In the world of digital connectivity, a reliable LAN cable connection can mean the difference between a smooth video call and an embarrassing freeze-frame. Yet, the humble LAN cable connector—specifically the RJ45—is often overlooked, despite being the very point where data flow either thrives or breaks down. Whether you’re a home DIYer, an IT engineer, or an OEM manufacturer, mastering the skill of crimping a LAN cable connector isn’t just technical—it’s essential.

At Sino-conn, we’ve helped thousands of clients worldwide—ranging from trade distributors to R&D engineers—achieve strong, error-free cable connections through precision-designed connectors and OEM assembly services. And we’ve learned that even the best cable is only as good as its crimp. One of our European customers once discovered their network issues stemmed from poor DIY crimps. We helped redesign their connector spec and provided custom drawings in 48 hours. Their new batch performed with 99.99% transmission reliability—and a lot fewer tech support calls.

Curious how you can get it right the first time? Let’s dive in.

What Is a LAN Cable Connector and Why Crimp It?

A LAN cable connector is a modular plug—typically RJ45—that terminates Ethernet cables and enables devices to connect to a local network. Crimping ensures that the copper wires inside the cable make precise contact with the connector’s metal pins, providing a secure and stable data transmission path.

LAN cable connectors serve a critical role in both residential and commercial networks. Without them, Ethernet cables would be nothing more than insulated copper strings. The RJ45 connector features eight metal pins aligned to mate with corresponding conductors in network ports.

The act of crimping attaches each copper conductor to these pins by pressing them into sharp contact blades inside the plug. A properly crimped connector guarantees a low-resistance electrical pathway—essential for stable signal flow. Improper crimps, by contrast, often result in intermittent connectivity, high latency, or total data loss.

Sino-conn designs RJ45 connectors to meet international standards like ISO/IEC 11801 and ANSI/TIA-568. The engineering behind them ensures compatibility across devices and minimizes EMI (electromagnetic interference).

Use cases vary: engineers use custom LAN cable assemblies during prototyping; OEMs build high-volume, end-device cables; while DIY users create short patch cables for home routers. In every case, the reliability of the crimped connector defines the user experience.

Which Tools and Materials Are Needed for Crimping?

You need a quality crimping tool, the right type of RJ45 connector (shielded or unshielded), and an appropriate LAN cable (Cat5e, Cat6, or Cat6a) to ensure proper termination.

Crimping tools come in several forms, but for most users, a ratchet-style crimping tool offers the best blend of precision and ease.

Unlike basic models, it prevents under- or over-crimping by using a mechanical lock-release.

Tool Comparison Table:

| Tool Type | Best For | Precision | Price Range |

|---|---|---|---|

| Basic Crimper | Home DIY | Low | $10–$20 |

| Ratchet Crimper | Professional/Field | High | $25–$60 |

| All-in-One Tool | OEMs & Installers | Very High | $60+ |

Connector Type Matters:

- Unshielded RJ45 (UTP) – cost-effective and common for Cat5e

- Shielded RJ45 (STP) – essential in high-interference areas (industrial, hospital, lab)

Cable Choice:

- Cat5e – up to 1 Gbps, 100 MHz

- Cat6 – up to 10 Gbps, 250 MHz (ideal for professional settings)

- Cat6a – shielded and supports long-distance high-speed transfers

Sino-conn supplies all major connector types and helps clients match connectors to their exact cable OD (outer diameter), EMI requirements, and pinout specs.

How to Prepare the Cable Before Crimping?

Strip the jacket cleanly, untwist the wire pairs minimally, and arrange wires into the proper T568A or T568B configuration for optimal signal performance.

Preparing your LAN cable correctly before crimping is essential to avoid wasted materials and poor performance. Incorrect preparation is one of the most common reasons for network failure and crosstalk in cables.

Start by cutting the cable cleanly using a sharp cable cutter. Avoid crushing or distorting the shape of the cable, as this can affect the internal twist rate, which is critical for signal integrity. Once cut, use a precision stripper to remove about 1 to 1.5 inches (2.5 to 4 cm) of the outer jacket. Be careful not to nick or cut the internal twisted pairs.

After removing the jacket, carefully untwist each pair just enough to organize them in the correct wiring scheme. Minimizing the untwist length helps maintain the cable’s electrical performance by preserving the original impedance and reducing electromagnetic interference (EMI).

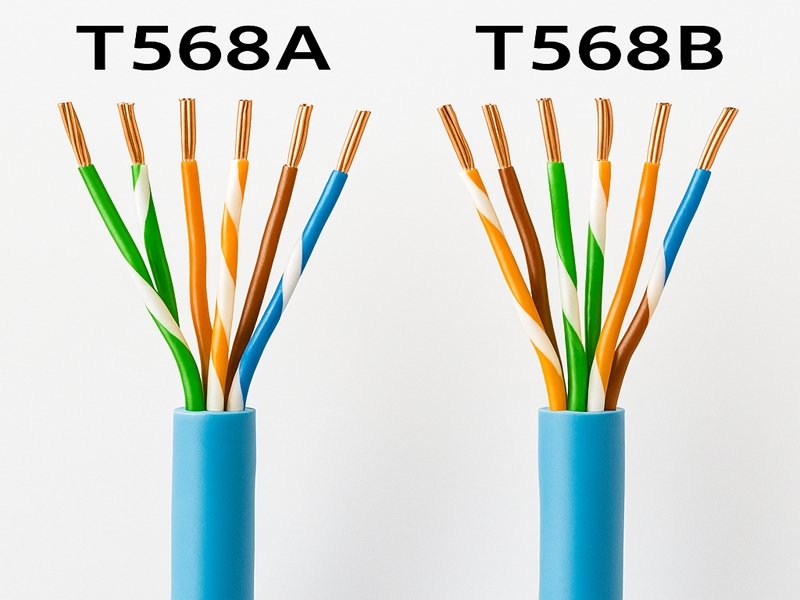

Wiring Standards: T568A vs T568B

| Pair | T568A Color | T568B Color |

|---|---|---|

| 1 | Green/White, Green | Orange/White, Orange |

| 2 | Orange/White, Orange | Green/White, Green |

| 3 | Blue/White, Blue | Blue/White, Blue |

| 4 | Brown/White, Brown | Brown/White, Brown |

Both configurations are functionally similar, but T568B is more widely used in commercial installations, while T568A is preferred in residential and government settings. Choose one standard and stick with it consistently on both ends.

Once arranged, flatten the wires and trim them evenly so the copper ends are flush. If you’re using pass-through RJ45 connectors, make sure the wires extend slightly beyond the front end of the plug so you can visually confirm the order before crimping.

Common Mistakes to Avoid:

- Over-stripping the outer jacket, exposing too much wire.

- Mixing up the color order, especially with green and orange pairs.

- Leaving unequal lengths of wire, causing weak contact in the connector.

At Sino-conn, we provide OEM customers with detailed CAD drawings to ensure correct preparation for all cable assemblies. Our team can deliver these documents in PDF format within 30 minutes of request, expediting development timelines significantly.

Proper preparation not only guarantees performance but also reduces the chances of rework and quality failures in mass production. Whether you’re working on prototypes or scaling to thousands of units, this step is one of the most crucial in ensuring network reliability.

How to Crimp a LAN Cable Connector Step by Step?

Insert the aligned wires into the RJ45 connector, verify full insertion, and use a crimping tool to compress the connector evenly until it locks—ensuring each pin pierces its wire cleanly.

The actual crimping step is where all your preparation pays off—or fails. A good crimp results in a secure, low-resistance electrical connection; a bad crimp can render the entire cable useless.

Here’s a detailed guide to crimping your LAN cable connector the right way:

Insert the Wires: Slide the trimmed and arranged wires carefully into the RJ45 plug. Make sure each wire follows its dedicated channel inside the connector housing. Push them all the way to the front. If using a pass-through connector, the wires should stick out slightly.

Double-Check Wire Order: Use the transparent housing to confirm the wiring sequence (T568A or T568B). A mirror or bright light can help during visual inspection. Ensure the cable jacket is inserted enough to be held by the connector strain relief tab.

Crimp the Connector: Place the loaded RJ45 plug into your crimping tool. Squeeze the handles firmly until you hear or feel the click. This action pushes the connector’s gold-plated blades into each wire, establishing contact. On pass-through connectors, the tool simultaneously trims the excess wire.

Test the Cable: Always use a LAN cable tester to check the connectivity and pin assignment. This helps detect wiring errors like crossed pairs or open connections before deployment.

Troubleshooting Tips:

- If the cable doesn’t pass the test, cut off the connector and re-strip the cable.

- Make sure no wires have slipped out or bent inside the connector.

- Avoid reusing connectors—they’re designed for one-time crimping only.

Sino-conn supplies RJ45 connectors with guide-through channels and gold plating for maximum reliability. For high-end applications, our connectors meet ISO, UL, and RoHS compliance, and are designed for both standard and shielded installations.

Our engineering team also supports high-frequency signal integrity simulations for demanding customers in automotive, industrial, and telecom sectors. This ensures every crimp you make with a Sino-conn connector performs exactly as intended—consistently, and at scale.

Do Crimped LAN Connectors Affect Network Speed or Signal?

Yes. Poorly crimped connectors introduce resistance, noise, and instability—often resulting in slower speeds, dropped packets, or total link failure.

Once crimped, your cable becomes a data pipeline. But like plumbing, weak seals create leaks. In networking, those “leaks” are data loss, latency, and interference.

Testing Tools:

- Basic Cable Tester – Checks continuity

- Time Domain Reflectometer (TDR) – Measures signal reflection and loss

Typical signal problems due to bad crimps include:

- Crosstalk (XT)

- Return loss

- Excessive insertion loss

Studies show that 68% of field wiring issues are due to improperly terminated cables (Fluke Networks, 2023).

To avoid this, Sino-conn tests 100% of their connector samples using in-house Fluke DSX-8000 analyzers. Every batch includes performance reports for OEM and industrial clients.

Ready to Custom-Build Your LAN Cable Connector?

Whether you’re an engineer developing a new device, an OEM factory with urgent high-volume needs, or a distributor looking for a long-term supplier—you deserve connectors that deliver both quality and flexibility.

At Sino-conn, we:

- Provide custom drawings in as fast as 30 minutes

- Support low MOQ (even 1 pc)

- Offer both brand-name (original) and flexible substitute options

- Can meet complex specs: EMI shielding, flame resistance, UV protection, halogen-free builds, etc.

- Ship samples in 2–3 days and mass orders in as fast as 2 weeks

Want to get your prototype moving fast or simplify your supply chain?

Contact Sino-conn Now for a Custom Quote

Let us help you crimp it right—the first time.