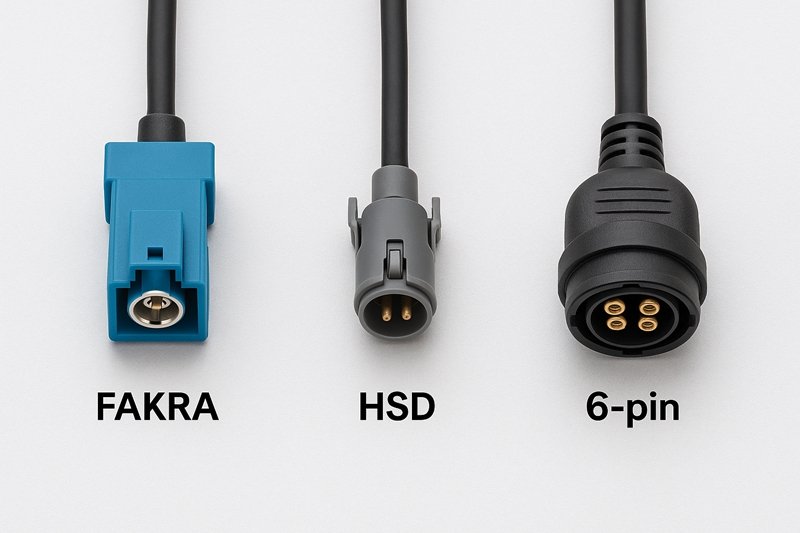

Connector variations (FAKRA, HSD, etc.)

Common automotive LVDS connectors include FAKRA (for cameras), HSD (High-Speed Data) for modular display modules, and 4‑/6‑pin round connectors for infotainment pathways. Each connector has trade‑offs:

- FAKRA: secure locking, high EMI resistance, but larger footprint.

- HSD: slim, low-profile, designed for multi-channel specification.

- Round connectors: weather-resistant and easy to route through dash openings.

Original vs compatible alternatives: OEM connectors are often proprietary and expensive; aftermarket or compatible replacements can offer similar fit-function if pinouts and shielding match. However, engineers and end users need to know trade‑offs: OEM may have longer lead time and higher MOQ, aftermarket allows flexibility in length and configuration.

Flexibility for OEM vs aftermarket needs

OEM buyers (e.g. trade customers, mass‑volume purchasers): Require consistent batches, certified quality (ISO, UL, RoHS, REACH). They may accept longer lead times and higher prices but demand rigorous documentation and supply stability.

Aftermarket / engineering clients: Prefer custom lengths, non‑standard pinouts, fast turnaround, and low MOQ. They often provide sample quantities or prototype needs—Sino‑conn supports samples in 2‑3 days, full production in 2 weeks; no MOQ, 1 pc acceptable.

Sample Variation Overview

| Cable Type | Connector | Model Range | Pair Count | Sample Lead Time | MOQ |

|---|---|---|---|---|---|

| 6‑pin round | BMW NBT | F20–F10 series | 3 differential pairs | 2 weeks (normal), 2‑3 days (urgent) | 1 pc |

| HSD ribbon | G‑series | G30, G05, G70 | 4 pairs + clock embedded | same as above | 1 pc |

| FAKRA camera | All models with ADAS | multiple | 1‑2 pairs | custom | custom |

Multi-angle perspective

From an engineer’s view, these differences matter for signal integrity and compatibility. From a procurement view, speed, cost, and stock availability drive decisions. OEM clients prefer original connectors; others choose high-quality substitutes—for flexibility, pricing, and customization. Sino‑conn handles both needs.

Ready to Customize Your BMW LVDS Cable?

At Sino‑conn, we understand that every BMW project—whether it’s OEM-level production or custom retrofit—has unique demands. We offer:

- Full technical spec sheets and detailed drawings (CAD to PDF within 30 minutes, full set in ~3 days).

- Complete parameter data: size, materials, voltage/current spec, impedance, bending radius, shielding, high‑temperature, anti‑oil/UV, halogen‑free compliance.

- Sample lead time: normal 2 weeks, urgent 2‑3 days; large orders in 3‑4 weeks.

- Full certificates: UL, ISO, RoHS, REACH, PFAS, COO, COC.

- Connector options: OEM genuine or equivalent replacements; customizable pin-out, length, shielding.

- No MOQ—start from 1 piece; full inspection (3× quality checks) for every product.

- Quick, expert technical support via online video meetings.

Interested in getting a tailored LVDS cable solution for BMW infotainment, ADAS, or instrument cluster? Contact Sino‑conn today to request a quote, sample, or custom drawing. Let us help you support your clients, streamline your supply chain, and deliver reliable, automotive‑grade LVDS cabling.