In the fast-moving world of compact electronics, every millimeter of space matters. Engineers are constantly challenged to design smaller, lighter, and more powerful devices while ensuring connections remain stable. That’s where the PicoBlade cable assembly comes in—a tiny but mighty solution that enables secure connections in laptops, wearables, automotive sensors, and even medical devices. While the connector itself is just 1.25mm pitch, it carries the responsibility of ensuring power and signals flow reliably in mission-critical systems.

A PicoBlade cable assembly is used to provide reliable, space-saving electrical connections in compact devices. It supports low-power signals, saves board space, and comes pre-assembled for quick integration in consumer electronics, automotive modules, industrial sensors, and medical equipment. Its value lies in stable performance, customizable options, and reduced assembly errors.

Now, imagine holding a smartwatch in your hand. Inside, multiple tiny connections are at work—but one of them is a PicoBlade cable assembly quietly ensuring that data from sensors reaches the circuit board without interruption. Without it, the wearable you love might fail to deliver accurate health readings. Let’s dive deeper and explore why engineers across industries choose PicoBlade assemblies, and how Sino-conn makes them even more effective.

What is a PicoBlade Cable Assembly?

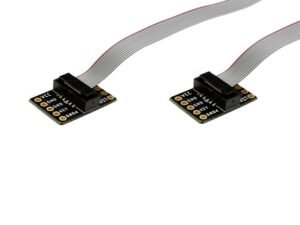

A PicoBlade cable assembly is a pre-crimped wire harness that connects to Molex PicoBlade connectors. It combines miniature size (1.25mm pitch) with reliable performance, saving space while transmitting low-power signals. Instead of crimping terminals manually, engineers use ready-made assemblies for easier integration, faster production, and reduced error rates.

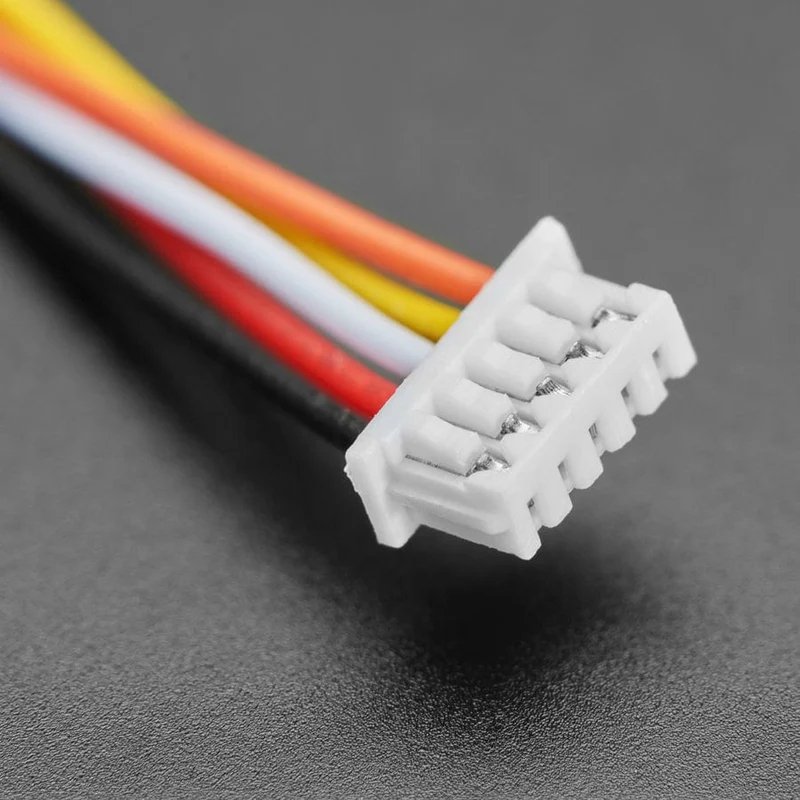

At its core, the PicoBlade system is about miniaturization without compromise. With conductor sizes ranging from AWG 28–32, each cable can carry up to 1A per circuit, making it perfect for low-power applications. The terminals, typically made of phosphor bronze with tin or gold plating, provide excellent conductivity and corrosion resistance.

| Parameter | Specification |

|---|---|

| Pitch | 1.25mm |

| Wire Gauge | AWG 28–32 |

| Current Rating | Up to 1A per pin |

| Operating Voltage | 125V AC/DC |

| Operating Temperature | -25°C to +85°C |

| Housing Material | Nylon PA66 / PBT |

| Terminal Material | Phosphor Bronze, Tin/Gold plated |

Assemblies can be wire-to-board (plugging directly into a PCB connector) or wire-to-wire, linking two modules together. Custom variants allow one end to be PicoBlade while the other could be JST, PH, XH, or even USB depending on the OEM’s requirements.

Instead of sourcing terminals, housings, and wires separately, OEMs benefit from pre-assembled PicoBlade harnesses that reduce labor, shorten lead time, and minimize connection failures. For manufacturers like Sino-conn, this is where expertise matters—ensuring every crimp is correct, every length precise, and every assembly meets certification standards such as UL, RoHS, and ISO.

Which Devices Commonly Use PicoBlade Cable Assemblies?

PicoBlade cable assemblies are widely used in consumer electronics, automotive sensors, industrial controllers, LED lighting, and portable medical devices. Their 1.25mm pitch allows them to fit in ultra-compact designs where space is limited but reliability cannot be compromised.

Where PicoBlade Cable Assemblies Are Used

When potential customers evaluate PicoBlade assemblies, the first question is: “Does this fit into my product design?” To answer, let’s look at actual industries:

Consumer Electronics

- Devices: Laptops, tablets, cameras, drones, smartwatches.

- Why PicoBlade? Small pitch saves PCB space, ensures stable data/signal transmission, and reduces wiring errors during assembly.

- Buyer’s Concern: Wearables and laptops demand flexibility, lightweight wiring, and anti-fatigue performance.

Automotive Electronics

- Devices: Parking sensors, dashboard controls, infotainment units.

- Why PicoBlade? Withstands vibration and temperature fluctuations common in vehicles.

- Buyer’s Concern: Engineers want long lifecycle reliability and certifications like IATF16949, RoHS, and REACH.

Industrial Equipment

- Devices: Robotics, smart sensors, detection modules.

- Why PicoBlade? Compact design allows multiple connections in small control boxes, while optional shielding minimizes EMI in factories.

- Buyer’s Concern: OEM factories need custom harnesses with fast lead times to meet tight production schedules.

Medical Devices

- Devices: Portable diagnostic tools, monitoring devices, imaging systems.

- Why PicoBlade? High precision, stable signal delivery, biocompatible materials available.

- Buyer’s Concern: Engineers in healthcare look for low-defect rate and safety compliance (UL, ISO 13485).

LED & IoT Applications

- Devices: Smart lighting, controllers, sensor hubs.

- Why PicoBlade? Handles low current with ease and enables compact, efficient wiring in IoT modules.

- Buyer’s Concern: Flexibility in length customization and quick prototyping samples.

PicoBlade cable assemblies are not a “generic wire”—they are designed to solve real-world space and reliability challenges. That’s why major industries—from consumer wearables to automotive OEMs—choose them for projects where compact size + durability are non-negotiable.

How Are PicoBlade Cable Assemblies Designed and Made?

PicoBlade cable assemblies are designed using copper conductors, phosphor bronze terminals, and durable insulation materials such as PVC or nylon. They are manufactured by crimping terminals, inserting them into housings, and assembling them into wire-to-board, wire-to-wire, or custom harness formats.

The design process involves balancing electrical, mechanical, and environmental factors:

- Conductors: High-conductivity copper ensures minimal resistance.

- Terminals: Phosphor bronze with tin/gold plating guarantees long-term contact reliability.

- Insulation: PVC, PBT, or LCP withstands heat, friction, and chemicals.

- Housing: Nylon PA66 ensures fire resistance and secure locking.

Manufacturing steps:

- Wire cutting & stripping – precision automated machines.

- Terminal crimping – ensuring firm electrical connection.

- Housing assembly – terminals inserted into plastic shells.

- 100% QC testing – continuity, pull strength, and visual inspection.

By outsourcing assembly to specialists like Sino-conn, OEMs avoid costly errors, accelerate product launches, and access flexible customization (length, pinout, materials, shielding, EMI protection).

Do PicoBlade Cable Assemblies Solve Connectivity Problems?

Yes. PicoBlade assemblies solve key issues in compact electronics: they save space, reduce wiring errors, improve connection reliability, and allow flexible customization. Shielded versions also minimize EMI interference.

Connectivity challenges in modern electronics include limited space, vibration, EMI interference, and assembly time. PicoBlade assemblies address them effectively:

- Space Saving: 1.25mm pitch fits where larger connectors cannot.

- Error Reduction: Pre-assembled harnesses eliminate manual crimping mistakes.

- Reliability: Locking features prevent loose connections under vibration.

- Customization: Tailored lengths, pinouts, and materials adapt to unique designs.

- EMI Protection: Optional shielding ensures signal integrity.

From a customer’s perspective, these benefits translate into fewer device failures, faster production, and greater design flexibility—a strong value proposition.

Are PicoBlade Cable Assemblies Cost-Effective for OEMs?

Yes. PicoBlade cable assemblies save cost by reducing manual labor, minimizing defects, and speeding up integration. OEMs can select between genuine Molex connectors or compatible alternatives to balance price, flexibility, and lead time, making them highly cost-effective for both small and large orders.

Cost-effectiveness doesn’t just mean cheap—it means finding the optimized balance between price, flexibility, and performance.

| Factor | Buying Loose Components | Buying Pre-Assembled PicoBlade (Sino-conn) |

|---|---|---|

| Assembly Labor | High (manual crimping) | Zero (ready-to-use harness) |

| Defect/Rework Rate | Higher risk | 3× QC tested, lower defect rate |

| Lead Time | 6–8 weeks (international) | 2–3 weeks bulk, 3 days samples |

| MOQ Requirement | Often 1K pcs+ | No MOQ, even 1 pc available |

| Overall Cost | Higher (hidden labor cost) | Lower TCO (Total Cost of Ownership) |

Cost, Value, and Buyer Priorities

Cost-effectiveness isn’t just about “cheap pricing”—it’s about finding the right value-to-performance ratio. Buyers from different backgrounds (engineers, OEMs, traders) evaluate PicoBlade assemblies differently:

1. Original vs Compatible Versions

- Original Molex: Higher price, longer lead time, premium branding, strong preference for end-users and European clients.

- Compatible Versions (by Sino-conn): 20–40% cheaper, faster delivery, flexible customization (length, pinout, EMI shielding). Ideal for OEM factories needing speed and scale.

Example Cost Comparison:

| Option | Lead Time | Flexibility | Relative Cost | Best For |

|---|---|---|---|---|

| Original Molex | 4–6 weeks | Low | $$$ | Premium brands, critical projects |

| Sino-conn Compatible | 2–3 weeks | High | $–$$ | OEM factories, cost-driven buyers |

2. MOQ & Lead Time Flexibility

- Sino-conn Advantage: No MOQ – from 1 piece prototype to mass production.

- Samples: as fast as 3 days.

- Bulk: 2–3 weeks vs international suppliers’ 6–8 weeks.

This is critical for R&D engineers who need fast prototypes and OEMs who can’t afford production delays.

3. Pricing Tiers for Different Buyers

- End-users / Brand Owners: Willing to pay more for reliability and certifications.

- OEM Factories: Price-sensitive but order in bulk, expecting stable quality + competitive pricing.

- Trading Companies: Need both price flexibility and fast availability to serve their downstream customers.

4. Hidden Savings in Quality Control

Every assembly at Sino-conn is tested 3 times (in-process, finished product, pre-shipment). This cuts defect rates, saving OEMs from costly rework or recalls.

PicoBlade assemblies are not just a wiring cost—they’re a risk-reduction investment. With Sino-conn’s fast lead times, no MOQ policy, and dual options (original or compatible), OEMs achieve lower TCO (Total Cost of Ownership) without sacrificing performance.

Conclusion

PicoBlade cable assemblies may look small, but they carry a big impact in today’s compact electronics industry. They provide reliable, space-saving, and customizable solutions that engineers, OEMs, and traders all rely on. From consumer electronics to medical devices, their applications are vast and growing.

At Sino-conn, we combine technical expertise, fast response, and strict quality control to deliver PicoBlade cable assemblies that meet global standards. With no MOQ, 100% inspection, and quick sample turnaround, we’re the partner you can trust for both prototypes and mass production.

Ready to source your next PicoBlade cable assembly? Contact Sino-conn today for drawings, samples, and tailored solutions that match your exact needs.