In a hyper-connected world, reliable signal transmission is the invisible engine driving innovation in telecom, defense, healthcare, and industrial systems. Behind every seamless data stream and high-frequency signal is a critical yet often overlooked component: the custom RF cable assembly. As the demand for speed, bandwidth, and system integrity grows, so does the importance of these tailored coaxial solutions.

Custom RF cable assemblies are designed to deliver high-frequency signal transmission with precision and reliability across complex environments. They are essential in telecom, aerospace, medical, automotive, and industrial applications where off-the-shelf cables fall short in terms of performance, shielding, durability, and fit.

Imagine an aerospace engineer needing a cable with 90-degree connectors and triple-shielding to prevent signal loss at 30,000 feet, or a medical OEM requiring ultra-flexible, sterilizable cables for an MRI system. These aren’t theoretical scenarios—they’re everyday challenges solved through customization.

In this article, we unpack how custom RF cable assemblies function, where they are used, why engineers trust them, and how Sino-conn helps customers turn technical demands into physical solutions. Let’s explore why these cable assemblies are the unseen heroes of modern systems—and how you can benefit from them.

What Are Custom RF Cable Assemblies?

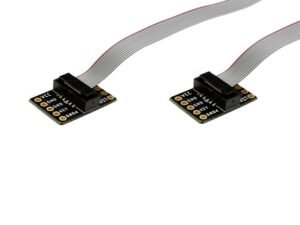

Custom RF cable assemblies are purpose-built coaxial cable systems tailored for specific electrical, mechanical, and environmental requirements.

Unlike standard coaxial cables, custom RF assemblies are engineered to deliver high-frequency signal integrity under defined constraints. They include:

- Conductors: bare or silver-plated copper, or copper-clad steel

- Dielectric insulation: PE, PTFE, FEP

- Shielding: single or multi-layer braid/foil combinations

- Jackets: LSZH, PVC, TPU for rugged or regulated use

- Connectors: SMA, N-type, BNC, TNC, MCX, MMCX, and more

Sino-conn engineers consider every element—impedance, length, bend radius, thermal range, frequency bandwidth, EMI resistance—based on your exact use case. Whether you need a mil-spec solution or high-flex robotic cable, we tailor assemblies that support long-term performance.

The result? Cables that prevent signal loss, minimize downtime, and integrate seamlessly into your system architecture.

Which Applications Require Custom RF Cable Assemblies?

Custom RF cable assemblies are not one-size-fits-all components. They are designed to thrive in demanding environments and deliver precise electrical performance under conditions where generic coaxial cables fail. Their application scope is broad, but especially critical in high-reliability sectors where failure is not an option.

Telecommunications & 5G Infrastructure

Aerospace and Defense

In air and space, cables are exposed to mechanical stress, high altitudes, UV radiation, and temperature extremes. Signal transmission in radar, avionics, and satellite systems must be shielded and uninterrupted. This is why aerospace and defense contractors use RF assemblies with triple shielding, MIL-DTL compliant connectors, and lightweight materials. Sino-conn’s solutions are engineered to meet specifications like MIL-STD-1553 or ARINC standards.

Medical Devices and Imaging Equipment

For MRI, CT, and ultrasound machines, signal clarity directly impacts diagnostic accuracy. Any EMI or crosstalk could compromise readings. Custom RF cables in this field must be biocompatible, often sterilizable, and flexible to fit inside small, moving assemblies. Sino-conn provides solutions using PTFE insulation, FEP jackets, and ultra-miniature coaxial connectors like MMCX or U.FL.

Automotive and EV Technologies

Advanced Driver Assistance Systems (ADAS), GPS modules, rear-view radar, and infotainment hubs all require custom RF cables that can handle vibration, humidity, and constant electrical activity. Assemblies may include overmolded connectors, flexible routing paths, and heat-resistant jackets. Sino-conn supports both prototype and mass production runs with assemblies that meet ISO/TS 16949 compliance.

Industrial Automation & Robotics

Factories and robotics environments involve frequent movement, signal complexity, and high EMI. Custom RF cable assemblies here must be highly flexible (sometimes with >10 million bend cycles), resistant to oils and chemicals, and shielded for interference-free operation. Hybrid cable assemblies—combining RF, data, and power—are also common in this domain.

| Industry | Key Requirements | Recommended Features |

|---|---|---|

| Telecommunications | Low loss, outdoor-rated, phase stability | Weatherproof jackets, 50Ω impedance, N-type connectors |

| Aerospace & Defense | High vibration, EMI shield, temperature extremes | MIL-spec connectors, triple shielding, PTFE insulation |

| Medical Imaging | Biocompatibility, small size, sterilizability | FEP jacket, ultra-flex coax, RoHS/PFAS-free materials |

| Automotive & EVs | Vibration, temperature tolerance, tight space routing | Right-angle connectors, overmolded design, UV-resistant jackets |

| Industrial Automation | High flex life, EMI resistance, oil/chemical exposure | TPU jackets, hybrid power-RF cables, IP67/IP68 rated design |

Why Do Engineers Prefer Custom RF Cable Solutions?

For engineers, designing with precision means choosing components that perform exactly as needed in exact spaces under exact conditions. That’s why so many prefer custom RF cable assemblies: they offer control, confidence, and compatibility that off-the-shelf products can’t match.

Electrical Performance Without Compromise

Custom assemblies allow engineers to control impedance, frequency range, and signal attenuation. For example, choosing a silver-plated copper conductor combined with PTFE dielectric ensures low VSWR and high thermal stability. Engineers working in high-speed digital environments (RFID, radar, telecom) can specify assemblies that match their required insertion loss and shielding effectiveness—removing guesswork and risk.

Design Integration and Mechanical Fit

Space is often the enemy of electrical design. RF cables must snake through cramped enclosures or wrap around hinges and moving parts. Standard cables are often too stiff or too long, creating stress points or causing signal reflection due to incorrect routing. Custom assemblies are designed with exact length, connector orientation (straight, right-angle), and cable flexibility in mind. Sino-conn provides assemblies optimized for routing paths and ease of installation, reducing the risk of assembly-line errors.

EMI Shielding and Environmental Resistance

In both medical and industrial applications, signal purity is vital. Engineers rely on custom assemblies with multi-layer braided shielding and foil wrap to mitigate EMI and RFI. Additionally, jackets such as LSZH or TPU add protection against heat, oils, UV rays, and chemical corrosion. These materials extend cable life and prevent catastrophic failure in mission-critical systems.

Accelerated Prototyping and Testing

Speed matters. Engineers value Sino-conn’s ability to turn around drawings in under 48 hours and samples in as few as 3 days. This flexibility allows fast iteration during development and avoids bottlenecks. For R&D projects, where configuration may change, the ability to modify connector types or pinouts quickly makes custom assemblies essential.

Peace of Mind Through Compliance

Finally, engineering doesn’t stop at functionality—it extends to documentation and traceability. With Sino-conn, engineers receive full certifications (UL, RoHS, ISO) and inspection reports, ensuring internal teams and external auditors are satisfied. Custom labels, serialization, and barcoding also make inventory and quality tracking seamless.

In essence, engineers choose custom RF cable assemblies not just for performance—but for precision, protection, and process efficiency.

How Are These Cable Assemblies Customized?

Customization includes selecting suitable materials, shielding levels, connector interfaces, and mechanical properties based on use-case requirements.

Here’s how the Sino-conn process works:

| Component | Customization Options | Typical Use Case |

|---|---|---|

| Conductors | Bare copper, silver-plated, copper-clad steel | High-frequency signal, cost-sensitive builds |

| Insulation | PE, PTFE, FEP, PFA | Thermal stability, medical or aerospace devices |

| Shielding | Braided, foil, combo (dual shielding) | EMI-sensitive environments, defense systems |

| Jacket | PVC, TPU, LSZH, TPE | Flame retardance, UV/oil resistance, halogen-free |

| Connectors | SMA, BNC, TNC, N-type, MCX, MMCX | Telecom, lab test equipment, IoT, radar |

| Configurations | Straight, right-angle, panel mount, bulkhead, Y/T split | Space-constrained systems, robotic arms |

- Engineering for Function Clients may need resistance to fire, oil, UV, or chemicals. Some require flexibility under motion (robotics) or precision impedance control (RF testing). Every variable is tuned.

- Custom Lengths & Designs Whether it’s a 10cm jumper for IoT or a 20m link for radar, length precision matters. Mechanical layout, mounting interface, and strain relief are designed per use-case.

- Connector Versatility Assemblies can feature mixed connectors on each end, right-angle or straight configurations, and branded or alternative parts depending on price-performance goals.

- Fast Prototyping & Documentation CAD to PDF drawings are delivered in 30 minutes to 3 days. Clients receive clear specs, 3D renderings if needed, and samples within 2–7 days.

Do Certifications and Testing Matter in Custom RF Assemblies?

Absolutely. Certifications and rigorous testing ensure that assemblies comply with industry standards and perform reliably under field conditions.

Regulated industries like medical, aerospace, and telecom demand documented compliance. Here’s how Sino-conn delivers:

- Certifications Offered

- UL, ISO 9001: Manufacturing and process quality

- RoHS, REACH: Environmental compliance

- PFAS-free, Halogen-Free: Safety in sensitive applications

- COC, COO: Traceability and origin documentation

- Triple-Stage Testing

- Process Check: Mid-assembly performance verification

- Final Inspection: Mechanical, visual, and electrical tests

- Pre-Shipment QA: Each unit is validated against order specs

- Trust Through Transparency Clients receive test reports, certificates, and compliance documentation with each batch. This builds trust and enables global export with fewer hurdles.

Ready to Customize Your RF Cable Assembly?

Whether you’re developing an aerospace prototype, launching a 5G product, or upgrading industrial machinery, your signal chain depends on the right cable solution. Sino-conn is your strategic partner for custom RF cable assemblies that check all the boxes: performance, flexibility, speed, and cost.

✅ No MOQ

✅ 30-minute quotes

✅ 3-day sample turnaround

✅ 2-week volume delivery

✅ CAD drawing services

✅ Full certification packages

Got a part number, sketch, or just a use case? Let Sino-conn help turn it into a reliable, production-ready cable assembly.