Military technology is built for extremes — scorching deserts, icy mountain passes, turbulent seas, and high-speed aerial maneuvers. Yet in all these environments, there’s one constant: the need for stable, secure, and uninterrupted signal and power delivery. That’s where military cable assemblies come in. These aren’t your average off-the-shelf cables; they’re engineered lifelines that keep mission-critical systems connected, even when lives are on the line.

Military cable assemblies are rugged, specialized wiring systems designed to transmit power and signals reliably in extreme conditions. Used in defense vehicles, aircraft, ships, communication systems, and weapon control, they feature MIL-SPEC connectors, EMI/RFI shielding, environmental sealing, and durable materials like PTFE and polyurethane. They ensure mission-critical performance where failure isn’t an option.

At Sino-conn, we’ve seen how the right cable assembly can mean the difference between flawless mission execution and costly downtime. In fact, one of our NATO clients once told us their upgraded assemblies performed perfectly after 200 hours in sandstorm conditions — a true field trial. Let’s break down what makes these assemblies so indispensable, and why defense clients around the globe turn to specialists like Sino-conn.

What Are Military Cable Assemblies?

Military cable assemblies are purpose-built wiring harnesses and connectors that meet strict defense standards (MIL-SPEC) for durability, reliability, and environmental resistance. They are designed to transfer power, data, and signals in extreme operational conditions.

Military cable assemblies differ from standard industrial cables in several key ways:

- Performance standards: They follow MIL-SPEC certifications such as MIL-DTL-38999 and MIL-C-5015, ensuring compatibility and ruggedness.

- Operational environments: Built for shock, vibration, extreme temperature swings (-55°C to +125°C), and exposure to oil, saltwater, and chemicals.

- Custom design: Many are tailor-made for specific military platforms, whether a submarine’s sonar array or a fighter jet’s avionics system.

For example, while a standard industrial cable might fail after repeated high-vibration exposure, a properly constructed military assembly can operate flawlessly after thousands of cycles. Sino-conn’s designs often include triple shielding, overmolded connectors, and low-smoke, zero-halogen materials, making them ideal for both safety and stealth.

Which Industries and Applications Require Military Cable Assemblies?

They are essential in ground vehicles, aircraft, naval ships, radar systems, portable field communications, and weapon control systems — anywhere reliable connectivity is mission-critical.

Military cable assemblies aren’t exclusive to one branch of defense — they span land, sea, and air applications:

- Ground Forces: Tanks, armored personnel carriers, and mobile command units use rugged assemblies for navigation, targeting, and internal communication.

- Aviation: Fighter jets, drones, and transport aircraft rely on assemblies for avionics, flight controls, and secure communications.

- Naval Operations: Submarines, destroyers, and aircraft carriers demand assemblies resistant to salt spray and constant vibration.

- Tactical Communication: Field radios, satellite uplinks, and battlefield networks require lightweight, deployable cables that can be set up in minutes.

One striking data point: according to defense procurement reports, over 60% of mission-critical electronic failures in the field are due to cable or connector issues — highlighting why industries choose suppliers like Sino-conn who understand defense reliability requirements.

How Do Military Cable Assemblies Withstand Harsh Environments?

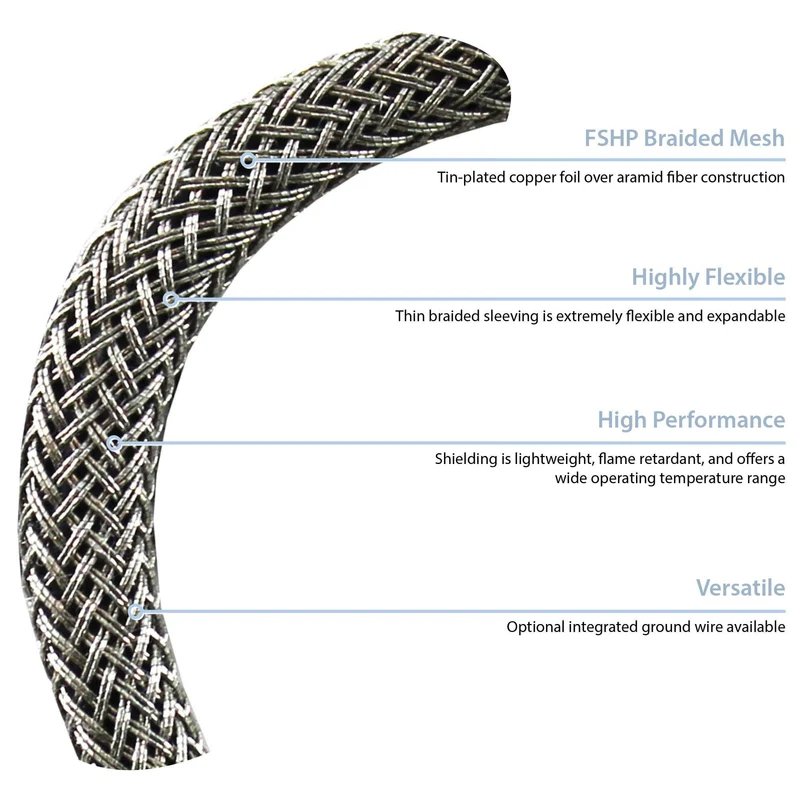

Military cable assemblies withstand harsh conditions through advanced materials like PTFE, FEP, and marine-grade polyurethane, reinforced by EMI/RFI shielding, overmolding, Kevlar strength members, and IP67/IP68 sealing. They remain fully functional in extreme heat, cold, vibration, moisture, and chemical exposure, ensuring mission continuity in any environment.

Unlike commercial-grade cables, military cable assemblies are designed with a zero-failure tolerance philosophy. The field conditions they face often combine multiple stress factors simultaneously — for example, a UAV data link cable must handle high vibration, salt spray during carrier takeoff, and sub-zero temperatures at cruising altitude.

Key construction features include:

- Thermal endurance: PTFE and FEP insulation keep dielectric integrity from –55°C to +200°C, surpassing industrial cable limits by over 40%.

- Environmental sealing: Overmolded connectors with IP68 rating can be submerged for 72 hours without water ingress.

- Mechanical reinforcement: Kevlar or aramid braids inside the jacket prevent stretch or breakage even under a 150 lb tensile load.

- Chemical resistance: Jackets withstand hydraulic fluid, jet fuel, and decontamination agents like sodium hypochlorite without degradation.

Real-world example:

During a NATO desert trial, Sino-conn’s armored vehicle communication cable maintained full operational integrity after 200 continuous hours in a sandstorm, with zero signal loss — a performance milestone that earned multi-year procurement approval.

| Environmental Threat | Sino-conn Engineering Response | Benefit to Client |

|---|---|---|

| High vibration in vehicles | Overmolded MIL-DTL-38999 connectors | Maintains lock-tight connection under shock |

| Saltwater corrosion | Marine-grade polyurethane jacket | 5+ years without degradation |

| Radar EMI | Triple-layer braided shielding | Zero data packet loss |

| Desert sand ingress | Seamless overmold & seal | Prevents mechanical wear |

Are There Different Types of Military Cable Assemblies?

Yes — including coaxial assemblies for RF, fiber optic assemblies for high-speed secure data, multi-conductor harnesses for combined power and signal, hybrid assemblies, overmolded assemblies, and battlefield deployable cables.

Military Cable Assembly Types and Recommended Applications

| Cable Type | Best Use Case | Key Advantages |

|---|---|---|

| Coaxial Assemblies | Radar systems, RF antennas, satellite uplinks | Low signal loss, high-frequency stability, EMI resistance |

| Fiber Optic Assemblies | Secure high-speed data links, long-distance comms | Immunity to EMI, lightweight, high bandwidth |

| Multi-Conductor Harnesses | Power + signal in one assembly (vehicles, control systems) | Simplified wiring, space-saving, reduced installation time |

| Hybrid Assemblies | Platforms needing mixed copper, fiber, and RF in one cable | All-in-one solution, reduced weight, less maintenance |

| Overmolded Assemblies | Harsh, high-vibration environments | Superior sealing, strain relief, moisture/dust protection |

| Battlefield Deployable Cables | Temporary tactical networks, mobile command units | Flexible, reelable, abrasion-resistant, quick deployment |

Sino-conn frequently customizes these types to meet niche needs — from fitting into tight submarine control rooms to withstanding desert sand infiltration in armored vehicles.

How Do Manufacturers Test and Certify Military Cable Assemblies?

Manufacturers perform electrical, mechanical, and environmental tests, including continuity, insulation resistance, dielectric strength, EMI shielding effectiveness, vibration endurance, and salt fog exposure, and provide certifications like UL, ISO, RoHS, and REACH.

At Sino-conn, every assembly undergoes three layers of inspection:

- In-process checks — at every production stage.

- Final QC — full function test before shipment.

- Pre-shipment inspection — customer-approved drawings and specs are matched against the finished product.

Certifications prove compliance, but field performance is the ultimate test. Sino-conn’s assemblies have passed 1,000+ hour salt fog tests and maintained operational performance in electromagnetic fields exceeding 200 V/m — benchmarks few competitors can match.

Do Custom Military Cable Assemblies Solve Specific Customer Needs?

Custom military cable assemblies meet unique operational requirements by tailoring length, pinout, connector type, material, and environmental protection. Sino-conn offers rapid prototyping, no MOQ, and the ability to adapt designs quickly, enabling faster deployment and reduced downtime.

Every defense project has non-standard demands that off-the-shelf solutions can’t meet — and in military operations, “almost right” is just another word for “unreliable.”

Sino-conn’s customization process is built around speed, flexibility, and engineering depth:

- Rapid prototyping: CAD drawings in as little as 30 minutes, samples shipped in 3 days for urgent missions.

- Full design flexibility: Adjust cable length to fit tight vehicle compartments, change pinouts for interoperability, or select overmold color for easy field identification.

- Connector choice: Original-brand MIL-SPEC connectors for maximum compatibility or high-quality equivalents for faster lead times and cost savings.

- Material optimization: Swap insulation types for higher temperature resistance or lower weight depending on the platform.

- No MOQ: Build one prototype for R&D, or ramp straight to production runs — with the same quality controls.

Case in point:

A European UAV manufacturer required a hybrid cable combining coaxial, fiber optic, and power conductors in one assembly. Their goal: reduce weight while simplifying onboard wiring. Sino-conn delivered a tested prototype in 72 hours, which passed flight testing on the first try, cutting 6 weeks off the deployment schedule.

Custom Options Table:

| Customizable Feature | Examples | Operational Benefit |

|---|---|---|

| Cable length & OD | 0.5m micro-harness to 50m deployable | Fits exact installation constraints |

| Pinout configuration | Reversed, custom, multi-branch | Matches legacy and new systems |

| Connector selection | MIL-DTL-38999, MIL-C-5015, alternatives | Balances cost vs lead time |

| Material choice | PTFE, FEP, XLPE, TPE, PUR | Optimizes weight, temp, and flexibility |

| Shielding type | Single, double, triple braid + foil | Adjusts EMI protection to mission risk |

Why You Should Contact Sino-conn Today

Whether you’re equipping a new fleet of unmanned aerial systems or upgrading a naval communications hub, the reliability of your cable assemblies determines the reliability of your mission. Sino-conn combines deep MIL-SPEC expertise, rapid customization, and a zero-compromise approach to quality — all with competitive pricing and flexible MOQs.

Contact Sino-conn today to discuss your custom military cable assembly project. Our team can deliver drawings in under an hour and samples in days — ensuring your next mission has the connectivity it needs to succeed.

EMI immunity: Triple-braided tinned copper shields achieve >90 dB attenuation at 1 MHz–10 GHz, protecting against radar and onboard electronics interference.