When it comes to display technology, especially for high-resolution, ultra-thin devices, choosing the right internal cable interface is more critical than ever. As devices evolve to become lighter, slimmer, and more powerful, the debate between eDP (Embedded DisplayPort) and LVDS (Low-Voltage Differential Signaling) cables continues to intensify. Many engineers, designers, and OEM procurement managers struggle with the same question: Which cable really fits my application needs best?

eDP cables offer higher resolution support, lower power consumption, and reduced EMI, making them ideal for modern, thin, high-performance displays. LVDS cables, on the other hand, remain reliable and cost-effective for industrial and automotive displays requiring stability and longer cable runs. Your choice should depend on resolution needs, form factor, and overall system design.

Let’s imagine you’re designing a cutting-edge gaming laptop or a sleek medical diagnostic monitor. Your product needs to deliver ultra-clear visuals while staying lightweight and energy-efficient. In these scenarios, the choice between eDP and LVDS is not just technical—it can define your product’s market success. This article will take you through a comprehensive journey, breaking down everything you need to know in plain English. Stick around, and by the end, you’ll feel like a display cable expert ready to make the perfect decision for your next project.

What is eDP and what is LVDS?

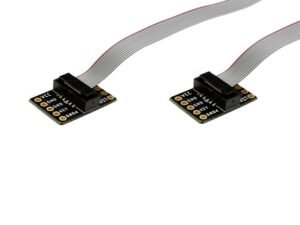

eDP (Embedded DisplayPort) and LVDS (Low-Voltage Differential Signaling) are internal video interface cables connecting the motherboard to the display panel. eDP supports higher resolutions and lower power, while LVDS offers stable, proven performance for various industrial and automotive displays.

At its core, both eDP and LVDS are designed to transmit image data from the graphics processor to the display panel. However, the way they achieve this is fundamentally different.

LVDS has been the industry standard for years. It transmits data using differential signals at low voltage, typically around 350 mV. This approach reduces noise and EMI (electromagnetic interference) while supporting moderate resolutions. LVDS is popular in automotive dashboards, older laptops, industrial control panels, and large LED displays due to its robustness and cost efficiency.

eDP, introduced by the Video Electronics Standards Association (VESA), is an extension of DisplayPort technology adapted for internal connections. It delivers significantly higher bandwidth, supporting 4K and even 8K displays with smoother refresh rates. Moreover, eDP reduces the number of wires needed, enabling thinner and lighter designs, a crucial factor for ultra-slim laptops and tablets.

Originally, most laptops and monitors relied on VGA and later DVI for external connections, with LVDS dominating internal panels. As consumer demand for better resolution and slimmer devices skyrocketed, eDP started to replace LVDS, bringing efficiency and performance benefits from external DisplayPort to internal usage.

Both technologies utilize differential signaling to minimize interference. However, eDP’s advanced protocols allow for improved error correction and adaptive sync features, enabling better color accuracy and smoother visuals.

Table: Basic Feature Comparison

| Feature | LVDS | eDP |

|---|---|---|

| Resolution | Up to 1080p | Up to 8K |

| Refresh Rate | Up to 60Hz | 120Hz+ |

| Cable Complexity | Higher | Lower |

| EMI | Low | Even lower |

| Power Usage | Moderate | Lower |

How do eDP and LVDS cables impact performance, design, and power consumption?

eDP cables enhance resolution, reduce weight, and consume less power, making them ideal for modern portable devices. LVDS cables, though heavier, provide strong EMI performance and stable signal integrity for industrial and automotive uses.

Choosing between eDP and LVDS is not just a matter of specs on a datasheet. It directly influences how your product feels in the user’s hands, how long it lasts on a single charge, and even how it performs under extreme conditions.

One of the biggest advantages of eDP is its superior support for higher resolutions and faster refresh rates. While LVDS is typically limited to resolutions up to 1080p, eDP can handle 4K, 5K, and even 8K resolutions with ease. Additionally, eDP supports refresh rates of 120Hz and beyond, which is essential for applications like gaming laptops and professional creative monitors. This enables smoother animations, reduced motion blur, and an overall more immersive visual experience.

Devices designed today often have to support upgrades for years to come. eDP allows you to keep up with rapid panel improvements without redesigning the entire cable assembly.

Another major factor is the physical design of the cable. eDP cables are thinner and require fewer wires due to their advanced data multiplexing. This reduction in wire count makes the cable lighter and easier to route through tight spaces, which is crucial for ultra-slim laptops and tablets. In contrast, LVDS cables are generally thicker and more rigid because they require more individual signal pairs. This can restrict industrial design options, especially if you’re trying to create a minimal bezel or a very thin chassis.

While both technologies use differential signaling to combat electromagnetic interference (EMI), eDP has a significant edge. Its enhanced error correction and adaptive sync technologies help maintain signal integrity even at very high data rates. This reduces the chance of artifacts on screen, color banding, or flicker issues—key points in premium products.

In industrial or automotive environments, LVDS still holds strong due to its robust shielding and simpler design. It’s less sensitive to environmental noise and can be easier to implement where rugged reliability is more critical than pixel-perfect image quality.

Finally, power consumption is a decisive metric. eDP typically consumes 15–20% less power than LVDS setups in equivalent resolutions. For portable devices, this directly translates to longer battery life—a huge selling point for consumers.

In contrast, devices that are always plugged in, such as factory control panels or automotive displays, can tolerate LVDS’s higher power draw since battery life isn’t a concern. However, even in these scenarios, shifting to eDP might offer lower overall thermal output, which can simplify thermal design and improve component longevity.

Performance & Design Impact

| Parameter | LVDS | eDP |

|---|---|---|

| Max Resolution | 1080p | Up to 8K |

| Refresh Rate | Up to 60Hz | 120Hz+ |

| Cable Thickness | Thicker | Thinner |

| Flexibility | Low | High |

| Power Usage | Moderate | Low |

Which applications require eDP or LVDS cables?

eDP suits ultra-thin laptops, tablets, and high-resolution monitors, while LVDS is best for industrial, automotive, and legacy display applications needing stability and longer cable runs.

Understanding where each cable shines can guide you in designing products that meet end-user expectations.

eDP’s thin profile and low power draw make it ideal for modern portable devices. Designers can create ultra-slim form factors without sacrificing display quality. Plus, support for adaptive refresh rates and HDR offers additional value to consumers.

A high-end gaming laptop from a leading brand transitioned from LVDS to eDP, achieving a 25% reduction in hinge thickness and improved color accuracy.

LVDS continues to be the standard in many industrial and medical displays. Its reliability, stable signal integrity, and simpler controller requirements keep it relevant. In medical environments, the slightly higher thickness is offset by exceptional EMI performance and proven track records.

Medical imaging workstations often maintain LVDS due to strict compliance standards and existing system compatibility.

In vehicles, durability against vibration and extreme temperature swings is crucial. LVDS excels here due to its robust cable shielding and mature ecosystem. Large-format advertising screens also leverage LVDS for long-distance runs and simpler maintenance.

LVDS assemblies can be customized with unique connector configurations to fit curved or non-standard dashboard designs.

Are eDP cables more expensive than LVDS cables?

eDP cables generally cost more due to advanced materials and higher performance, but they offer better long-term value through improved efficiency, reduced weight, and future-proofing capabilities.

eDP cables involve advanced connectors and higher-grade shielding to support high data rates. Costs can vary widely depending on connector type, cable length and pin count, shielding complexity, and material choices (e.g., halogen-free, ultra-flexible insulations).

Premium gold-plated or original branded connectors can raise costs but ensure reliability and longer lifespan.

While upfront costs may be 20–40% higher than LVDS, eDP’s contribution to device battery life, thinner designs, and higher display quality can justify the investment.

eDP may reduce service costs and increase product competitiveness in premium markets, resulting in higher margins for brands.

Cost Comparison

| Cable Type | Typical Cost (Standard) | Typical Cost (Customized) |

|---|---|---|

| LVDS | $5–$15 | $20–$35 |

| eDP | $15–$30 | $35–$60 |

These ranges vary based on order volume, design complexity, and connector authenticity.

Do you need to switch from LVDS to eDP now?

Switching depends on your application’s need for higher resolution, power savings, and slim design. If future-proofing and premium performance are priorities, eDP is the recommended choice.

Choosing whether to transition from LVDS to eDP is a strategic decision that can shape the direction of your product development and impact your long-term brand value.

If your upcoming products aim to integrate 4K or higher resolution displays, or if you want to provide high refresh rates and HDR capabilities, eDP becomes a natural choice. Consumer trends heavily favor ultra-slim, lightweight devices with long battery life. In fact, by 2025, nearly 80% of all new laptops have already transitioned to eDP, demonstrating a clear market direction.

For companies competing in premium segments, staying with LVDS could mean missing out on features that buyers now expect as standard. Moreover, as component suppliers phase out older LVDS controllers, future support and component sourcing may become more difficult.

Switching to eDP isn’t without challenges. You need to account for:

- Controller IC changes

- Mechanical adjustments

- Software and driver updates

Addressing these factors early in the design phase can prevent costly delays or recalls later.

Sino-conn excels at helping clients navigate this transition smoothly. We offer custom design drawings, typically delivered within 30 minutes to 3 days, depending on complexity. Our engineering team works closely with your R&D to ensure that new cable assemblies fit perfectly into your existing system design.

We also provide fast prototyping—urgent samples can be delivered in as little as 2–3 days, with no minimum order quantity (MOQ). This flexibility empowers even small or experimental projects to test eDP solutions without large financial risk.

Sino-conn supports a wide range of connector options, from original branded parts to high-quality alternatives that reduce cost without compromising functionality. Combined with our strict 100% inspection policy (process inspection, final inspection, pre-shipment inspection), you can be confident in quality and reliability.

Switching now can position your brand as a technology leader rather than a follower. By offering advanced display capabilities today, you not only meet current customer expectations but also prepare your products for future demands.

Ready to upgrade your display cables?

Choosing between eDP and LVDS is no longer just a technical specification—it’s a strategic business decision that affects your product’s appeal, performance, and lifecycle. From ultra-thin gaming laptops to rugged automotive dashboards, understanding which technology fits best can save costs, avoid redesign headaches, and open doors to new market segments.

At Sino-conn, we don’t just provide cables; we provide complete solutions. Our deep engineering expertise, rapid response (drawings and quotes in as little as 30 minutes), and 100% quality inspection make us a trusted partner worldwide.

Ready to customize your next cable solution? Contact Sino-conn today for a personalized consultation and quote!